Executive Summary

The COVID-19 pandemic has highlighted the vulnerability of global supply networks due to a lack of raw materials and disruptions in manufacturing and logistics. To guarantee the sustainability of the organizations and distribution networks, businesses must clearly identify the challenges that may arise throughout the recovery period and develop suitable plans. This study aims to investigate and analyze how the COVID-19 pandemic has impacted global supply chains and to provide advice and recommendations for enhancing resilience by improving effectiveness and adaptation. The two participants of the research indicated the vulnerabilities of both cyclical and non-cyclical businesses from professional and personal perspectives. Adverse factors that result from global supply chain disruptions are financial, consumer, and manufacturing performance deteriorations. The study’s conclusions can help companies build flexible supply networks to meet the difficulties of the post-COVID-19 environment.

Introduction

COVID-19 is a virus that was induced by severe acute respiratory syndrome. It suddenly appeared in December 2019 and yet soon spread to other nations in Asia, European, and North American regions and was confirmed to be a pandemic by the World Health Organization in March 2020 (Guan et al., 2020). Almost every nation in the world has since documented reports of COVID-19 (Guan et al., 2020). Subsequently, the World Health Organization has prompted impacted nations to impose quarantine and inhibition actions to slow viral genome distribution. Now, every country around the globe is dealing with health issues and the economic repercussions of the virus.

The COVID-19 pandemic has revealed the flaws in global supply chains and raised serious concerns about their future. Global reverberations have resulted from China’s abrupt decline in industrial output, which fell 13.5% in the first months of 2020 (Free and Hecimovic, 2021). Although it is too early to adequately measure the impact of supply chain disruptions triggered by the disease outbreak, the preliminary drop in production in Asia has greatly influenced consumers and producers in regions connected to supply chains. The repercussions of the global pandemic have been impactful, and, per some experts, they will not fade by the end of 2022 (Magableh, 2021). Businesses are compelled by this to enhance their strategy for fast recovery and ongoing disruption prevention.

Global chain disruptions have caused major damage to consumers and businesses via distorted demand and supply, which prompted this report. The research aims to explore and examine how the COVID-19 pandemic has affected international supply chains and offer information and suggestions for building resilience by increasing efficiency and adaptability. The main question of the research is as follows: To what extent has COVID-19 impacted global supply chains and how has it influenced consumers and businesses? The given report is important for understanding the essentials of supply networks, their resilience, and approaches that can reinforce supply chains.

Review of Literature

Overall Impact of COVID-19 on Supply Networks

The COVID-19 disease outbreak is not the first crisis that suddenly compromised the global supply chain. Other extreme events, including the 2011 earthquake in Japan, the 2003 SARS pandemic in China, and the 2004 tsunami in Indonesia, have resulted in disruptions of components and good production and distribution (Xu et al., 2020). It is important to note that the output recovers quickly from these setbacks (Chowdhury et al., 2021). Nevertheless, the repercussions of COVID-19 are distinct from those of any other catastrophe because of its extent and scale. Most of the time, calamities such as earthquakes, storm surges, nuclear or chemical incidents, and conflicts are confined to a small region and last only a brief time. The COVID-19 pandemic, nonetheless, propagated globally for four months after its first breakout. As a result, it put billions of people under quarantine, confining them completely and aiding in the partial or complete closure of key economic sectors (Yu et al., 2021). Additionally, it is impossible to forecast when this virus will be terminated because each contaminated region on the planet is unquestionably at significant risk for a new epidemic.

In this context, the COVID-19 event exposed the supply chains’ weakness and low resilience, indicating their feebleness. Additionally, the outbreak caused an issue that has an impact on both supply and demand at the same time, making an effective response more difficult. Initially, there was a supply-side shock, and then there was a significant spike on the consumer side with the introduction of restriction measures (Paul et al., 2021). Authorities were most concerned with addressing COVID-19 health concerns by placing social distancing restrictions on the populace, increasing the number of hospital facilities, and accumulating medical resources, diagnostics, and technology, such as ventilators (Meier and Pinto, 2020). To compensate for missed shipments, however, choosing and qualifying new suppliers can be difficult, notably in extended global supply chains, which have shown to be the most sensitive.

The likelihood of a disruption rises as both the number of participants and the space range between them do. One of the insights that may already be derived from this issue is the critical requirement to construct more durable, flexible, and efficient supply networks (Fonseca and Azevedo, 2020). Decentralization of capacities, multisourcing, small-batch manufacturing, and digitalization may be important in this growth trajectory for creating future distribution networks.

