Introduction

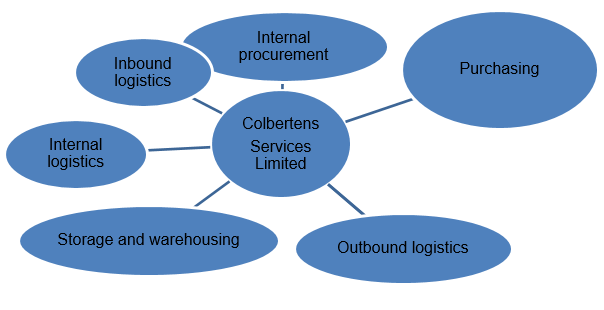

This paper will examine the sourcing plan which is a significant aspect of expenditure within the Colbertens Services Limited, which is a Dubai-based service company. When reviewing the cost aspects, the paper examines products, services, and logistics involved in the supply chain management at the company. From the research, it is apparent that the company spends millions in supply chain management, since it operates in the volatile service industry in Dubai.

The paper addresses the balance in cost and quality with an intention of increasing the profits at the company. Thus, selecting important service balance in the cost efficiency in supply chain management for the case of this company is necessary to create a sustainable sourcing plan. Through proactive consultation with the company stakeholders, I established that the Colbertens Services Limited has a high expenditure in logistics involved in managing its supply chain.

This means that the paper will concentrate on the company as an important entity that should manage efficiency in the supply chain management to reduce costs and increase profits. The business is positioned to gain from different customer segments since the online platform has been positioned to serve interests of all customers through provision of stratified services that matches the demands of these clients. This means that the business will gain from self competition and may even grow further as the online product ordering line is embraced by the targeted clients.

Role of Procurement and Supply in Managing Expenditure: Stakeholder Inputs

Logistic and supply chain management is critical in monitoring the efficiency in line with the objective, goals, and mission of an organization. Efficiency improvement facilitates sustainable and optimal functioning of different aspects of the supply chain. In most cases, many organizations have dysfunctional supply chain system due to lack of a proper balance in the factors such as efficiency, automation, costs, and communication, which are stakeholder inputs.

The aspect of efficiency guarantees complete management of the expenditure processes to ensure that bottlenecks and other challenges are dealt with appropriately. For instance, when allocating costs for streamlining the supply chain, it is necessary to put the stakeholders on board to ensure that any decision made augers well with their interests (United Nations Economic Forum for Europe 27).

This is necessary as a back-up for any eventually, especially in the short-term. On the other hand, the aspect of automation is vital in managing the cost from a management perspective. In the field of supply chain management, any decision by the control team should be streamlined to the desires of the stakeholders, especially when the process is winding and continuous. For instance, when adopting a new technology in managing costs, it is the stakeholders, especially the shareholders who have to pull resources or approve expenditure (United Nations Economic Forum for Europe 25).

This means that they have to be consulted to ensure that any changes in the cost management are convenient and supported by them. An otherwise decision might result in conflicts of interests, especially when the stakeholders reject any decision they deem is not in their interest. Moreover, communication is a vital tool for complete supply chain functionality, when all other factors are smoothly operating. Communication is like a puzzle that synchronizes the desires of the shareholders in the form of a flowchart.

For instance, when making any decision that touches on expenditure, it is vital to write down or articulate the rationale behind each decision to give the stakeholders enough time to brainstorm and react before such ideas are turned into policies. Lack of communication in a timely manner may compromise the entire cost management flowchart since stakeholder interests will not inform the final decision. In such an event, the results of imbalanced communication flowchart would undermine the ideals and strategic framework for decision making, which is inclusive of the stakeholder interests (Teece 176).

In the above elements, stakeholder participation determines their success in the short-term and long-term. In a perfect environment, the above factors should occur simultaneously, despite being extremely independent of each other. This is necessary to complete the entire process of logistics and supply chain function that incorporate the interests of the stakeholders. The balance in efficiency, automation, and communication as part of the stakeholder functions in the supply chain management would guarantee complete and sustainable expenditure management, irrespective of the size of structure of the logistics involved in executing decisions (United Nations Economic Forum for Europe 28).

Basically, “supply chain analysis is the examination of the management of the flow of information, inventory, processes, and cash flows from the earliest supplier to the ultimate consumer, including the final disposal process through value chain analysis” (Teece 178). In order to achieve the functional value chain balance, there is need to use tools that support strategic cost management to minimize economic risks of sourcing raw materials such as the single window system.

Once processes have been mapped, keeping the value proposition in mind, the organization can determine which tools to use to better understand the cost through applying cost analysis, price analysis, total cost of ownership, and targeting cost.

