Abstract

Companies operating in the manufacturing industry need to consider various strategies to maximize production while reducing potential defects. This discussion presents four case studies that organizational leaders can consider to make their businesses more successful. The first part describes how AutoNation can implement an effective product development process for its cars and attract more customers in the American sector. The second section describes the major procedures companies in the automotive industry can pursue to improve manufacturability, increase quality, and eventually reduce operational costs. The third section uses a Quality Function Deployment (QDD) diagram to describe the major customer and technical requirements for a laptop and how both the buyers and companies need to target their aims while focusing on the demands of all key stakeholders. Using the fishbone diagram, the last part presents the example of General Motors to describe the major causes of defects and the best initiatives to mitigate them.

Product Development Process

AutoNation is one of the leading retailers of both used and new vehicles in the United States. Since 1996, this organization has expanded by opening over 360 outlets in different parts of the country. It also provides support systems and spare parts for some of the common brands in the selected regions. According to Nguyen (2019), this auto retailer was reported to have been selling defective or recalled cars. The reason for such a decision was because some of them were faulty and incapable of protecting and meeting the demands of the user. The nature of this challenge means that AutoNation might become unprofitable and lose most of its customers if the leaders fail to introduce superior solutions.

The selected product for this organization is the vehicles it acquires from dealers and markets them at a profit. The most appropriate product development process for these cars is to hire competent professionals to inspect all automobiles before they can be listed for sale. Such individuals should be conversant with the mechanical and electrical parts of the cars. The use of modern technologies for diagnostic purposes can address the identification of defects (Singh & Banton, 2016). Vehicles that have such flaws will then have to be refurbished or improved to meet the requirements of the targeted customers. This initiative will ensure that all clients are convinced that every car will deliver the anticipated expectation.

Similarly, AutoNation needs to liaise with the leading manufacturers and suppliers of the targeted automobiles. Nguyen (2019) indicates that this company’s new vehicles amount to 59 percent. A collaborative approach will make it easier for the partners to identify the potential sources of defects and single out cars that have increased chances of being recalled. The implementation of these product development processes means that all cars, both new and old, will get the relevant adjustments and improvements to meet the outlined sustainability and quality standards. Such measures will make AutoNation a competitive company in its sector.

Improving Manufacturability

The automobile industry has continued to transform human experiences and lives by delivering high-quality vehicles that support a wide range of activities, such as transport and shelter during harsh weather conditions. Customers have become selective due to the issues of sustainability and the availability of more rival products. Consequently, most of the manufacturers have implemented powerful systems and models to streamline the entire production process (Lumsakula et al., 2018).

The car is, therefore, identified as the best product for this analysis and description. Many corporations in different parts of the globe have been keen to innovate and design new vehicles that resonate with the changing expectations of the identified users. However, some design flaws and defects tend to emerge, thereby affecting the profitability of such organizations.

Several design guidelines are worth considering if most of the companies in the global automobile industry are to overcome such obstacles. The guiding concept that different stakeholders in the sector need to take seriously is that of design for manufacturing (DFM). First, organizations can ensure that their cars have many standardized parts to minimize chances of failure or delays. Second, such parts are multi-functional and capable of supporting different aspects or stages of the car manufacturing process (Evans & Lindsay, 2016). Third, companies can ensure that most of the parts can be joined together without the use of screws. Such a design approach means that the manufacturing process will be shorter and accurate. The initiative is also capable of minimizing labor costs and time.

Fourth, the implemented process needs to be appropriate depending on the tasks being undertaken. Fifth, organizations can design their parts in such a way that the workers will only have to interact with them minimally (Lumsakula et al., 2018). Sixth, all procedures and surface finishes need to meet acceptable standards without the need to focus on flashy or unnecessary outcomes for the targeted cars. Finally, manufacturers need to adjust the robotic system put in place to handle a wide range of parts depending on the nature of the car put on the production line.

