Introduction

Steel container making is a vivacious, ever-transforming manufacturing process. Consequently, processing used or abandoned materials for use in creating new iron units in steel containers demonstrates considerable opportunity for improvement; this involves many developments that consume raw or second-hand equipments, manufacturing thousands of commodities and by-products. However, in this project research paper, there will be an exploration on a brief introduction of the manufacturing company visited, which is James G Carrick & Co.

Limited Glasgow, London, and on the redesigning of part of steel container manufacturing process, purpose of the project and some vital issues relating to the production process of steel containers or liquid carrying drum in the like of the objectives which are the increase in the production rate, increase in the flexibility of making the various size steel containers, and lastly decreasing the operational (lead, transfer, manufacturing, setup) time according to the project research carried out on James G Carrick & Co. Ltd Glasgow, London.

James G Carrick & Co. Ltd has developed and improved dramatically in the production of steel containers. Some processes which the company uses in the production of steel container has improved drastically and replaced with the modern manufacturing technological machines. However, the general manufacturing goal for container recycling in this company is to recuperate 60% of the obtainable or accessible and ready for use iron units immediately.

James G Carrick & Co. Ltd has advanced in steel container making processes. However, they have with respect to history developed as a result to the aspects of industrial development, world wars, technological innovation, opposition and total creativity. Nevertheless, for the shipment of materials or chemicals and other products, the wide range of James G Carrick & Co. Ltd steel drums are the complete product of its kind and without defect or blemish alternative when transparency is vital. James G Carrick & Co. Ltd steel drums are made of hard-wearing, corrosive-resistant steel, which are produced in open- or tight-head modes with a comprehensive range of 7, 12, 25, 30, 57, 120 litres gallon contents.

These ranges of products are produced in a large-scale industrial operation from mild steel narrowed design gives room for more storage space.

There is awareness in the manufacturing industries on the improvement of business processes which are the development of manufactured goods, order fulfilment, preparation, sharing, and customer service. However, Steel containers position an arousing curiosity or attention in the engineering and policy challenge to society. They have to meet the condition of a countable quantity of structural and physical standard, must be reasonably priced, and must have a negligible impact on the environment.

Furthermore, this report paper won’t fail to state the Manufacturing machines and their availability but the key focus will be on flanger, beader and reducer machines, and what other company’s uses for their high rate productions.

The company Information

James G Carrick & Co. Ltd. Glasgow, London, was established dated back to 1851 by late David Carrick the father of James G Carrick to whom the company was named after. In 1921 James G Carrick was incorporated thereby, becoming a limited company. However, under the management of the Carrick family, there has been successful administration of the company, consequently, the company has benefitted under the management or leadership of the six Generations of the Carrick family.

In line with this, the manufacturing company of James G Carrick was first established as a tinsmith manufacturing company. In the then establishment, the company was into the manufacturing of ventilation units for roof tops of various factories and commercial building or industries. Accordingly, during the first and second world war, the company was assisting the British Government through the manufacturing of large cylindrical shells. Although, after the war, the company tend to return back to their earlier manufacturing of Tin plate containers for local industries and shortly after that moving further to the manufacturing of mild steel drums or containers.

In light with this, approximately thirty years ago, another department was introduced to the organisation profile and this was the plastic manufacturing department. The plastic department of this company indulged in the production of various range of plastic Jerry cans or kegs and shortly afterwards, they moved into the production of plastics for the Animal Pharmaceutical industry or better known and called the veterinary industry which was the key or core business of the plastic department of the company.

Additionally, in the last four years the company has made major investment in the introduction of a fabricating or fabrication department with the initial purpose of completing the range of Galvanised Bin liners that is being produced or manufactured for the waste management industries. With the innovation of this investment it has a major logical consequence to the change in the layout of the factory thereby bringing about the construction of a small extension which was simultaneously added to the back of the building.

It is amazing that the company has grown extra ordinarily within some decades with a high profit return annually. Presently, the company has a turnover of approximately five million pounds per annum within its four divisions or department which are: the department of steel drum, plastic department, fabrication department and lastly distribution department.

With the increase in the company’s production rate it has extended its market globally with their major customers being CPL (7, 12, 30, 120 lit), Anglo American (25, 57lit), r c treat (7, 12,25,30,57 lit), fragrance oils (30, 57 lit).

