Introduction

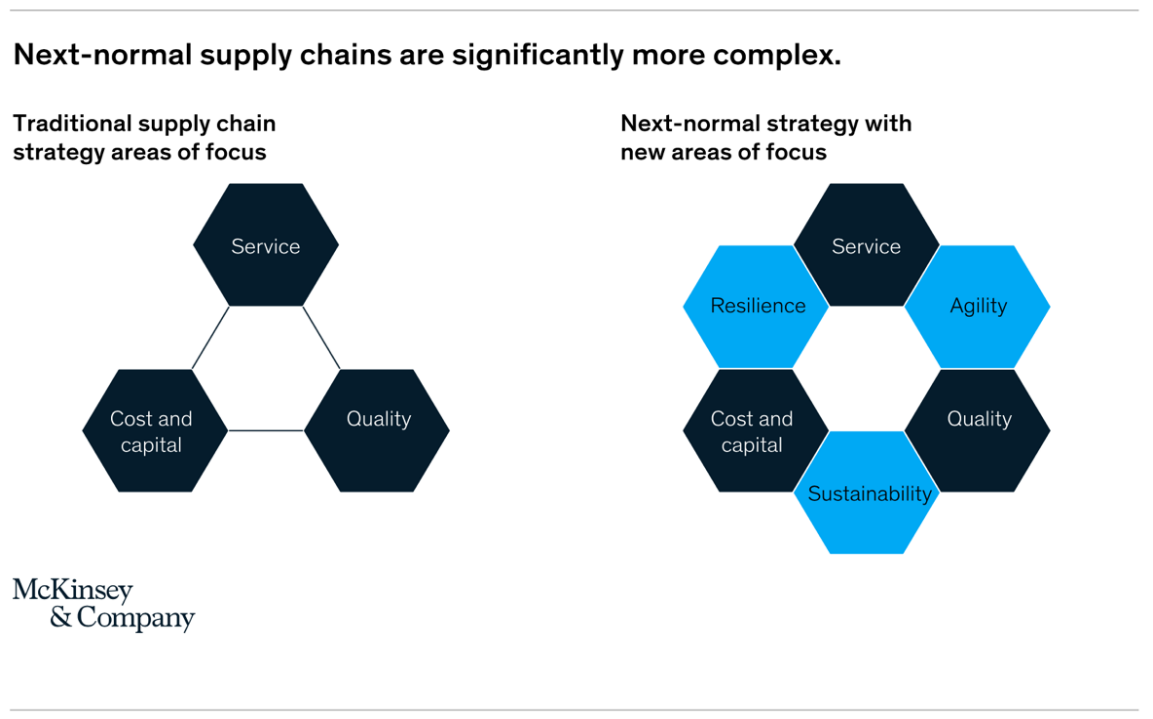

The traditional supply chain is one of the main agendas of many companies worldwide. The vulnerability of the world supply chain was evident from the COVID-19 pandemic and the economic impacts resulting from the pandemic (Henrich et al., 2022). Similarly, ongoing Russian war in Ukraine has contributed to the need to strengthen the supply chain. The major focus areas of the traditional supply chain included quality, service, and cost. Additionally, it led to supply chain leaders being in an unfamiliar position where they must make fundamental changes in the supply chain. The three new areas suggested by Henrich et al., (2022) are sustainability, agility, and resilience and they have been discussed in detail below.

Resilience

Resilience is a supply chain strategy that has helped overcome supply chain challenges. A supply chain that can withstand stresses and then bounce again is what defines resilience. This requires the capacity to prevent or lessen the severity of most supply chain interruptions. Multiple links in the supply chain might be jeopardized if operations are in danger or interrupted. Resilience helps mitigate risks like the COVID-19 collaboration (Villar et al., 2021). Another reason resilience should be implemented is the presence of cyberattacks, global health events, natural disasters, and geopolitical. If a company’s supply chain network is resilient, it will be better equipped to deal with disruptions and shifts in the supply chain and operations events (Manyika et al., 2020). An organization is versatile and fast to adjust to new demands and supply conditions. They employ cutting-edge statistics to foresee potential disruptions and act swiftly and confidently in response.

Agility

Agility is a business approach that helps organizations adapt quickly to the ever-changing want and demands of their consumers. Better and more timely data, increased visibility, the capacity to execute quicker than the competition, and integrated and collaborative connections with key supply chain partners are three of the most critical benefits of agility (Henrich et al., 2022). These benefits allow for faster and better reactions to new possibilities. To fully take advantage of the agility and its benefits, it is sometimes necessary to implement fundamental changes throughout a company (Alicke et al., 2018). A number of prerequisites must be met before the concept of an agile company can become a reality and an advantage in the marketplace. Through agility, the compound global supply chain is optimized. In addition, the supply chain can respond to shorter life cycles as fast commercialization is achieved. Lastly, efficient distribution of demand and supply is achieved through agility.

Sustainability

Sustainability refers to a strategy for management that ensures a company’s continued success from a financial, operational, and social perspective while also safeguarding the environment. It is the practice of managing a company in a way that has a net beneficial effect on the world around it. Sustainability is essential in reducing environmental impact and protects against reputation damage (Henrich et al., 2022). Since environmental responsibility is a central focus in modern industry, a supply chain built on a sustainable platform opens up additional potential for collaboration (Henrich et al., 2022). A company’s credibility and image will grow if eco-conscious decisions are made in all supply chain practices. Increased productivity and cost savings are two additional benefits of a sustainable supply chain. Buildings, cars, and other gear may all be made more efficient at a lower cost by employing eco-friendly methods and materials.

Conclusion

In summary, agility, sustainability and resilience are essential in strengthening the future supply chain. These new areas cannot be grafted onto current supply chain structures. They must be integrated into the supply chain and factored into every process step. Risk, sustainability, and agility key performance indicators should be examined alongside more traditional ones focused on cost, capital consumption, service, and quality. Workforce management and digital competencies will be required to succeed in these supply chain areas.

Reference List

Alicke, K., Rexhausen, D. and Seyfert, A. (2018) Supply Chain 4.0 in consumer goods. Mckinsey & Company, 1(11).

Henrich, J., Li, J., Mazuera, C., Perez, F. (2022) With supply chains in the spotlight, three new long-term transformation priorities form a fresh focus for competitive advantage.

Lund, S., Manyika, J., Woetzel, J., Barriball, E. and Krishnan, M. (2020) Risk, resilience, and rebalancing in global value chains.

Pla-Barber, J., Villar, C. and Narula, R. (2021) Governance of global value chains after the Covid-19 pandemic: A new wave of regionalization? BRQ Business Research Quarterly, 24(3), pp.204-213.