From the nature of this proposal, it is notable that any company that embraces such design guidelines will improve the speed and rate of manufacturing its cars. Most of the parts and processes will be identical for most of the vehicle makes. The company will eventually minimize operational costs since the handling and duplication processes will be reduced in a significant manner. The chances for error or damage of parts will reduce since most of them would not need to be fixed or jointed together. The robotic technologies will work seamlessly to ensure that the products are delivered promptly. Such a process will eventually support the production or manufacturability of high-quality cars that meet the demands of the end-users (Lumsakula et al., 2018). The costs will reduce and make it possible for the company to record increased profits.

Customer and Technical Requirements: QFD Format

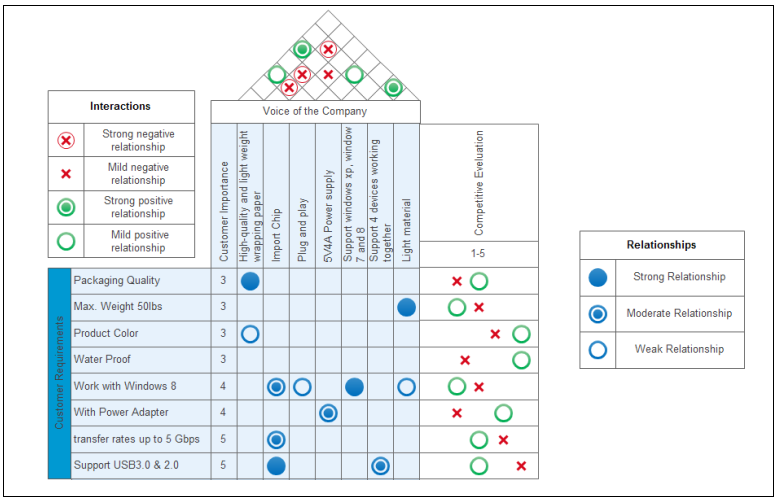

A product requirements (PRs) concept is essential since it guides stakeholders to understand the unique attributes associated with a given item or service. A detailed analysis of such aspects can make it possible for customers to make informed decisions and understand the unique benefits a specified product is capable of delivering. When done professionally, such an analysis should avoid detailing how such a product is capable of achieving the intended results (Min et al., 2018). The importance of such a strategy or model is to avoid influencing an individual’s purchasing decisions. The selected product for this analysis is that of a laptop.

The major customer requirements for such an item are worth considering before making the relevant decisions. The first one is that of packaging quality or material that delivers the laptop to the final user. With the emerging issues to do with climate change, many people would be focusing on this requirement in an attempt to improve the level of environmental sustainability (Min et al., 2018).

The second aspect to consider is that of weight whereby a good laptop is around 4-8 pounds. Such a product needs to be light and portable to meet the demands of the user. The third outstanding customer requirement that many individuals would monitor is the issue of color. Laptops can be of different colors, including maroon, red, black, white, or silver. The fourth unique requirement buyers would put into consideration is whether the computer is waterproof or capable of avoiding damage.

The fifth requirement is the product’s ability to work with Windows operating software. The sixth aspect many people would take into consideration is whether the product has a power adapter or not (Min et al., 2018). Customers would be unwilling to purchase a computer that does not provide such an accessory. The seventh requirement is the laptop’s ability to transfer large files in a short time. Computers that cannot complete such a task might be unreliable or unwanted to the customer. The final consideration different potential buyers can consider is the product’s ability to support USB versions 2.0 and 3.0.

Technical requirements are essential since they address the demands and expectations of the greatest number of stakeholders for the product’s lifecycle, including customers, government agencies, environmentalists, and community members. The first requirement is the importance the producer puts on the customer. The second one is the use of high-quality and lightweight material for wrapping the product. This is essential since it should protect the environment and meet the needs of all stakeholders (Min et al., 2018).

The import chip and the ability to plug and play are also essential technical requirements (see Fig. 1). The next one is the product’s ability to support most of the operating systems. Another unique aspect is the use of lightweight materials to protect the overutilization of scarce resources (Evans, 2012). The presented Quality Function Deployment (QFD) translates such requests to the solutions aimed at transforming the customer’s experiences (see Fig. 1).

