Introduction

Jianxi Ventures is a cosmetics production company that has been in operation for two years now. The company specializes in beauty products ranging from lotions, creams, and hair treatment products. This year, the company is in the process of introducing a new range of body creams that it believes will be a game-changer in the beauty products industry across the globe. So far, the organization has managed to secure a considerable market share in the lotions and hair products market worldwide. With the launch of the Himalayan range of body creams, Jianxi anticipates revolutionizing the body creams market. To start with, Jianxi intends to launch Himalayan Revitalizing Cream as the first product in the Himalayan range of body creams.

Production Process

Jianxi has been manufacturing beauty products for two years now. Among its beauty products, the organization has been producing the Glitter line of body creams that have not performed well. Himalayan Revitalizing Body cream is expected to change this narrative positively within a short period. This product is an improvement in the organization’s previous product line. It has been developed to provide lasting solutions quickly to its users.

Inputs

To manufacture the cream, Jianxi requires Machinery, raw materials, and labor. These inputs will play a significant role in the transformation stage. In addition to the highlighted ingredients, Jianxi has invested in a sleek design of packages materials that will be used to package the products. The methods of the packaging were reached as they will stand out from the competitors’ packaging. The production process will follow a new technology that is energy efficient to cut production’s energy cost.

Transformations

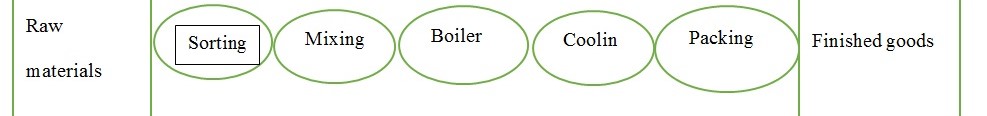

The raw materials required for revitalizing body cream undergo a series of transformations before it is finally distributed as cream. It is important to note that raw materials are regulated by global health values to ensure they meet the required standards for use. Failure to follow the laid out standards leads to banning the product’s production and sale in any global market. Besides, an organization faces a risk of compensation lawsuits filed by consumers who may suffer adverse effects after using the products.

To avoid this from happening, Jianxi Ventures should ensure that it follows all the laid down international standards for the production of its revitalizing body cream. The first step involves sorting and testing all the product ingredients to ensure that they meet the required standards. After sorting, the elements that meet the criteria are forwarded to the inventory, ensuring that they are allocated to the production team based on their expected output.

The next step involves mixing the ingredients, where all solid ones are added to the mixture based on the standard proportion. Since this process is extensive, Jianxi has invested in energy-efficient equipment, which assists in this process. After mixing the dry ingredients, the mixture is then passed to a boiler. The liquid ingredients are added to the mixture and then boiled for 30 minutes at 80°. The mixture passes through a cooling chamber cooled for 1 hr before being channeled to the packing section.

Output

In the packaging area, the product is put in containers with a net weight of 50g and 100g, respectively. Once the sealing is done, they are batched in boxes of 24 pieces each and sealed ready for distribution. The boxes are moved to the inventory warehouse, dispatched to the respective distributors and consumers. The only human capital required in the production unit is supervision and the engineering workforce.

Production System

Before a product is produced and distributed, it passes through a process referred to as the production system (Spacy, 2017, para 1). There are several production systems that an organization can adopt for its production plant. However, several factors have to be considered before an organization adopts an approach. Examples of production systems that an organization can use include mass, job, batch, craft, service, continuous, and mass customization.

Some of the factors that influence the organization’s choice of the production system are demand, nature of the products, and cost of raw materials; other factors include the availability of raw materials and the product’s character (Chand, 2020). Considering that Jianxi is a Fast Moving Consumer Goods (FMCG) firm, it adopted a mass-production model. A mass production system is a continuous production process, where a firm runs a series of manufacturing (Bhisan, 2018). The workstation in this model may run simultaneously where the product is at a particular stage. For instance, there is a product in the mixing chamber at any given time, either in the boiler, cooling, or packaging, which ensures the Himalayan Revitalizing Cream’s continuous production.

Reasons for Production System Selection

Jianxi has invested in sophisticated equipment, which ensures that all of its products are globally standardized. This approach is essential as it weeds out counterfeit products. Another reason for choosing this mode of production is to increase the volume of production. Mass production allows an organization to produce huge volumes over a short time. Following the rising demand for revitalizing body creams globally, Jianxi adopted a mass production process to scale up its production volume to satisfy the global market demand. Automation of the manufacturing process has also enabled the organization to benefit from the mass production system effectively.

Plant Location

Jianxi Ventures production plant is located in Guangzhou, China. Several studies were conducted by Jianxi Venture, which influenced the decision to have its plant in this region. To come up with this location, Jianxi Ventures followed the factor rating method. This method identifies various factors that influence the production plant’s place in a region (WisdomJobs, 2020). The factors considered are appraised based on their relevance to the organization. Each location is then categorized based on the merit of the site over the other. To calculate a location’s assessment, you multiply the graded factor with the fundamental elements (WisdomJobs, 2020). The higher the total location rating, the suitable it is for the establishment of the business. Considering this is a cosmetic production firm, the following factors were considered (WisdomJobs, 2020). The cost of labor, cost of raw materials, ease of doing business, ease of export of finished products from the region, and value of the production plant. The factors were then rated, as shown in the table below.