Under cost analysis, an organization should analyze zero-based pricing, as well as analysis of service provider cost elements. Price analysis involves understanding the prices available in the marketplace. Total cost of ownership involves analyzing the true cost of acquisition, use, maintenance and disposal of a good, services, capital equipment, or process (United Nations Economic Forum for Europe 29). These factors will form the cycle of value addition improvement that can remain sustainable in the short-term and long-term in expenditure management.

Inadequate analytical dimensions of supply chain such as business responsibility, customer service quality and cost may compromise the functionality of a supply chain, especially when it operates in a multi window platform. The core competency of the single window system lies in its capacity to reduce operational costs while at the same time reducing delivery times. This process constitutes a core competency since “improvements in delivery time, price, and product line-ups can add a significant value to a business’ offering and can help it to find a true niche in even the most crowded markets” (United Nations Economic Forum for Europe 29).

To determine its performance of the supply chain management, it is necessary to measure operations, logistics processes, and customer contentment to derive strategies for reducing operating costs together with increasing revenue growth. The measurement of operational costs indicates the healthiness of the logistics and supply chain performance. It also aids in the discovery of the necessary areas of improvement.

In the effort to attract and retain its customers, the supply function unit in a company should emphasize increasing price value of the services that it offers (David 56). This kind of communication is achieved through IT tools such as aramex.com, ePOD, and PACK for its single window system called the APC to measure the aspects of professionalism, speed, flexibility, competitive pricing, friendliness, and the provision of a variety of services within the supply chain system (Teece 189).

The value creation model cannot align cost effectiveness when logistics of operation are aligned to the SWOT matrix of an organization. For instance, lack of strong control systems and poor benchmarking approach (United Nations Economic Forum for Europe 19), as weaknesses, will compromise the organizational strategy of cost reduction, customer satisfaction, and reduction of risks when the supply chain management function is managed from different units.

The most notable trend in the current business environment is automating of the supply chain management through a single window system. This trend is becoming very common in many businesses since it has benefits such as strong distribution and retribution process, efficiency, and reduced inventory costs. Supply chain management from a single window system relieves a company of fixed costs irrespective of seasonal trends and market demand.

Through a competitive process, the single window unit will develop a balanced control system for sustainable level of efficiency, costing, dependability, speed, quality, and flexibility through value delivery, value addition, and creativity (Teece 186). However, what makes this strategy effective is the constant formulation and implementation of strategic policies based on its knowledge of the customer needs in the supply chain management as business strength. For implementation of the strategy, the management is to balance both the short term and long term consideration towards decisions making (United Nations Economic Forum for Europe 25).

Recommendations

Implementation of the single window supply chain management functionality is a systematic measure that is instituted by an organization in order to maintain efficient and cost effective operation matrix.

Further, Implementation of the single window system aid in safeguarding assets and resources of an entity, deterring inefficiencies, and sustaining completeness in management strategies. Besides, a company should be able to improve on the decision support system since the proposed turnkey strategy will endeavor to create a decentralized decision support system that incorporates planning, development, implementation, and discovery of different supply chain functions (United Nations Economic Forum for Europe 26).

An improved approach to supply management through decision support will establish a broader partnership with customers, suppliers, and employees. Such cooperation will turn supply into a competitive advantage instead of sole cost to a company through reviewing the external environment as proposed in the PESTEL Matrix (David 45).

The turnkey strategy will ensure that such a company is in a position to have full control of the quality of inputs used in manufacturing, employee retention, and distribution functions. The proposed backward vertical integration process will allow a company to produce, design, sell, and distribute its products globally within a short time span. This is possible due to internalization of a direct and complete control of the distribution and production process for its brands as proposed in the turnkey strategy.

Techniques to be applied in Managing Expenditure as Value Addition

The main techniques that can be applied in managing expenditure as value addition in the field of logistics and supply chain management are technical knowledge application, excellence facilitation, Just-In-Time (JIT) system, target appraisal, the kaizen valuation, value chain, and the activity-focused administration (United Nations Economic Forum for Europe 21). Besides, it is possible to integrate logistics outsourcing to complete the expenditure management.

In the ideal, the above tools are significant in tracking the value addition strategy, especially when they are integrated in the logistics decisions. For instance, it is imperative to balance the aspects of excellence facilitation and knowledge application to complete the value addition puzzle, especially when the process exists in the form of a flowchart strategy (David 45).

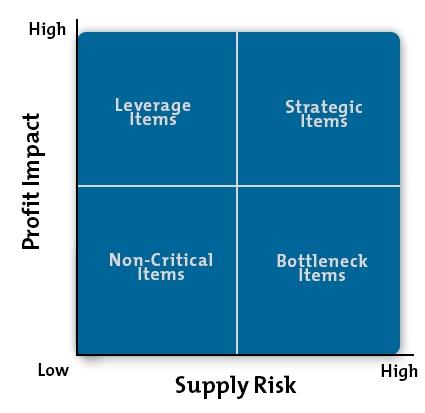

An ideal strategic cost management is based on the principle of the low-cost strategy as a competitive approach. For instance, Kraljic Portfolio Purchasing model would be ideal in strategic cost management. This model involves providing clear and consistent performance objectives, facilitating excellence, and the reduction of the complexity of the organization. Through this strategy, a company can ensure clear and aligned expectations and targets.