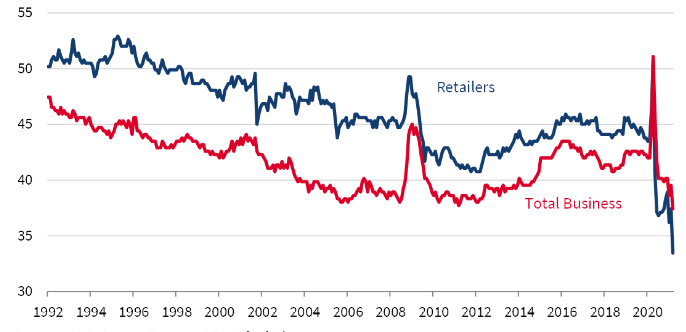

The White House presents the impact of COVID-19 on the global supply chain. The report reveals that while businesses had 43 days of goods in February 2020, as of now, they have merely 33 days, as seen in Figure 1 (The White House, 2021). In contrast to pre-pandemic stages of approximately two months for vehicles and 5.5 months for residences (The White House, 2021). Inventory levels of both vehicles and real estate are at or close to historic lows, being enough for only one month of vehicle sales and 4.4 months of property sales, respectively (The White House, 2021). In this sense, industry supply chains are experiencing compounding problems as a result of these minimal supplies. The most recent U.S. 36% of small firms experienced difficulties with local suppliers in the manufacturing, building, and commerce industries of the Census Small Business Pulse survey, which was conducted from May 31 to June 6 (The White House, 2021). Although there are no similar survey results from before the epidemic, assessments on supply shortages conducted by industry indicate these levels are substantially higher than typical.

Global Supply Chains Disruptions

The COVID-19 outbreak has had a significant impact on the networks of global supply chains, which are disrupted across all levels, from the supply of raw materials to the supply of products. All industries experienced difficulties and issues with global supply chains. Products may be broadly divided into two categories: inventive items and utilitarian products (Verschuur et al., 2021). In typical circumstances, the supply and demand of functional goods are steady. Nevertheless, due to the erratic demand and supply, certain items, such as masks, have evolved from practical products to inventive products. During the epidemic, global supply chains prioritize providing quick customer service and big earnings.

When it comes to the influence of COVID-19 and its repercussions on the global supply chains, the consequences involve various industry challenges, disrupted logistics, and demand. As for the first factor, it is vital to emphasize a few examples, such as the technology and pharmaceutical industries. Xu et al. (2020) give a clear overview of the impact on the given sectors and other affected industries. A lack of separate components affected supply chain operations in the technology sector, including items like cell phones, VR headsets, and other digital equipment (Xu et al., 2020). For example, the closure of Foxconn factories in China forced Apple to delay the release of its new goods in the market (Sharma et al., 2020). Manufacturing has been halted at Samsung and LG’s plants in India and South Korea, respectively (Xu et al., 2020). Tesla Motors, which shut down its operations in Shanghai, California, and New York, is another illuminating case in point (Xu et al., 2020). Airbus, Boeing, and Lockheed suspended manufacturing at several of their facilities in Europe and the US, affecting the aeronautic industry (Xu et al., 2020). In this situation, the tech companies that have been affected the most are those that have factories in the regions most affected by the pandemic.

Other industries whose supply chains were damaged are those of the pharmaceutical industry. According to estimates from Chinese producers, 40% of all pharmaceutical formulations are utilized globally (Xu et al., 2020). India serves as a crucial source of the necessary COVID-19 pharmaceuticals because it is the third-largest exporter of medicines in the world (Veselovská, 2020). Nevertheless, since more than 70% of India’s wholesale medication manufacturing is dependent on Chinese suppliers, Indian pharmaceutical businesses are experiencing acute material shortages as a result of the Chinese suppliers’ suspension of manufacturing.

Another impact of COVID-19 is the disrupted international transportation. According to numerous sources, due to quarantine limitations or diseases, both white-collar and blue-collar laborers were not readily accessible (Paul et al., 2021). This resulted in a scarcity of logistics personnel in the supply chain (Paul et al., 2021). Moreover, because of isolation, border controls, and the temporary suspension of several operations, key actors in the distribution chain were unable to carry out their responsibilities. For example, certain Chinese scientists and technicians were unable to visit the Indian lens manufacturing facility (Paul et al., 2021). Likewise, South Korean specialists were prevented from visiting the Samsung facility in Vietnam (Xu et al., 2020). Therefore, most companies experienced an inability to guarantee efficiency due to a lack of workforce.

The last impact of COVID-19 on global supply chains is the distorted consumer demand. Panic purchasing and concerns about scarcity are the major causes of the skyrocketing demand for common pharmaceuticals such as cough and flu remedies, pain medications, and children’s pharmaceuticals (Veselovská, 2020). The mechanism for supplying medicines has been hampered by the higher-than-average demand. Furthermore, customer demand for fabrics and clothes has been reduced as a result of quarantine procedures, retail store closures, financial difficulties, and consumer uncertainty related to making purchases during a recession (Veselovská, 2020). According to a study, the early stages of the US pandemic saw a 53% spike in sales of everyday necessities (Veselovská, 2020). Nevertheless, average sales in China fell by 29% in areas including home goods and equipment (Veselovská, 2020). This happened along with textiles and technology as a result of a dramatic decrease in consumer optimism.

