Introduction

Due to increased globalization, customer expectations are evolving and putting more pressure on supply chains. Thus, businesses must continually reinvent their supply chains to manage and mitigate risks. This study will focus on the Pepsi Co operations chain, which the company uses to satisfy demand between consumers and retailers. Pepsi Co’s operations chain has been effective; however, the high number of errors due to coding problems in the data input by retailers has been affecting the company’s supply chain (Gu, Yang, and Huo, 2020). This study seeks to propose a technology-integrated framework (Inventory Management Software) to help Pepsi Co overcome the coding barriers in its operations. The business information about Pepsi Co is that it is a food company with a high degree of specialization in drinks. The issue lies in an inefficiency and the lack of resilience of its supply chain as well as low utilization of effective technology to address the problems.

Context Definition

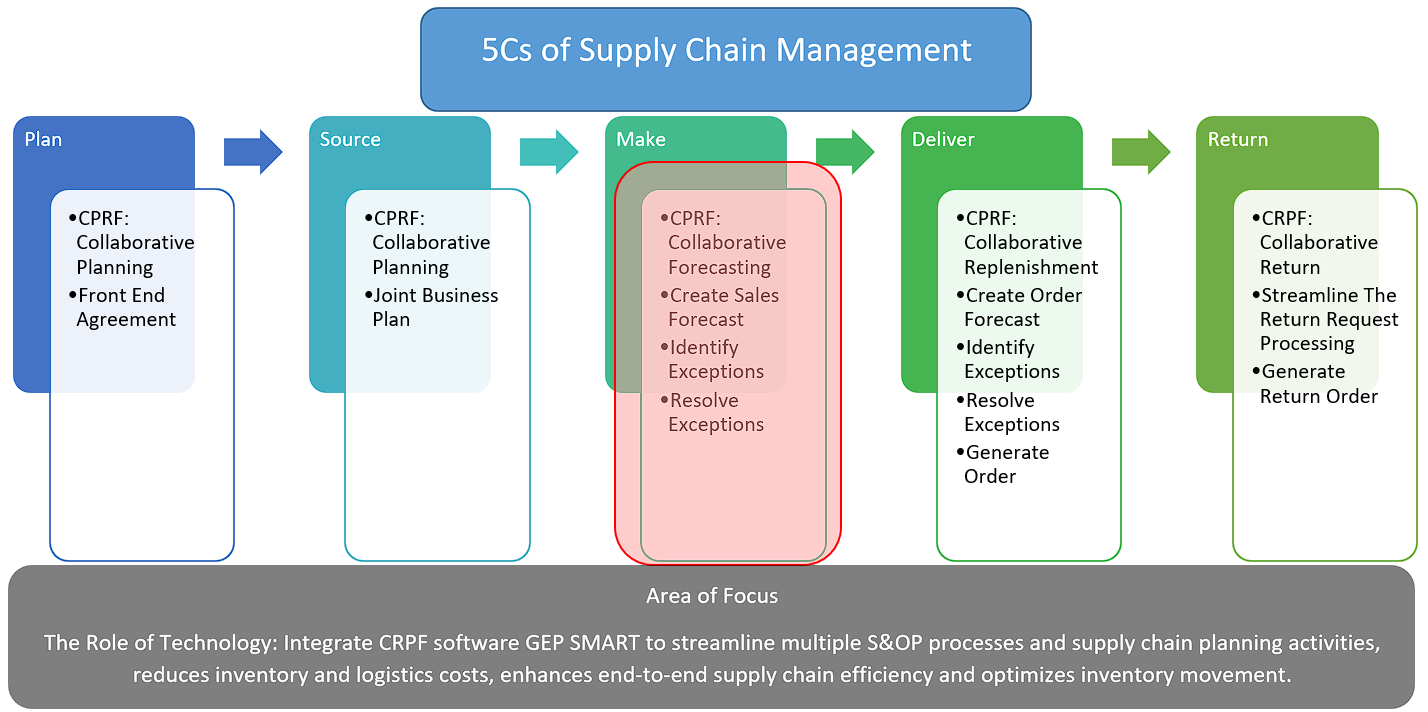

This project involves the implementation of a new technology-based framework in Pepsi Co’s Collaborative Planning, Forecast, and Replenishment model (CPRF). Its application in accordance with 5Cs of supply chain and its technological element as well as area of focus are shown in Figure 1 above. The current system involves four stages: strategy and planning, demand and supply management, execution, and analysis (Loten, 2021). CPRF simplifies “multiple S&OP processes and supply chain planning activities, reduces inventory and logistics costs, enhances end-to-end supply chain efficiency, and optimizes inventory movement” (GEP, 2022, para. 2), which serves as the basis for the reasoning and argument. Pepsi Co relies on its retailers to satisfy its customer’s demands. Therefore, the retailers input the data of the needed products using special UPI codes representing every product. The orders are processed by the firm’s regional distributor and then sent to the retailers who supply to the vendors.