The approach involves the elimination of unprofitable product lines together with dealing with issues of over expanded service and product lines through reviewing the supplier bargaining power as highlighted in the Porter’s Five Forces Matrix (Worthen, Tuna, and Scheck par. 12). For example, in the industry where the low-cost strategy determines success or failure, a company can rely on technical knowledge and products to build its success. This section of the paper presents the best strategies for managing expenditure in supply chain to guarantee value addition.

Through the facilitation of excellence, a company should not rely on performance improvement that is determined by the paradigm of conducting simple caparisons between the past and current performance as stipulated in the Kraljic Portfolio Purchasing model. It should evaluate its performance based on the no-late delivery and the year-in-year-out reduction of costs, including environmental costs. In a bid to reduce organizational complexity, a company interested in managing expenditure should evaluate its product offering and mechanisms for reducing the accumulation of costs (United Nations Economic Forum for Europe 25).

This process involves the crossing of non-profitable product lines due to the accumulation of high marginal costs. For instance, the leverage items and strategic items should be bundled together to have optimal profit impact and the least supplier risk. On the other hand, bottleneck items and non-critical items should be put together for the high supply risk to be managed by the bundling of the leverage and strategic items. This Kraljic Portfolio Purchasing matrix is summarized in the diagram below.

A company can use a variety of tools to facilitate its cost reduction strategies. They may include the Just-In-Time (JIT) system, target appraisal, the kaizen valuation, value chain, and the activity-focused administration. The JIT plan eliminates the necessity for storage through warehousing, which increases material-handling costs (David 48). Target valuation may entail the designing of the company’s supply chain in a manner that ensures customer appraisal at the targeted prices.

The plan also ensures that customers not only break even, but also make some targeted profit. Hence, the company retains customers while at the same time building long-term business relationships so that the company does not increase costs that are associated with searching new customers. Activity-focused administration involves the utilization of activity-based approaches to costing in a bid to improve the company’s operations.

It seeks to eliminate all non-value added activities. A company can use this approach to identify and eliminate all activities that do not add any value to its core activity, namely offering supply chain and logistics services, which increase operational costs. Value chain encompasses a methodology for building stronger customer relationships together with effective cost management.

The kaizen valuation approach involves cost reduction via continuous incremental improvement in the performance of the supply chain and logistics. This strategy opposes the approach to radical improvements via a huge investment in technology or an innovative tactic. Once processes have been mapped, keeping the value proposition in mind, the organization can determine which tools to use to better understand the cost through cost analysis, price analysis, total cost ownership, and target costing.

Cost analysis include reviewing “Should-Cost” or zero-based pricing, as well as analysis of service provider cost elements. Price analysis involves understanding the prices available in the marketplace (Worthen, Tuna, and Scheck par. 22). Total cost of ownership involves analyzing the true cost of acquisition, use, maintenance and disposal of a good, services, capital equipment, or process. Lastly, target costing involves determining what the market will bear and working backwards to see how much you can afford to produce the product or service for, and still make a profit.

Strategic cost management is important in managing the expenditure while optimizing the profit to anchor value improvement. Strategic costing involves proactive management of the supply chain and continuous review of the value aspect in business. The supply chain analysis examines the management of the flow of information, inventory, processes, and cash flows from the earliest supplier to the ultimate consumer, including the final disposal process (United Nations Economic Forum for Europe 27). Generic value propositions include cost leadership and differentiation strategies.

Logistics outsourcing relieves a company of fixed costs irrespective of seasonal trends and market demand, especially when the SMART matrix is integrated in the supply chain function (David 33). Through a competitive process, the outsourced unit will develop a balanced control system for sustainable level of efficiency, costing, dependability, speed, quality, and flexibility through value delivery, value addition, and creativity.

The outsource logistics team will have the responsibility to rationalize the scientific aspects of supply chain such as use of statistical tools, their application, and evaluation criteria in monitoring and managing the logistics. When the outsourced logistics regulator is properly balanced, efficiency in the supply chain management is achievable (Worthen, Tuna, and Scheck par. 21).

The element of increased competition as part of the future development is well assured when the objective of outsourcing is aligned to cost reduction in doing business. However, what makes this strategy effective is the constant formulation and implementation of strategic policies based on its knowledge of the customer needs in the supply chain management. Sustainable development is vital in business environment when outsourcing is incorporated in the business development goal (Teece 182). Generally, outsourcing and supply chain management strategies are interdependent to ensure that the business is sustainable. For implementation of the strategy, the management is to balance both the short term and long term consideration towards decisions making (Worthen, Tuna, and Scheck par. 15).