Project Purpose

In line with the company’s profile and introduction of the company as stated above and the conduction of research on the manufacturing process, this research project is on the subject of the redesigning the stages of UN/NON-UN standards fluid carrying steel containers or drums manufacturing process. The entire process of manufacturing steel container is quite vast. However, because of the immense production process, this project paper will only focus on three aspects of the production process which are locally called the Flanging Process, Beading and Reducer process of making steel containers. These production terminologies will be explained later on this paper. Furthermore, the main objective of this project is to increase the rate of production and/or minimise the operational times accounting various range of products.

Redesigning of parts of a steel containers manufacturing process

This research is on the redesigning of parts of a steel container manufacturing process, in line with the research carried out it was discovered that steel containers are made from sheet metal and it has to go through so many processes before getting to the final production stage.

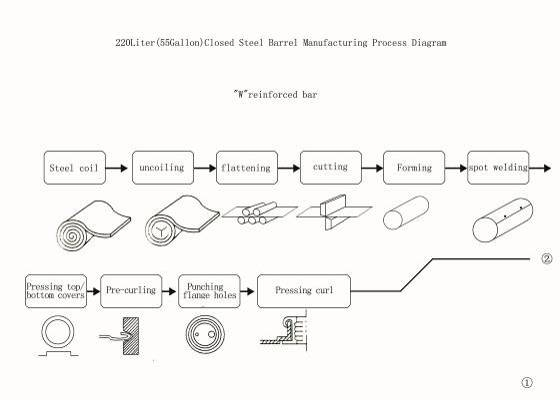

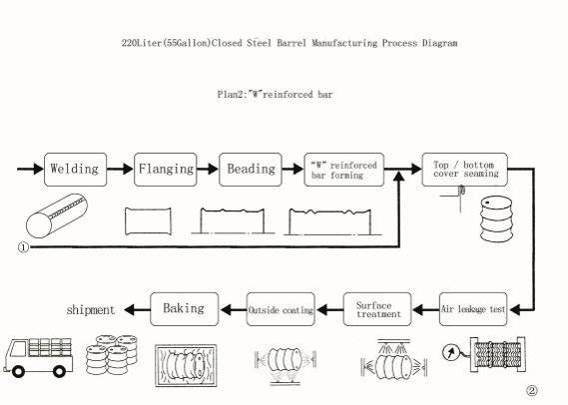

In addition to this, in a steel container redesigning or manufacturing company there are numerous processes which are embarked on and also various machines used in the implementation of the manufacturing process of the steel container. The processes utilized in the production of the steel container. In addition, the Process of making steel containers involves coiling of the steel, uncoiling, flattering, cutting forming, spot welding, welding of the steel, flanging, beading, bar forming, top/bottom cover sealing, air leakage test, surface treatment, rolling of metal sheet; welding the seam, making 90 degree bent on top and bottom of the container, making number of beads (according to size) and lastly reduce the diameter of one side of the container; fitting of lid to the containers, testing like pressure; coating internal (epoxy phenolic coating or plain) and external (stoving enamel gloss of various colour) and baking. Attached below is the diagram of the process undertaken in the production of steel container which will be discussed later on this paper in the process of making steel container.

Accordingly, the objectives of the steel container manufacturing plant of James G Carrick & Co. Ltd. are on the increase in production rate, increasing the flexibility of making various size steel containers and lastly decreasing the operational (lead, transfer, manufacturing, setup) time.

Increase in the rate of production

James G Carrick & Co. Ltd productions are decided upon by the end product from the manufacturing procedure, accordant with the component of production. An example of this is the measurement of the labour productivity which is measured as a proportional relationship of production according to the labour –hour, which is a contribution. Production rate could be visualized as a statistic for the measurement of an input and at times output.

Berglas, Anthony (2008) commented that the assigned measure of machine’s energy effectiveness is different from production rate, which if taken into consideration both the cost of what is manufactured and the cost of efforts used, and its different from the statistic of measuring the profitability, hence, deals with the issue of making a difference between the total income from output and the input expenditure.

