Introduction

Supply chain management (SMC) is an integrative role whose main job is to interconnect important business operations and business processes across and within organizations. Collaboration and coordination with affiliates, such as vendors, third-party service providers, and clients, is an essential aspect of SCM (Anca, 2019). Effectively managing this complex system of interrelated, often widely dispersed activities needs knowledge of the current processes from the standpoint of their implementation, input, output, and associated procedures. Therefore, the requirement of the activity description requires a robust concept. In particular, the supply chain operations reference (SCOR) model. The framework is intended to assess the efficacy and efficiency of an organization’s supply chain management.

In this regard, the SCOR model applies in the case study in that the present supply chain of the Department of Defense (DoD) has reached its maximum capacity and is not practical nor efficiently adequate to satisfy the needs of the Joint Force in the future operational environment. Thus, a new focus is required to create an ideal strategic balance between the national defense policy and the supply chain system. For example, it is improving the DoD logistics policy, strategy, organizational structure, management, and procedures, which will, in turn, make the fit feasible. Overall, a streamlined SCOR model attributes to achieving optimum business standards of a supply chain system of a firm that suits the needs of its future operation failure, which will lead to an undesired supply chain system.

The SCOR Model Analysis

The supply chain operations reference (SCOR) methodology is meant to assess a company’s supply chain in terms of how effectively and efficiently it plans and executes marketing and functional activities. According to Girjatovičs (2018), the concept was initially established in 1996 by managerial consulting company PRTM, now a division of PricewaterhouseCoopers LLP (PwC), AMR Research, now a division of Gartner, and the Supply-Chain Council (SCC), now a division of APICS. In this sense, the paradigm has been fundamental in ensuring organizations achieve robust logistics efficiency. For instance, the (SCOR) is used to address, enhance, and convey supply chain management choices inside an enterprise and with its suppliers and consumers (Büyüközkan & Göçer, 2018). The model outlines the business procedures necessary to meet a customer’s requests. Another importance is it assists in elucidating logistics processes throughout the supply chain and offers a foundation for enhancing such operations.

Additionally, SCOR’s strong supply chain performance data structure, which helps administrators identify productivity issues and suggest process-level improvement actions, is a significant advantage. The SCOR model describes the plan, source, make, deliver, return, and enable business processes. Utilization of the model procedures involves examining the existing status of a company’s operations and measuring business performance using a common set of measures.

How the Department of Defense (DoD) Should Optimize its Operations to Save the Supply Chain Costs

The purpose of this case study is to underscore the incorporation of the SCOR model into Department of Defense operations that will improve the company’s supply chain performance. The Department of Defense supply chain is a worldwide network that supplies the combined force with various types of equipment. Its primary purpose is to maximize the force’s preparedness while simultaneously maximizing the use of available resources (Banerjee, 2018). The satisfaction of resource procurements from the supply, the distribution process from deployment and allocation, and the mobility and retrogressive of fixable items to support repair work of the logistic abilities that add value to the Department of Defense supply chain (DOD) (Heinbockel et al., 2017). As a consequence of this, the firm does not produce anything of its own. As a result, the business decided to change the SCOR model’s five steps to the following: plan, source, deliver, and enable.

Plan

In the planning step Department of Defense should use various elements in streamlining its supply chain, for instance. Policing and strategizing the supply chain network to steer DoD’s endeavors into the future, the DoD’s concept to supply chain management must undergo a transformation at the strategic level. In spite of attempts to enhance organizations, leadership, and procedures, suboptimal circumstances will endure without strategic transformation. Moreover, reform at the strategic level is necessary owing to the problems described in the National Strategy for Global Supply Chain Security and the future operating environment. The guideline for supply chain management at the Department of Defense should not be mixed with recommendations for material management. This policy may live in a modified DoDI 4140.01, concentrating on the supply chain’s phases, procedures, and movements. Existing DoDI 4140.01 obligations must be limited to supply chain management and include all significant entities engaged in the end-to-end distribution chain.

Furthermore, the policy shall designate a tactical Combatant Command entity as the Supply Chain Process Owner tasked with ensuring the effectiveness, efficiency, and alignment of supply chain activities throughout the Department of Defense. Therefore, to improve the efficiency of DoD, supply chain concepts, methods, and techniques must maintain tempo with prospective needs for the Joint Force and the future operational scenario and be guided by excellent commercial practices (Acero et al., 2019). As seen by the H-60 helicopter, OIF, and OEF supply chain case studies, adopting this will enhance the tactical fit between the military and supply chain strategies, reducing poor supply chain performance.