Recommendations

To determine the performance of value addition strategy, the company should measure its operations, logistics processes, and customer contentment. The company can measure its logistics performance in a bid to derive strategies for reducing its operating costs together with increasing revenue growth. The measurement of operational costs can indicate the healthiness of the logistics and supply chain performance. It also aids in the discovery of the necessary areas of improvement.

In the effort to attract and retain its customers, a company may emphasize increasing price value of the services that it offers. Customers’ satisfaction is measured from their feedback on their experience. This kind of customer communication is achieved through IT tools that are aimed at collecting customer feedback to help in measuring client service satisfaction in areas such as professionalism, speed, flexibility, competitive pricing, friendliness, and the provision of a variety of services.

Through role shifting, a company can concentrate on the core activities, which add the highest value to its productivity and efficiency in its operations (Worthen, Tuna, and Scheck par. 19). For example, by focusing more on increasing quality as a measure of efficiency and effectiveness in delivering customer cargo, rather than developing and maintaining IT applications in-house, a company can attract more customers. This process has the effect of increasing the organization’s competitiveness.

Developing Contract

For a contract to be valid, it should posses certain characteristics. These characteristics are existence of two or more parties in agreement, the parties must assent to the content of the contract, and there should be a legal clause that makes the contract binding. The above elements form the ideal business contract in the field of supply chain management, irrespective of its content or dynamics influencing the position of each party involved.

When one or two elements are absent in the contract, the written or unwritten agreement will become null and void. The parties involved should be ready and willing to honor the contract due to legal ramifications of an otherwise decision. Besides, the assent manifestation should be accompanied by signatures, especially for written contract. Lastly, for the contract to remain binding, it is necessary to integrate the enforceable legal premises (United Nations Economic Forum for Europe 25). The above aspects are expounded to explore the process of creating an effective contract that guarantees sustainable procurement contracting.

In the procurement and supply chain management, the aspect of clarity, consistency, and scope should be easily identifiable and justifiable since the agreement involves more than one party for it to be valid. Besides, the aspect of moral commitment through a procedural agreement forms the foundation of legality of a contract. Moreover, a legal contract should be free of fraud, misrepresentation, and force.

Irrespective of the type, that is simple or specialty, a contract with a supplier must contain the terms and condition of the agreement which must be confirmed by both parties before accenting to it (David 34). Generally, a good contract in supply chain management should be based on a written agreement since implied (observed action) and oral commitments are very difficult to follow, when the procurement and supply chain management is multifaceted and the environment is dynamics, with different legal ramification clauses.

Besides clarity in contract formation, a party in a contract should critically review the aspects and assumptions of risks involved in the dynamic supply chain management field, especially from the side of a company contracting a supplier. In practicality, it is vital to establish the premise that any contractual tenure allocates the aspect of risk between the contracting company and a supplier to ensure that the costs or changes in supplies do not translate into additional cost for the company.

Risk evaluation determines possibility of optimal returns and cushion for any negative eventuality. Therefore, critical review of risks involved facilitates utility maximization out of a contract. Thus, terms of contracting in procurement and supply chain management should be representative of all risks aspects in order for the involved parties to be in a position to optimize incentive hedge and reduce the magnitude of risks that may surface during and after contract formation and execution (Teece 177).

The general rule of law of contract is that contractual obligations are created by the parties to the contract. They have the exclusive right of enforcement. Nevertheless, due to the complexity of business relations in the contemporary business world, the company contracting a supplier should define all important clauses to protect itself from any legal ramification that might arise. Thus, terms of contracting should be representative of all risks aspects in order for the company contracting a supplier to be in a position to optimize incentive hedge and reduce the magnitude of risks that may surface during and after contract formation and execution.

The topological structure of a binding and effective contract consists of communication and operations management system which help in determining efficient performance and optimal resource use. Based on the credo emphasize, it stresses on ethical behavior of the supplier within accepted standards of moral obligation on the forefront, while the stakeholders are at bottom of the triangle. This can be implemented with the view of long-term benefits.

The continuum of increasing the value of quality in operation of a contract lies in data, information, and knowledge (Tricker and Tricker 33). Based on needs of customers, the procurement and supply chain management team may decide to come up with decision support system that could help in supporting a single contract point as the basis of the operations management model. This system tracks input and output ratio and measures intrinsic efficiency of the supplier in line with set targets.

Besides, the aspect of efficiency is introduced to ensure scarce resources are optimally exploited. The consideration of this is based on optimal gain from every decision that is made towards ensuring that the organization continues to gain a competitive advantage in the market through strategic supplier engagement (Teece 178).