Individual Perspective on COVID-19’s Impact on Global Supply Chain

The COVID-19 epidemic has shown several weaknesses in retailers’ capacity to reduce supply chain inefficiencies. The majority of non-essential retail operations have been negatively impacted by this epidemic. However, the commerce industry is experiencing difficulties due to a lack of workers, significant disruptions in distribution networks, and a high demand for certain products. Additionally, the difficulties that businesses confront significantly impact the infrastructure and channels they employ to have complete access to their distribution network. Retailers in a variety of consumer areas, notably cycling items that saw an unexpected increase in demand during the COVID-19 epidemic, have been impacted by these difficulties. For example, pharmaceutical and retail businesses had to deal with growing demand, which necessitated increasing supply. Yet, in the face of the global pandemic, global supply chains could not meet such requirements, which put most companies at risk. In turn, other industries, such as automotive and textile industries, had to face the decreasing demand for their goods and the inability to transport items from overseas due to lockdowns and factory inefficiencies.

Methodology

In order to learn about the negative effects of the COVID-19 virus on global supply chains, this research employs an interview. Two senior executives from two firms participated in this study. The participants were given the letters P1 and P2 for privacy reasons. P1 is a female participant, 32 years old, who works in the textile industry. P2 is a male participant, 46 years old, who works in the automotive industry. On the basis of the pertinent material, interviews were performed, and a set of questions was created. The sample for this explorative research was chosen using the purposive sampling technique. Such kind of sampling is a strategy utilized in qualitative research to accomplish specific goals and obtain the required information. The setting of the interview was chosen to be appropriate for both participants. The following study questions were posed to examine and gather data on the impact of the COVID-19 epidemic on global supply chains:

- How did Covid-19 influence your company’s operations?

- How did the disruptions of global supply chains affect your company?

- How did the disruptions of global supply chains affect you personally?

Perspectives of Participant 1 and Participant 2

According to P1, customer demand for clothes has been reduced majorly due to COVID-19 and among the contributing factors are quarantine, retail store closures, and income cuts. The textile industry has been impacted negatively by global supply chain disruptions since, as per the participant’s narration, “around 20% of all factories were running at less than 50% output, and 50% of all factories that supplied the company with raw materials were not functioning properly”. The participant then mentioned the following: “Our inability to distribute the items has resulted in the firing of many employees, a loss in sales.” Along with other issues, such as isolation and decreased number of customers, the employees underwent stress at the workplace.

However, P1 emphasizes that while significant declines in the textile and clothing business were attributed to the lack of personnel, the most significant negative factor is the poor supply of raw materials. According to the participant, the company they work for relies on Chinese factories, and the outbreaks in local regions disrupt the supplies of goods, which in turn leads to shortages of P1’s inventory. As for personal experience, the interviewee claimed that global supply chain disruptions made some non-cyclical items more expensive. For example, the woman emphasized that with the growing demand for medical items, such as gloves, masks, sanitizing gels, and various foods, the prices began to rise.

The second participant claimed that the automotive sector had experienced challenges as well. The local manufacturer of vehicles owns several factories worldwide and relies on supplies of components. As per P2’s opinion, “the automobile industry’s overall production decreased dramatically by more than 10%”. The participant mentioned the following: “The demand for vehicles dropped significantly. There was simply low demand for vehicles and components due to such an unprecedented situation. Yet, the condition was exacerbated by the issues with supplies from abroad.” Due to logistic restrictions and a shortage of components, the participant’s company was forced to shut down its manufacturing facilities in China. The reason for such action was the pressure that came from supply issues. While the factory could still produce the components and vehicles, it was hardly possible to transport them due to lockdowns. As for personal experience, P2 claimed that they underwent difficulties buying cheaper devices. With the growing demand for phones and computers and decreasing supply, the prices for such items rose. The participant mentioned that this could be attributed to the inability to transport components as well.

Implications of Findings

In this sense, both cyclical and non-cyclical industries were affected by global supply chain disruptions caused by COVID-19. The former experienced lower demand and the closure of some international factories that supplied local manufacturers with vital goods and components. In turn, non-cyclical industries were bombarded with increasing demand and supply issues. Therefore, the aforementioned information, extracted from participants who work for international companies, can be useful to utilize the following findings and implications.