Nonetheless the economic considerations are of major importance in James G Carrick & Co. Ltd due to the processing theory. The precise evaluation of the factors of the economic is capable of eventually controlling the circumstances for the most efficient use of machines. Correct setting of cutting speed as well as choice of machines can lead to the most important economic development in a mechanical device operation because unimportant changes that may seem on the surface are accomplished. In countless situations, of having a deep influence on the costs of operation, especially when there is high request in the volume (Gorczyca, 1987, p.1).

The company uses sophisticated and highly built technology machines in the likes of the flanging machine, beader machine and the reducer in order to achieve good quality product. With the aid of these machines, the total production output of the manufactured goods has increased dramatically, and thereby meeting customers demand on time. These range of machines helps with the production input and output of James G. Carrick Company.

Increasing the flexibility of making various size steel containers

Flexibility has turn out to be an aggressive means of persuading. It consist of the capability of manufacturing an extensive range of manufactured goods, introduction of new manufactured goods and transforming the ones that are currently in existence quickly, hence the response to the needs of the customers. Flexibility is the capacity to alter or regulate so as to achieve accuracy or conform to a standard of changes in mix of production, production quantity, or design.

It is the performance quality of James G Carrick & Co. Ltd to present a broad diversity of goods to its clients. Hence, a way of evaluating how fast the company changes its procedure from producing an old line of goods to producing a new product line. Accordingly, in the new production process, in order to meet the customer’s heightening and differing demand it is absolutely necessary to process large indefinite quantity of different kinds of products.

For this reason, the series of stages through which a product passes between recurrences of a primary stage is becoming seeming limited in duration and the legerity in production is powerfully necessary for quick in responding to the change, though not merely in the diversity but also in the number of the goods without losing the degree of its excellence (Bititci, 1998; Carrie 1998).

Consequently, the manufacturing plant of James G Carrick & Co. Ltd has put in place the use of the flexible manufacturing system to improve the productivity in producing various size steel containers aspiring at an average manufacturing capability to perform or produce as a whole.

On account of the recurrent transformation in the varieties and the quantity of work pieces still in the large number of production such as steel containers, it is becoming essential to build up manufacturing arrangement not just with flexibility but also huge manufacturing capability which have make available by dedicated manufacturing systems such as flexible carry over lines.

In order to adapt to such requirement, the company recommended a new production system, known as the high volume flexible manufacturing system, for agile production and demonstrated the effectiveness of the parallel-serial arrangement of the machining cells by simulation study (Fujji et al 1988).

Currently, James G Carrick & Co. Ltd is progressively more dependent on supply from external sources, and the company is growingly conscious of the need to control and incorporate the entire chain of value in reference to the following authors assertion (Fisher, 1997).

Consequently, the necessity of learning flexibility in a broader circumstance of supply chain, in addition to the definite level, is now generally approved or compelling recognition (Eloranta et al., 1995; Krajewski et al.,2005; Schmenner and Tatikonda, 2005).

However, James G Carrick & Co. Ltd needs flexibility because it is very important for the accomplishment of the supply chain, because the supply chain subsist in a location which is not certain.

Flexibility characterizes a probable means of improving the effectiveness and is an important measure of the performance in the supply chain of James G Carrick & Co. Ltd (Vickery et al., 1999).

Production related times

Martin (2007, p.123) stated that Production is a process used in operating objects, parts, collect and assembles, starting with their unprocessed or initial stage to the final stage in an organized and proficient way. Nevertheless, this process comprises of activities like planning, scheduling, routing, dispatching, storage. However, production control or manufacturing resource planning therefore refers to the controlling or managing of the rate of production of all company supply or the production as per the set up arrangement.

However, in any manufacturing company, there has to be a designed way of setting time needed for the product to get to the market (lead-time). If a product is to be delivered in maybe two weeks’ time, and during this lead time, there happens to be a reduction or increment in customers demand, the production rate will either be in excess or shortage. Nevertheless, if in a mixed model production, the lead time would be reduced to incorporate the customers demand. At James G Carrick & Co. Ltd there is the ability to cooperate both with external and internal changes like the breakdowns. Such scenarios if not considered well in advance can affect the production in the company (Chryssolouris, p. 23, 2006).

All in all, the mixed-model system brings about commonness in product design and procedure design which shorten set up times for all products allowing amalgamation of the manufacturing program.