Recommendations

Despite having efficient supply chain management systems, many companies have not fully established a mechanism for monitoring progress at micro level and majorly depends on macro auditing in decision making and has to deal with the risk of supplier redundancy. This might occur when the contract is silent on efficiency, value, cost, and sustainability of the supplier-company contract. In order to reverse this trend, procurement and supply chain management departments should endeavor to create a decentralized decision support system in contracting suppliers in a competitive manner to reduce any conflict of interest (Bowman 9).

The decentralized system may incorporate planning, development, implementation, and discovery in managing the contracts, in terms of their authenticity again value addition. Reflectively, the process captures organization chart, status reports, process map, compliance requirements, review structure, activities, dates, and resources employed within a specified period of time in the supplier contracting activities (CIPS par. 9).

Since effective supply chain management system determines success of business decisions in contracting suppliers, companies should introduce a micro auditing unit for internal decision making rather than depending majorly on macro environment when making and implementing contracts. The area that will present challenges using the decentralized decision support system is the cost aspect since more channels will be introduced in the decision making and implementation.

However, this shortfall may be addressed through adopting the second-Tier sourcing contract arrangement. In order to successfully executed contracting aspect, there is need to introduce the second-Tier sourcing contract arrangement, especially when targeting suppliers from different regions (Tricker and Tricker 29).

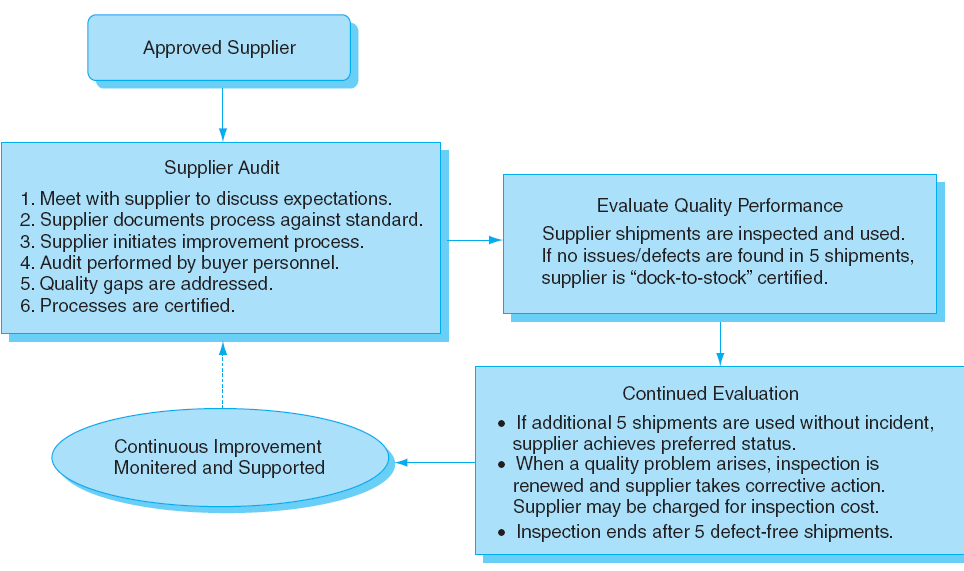

This sourcing contract arrangement provides for a room to coordinate purchasing with first-tier suppliers and allows for aggregation of purchases. This means that the company contracting a supplier will have leverage in purchasing power to reduce cost. It is also important to ensure clear supplier certification. Basically, supplier certification is the formal process of working with selected suppliers to evaluate and improve supplier quality.

Sourcing Essentials: Selecting Effective Suppliers

Outsourcing in supply chain management refers to a business arrangement in which an organization provides some services and/or makes products for another organization, rather than accomplishing the same task in-house. Outsourcing comprises an important cost reduction strategy. For example, outsourcing logistics services to suppliers reduce the operations cost compared to when such processes are conducted in-house.

Outsourcing constitutes a tool for ensuring the competitive advantage of the organizations against their competitors (Teece 179). Organizations also outsource to take advantage of the best skills and technology in an industry, especially in guaranteeing efficiency in the procurement and supply chain management. When the process is carried out in an organized and legal manner, the results will be in the form of effective supplier selection for sustainable business.

Although global and local markets are the places where organizations outsource their supply chain and logistics services, there is need to zero down on the most effective and experienced suppliers as a strategy for optimizing output. The ideal strategy would be to form strategic partnership with the appropriate supplier for the delivery of products with various liaison delivery centers, especially where the company does not have operational offices (Bowman 9).

Amid the significance of outsourcing on cost reduction, it may lead to the risk of losing a direct control of some operations. This situation makes an organization experience shocks that emanate from problems such as labor turnover, decreased productivity, and trade conflicts in organizations where it outsource the supply chain function through independent suppliers. Supply chain optimization is a process of determining an appropriate number of suppliers to retain in a business.

