Operations management is one of the main components of any business and enterprise functioning. This function is necessary for the implementation of processes that ensure the creation of a quality product or service, as well as its successful implementation on the market on an ongoing basis. Processes are its central interest, since all the activities of companies are built on them, and they need to be regulated, controlled, and created to gain a profit. Finance and marketing are also integral parts of any business as they make the existence and realization of the product possible. However, operations management is the main component of an entire company’s business because manufacturing, advertising, and marketing of products are impossible without establishing appropriate business processes.

The concept of operations management includes a wide variety of components, as production has many departments and functions that need to be controlled. According to Reid and Sanders (2019, p. 2), “Operations management (OM) is the business function that plans, organize, coordinates, and controls the recourses need to produce company goods and service”. Companies always work in a competitive and unstable environment with a high risk of losing profits in the event of adverse changes. At the same time, resources are also limited, even if the business has high production rates and scales, as in the case of multinational companies. Operations management is a way to implement and streamline all business processes on which the activities and profits of the production of goods or services depend. Therefore, OM includes functions that cover the entire production process and its implementation. In addition, these functions are implemented with people, equipment, technologies, information, and other resources, thereby covering all sectors of the company (Reid & Sanders 2019). Consequently, without operations management, the work of personnel, a supply of raw materials, search for customers, marketing of products cannot be provided.

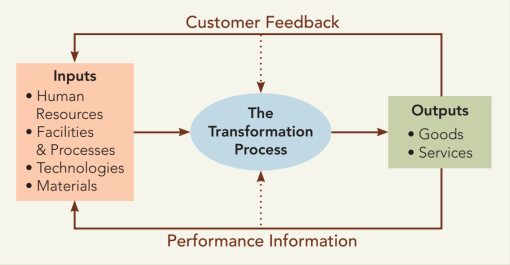

The main purpose of operations management is to make a profit by converting resources to goods. In other words, the input should turn into output in the process of control and adjustment, as shown in Figure 1. Then, the manager adjusts and improves the input data to obtain a better result after receiving performance data and customer reviews. In this case, the input can be human resources, such as employees, capacities, and processes, for example, equipment, as well as materials, technologies, and information (Reid & Sanders 2019). There are also supporting branch departments, such as human resources, engineering, purchasing, and others, to ensure stable and accurate work of a company, since operations management covers such a wide variety of processes.

Scientists also divide the theory of operations management into two parts for study, since it has to understand all sides of processes. These parts are social aspects, which are aimed at managing people, and engineering, which help the successful implementation of processes that require an accurate solution to the problem (Holweg et al. 2018). This separation is logical and appropriate since some tasks require mainly mathematical calculations. For example, managers need to know the number of raw materials necessary to produce the ordered goods and their prices from a different supplier to get a more significant profit. At the same time, it is essential to understand the needs of workers to attract and retain the most professional employees. Knowledge in social science is also necessary for understanding customer requirements, predicting demand, and other issues not related to accurate calculations. Thus, it is worth noting that operations management is a key function for the implementation of any company’s work, regardless of its size and type of production.

One can identify dozens of operations management functions by considering them in more detail. Conventionally, these functions can be divided into three types according to the kinds of key elements, such as design, measurement, and improvement (Holweg et al. 2018). Design, in this case, means understanding that different processes have their strengths and weaknesses, and therefore they must be used in the right place to obtain the necessary results. Its functions may include product development, staff responsibilities, methods of work, communication with suppliers, and resource allocation (Reid & Sanders 2019). Measurement is the most crucial element for understanding the functioning of both the company in general and its parts. In this case, managers need to know which components influenced the total profit, and which elements show the highest and lowest productivity. Improvement is a continuation of the measurement, since identifying production shortcomings, operations management should eliminate them and improve performance. These functions may include different improvements from changing the supply chain to adjustment a schedule for employees (Reid & Sanders 2019). Thus, operations management is necessary to control and improve the production of goods and services in limited market conditions.

Moreover, operations management is built on ten principles divided into several categories that help to distribute all processes in companies correctly. The first category includes fundamental principles that say that all operations consist of processes in which timing, quantity, and quality of tasks and data and their capacities can be combined (Holweg et al. 2018). These features apply to any area of the company’s activities and should be considered for setting goals. Design defines such principles as determination of work-in-process throughput time and rate and process choice due to task and external requirements, and it tells that the complexity of the process enhances the problems of management. (Holweg et al. 2018). The measurement principles are expressed in statements that a single measurement does not evaluate total results and that unmeasured indicators cannot be improved. The last category of rules relates to improvement and emphasizes that processes cannot work in isolation, and their improvement should be aimed at reducing the time of operations and their negative consequences (Holweg et al. 2018). These principles determine the main features and disadvantages company you need to pay attention to build business processes in operations management.

In conclusion, the essence of operations management in the construction and regulation of business processes in limited and changing market conditions. Any external changes in the politics, economy and even the social environment of consumers affect the business, so companies must know their strengths and weaknesses to adapt to new conditions quickly. In addition, the entire activity of companies consists of dozens and hundreds of processes that ensure the work of different departments and their interaction, thereby turning inputs into outputs. Operations management stands on the top of all these processes guiding and regulating their implementation in conditions of limited time and production capacities. Thus, the essence of OM is the planning of the entire enterprise based on the measurements and data obtained to get financial and working advantages.

Reference List

Reid, D & Sanders, R 2019, Operations management: an integrated approach, Wiley, Hoboken.

Holweg, M, Davies, J, De Mayer, A, Lawson, B & Schmenner, R 2018, Process theory: the principles of operations management, Oxford University Press, Oxford.