Product Defects

Every customer expects to receive a high-quality product that meets his or her expectations. Companies need to implement powerful initiatives to identify possible causes of defects and rectify them before they can affect the functional and aesthetic aspects of the item. Such imperfections might be minor, critical, or even major depending on their potential impact on the product. When defects occur, chances are high that the affected organization will fail to meet the changing demands of the customers (Pyzdek & Keller, 2012). Business firms need to identify possible causes of such errors and rectify them to increase the level of customer satisfaction and eventually maximize sales.

The selected company for this analysis to understand the potential triggers of product defects is General Motors (GM). In 2014, GM faced a major scandal after it was forced to recall over 30.4 million cars that had already been marketed globally. Such vehicles had been fitted with defective ignition switches that we’re able to shutdown engines within giving a prior warning. Such a process could disable braking systems, power steering, and airbags (Wright, 2015). This defect resulted in around 124 deaths in different parts of the world. The first possible cause of this outcome was the poor design of such ignitions for the 2014 cars.

This would be grouped under the technical aspect of the manufacturing process. The second was GM’s failure to test the ignition systems before releasing them into the market. This gap can be analyzed from the lens of the human resources or workforce attribute (Goetsch & Davis, 2014). The third cause of such a defect was the nature of the assembly line that failed to inspect the ignition before fitting it into the cars (see Fig. 2). The fifth potential factor that led to this challenge was the failure to test the final car effectively and identify any possible cause of failure.

These malpractices explain why the delivered car in the market was defective and capable of causing deaths. A detailed understanding of these possible causes of imperfections in different cars can guide more companies to identify and mitigate them since they have the potential to affect the level of profitability (Wright, 2015). The coordination of all workers, engineers, and stakeholders could have made it possible for this company to identify the faulty switches and ensure that they were not produced on large scale. Such a move would have also become a new opportunity for minimizing the losses GM recorded after recalling the affected cars.

Conclusions

The completed exercise has outlined evidence-based strategies that companies can consider to develop their products and make them more admirable in the market. The use of experts, research and development (R&D), and continuous monitoring of customers’ needs can result in the delivery of high-quality products. The consideration of effective design guidelines can improve the manufacturing process and minimize operational costs. The exercise has presented customer and technical requirements as essential when developing a given product and marketing it successfully in the specified market. Such attributes will inform the most appropriate considerations to ensure that the demands of all stakeholders are met. Finally, the fishbone diagram has emerged as a powerful tool for analyzing or locating the potential sources of product defects and implementing superior measures to mitigate them.

References

- Evans, J. R. (2012). Management and control of quality (8th ed.). South-Western College Publisher.

- Evans, J. R., & Lindsay, W. M. (2016). Managing for quality and performance excellence (9th ed.). Cengage Learning.

- Goetsch, D. L., & Davis, S. (2014). Quality management for organizational excellence: Introduction to total quality (8th ed.). McGraw Hill.

- Lumsakula, P., Sheldrickb, L. & Rahimifarda, S. (2018). The sustainable co-design of products and production systems. Procedia Manufacturing, 21, 854-861. Web.

- Min, H., Yun, J., & Geum, Y. (2018). Analyzing dynamic change in customer requirements: An approach using review-based Kano analysis. Sustainability, 10(3), 746-762. Web.

- Nguyen, T. (2019). America’s largest auto retailer sells recalled cars. That isn’t against federal law. Vox.

- Pyzdek, T., & Keller, P. (2012). The handbook for quality management: A complete guide to operational excellence (2nd ed.). McGraw Hill.

- Singh, V., & Banton, S. (2016). AutoNation: Driving customer loyalty in a fragmented industry. Applied Marketing Analytics, 2(2), 162-168. Web.

- Wright, R. (2015). GM faces paying more than $1.5bn over fatal ignition switch fault. Financial Times.