Companies should be keen to ‘right-size’ its supplier base. For example, a company may reinforce partnerships with traditional supplier trade partners, especially in the IT sector, surveillance systems manufacturers, and courier manufacturers among others. The goal is to ensure that such a company continues to enjoy reliable and available services that make the organization celebrated for its long-term experience (Smithson 172).

This promise has the merit of increasing the quality of the services that are offered by the company to its customers as the basis for building long-term customer relationships through supplier contracting. For instance, in selecting the ideal supplier, the interests of the customers and that of the company should override that of the supplier to protect the business processes.

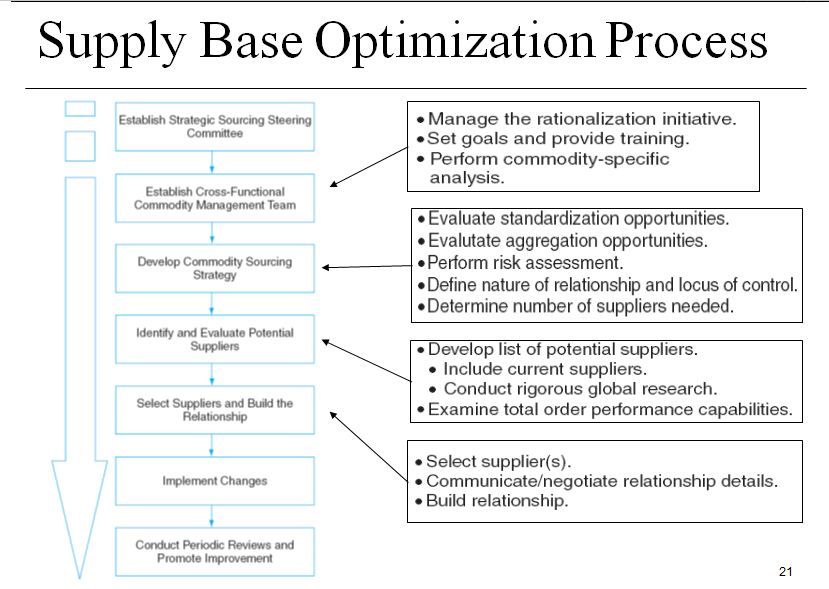

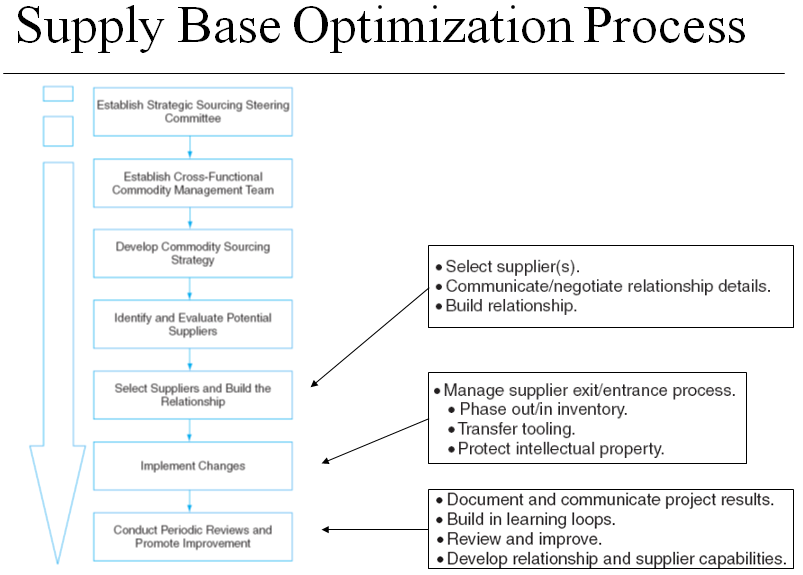

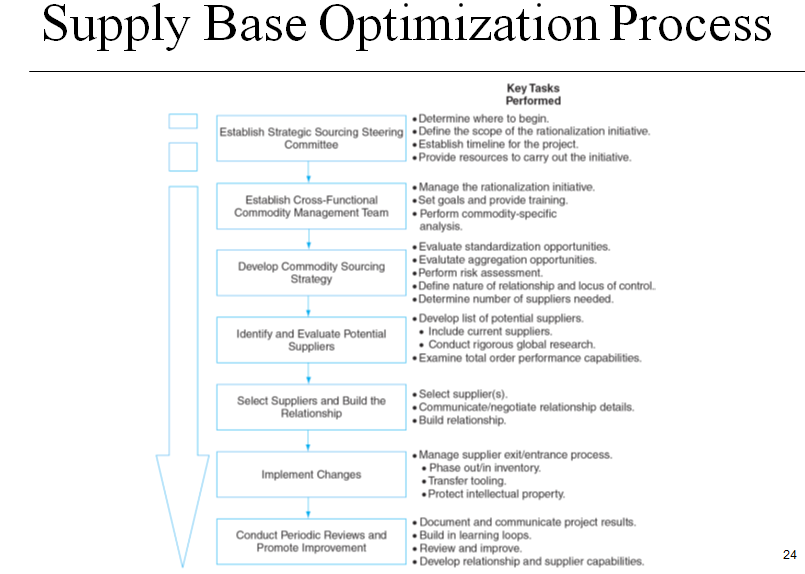

Most companies are facing challenges in handling suppliers because they have not optimized their supply chain. For instance, excessive focus on trade relationships with traditional partners does not provide adequate opportunity to do business with the emerging organization, which may provide better value for money (United Nations Economic Forum for Europe 26). Therefore, there is need to create a strategic and systematic process of selecting an ideal supplier as summarized in figures 1, 2, and 3 below.

A company may deploy various tools for measuring its supply chain management performance in terms of value addition in a situation where two suppliers are involved. A good example is the use of performance ratings. Under this approach, the actual performance is given a rating out of a given base figure. For example, a company may compute its SCM performance rating as shown in Table 1. The table only shows SCM performance rating for cost management strategies to guarantee value addition.

Table 1: SCM expenditure management.

This mean that a company interested in choosing a supplier might use the rating to achieve optimal results. In the above example, supplier A has better rating and would give value for money to a company as compared to supplier B. Sharing supply sub-system facilitates direct transactions and generation of reports that rate a supplier’s performance. Due to its dynamic reporting, anomalies in supply quality are communicated instantaneously to the supplier to initiate corrective action.

With a supplier audit, non-conformance to specifications in supplied commodities and modes of supply are identified. As a balanced assessment of a supplier’s performance, the scorecard is thus an objective tool to guide quality in supply. An improved approach to outsourcing supply management through automation will establish a broader partnership with customers (Smithson 168). The buyer will make an effort to learn the supplier’s values, vision, challenges, and operating environment. A spirit of collaboration established will offer positive contribution to the partnering businesses. Such cooperation will turn supply into a competitive advantage instead of sole cost.