Analysis on the pattern of customer demand

This section of activity however, emphasizes on the relevance of the analysis techniques for the demand in a supply sequence. The importance is on the time sequence advancement. The paper implies or hints on the systematic approach of the customer demand assessment and investigates or studies its importance in the system of achieving the company’s objective and forecasting.

Every person in the product supply system is equally dealer and purchaser of a product in respect to the consumer. Therefore, for the solution to the penetration in the aggressive benefit, the understanding of the end consumer need is imperative.

This deliberation has to comprise a clear understanding of the customer’s needs and acting as a value added services to convene those needs, in other word vigorously acting in response to change and set up a closer interface. Despite the fact that interim customers are important, the solution to competitive advantage is held by the end user who is barely the true customer (Bockerstette and Shell 1993).

Customers will be attracted to manufacturers that provide the highest value and be willing to transact business with them. In the customer’s viewpoint value comes from the most favourable equilibrium of manufactured goods quality, cost, and reaction to time and customer service.

Along with these changeable, customers are showing rising attention for response times. Response times can be mostly being linked to two times changeable: the lead time to deliver manufactured goods to the customer for a precise order and the time to build up the manufactured goods from the concept to final delivery to the market (Blackburn 1991).

In a time-based manufacturing company, the reduction of manufactured goods supply lead time is the tactical objective.

Any time further than the time that is essential to add value to the manufactured goods symbolizes excess costs and waste to the customer and the dealer. On the other hand, a customer will pay a premium to the manufacturer who can supply its manufactured goods more rapidly and more consistently than the competition.

Decreases of the lead time also have an optimistic force on the quality of the produce, cost and customer service, (Bockerstette and Shell 1993, Stalk and Hout 1990).

In significance of the transformation from a “seller’s market” to a “buyer’s market” and of speed up in the hi-tech expansions, manufacturing industries are obliged to restructure their business procedures, to be proficient in speedily and cost efficiently act in response to fast-changing market demands (Slats et al. 1995).

In addition to this the management of a manufacturing company must consider how their companies create value in both the physical globe and the virtual globe. In the two worlds, the procedures of executing the worth are not the same (Rayport and Sviokla 1995).

Porter (1985) mentioned that in the physical world the value chain is a sequence of value-adding actions between a company’s supply side with its demand side

The term customer demand chain is used to formally describe an industries input to provide products that caters for the customers need. The choice of specialized vocabulary is contingent on the emphasis considered necessary, in that the word customer demand supply chain emphasizes the significance of the customer demand strong force or impetus (motivation) of the entire chain while further emphasising the fact that the demand and supply flows have to be synchronized (Heikkilä, 2000).

Cimorelli (2005 p.55) stated that in a manufacturing company the customer is the most important factor which cannot be controlled but the factors affecting making of an inventory in the use of money for future profits in manufacturing companies can be controlled. The factor that can be controlled is the internal manufacturing process and the inventory techniques. Cimorelli further noted that it requires efficiency and reliable data in understanding the need and pattern of the customer. Although in providing a dependable customer service the company must understand how the inconsistency of customer demand influences the organization and taking necessary actions on it which are the most important factor.

With the customer’s diverse and variable demand on products, the steel industry of James G Carrick has put in place the production of overwhelming steel containers for the customers whose requirement is complex.

According to research on customers demand it show that the manufacturers have to usually make ideas or proposal within a short time to their customers and provide them with that will assist them on deciding the manufactured goods to take on. As a basic step in most manufacturing company, actual time of occurrence and vigorous and purposeful customer demand analysis is required by most, if not all manufacturing companies to efficiently and automatically act in response of customers demand.

Schafer et al (1999) stated that a successful and favourable system can help enhance the manufacturing marketing in many ways and some of the ways are stated below:

The conversion of online searchers or online customers into buyers by researching or marketing for customers through interaction, thereby simplifying the customers of consumer process of finding the products they wish to buy. Secondly, the increase in cross-sell by charming or pleasing the customers by upgrading the quality of the manufactured goods which is one of the factors that are not originally implemented and thirdly, creating successful relationship between customers.

Accordingly, present ordinary move towards the modified recommendation systems are the content-based advancement and combined filtering approach (Balabanovic and Shoham, 1997; Sarwar et al, 2000; Lawrence et al, 2001; Wu et al., 2001).

