Executive Summary

The current report touches upon the topic of supply chain management adjustment to the renewed needs of a corporation formed after two companies unite through a business takeover. The major company in this case needs to carry out considerable business activities including strategic planning, competition analysis, SWOT, PESTLE, and Kraljic analyses. Understanding of the supply chain management importance also plays an essential role in the successful integration of the two companies discussed with the help of an efficient supply chain management.

Introduction

Supply chain is the process that the goods go through from being raw materials up to being sold by retailers. It also encompasses transportation, processing, or manufacturing, and distribution, until the goods finally are in customer’s hands. To organize a proper supply chain means to plan, obtain, store, distribute, serve the goods to the customers, to form interface between customers and supplier, and, as a result, to satisfy customers’ needs (Van Weele, 2005, pp. 11 – 12).

I am aware of these considerations because I am the operations manager of the shoe store and a factory in Guangzhou, China. My store’s name is Teng Da. The store employs 3 sales persons and 1 shop-keeper. My factory has 20 employees and 5 technologists responsible for shoe-making and design. I set up the company in 2004. Recently, my company has become the best manufacturer and shoe-seller in Guangzhou city. Fashionable design has made our products popular among female customers aging between 25 and 40. In 2009, my company took over our main competitor, Xin Yi Company that employed 1 shop-keeper, 5 product-makers and 5 sales-persons in the shop. The company dealt with the original production of goods, among which sport and casual shoes were the main items. We are integrated now, and the current paper is the report concerning the strategy of the supply chain of my organization for its future integration with Xin Yi.

Analysis

General Notions

According to Saunders (1997), major problems associated with supply chain integration are observed in “purchasing, stores management and stock control, material control, production planning and control, materials handling and transport and distribution” (Saunders, 1997, p. 204). This paragraph will focus on solving the problems observed in the listed spheres.

Firstly, the differences in the quality of goods, and various prices associated with them, can be perceived as a problem. Compared with their products, our goods quality is better, and the price is proportionately higher. Secondly, Xin Yi obviously experiences human resource shortages in their production process. So, I have decided to expand the employee base of the organization to include the people charged with the production process, decision making, and strategic development. In addition, I have decided to let the manager control the whole supply chain efficiently. Further on, I have observed the necessity to design separate departments dealing with the issues of logistics, transport, production, and purchasing cost monitoring to provide effective after-service product maintenance. For example, if a customer gets poor-quality products, we guarantee the change for the high-quality ones. Such an approach is called merchandise sale and after-sales service.

The next step of the strategy I have developed is the elimination of old fashion products from our lines. The point is that our target customers, females between 25 and 40 years of age, lose interest in such old fashioned shoes. Accordingly, the way to change the situation is to send Xin Yi designers together with ours abroad to learn new skill and fashion trends. At the same time, it is necessary to carry out an interview to encourage our new employees that come from Xin Yi. They have had different experiences, and it would be beneficial for them to refresh their ideas. In addition, the prices for goods of both companies can be reviewed and put in accordance with each other.

Thirdly, inefficient transport is often the reason for the company’s sales representatives to face the product shortages. If the company has several shops, it often can not supply the products on time for all of them. Accordingly, the idea is to make sure that the transport can supply variety of complete products and supplements on time.

Fourthly, the equipment in the Xin Yi factory was rather old and outdated, and this was the reason why the factory could not finish the work within the day. The way out is to provide advanced machinery for the factory. New technology can save time and resource for product manufacturing, product planning, design, commercialization, work for commodity production, and quality management: “Advances in technology have also opened up new opportunities in the field of storage, transport and distribution; and exploitation of these innovations has contributed to improved performance in supply operation” (Saunders, 1997, p. 204).

Finally, the shop of Xin Yi was located far from city centre, which is not convenient for the majority of customers. The way out is to change shop the location for the city centre. Obviously, the above discussed problems are the challenges that the integration of the kind always presents. However, as we can see, cooperation brings more choice for customer and for suppliers, who can learn different skills, new ideas, innovative technology, and bring more resources to both cooperating companies.

SWOT Analysis

The following table illustrates the above presented considerations regarding the issues and opportunities faced by the integrating companies:

Table 1. SWOT analysis for the corporation:

Impact on Corporate Strategy

The next step of the research is the analysis of the integration impact on the corporation. The first point of this analysis is planning for the future. If the company expects success, it requires a person to direct its activities, according to the customers’ needs, strategic planning initiatives, and simply giving the right stuff in the right place. Another issue is the environment, which can be external and internal. The internal environment is the sum of the cooperation’s advantages and disadvantages.

If the company expects the proper development in the future, the most important is to coordinate the internal environment, control stock, and extend the boundaries of the organization. We will take a series of activities and operations to meet customers’ increasingly high expectations. Regardless of how large your company is, and regardless of what business you are in, these are basic facts. Also, customer satisfaction is essential for the success of the supply chain management.

Further on, the suppliers should keep track of inventory information, organization of production, replenish the stores to avoid shortages. So, the business no longer needs to maintain high inventory levels as everything is under control and be delivered whenever necessary.