Production efficiency is critical in the production line since it is characterized by optimal utilization of allocated factors of production within the least possible cost. Quality improvement will be used to measure, assess, and improve client service delivery outcomes. The success for quality improvement and organizational change management is dependent on alignment of the production soft skills and sustainability strategy. This process can be achieved through outsourcing. Important tools in safeguarding quality are the supply management system, supplier manual, supplier’s scorecard, and supply contract.

Recommendations

Apparently, the outsourcing decision for the sensitive production department is often very challenging since companies have to trust an external party to earn comparative advantage. In order to ensure production sustainability in outsourcing suppliers, companies should correctly review the activities within the current production cycle to be outsourced. The companies may also consider a tight contract and avoid the lowest bidders when calculating the gain from outsourcing suppliers.

There should be clear channels to manage the outsourced suppliers, which define the objectives and expectations of the company, in terms of efficiency and functionality of the procurement and supply chain management (David 24). The supplier outsourcing strategy must have the aim of reassuring confidentiality since the outsourced supplier may have ill intentions with the company’s production segment. Therefore, there is need to integrate the vendor-managed replenishment in sourcing suppliers as summarized in the diagram below.

Negotiation

In order to lead successful negotiation in the multi-cultural group as is the case between the procurement and supply chain management and suppliers, the parties should strive to balance the dimension of power/distance to minimize the degree of stereotyping attitude when handling the potential suppliers as captured in the Mandelow’s Matrix. In order to achieve this, the negotiation leadership approach of the contracting company should embrace the low power/distance score to make the bridge between itself and other negotiators accommodative (David 33).

As a result, there will be continuous teamwork that involves as many people of different cultures as possible, without creating a feeling of stereotyping the personal cultures involved (Smithson 167). The decision made in such environment will not only be friendly to a larger percentage of the negotiators, but also accommodative to different cultures involved in the actual negotiation.

Reflectively, applying individualism dimension as the leader of negotiation the multi-cultural team will create a conducive organizational cultural and feign a common communal connection among the negotiators. In order to make the individualism dimension as dynamic as possible, it will be critical to introduce strategies that will ensure that the score is very low (Bustin 14). For instance, the strategies will emphasize on skill building, systematic communication within set time limits, and harmony among the negotiators.

Therefore, the proposed negotiation leadership approach for procurement team should revolve around showing respect to all, promoting harmony through suppressing negative feelings, and introducing changes progressively without having to interfere with the existing structures of the potential suppliers as discussed in the Mandelow’s Matrix (Smithson 168). The entire process should be well articulated to guarantee complete and agreeable negotiation procedure. This is summarized in the diagram below.