Grant (2005 p.265) stated that with the continuance in the competing level of most market, manufacturing companies are repeatedly being forced to seek new opportunities for cost reduction. The force for the drop in the cost is physically powerful in the companies where cost rivalry is fiercest due to products, excess capacity, and numerous competitors. Consequently, the possibility in any manufactured goods for differentiation is incomplete only by the limits of the human thoughts (Grant, 2005).

According to the illustrated diagram of the company’s sales chart, the 30 litre UN 1A1 is the most popular size all round the four years, followed by the 25 litre UN 1A1 and 57 litre UN 1A1. The most unpopular size is the 10litre UN1A1 which is stagnant and no change at all. From the diagram, the customers past and future demands for the 30 litre UN1A1, 25 litre UN 1A1 and 57 litre UN 1A1 has had the best demand and it keeps on increasing, unlike the 10 litre UN 1A1 which does not show any sign of increment in demand.

Production/Manufacturing techniques research

In modern times the production of steel containers are mostly carried out with power-driven machine tools, such as lathes, milling machines, and drill presses which are again computer based where the operator is required to feed a set of instruction which are again CAD/CAM programs that are to be carried out using computer numerical control. These automated machines can produce very high precision products.

The operation at James G Carrick begins with the already cut into required sizes flat sheet of metal from supplier which is then processed by going through the Longitudinal Rolling of the sheet.

In the longitudinal rolling, the distance from the base of metal to the top of the section of the metal becomes smaller or shorter as the metal go across or through the rolls, while there is increase in the length and width. However, the variation in the altitudes of the cross sections of the metal previous to and subsequent to transient between the processes of rolling is known as the linear reduction.

Spreading enhances with decrease, roll width, and the constancy of resistance between the metal entity and the rolls exterior.

In addition to this, the region between the rolls where the work consisting of the piece of metal being turned, shape, mould, or otherwise finish by machinery move towards straight contact among the rolls is described as the region of deformation; furthermore, the metal is reduced here. However, in these regions, the metal is merely somewhat deformed.

Consequently, this process is followed by the Welding of seam. The welding of seam is another process in the making of drums when it is engaged for both longitudinal seam and flanged ends.

A disparity in the methods permits the convergence in the sheets to be forged down pouring welding to produce flush joint. This is further called mash seam in which the sheet overlap is no more than 11/2 times the thickness of the material. Moreover, seam welding is used on materials which the thickness ranges between 0.5mm to 3mm.furtherance to this, it is applied to mild and alloy steels, stainless and heat resisting alloys, aluminium and copper alloys.

In addition to this, seam welding is relatively rapid method of welding which is mechanised and readily controlled as regard quality (Houldcroft, 1990).

The joint is, however, a lap which is improper for application in which the notch would provide a seat for the start of corrosion or fatigue. The tool is more costly to maintain than other resistance welding plant. Furthermore, it is unusual to use the process for welding metal that is thicker than 3mm because of the mechanical difficulties in applying pressure and the wear on the electrode wheels (Houldcroft, 1990). The flanging process is the next process after this, after the seam welding of hot rolled steel plate in the form of open end cylinder. This cylinder is manually removed and placed into the next machine locally called as ‘Flanger’ that folds one or both ends (as per the product specification) of the cylinder at 90 degree’s which would encompass and pressed to seal of the cylinder at a later stage of production.

There are two types of flanging machine namely the double ended or hydraulic flanging machine and the rotary type. The rotary type of flanging machine is a kind of apparatus that is used in making flange to the containers. However, the flanging machine can be used to serve two purposes, which are changing rollers and single beading. The body of this device is made-up of heavy duty gear and extremely steady structural plan and easy to operate. The most important rudiments of this mechanism are well-built force, toughened and heavy duty pneumatic cylinder.

This machine helps in the production of top good quality flange in the production process. In the production process of steel containers various diameters there is no need for a separate tool. This device contains two flanging tools produced from high-quality steel, which went through the process of heat treatment and grounding. It also has a take apart hydraulic power pack of all benchmarked parts, highly flexible tubing, logic, and organizing panel, and high quality hydraulic cylinder. The most important benefit of this machine is that rejection rate is almost low processes the flange at the same time. In addition to this it is efficient and easy to use in production, and inexperienced operator can also operate this machine.