In the table above, Guangzhou has a score rating of 250 against Shangai, which has a score rating of 131. This score informed the decision to establish the production plant In Guangzhou as the location favored the organization’s operation in the region spacing should be 2.0, not 1.5

Production Layout

Jianxi Ventures adopted a line production plant layout. The diagram below shows the intended production plant layout for Jianxi Himalayan Revitalizing Body Cream. The line production layout is beneficial as it allows the plant to continuously produce large volumes of its products without stopping (Shrouf, Ordieres, and Miragliotta, 2014). However, it is essential to note that one production line station’s failure affects the whole plant operation.

Material Handling Equipment

For the line plant layout to work effectively, various equipment is required. The first part of the design involves sorting the raw materials to ensure they meet the required standards. In this stage of production, quality measuring and sorting machines are needed. In the mixing stage, Jianxi has invested in state-of-the-art body cream-making ingredients. The mixing engine ensures that it only holds the required amount of components for production. It eliminates the process of physical measuring of ingredients, which may be erroneous. The boiling compartment requires that you have energy-saving equipment that ensures efficient use of energy for production. Refrigeration equipment is another critical component needed in the production process to provide an effective cooling process for the cream. Finally, the packaging equipment is required to ensure that the final product is effectively bundled.

Input to Procure Externally

Himalayan salt is one of the production inputs sourced outside China to produce Himalayan Revitalizing Body Cream. The information can only be imported from Punjab in Pakistan, where it is mined. The amount required for six months’ production of approximately 200,000 units of 100g package is about 20 tonnes. The Himalayan salt’s current price is USD 150 per metric ton, which is manageable for the company to import to China effectively. Considering that the pant requires 18.1437 metric tonnes every six months, Jianxi will incur around USD 2721.55. The carrying cost is approximately USD 1523 (Market, 2020). In addition to the other price, this amount is economical for the Production of Himalayan Revitalize Body Cream. Considering all Himalayan Revitalizing Body Cream production factors remain as anticipated, the production cost per piece will remain low. Jianxi Ventures will, in essence, have a competitive advantage following its low cost of production and import in the market compared with the other industry players in the market.

Just in Time Production (JIT) Evaluation at Jianxi Ventures

Just in time (JIT) is a manufacturing management philosophy that emerged from Japan in the early 1950s (Javadian Kootanaee, Babu and Talari, 2013). JIT philosophy involves having the right raw materials, the right quantity and quality, and the right time. Since its emergence, the philosophy was only used by manufacturing firms in Japan. It was not until the 1970s that manufacturing firms adopted philosophy worldwide (Lai and Cheng, 2016). JIT increases quality, productivity and reduces wastage and production costs in manufacturing. Based on the JIT benefits, then JIT is appropriate for the Jianxi Ventures production process.

Further, JIT will help to align raw materials from suppliers directly with Jianxi schedules. Using this method, the firm will reduce defects while providing a better changeover approach by setting reductions. Further, products will arrive at the market earlier, reducing operation costs (Lai and Cheng, 2016). However, Jianxi will have to mitigate against some risk by sourcing suppliers close to its location, who can deliver materials quickly without advance notice.

The production cost is one of the major concerns for Jianxi Ventures. It is important to note that wastage in the process significantly increases the value of production. Appropriate implementation of JIT will dramatically reduce wastage in the Himalayan Revitalizing Body Cream production at Jianxi. The lower the production cost, the lower the selling price per unit, and the higher the profit margin. Another significant benefit will be the maximization of the volume within the shortest time possible.

Storage Management

Jianix will invest in bar-coding technology to help prevent merchandise loss through theft, pilferage, and spoilage while at the store. It will secure a technology that will monitor material and finished goods, keeping an eye on the staff and customers; storage management can optimize the buying process (Market, 2020). They can reduce the amount of damage by keeping a close eye on easy-to-steal things.

Additionally, being a cosmetics production firm, hygiene is a matter of concern at Jianxi. With the adoption of JIT in their manufacturing process, Jianxi Ventures will manage to maintain high hygiene levels in their productions. It is important to note that having high volumes of a product inventory that is not moving increases the cost due to the rising cost of storage. To eliminate this, JIT will play a significant role in ensuring that the organization manufactures the right volume that satisfies its products demand globally.

Reference List

Chand, S. (2020) Four main types of plant layout. Web.

Javadian Kootanaee, A., Babu, K. and Talari, H. (2013.) ‘Just-in-time manufacturing system: from introduction to implement’. SSRN Electronic Journal, 1(2), pp. 7-25.

Lai, K., and Cheng, T. (2016). Just-In-Time Logistics. 2nd ed. New York: Routledge, pp.1-31.

Market, G., 2020. Shipping Leads From Foshan To Karachi. SeaRates. Web.

Shrouf, F., Ordieres, J., and Miragliotta, G. (2014). Smart factories in Industry 4.0: A review of the concept and energy management approach in production based on the IoT paradigm. 2014 IEEE International Conference on Industrial Engineering and Engineering Management, pp.697-701.

Spacey, J. (2017). 6 Types Of Production Process. [online] Simplicable. Web.

WisdomJobs. PLANT LOCATION MODELS In Production And Operations Management Tutorial 07 November 2020 – Learn PLANT LOCATION MODELS In Production And Operations Management Tutorial (9476) | Wisdom Jobs India. [online] Wisdom Jobs. Web.