Applying masculinity in multi-cultural negotiations between the two parties would involve creating a leadership system that balances the roles between the representatives of the company interesting in outsourcing a supply chain function and the potential suppliers (Bustin 16). The system will embrace the diverse roles and provide a structure for leadership based on skills and not just cultural differences as is the current case. For instance, through creation of a skills training program for the negotiation team, it will be easy to balance the discontent as a result of different approaches or dynamics in managing the supply chain.

The last dimension is the balance of the uncertainty/avoidance index within the multi-cultural negotiation team. This strategy is achievable through creating systems that address the sources of stressors and provide coping instruments, especially when planning to engage a supplier for a long time. Therefore, a low score is ideal for this index to ensure that the representatives of the company engage on the content of the negotiation rather that the personalities in the negotiation team representing the interests of the potential suppliers (Smithson 169).

This is achievable through minimal interference with the organizational structure, limited emotional response to personalized criticism, and proactive expression of an otherwise situation that might complicate the interaction between the negotiators. In order to balance the pros and cons of a lower score, within this index, the proposed cultural bridge building strategy will concentrate on the long terms benefits of the successful negotiation, rather than the challenges in executing the negation process as discussed in the Kralijic Matrix (Bustin 14).

The last cultural dimension is the long term orientation in balancing the cultural differences and the content of the negotiation. It is important to implement strategies that are critical in maintaining a low score in this dimension. A low score dimension translates into novel ideas and creative expression among the negotiators, especially for the company interested in engaging suppliers, despite the variances in cultures (CIPS par. 15).

This is achievable through promotion of equality, creativity, and self-actualization. Therefore, the leadership approach should create a uniform behavior standard between the negotiators of the two teams. In summary, the elements of respect, proactive attitude, and freedom of expression will create a steady negotiation process when the above dimensions are balanced.

Recommendations

Based on the above cultural and content dynamics, implementing the cultural bridge building strategy for the success of negotiation is achievable through adhering to the following recommendations.

For a company to emerge as the winner in the negotiation with a potential supplier, its representatives should be properly prepared in terms of the best negotiation practices. This will give the company advantages such as effective and efficient analysis of the offers by the supplier, mastering the dynamics of concession making, and proactively achieving all the negotiation goals without much strain (Bustin 14).

Since the negotiation with potential suppliers operates within the boarder of distributive and integrative conciliation, the team should be conscious in unanimous use of matching decision on what to say and course of action in each stage of the negotiation. As a result, the balance in the distributive and integrative negotiation will give the company a competitive edge and a sure path to success.

The company negotiators should explore the Best Alternative to Negotiated Agreement (BATNA) to ensure that the company remains in the best-off position when dealing with potential suppliers selected (Andrea 26). This will guide the negotiators on the best approach or plan b should the first approach fail. However, the BATNA should be aligned to the primary goal of winning the best deal rather than serving the egos of the representative agents.

A quality integration management system performs optimally via integration of appropriate scientific methods and techniques of negotiation. To enrich artistic managerial talents, the scientific techniques come in handy to not only magnify the margins of success, but also to ensure smooth transition of ideas or events after another. Besides, to avoid an eminent failure, it is vital for the integrated negotiation management system to focus on strategies of product proliferation, corporate culture, foresight, and product development to achieve the goal of internationalization of the supplier contract and maintain its competitiveness.

Therefore, it will be easy for such a company to rationalize the scientific aspects of supply chain such as use of statistical tools, their application, and evaluation criteria in monitoring and managing the logistics to guarantee efficiency in the negotiated contract.

Works Cited

- Andrea, Arnold. “Understanding how Formal and Informal Communication Affect Purchasing, Manufacturing and Logistics Integration.” Advances in Management 4.7 (2011): 22-32. Print.

- Bowman, Singh. “Corporate Restructuring: Reconfiguring the Firm.” Strategic Management Journal 1.4 (2003): 5–14. Print.

- Bustin, Gerald. Take Charge: How Leaders Profit From Change, Irving, Texas: Tapestry Press, 2004. Print.

- CIPS. Practitioner Programme Modules: Procurement and Supply Chain Management. 214. Web.

- David, Fred. Strategic Management Concept and Cases, a Competitive Advantage Approach, New York, NY: Prentice Hall, 2012. Print.

- Smithson, Samuel. “Analysing Information Systems Evaluation: Another Look at an Old Problem.” European Journal of Information Systems, 7.3 (2008): 158-174. Print.

- Teece, David. “Business Models, Business Strategy, and Innovation.”Long Range Planning 43.1 (2010): 172-194. Print.

- Tricker, Bob and Robert Tricker. Corporate Governance: Principles, Policies and Practices, London, UK: Oxford University Press, 2012. Print.

- United Nations Economic Forum for Europe. The Single Window Concept. DAM no. 324. Geneva: United Nations Publication, 2012. Print.

- Worthen, Ben, Cari Tuna and Justin Scheck. Companies More Prone to Go Vertical. 2009. Web.