Firstly, the findings emphasize the value of reinforcing connections with suppliers. Findings particularly point to the possibility of developing even more robust distribution networks by holding regular meetings between critical distributors and buyers. For example, retailers might broaden the supply periods and use flexible financing terms with their selected partners in addition to working with them to enable suppliers to fulfil the demand for their products. According to this report, merchants should consider changing their suppliers’ purchase agreements. In order to fulfill customer demand, they should make every effort to direct their workers into the departments handling high-demand commodities. Secondly, it should be advised that retailers narrowly emphasize acquiring essentials while further adjusting their inventory levels strategy to accommodate consumers. Furthermore, in order to prevent supply chain disturbance, research findings suggest that retailers forecast prospective sales growth and modify their purchasing strategies accordingly. Additionally, businesses might shift personnel to high-demand sectors and change their procurement strategies.

Conclusion

The COVID-19 pandemic occurred in 2019, affecting every country. It has exposed a number of vulnerabilities in retailers’ ability to improve supply chain efficiency. The effects of the worldwide epidemic have been significant, and some scientists predict that they will not leave by the end of 2022. This pandemic has had a detrimental effect on most non-essential retail enterprises. This study aims to investigate and analyze how the COVID-19 pandemic has impacted global supply chains and to provide suggestions and guidance for enhancing resilience by improving effectiveness and adaptation. In terms of COVID-19’s impact and its effects on global supply chains, the implications include a variety of business issues, interrupted logistics, and demand. From a professional and personal standpoint, the two research participants highlighted the vulnerability of cyclical and non-cyclical organizations. Impairments in financial, consumer, and manufacturing performance are negative effects of global supply chain disruptions. The study’s findings can assist businesses in creating adaptable supply networks to handle the challenges of the post-COVID-19 environment.

Recommendations

The given research has analyzed the material on COVID-19 and its repercussions on global supply chains to give insights into the issue. However, while accentuating the use of participants’ perspectives, the research lacks the regional diversity of the sample. The COVID-19 problem is still in its early stages, and it is unclear if immediate adjustments and reactions will establish a new standard. It can be essential for further research to make modifications to present ideas or new conceptual advancements and utilize bigger and more diversified samples. Additionally, there are more supply chain-related topics that emerge and cannot be handled in a single piece; this research only introduces the topic. The potential effects of the worldwide supply chain issue caused by the coronavirus have been recognized and examined in this study. With the help of new leadership and operational practices, as well as technologies for digitalizing their interconnected processes, businesses and supply chains can strengthen their adaptability and better understand their upstream and downstream operations. As a result, a number of suggestions that have been made to address the current issue can be observed in practice.

References

Chowdhury, P., Paul, S. K., Kaisar, S., & Moktadir, M. A. (2021). COVID-19 pandemic related supply chain studies: A systematic review. Transportation Research Part E: Logistics and Transportation Review, 148, 1-27.

Fonseca, L., & Azevedo, A. L. (2020). COVID-19: Outcomes for global supply chains. Management & Marketing. Challenges for the Knowledge Society, 15(1), 424-438.

Free, C., & Hecimovic, A. (2021). Global supply chains after COVID-19: The end of the road for neoliberal globalisation?. Accounting, Auditing & Accountability Journal, 2021, 1-27.

Guan, D., Wang, D., Hallegatte, S., Davis, S. J., Huo, J., Li, S.,… & Gong, P. (2020). Global supply-chain effects of COVID-19 control measures. Nature Human Behaviour, 4(6), 577-587.

Magableh, G. M. (2021). Supply chains and the COVID‐19 pandemic: A comprehensive framework. European Management Review, 18(3), 363-382.

Meier, M., & Pinto, E. (2020). Covid-19 supply chain disruptions. Covid Economics, 48, 139-170. Web.

Paul, S. K., Chowdhury, P., Moktadir, M. A., & Lau, K. H. (2021). Supply chain recovery challenges in the wake of COVID-19 pandemic. Journal of Business Research, 136, 316-329.

Sharma, A., Gupta, P., & Jha, R. (2020). COVID-19: Impact on health supply chain and lessons to be learnt. Journal of Health Management, 22(2), 248-261.

The White House. (2021). Why the pandemic has disrupted supply chains. Web.

Verschuur, J., Koks, E. E., & Hall, J. W. (2021). Observed impacts of the COVID-19 pandemic on global trade. Nature Human Behaviour, 5(3), 305-307.

Veselovská, L. (2020). Supply chain disruptions in the context of early stages of the global COVID-19 outbreak. Problems and Perspectives in Management, 18(2), 490-500.

Xu, Z., Elomri, A., Kerbache, L., & El Omri, A. (2020). Impacts of COVID-19 on global supply chains: Facts and perspectives. IEEE Engineering Management Review, 48(3), 153-166.

Yu, Z., Razzaq, A., Rehman, A., Shah, A., Jameel, K., & Mor, R. S. (2021). Disruption in global supply chain and socio-economic shocks: a lesson from COVID-19 for sustainable production and consumption. Operations Management Research, 15, 1-16.