H-60 helicopter, OIF, and OEF supply chain case studies

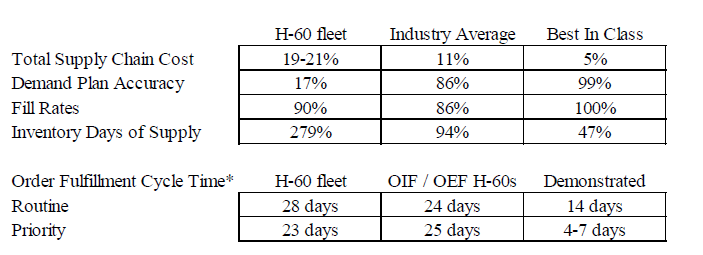

From the above figure, it is evident that in comparison to the usual supply chain in the commercial sector, the H-60 supply chain is unproductive. As seen by the overall supply chain expenses and inventory days of supply, the expenses of managing the H-60 supply chain are significant.

Source

In the sourcing phase, the organization should utilize the best value selection from the vendor selection process. As a result, it will render the supply chain low risk by using sufficient supply providers, for example. The Defense Logistics Agency (DLA) is one of the Department of Defense’s six Combat Support Agencies (CSAs). It should offer efficient and effective global logistical assistance to the Army Agencies. The partnership with different institutions, including the Military Services and USTRANSCOM, assists the Defense Logistics Executive in unifying and enhancing the worldwide supply chain. DLA’s functional reach encompasses the entire DoD supply chain, from supplier to customer and from procurement through restocking. In addition, DLA is expressly entrusted with working with USTRANSCOM to optimize distribution processes within the framework of the Global Supply Chain Management System.

Deliver

In this stage, all materials should have robust balance support goals; to be precise, the inclusion of Supply Chain as a Logistics JCA, coupled with the subsidiary Joint capability areas (JCA) abilities, would trigger significant DoD reforms. This modification to the JCA will facilitate end-to-end supply chain extensive analysis, strategy formulation, investment preferences, capacity portfolio construction, prowess force formation, and planning process. The current Rollout and Circulation, Maintain, and Supply JCAs will require changing to accommodate the new Supply Chain JCA functionalities.

Enable

In this step, the material manager should ensure value support by optimizing relationships with vendors. It is required for effective supply chain operations due to internationalization and increased interconnections within the supply chain. The Operation Enduring Freedom (OEF) supply chain case study is an excellent illustration of the significance of risk management in DoD logistics. Therefore, quality management must be included in organizational mindset, planning, and operations to mitigate the effect of interruptions on potential DoD distribution networks. This will decrease risks by increasing the safety, adaptability, and resilience of the supply chain. The objective is a robust supply chain that mitigates disturbances. Thence, to guarantee the achievement of this objective, a logistic risk office should be formed inside the OSD-level SCI office, the J-4, and the redesigned Combatant Command offices. These changes will guarantee that supply chain risk management is included in DoD supply chain and Combatant Command planning, as well as strategy and policy.

Conclusion

From the case study, it can be deduced that the SCOR technique can assess a company’s supply chain at several levels of granularity. It provides businesses with a sense of how sophisticated their supply chain is. The process enables businesses to comprehend how the five processes are repeated between suppliers, the business, and consumers. Each connection in the supply chain is vital to the effective progression of a product through each level. Identifying supply chain issues using the SCOR model has proved beneficial for businesses. The approach provides total capital investment leverages, the development of a supply chain road plan, the synchronization of business operations, and an estimated return on investment of two to six times the initial expenditure.

References

Acero, R., Torralba, M., Pérez-Moya, R., & Pozo, J. A. (2019). Value stream analysis in military logistics: The improvement in order processing procedure. Applied Sciences, 10(1), 106.

Anca, V. (2019). Logistics and supply chain management: An overview. Studies in Business & Economics, 14(2).

Banerjee, A. (2018). Blockchain technology: supply chain insights from ERP. In Advances in computers, 111, 69-98. Elsevier.

Büyüközkan, G., & Göçer, F. (2018). Digital supply chain: Literature review and a proposed framework for future research. Computers in Industry, 97, 157-177.

Girjatovičs, A., Rizoto-Vidala-Pesoa, L. M., & Kuzņecova, O. (2018). Implementation of SCOR based business process framework for logistics and supply chain in retail company. Information technology and management science, 21, 69-74.

Heinbockel, W. J., Laderman, E. R., & Serrao, G. J. (2017). Supply chain attacks and resiliency mitigations. The MITRE Corporation. Web.