This project involves implementing a new information system to the CPRF model, which will help analyze the data and reduce errors. According to the company operations, there have been inconsistencies in the supply and distribution of their products to their retailers, which has given an advantage to their competitors such Coca Cola. Although the company adopted Trifacta and Tableau information systems, they have not solved this problem adequately (Maloney, 2021). Thus, this project proposed the adoption of Inventory Management Software to help bridge the gap between retailers and manufacturers.

Various challenges are expected in the implementation of this project, such as the high cost of financing the project. Buying and installing the new information system will be costly because it will cost the company a monthly subscription of $50 – $200 per user (Loten, 2021). Thus, the company will have to set aside a budget for this information system and apply it to a single region to evaluate its feasibility. The other challenge is resistance from retailers because adopting new technology may be challenging for them. However, the company will conduct training for all employees and retailers who shall use the system and explain to them the importance of the system.

Element Definition

The proposed framework is Collaborative Planning, Forecasting and Replenishment (CPFR). It is critical are improving key supply chain elements by streamlining “multiple S&OP processes and supply chain planning activities, reduces inventory and logistics costs, enhances end-to-end supply chain efficiency and optimizes inventory movement” (GEP, 2022, para. 2). The real-time inventory management software helps track a company’s inventory levels, sales, orders, and deliveries. It is commonly used in manufacturing to ensure coordination between orders and supplies. In addition, the system can help forecast and ensure that a firm knows the expected demand in a specific market (Ran, 2021). The inventory management system can help to track assets in the warehouse and; automatically determine the demand required to satisfy a specific market. In addition, the system will help to increase accuracy to 90% because it tracks stock more effectively and efficiently (Ran, 2021). The inventory management system will replace the already used information system in Pepsi Co for more accurate order processing.