The external environment means the knowledge of competitors’ products, analysis of their strategy, of the levels of public’s consumption of their products, and of market supply and demand. The knowledge of the market competition thus helps avoiding failures in marketing and sales activities. In addition, our company should consider the political aspect of business activities and work to reduce the tax pressure. Accordingly, the plan is to cooperate with foreign and local companies. Such an approach will wider our company’s business scope and enrich potential resource bases. Finally, the resource-effective approach to material supplies and supplier deals will be exercised.

In this respect, the choice of products and services, the provision of goods and services suppliers will become essential for pricing, distribution, and payment processes. The methods used to monitor and improve management, supplier policies, transfer of goods, and payment techniques can thus be improved.

Thus, the most significant in this situation is to make up a plan and attempt to predict the development of the market. Even the companies with the greatest potential face various risks conditioned by the fierce competition. There are international standards of competition, sometimes complicated by considerable uncertainty.

To avoid this uncertainty, companies form diffuse networks, in which each of them still maintains its individual characteristics but maximizes the effort to achieve win-win results. Accordingly, in this context the prominent role in business development is always attributed to the supply chain management and proper development. Our factory produces the goods according to our strategic goals and certainly, we have numerous competitors.

Thus, a properly developed marketing strategy helps us compete with them and exercise the cost-effective manufacturing, distribution, and sales strategies. The PESTLE analysis will be of considerable help in illustrating the ideas presented in the above section.

PESTLE Analysis

The table below illustrates the external developmental conditions for our company (Renewal, 2010):

Table 2. PESTLE for the corporation:

Justification of Choices Made

According to the analysis, I have made the following choices and decisions. Firstly, the quality of our products should be improved, because customers always make product selection based on the quality and price relation: “Improved quality and lower costs increase customer satisfaction and this contributes to higher sales, which in turn result in higher profits” (Saunders, 1997, p. 204).

Secondly, improvement of the enterprise management level is needed. Supply chain management is an important aspect of optimization process, reengineering, and design, on which the enterprise management level can be improved. At the same time, advanced enterprise supply chain management, the enterprise management systematization and standardization can improve the levels of corporate governance.

Thirdly, greater attention should be paid to the needs of our target customers. So, training of our designers aboard and attending of some fashion shows will be regular. They must be the people to express the dominant the fashion trends in their fresh ideas to improve customer satisfaction levels. This goal is also the fundamental for business survival.

Fourthly, there is a need for stricter financial and human resources control in our company. The supply chain should also be a part of this control. Finally, efficient planning is essential for the market success of our organization. For instance, the issues of environmental protection should be communicated before the production process. All these ideas will definitely allow our company to increase its market share and gain considerable competitive advantages.

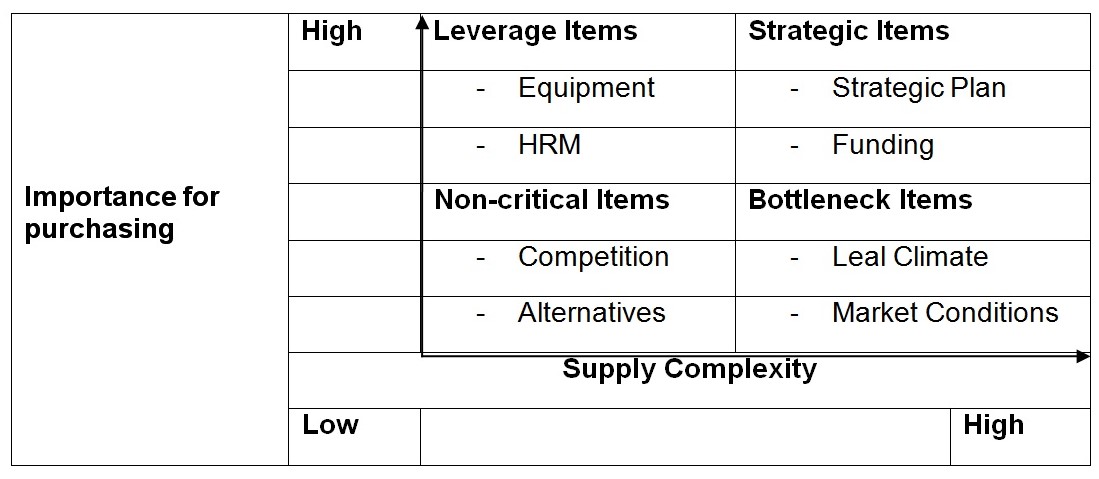

Kraljic Matrix

The following Kraljic matrix allows illustrating the implications of all the above discussed points on the supply chain management and supply chain complexity as developed by the two integrated companies (Ford, 2005):

Conclusions and Recommendations

Thus, the whole above discussion reveals that Teng Da can achieve the proper level of integration with Xin Yi through the properly developed supply chain management. Accordingly, it is recommended to the company that it should take the advice presented in this report and implement the four points discussed above. In more detail, to facilitate the mentioned integration, Teng Da and Xin Yi should improve the products’ quality, work on the management improvement, pay attention to customers’ needs, and introduce stricter resources and funds control.

Reference

Ford, D. (2005) Better Purchasing Techniques. IfM. [online] EGTN. Web.

Renewal. (2010) PESTLE Analysis. [online] Renewal. Web.

Saunders, M. (1997) Strategic purchasing and supply chain management. Pitman.

Van Weele, A. (2005) Purchasing and Supply Chain Management, South-Western, 5th Edition.