Introduction

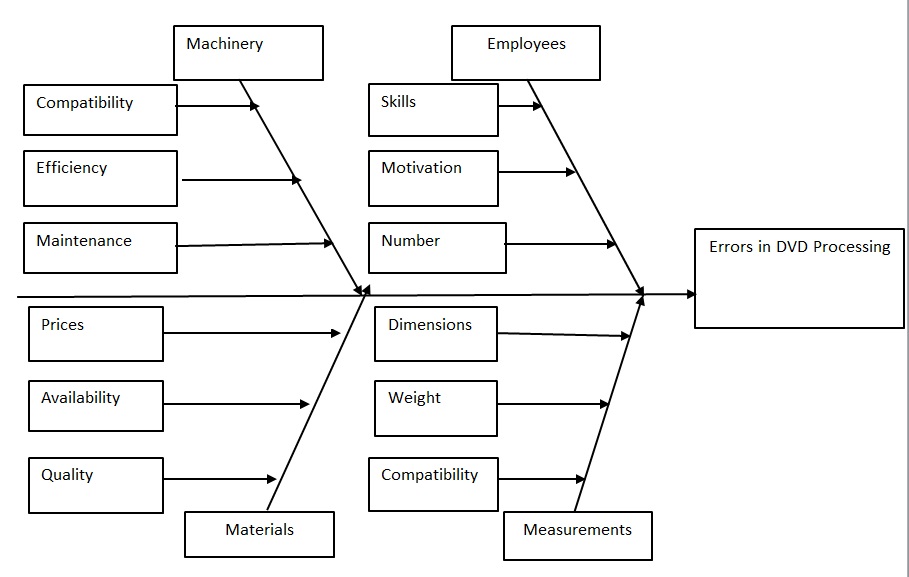

Business enterprises are established with an aim of generating profits by producing quality and affordable goods. However, sometimes it is not possible to get the anticipated profits due to some reasons. It is crucial to note that while most of these problems may be solved using internal mechanisms some are difficult to handle and may require an expert’s attention (Schragenheim 2009). However, by developing a cause and effect approach it becomes easy to handle them within a short period. This essay presents a cause and effect diagram and feasible solutions for challenges facing company XYB that produces a variety of DVDs as shown in the diagram below.

Explanations

The production of all electronic devices requires professional knowledge and skills since a slight mistake may lead to serious problems. This is an expensive undertaking that requires attention to detail and extreme carefulness to ensure there are no losses and efficiencies (Haines 2011). However, this does not rule out the fact that there may be unavoidable challenges during the production process.

Some challenges are unpredictable and this means they get most manufacturers by surprise. However, this company managed to identify the major causes of errors when manufacturing its products. Initial investigations showed that there were four causes of errors in DVD processing. These challenges originated from their machines, employees, measurements, and materials used in production.

Machinery

Machines are important elements in any production process after land and capital. This company deals with the production of electronic machines and this means that a greater percentage of its production process involves machines. Human labor is used in the final stages of assembling various DVD parts like lenses, motherboards, transmitters, and others. It is necessary to note that machines must be efficient in order to facilitate faster and quality production (Oskaloosa 2012). However, the following machinery aspects are responsible for the errors occurring in the production process.

First, the machines used may not be compatible with some of the production processes. This means that they may have been manufactured to produce other electronic goods like televisions and cameras but not DVDs. Secondly, these machines may be out of date and thus not efficient enough to produce quality DVDs. The company may have purchased new machines that are much faster than others and this lowers their efficiencies (Haines 2011).

Lastly, machines are just like human beings and require regular maintenance and servicing to ensure all parts are working well (Schragenheim 2009). Human beings require food, rest, and medical attention in order to function well. Similarly, these machines require greasing, oiling, and repair of worn-out parts due to the wear and tear effects experienced during production.

Employees

This is also a key factor of production and it involves the use of human labor in terms of energy or expertise. The errors experienced by this company may have been caused by unskilled employees. Electronic machines require experts to handle their production process in order to eliminate chances of any errors occurring.

Secondly, they may be lacking the necessary skills and experiences to handle this task since most of them may be recruits or inadequately trained (Schragenheim 2009). Secondly, there are high chances that these employees are not motivated to work hard and deliver the expected results. It is also true to propose that they may not be aware of their roles in the company and this leads to confusion.

There may also be chances that they lack the professional discipline that ensures employees follow work policies. Lastly, they may be fewer than what the company requires to produce these goods (Schragenheim 2009). Therefore, most of them may be straining beyond their abilities and this usually compromises the quality of work done. In addition, they may be doing more work than is necessary and this leads to fatigue and boredom which are productivity killers.

Measurements

Accuracy in terms of measurements is an important consideration that determines the quality of finished products. However, this company seems to have problems with this issue since there are many errors during the final production stages (Oskaloosa 2012). First, the company does not pay attention to the dimensions required for various components. It is evident that some parts of the DVDs like the cases, CD belts, and transformers are acquired from other companies. Their partners usually pay attention to measurements to ensure they are universal and can fit in most DVDs.

Secondly, some parts are made from delicate substances that require careful handling to avoid breakage. However, this company produces components that are heavy and thus they break before being distributed to various stores. Lastly, the measurements of most components produced by this company are not compatible with other parts from different companies. This means there are variations in measurements that cause errors while assembling these machines.

Materials

The errors noted in these machines may be a result of poor quality materials used to produce them. These machines require asbestos to connect all power-related components since the wires are made from heat resistance substances (Oskaloosa 2012). However, the company seems to be using local wires for these purposes and this makes the machines not work properly.

In addition, the required materials for making the cases and other parts may not be available in the local market and thus the company opts to improvise them (Haines 2011). This does not seem to work as expected and leads to the production of faulty machines. Lastly, this company may be trying to cut costs by purchasing cheap materials that do not have huge transportation and taxation costs. However, these materials are not able to perform their functions properly and this leads to errors and inefficiencies in the final products.

Recommendations

The company should purchase modern machines that can multitask and are more efficient and compatible with most applications. They need regular checkups, maintenance, and replacement due to friction and other effects. In addition, employees should be trained on various production activities, and where expert advice is needed the company should not hesitate to hire professionals.

There should be specialization and division of labor to ensure transparency and accountability are maintained. Workers must not be overworked since this undermines their productivity. They should be motivated to do their best through the increase in salaries and improved working conditions. The company should pay attention to measurements and weights when producing various components to allow them to fit into others.

Lastly, it should focus on acquiring quality raw materials and other products to ensure they are of a high standard. Even though, these materials may be expensive they are necessary to ensure the company does not incur losses due to errors related to poor materials.

Conclusion

Cause and effect diagrams are simple tools that perform significant roles in highlighting inefficiencies in production. They can help investors adopt a direct approach to dealing with various challenges.

References

Haines, S. (2011). Managing Product Management: Empowering Your Organization to Produce Competitive Products and Brands. New York: McGraw-Hill.

Oskaloosa, D. (2012). Quality Management for Organizational Excellence: Introduction to Total Quality. New Jersey: Pearson Learning.

Schragenheim, E. (2009). Management Dilemmas: The Theory of Constraints Approach to Problem Identification and Solutions. Florida: CRC Press.