The Framework

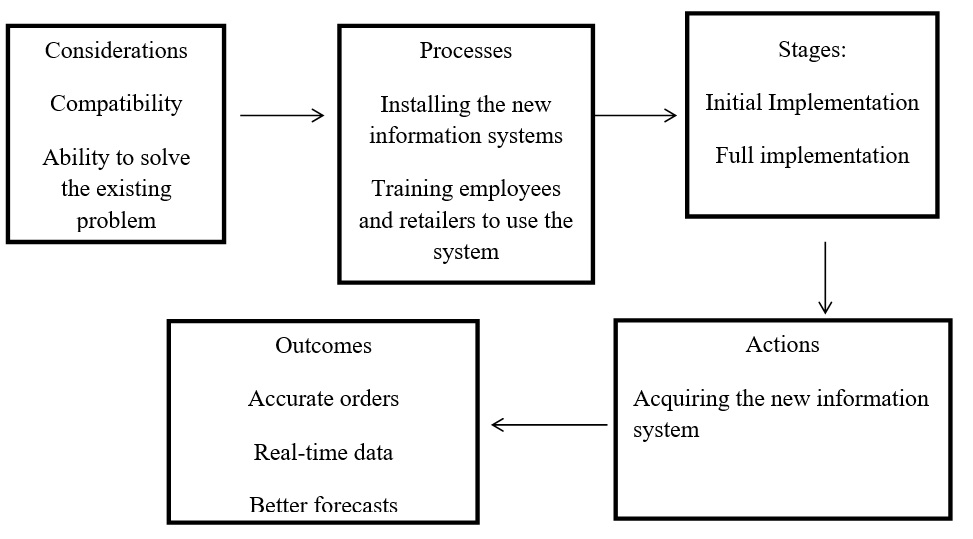

Considerations

The first step is checking the system’s compatibility with Pepsi Co systems. The Inventory management software is compatible with the system because the company has upgraded its systems to the latest version. (Zhao and Tu, 2021) The other consideration is the ability of the software to solve the problem. It has proved to solve the problem by providing error-free orders and its ability to transmit data in real-time. The core technology is based on the CPFR-based software to called GEP SMART, which improves “communication, collaboration and information sharing … ensuring the successful implementation of this strategy” (GEP, 2022, para. 3). GEP software needs to be utilized and integrated to ensure the implementation of CPFR framework.

Process

The process involves installing the new information on system top Pepsi Co information system. Technicians must be involved in the installation process to ensure the software works seamlessly (Zhao and Tu, 2021). The other process will be training the employees and retailers on the usage and importance of the system. This will help reduce resistance to the new technology from the employees.

Stages

The implementation process will be carried out in stages, whereby the first one will be the initial implementation based on a specific region. If the initial implementation is successful, it shall be followed by the full implementation (Sheakh, 2018). The full commission is whereby the implementation shall be conducted on a large-scale basis in all other regions.

Actions

The main actions in this framework will involve acquiring a new information system and installing it to replace the existing one. This shall involve the testing, actual payment of the system, and visiting various retailers to install the new systems (Sheakh, 2018). The management representative will conduct these activities with technology experts from Pepsi Co and the tech company.

Outcomes

The outcomes for this project will involve having accurate orders without a high number of errors as experienced in the previous system. The system will help transmit real-time data, making it easier to manage deliveries to different retailers. Finally, it will lead to better forecasts which will help to ensure better customer satisfaction.

Conclusion

The presented framework is effective for Pepsi Cop because it will help improve relations with its retailers and customers. The system is expected to streamline the ordering process whereby there will not be any losses as a result of ordering errors. The justification is based on evidence presented in the information above as well as the strength of the CPFR framework, because it can be integrated as a software solution. However, a possible shortcoming might be found in an organizational inability to properly collect and input its data into the system, which is why it is critical to ensure that data is both gathered and organized beforehand. In addition, it will provide real-time data of the company to rely on as it will monitor the inventory, stock, and orders. Some potential problems will include issues in understanding the use of the new systems. However, this challenge will be overcome when the training process is done effectively.

Reference List

GEP. (2022) What is CPFR?

Gu, M., Yang, L. and Huo, B. (2020) ‘The impact of information technology usage on supply chain resilience and performance: an ambidexterous view’, International Journal of Production Economics, 13(2), p.107956. doi:10.1016/j.ijpe.2020.107956.

Loten, A. (2021) ‘PepsiCo bottles tech collaboration effort into new digital hubs’, Wall Street Journal. [online]

Maloney, J., and Sebastian, D. (2021) ‘PepsiCo juggles strong demand and supply-chain challenges’, Wall Street Journal. [online]

Ran, H. (2021) ‘Construction and optimization of inventory management system via cloud-edge collaborative computing in supply chain environment in the Internet of Things era’, PLOS ONE, 16(11), p.e0259284.

Sheakh, T. (2018) ‘A study of inventory management system case study’, Journal of Dynamical and Control Systems, 10(10), pp. 1176-1190.

Zhao, B. and Tu, C. (2021) ‘Research and development of inventory management and human resource management in ERP’, Wireless Communications and Mobile Computing, [online] 2021(13), p.e3132062. doi:10.1155/2021/3132062.