Operations Management

Facility design or layout mainly relates to the business’s location and the different incentives that come with it. An important factor to consider is the proximity of the location to the market and the value that the location adds to the entire organization (Reid & Sanders, 2019). Suppose the distance to the market is too long. In that case, the company will have to factor in substantial transport costs that may reduce the projected revenue and affect the company’s sustainability in the long term. Other factors to consider are the expansion of the potential and financial incentives in the location. The space must be large enough, and there must not be too many regulations limiting movement and waste management. Restrictions do not give the management enough will to tackle challenges as they arise.

Car Manufacturing Industry

The best industry to focus on is car manufacturing. Numerous companies can be used to give specific examples of how operations management is essential and determines the success or failure of a single company or the entire sector. The assembly line is one of the most important installments in the car industry. Most of the labor is situated. A car company usually occupies a large tract of land because of the hive of activities needed to ensure that the product fits the markets’ demands and fit the safety standards from the regulatory agencies. Various internal and external people ensure the product fits the set standards and collaborates to meet the set objectives.

Layouts

For the mentioned industry, cellular layout may be considered as a good option. Such an approach aims “to combine the flexibility of a process layout with the efficiency of a product layout” (Russel & Taylor III, 2019, p. 274). It is founded on the concept of group technology, according to which different machines and processes are assorted into work centers, or cells, to deal with elements and customers with corresponding requirements. Within the scope of the car manufacturing industry, the crucial reasons for applying the cellular layout are reduced material handling and work-in-process inventory, given the necessity of a considerable number of cars’ parts and their complexity (Gutta et al., 2018). However, the disadvantage here will be the difficulties during the process of balancing cells due to the presence of a plethora of parts’ families in car production.

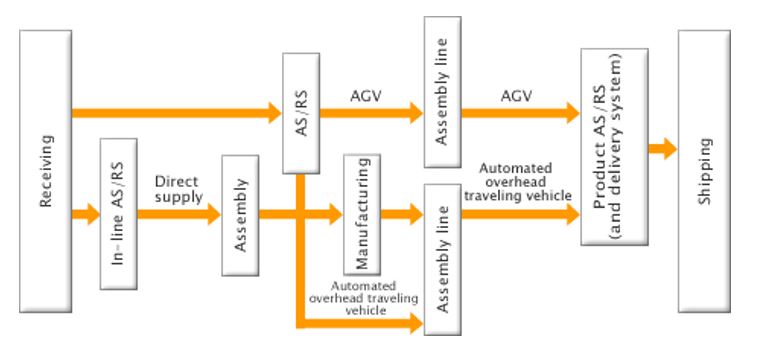

Thus, an alternative should also be provided. A flexible manufacturing system, or an FMS, contains many programmable instruments that are linked by an automative material handling frame and regulated by an advanced computerized network. The described approach implies both flexibility and effectiveness because these instruments automatically change from vast storage tools at all machines, which holds a substantial variety of opportunities.

According to Russel & Taylor III (2019), “The efficiency of an FMS is derived from reductions in setup and queue times” (p. 278). Given the number of processes, tasks, and variables during car manufacturing, the mentioned advantage may be considered essential. The below layout is a notable example from the car production industry. If it is advanced to the level of an FMS, it might be assumed that the processes will be coherent, harmonized, and consistent.

Layout for Car Production

The manufacturing plant has a combination of both imported and locally made parts. Suppose the company manufactures all parts in its main location. In that case, it will incur considerable costs, and the likelihood of getting losses is high (Gutta et al., 2018). The company may work on the body structure and the chassis, but the rest of the parts like windows, stereo, tires, and operating system are imported. At the front of the company should be reception and inspection center to receive the imported parts and ensure they meet the required specifications. This step is critical in ensuring that the final product meets the set requirements.

They are then forwarded to the assembly, where the imported parts are combined with internally produced items. For example, hinges that hold the stereo into place are fixed (Kikolski & Ko, 2018). The lining of the windows is streamlined according to the car model. These merged parts come from the internal manufacturing line that has its inspection center. The item is then sent to the assembly line, where the car’s body is being assembled, and the remaining parts are inserted.

However, before this activity, the body must also be inspected, and the defects are corrected or discarded. The imported parts are only fitted in inspected car models. Testing is essential, and the internal systems follow the state and federal authorities’ safety guidelines. Sometimes inspection from such agencies may be conducted at the site or while in the market. Nevertheless, the manufacturers must always have the policies. After either internal or external inspection, the cares are delivered to the market, or return chances are left open if the client notices a defect. The entire system is set to operate without managers’ direct intervention, and there are clear guidelines on how all activities are to be conducted.

References

Barnes, D. (2018). Operations management. Macmillan International Higher Education.

Gutta, P. R., Chinthala, V. S., Manchoju, R. V., MVN, V. C., & Purohit, R. (2018). A review on facility layout design of an automated guided vehicle in flexible manufacturing system. Materials Today: Proceedings, 5(2), 3981-3986. Web.

Kikolski, M., & Ko, C. H. (2018). Facility layout design–review of current research directions. Engineering Management in Production and Services, 10(3), 70-79. Web.

Reid, R. D., & Sanders, N. R. (2019). Operations management: An integrated approach. John Wiley & Sons.

Russel, R. S., & Taylor III, B. W. (2019). Operations and supply chain management. Wiley.