Operating this machine is safer because it gives no room for the container to rotate hence, producing a level flange and accurate width of the container, besides, this type of machine helps in avoiding wrinkle to flange and also produces products with uniformity.

Furthermore, the flanged cylinder is then moved to the next machine called ‘Beader’ to carve the bead or rolling hoops onto the cylinder body in order to give added strength to the container.

However, the beader machine furnishes the drum by beading it. Though, the bead applies additional property of being physically strong to the body cell. However, the Hydraulic cylinder of the beading machine is very speedy and the rate of negative response is absolutely low. A split power set is made available. Moreover, inexperienced operator can also run this machine.

There is availability of these machines in most companies in the world but the price range varies with the make and quality of the machine.

In line with the production process, once this process is completed the semi-finished container is moved on to next stage of production where top end diameter is reduced so as to sit one container on top of another. This stage of operation is carried out in ‘Reducer’. The prime challenge involved in these three stages of production is the effort and time consumed to manually transfer the containers and to set the different machines to carry out the operation in case of change of product specification. Having to carry out these operations on different machines also increases the number of persons involved thereby increasing the incurring production cost and lowering the productivity.

The prime challenge involved in these three stages of production is the effort and time consumed to manually transfer the containers and to set the different machines to carry out the operation in case of change of product specification. Having to carry out these operations on different machines also increases the number of persons involved thereby increasing the incurring production cost and lowering the productivity.

The next process after the reducer is the internal coating. The internal coating is the application of a primer coat to the steel container covering by heating the container to a temperature of 1800-2200 F. This process involves the electro-statically spraying of the steel with a thermosetting epoxy phenol coating, after which the drum goes through the process of dry through oven, then attaching of the top and bottom and testing for leak before it finally goes through the process of dry again and then external painting by stoving enamel gloss of various colour and baking.

On completion of the steel container or drum, the next concentration will be on the process of making the lids.

In the lid making process the flat sheet metal from the supplier which has already been cut to respected sizes is cut into circles. On accomplishing this shape it is then pressed to form the tops and bottoms; however there is a continuous process of pressing again to form the required shape of the small hole. Furtherance, to this the circle that was cut and pressed is again pressed to form the required shape of the big hole. After this it goes through the process of flanging, whereby a flange is being inserted in order to achieve the dimension of fitting into the holes. This is then followed by the internal coating of the lids whereby a primer coat to the steel container covering by heating the container to a temperature of 1800-2200 F. This process involves the electro-statically spraying of the steel with a thermosetting epoxy phenol coating afterward, going through the process of dry through oven just like that of the drum.

Consecutively, this process is also similar to that of the drum making just some slight dissimilarity in the process.

Reference List

Balabanovic, M. and Shoham, Y., 1997. Fab: content-based, collaborative recommendation, Communications of the ACM. 40(3), Pp.66–72.

Berglas, A., 2008. Why it is Important that Software Projects Fail. Web.

Blackburn, J. D., 1991. Time-Based Competition. The Next Battle Ground in American Manufacturing. Illinois. Irwin, Homewood.

Bockerstette J. A. and Shell R. L., 1993. Time Based Manufacturing. New York, NY: McGraw-Hill.

Carrie, A. and Bititci, U. S., 1998. Strategic management of the manufacturing value chain: proceedings of the International Conference of the Manufacturing Value-Chain, August 98, Troon, Scotland, UK Volume 2 of Ifip International Federation for Information Processing Series. Massachussetts: Springer.

Chryssolouris, G., 2006. Manufacturing systems: theory and practice Mechanical engineering series. New York, NY: Springer.

Eloranta, E., Lehtonen, A. and Tanskanen, K. (1995), “Fast, flexible and cooperative supply chains – key issues for the survival of European industry”, Production Planning & Control, Vol. 6 No. 3, pp. 238-45.

Fisher, M. L. (1997) “What Is the Right Supply Chain for Your Product?,” Havard: Harvard Business Review, 75 (2), 105-116.

Fujii et al., 1998. A Basic Study on High Volume Flexible Manufacturing System for Agile Manufacturing, In Advance in Production Management Systems (N.Okino et al. eds) London. Chapman & Hall.

Gorczyca, F. E., 1987. Application of metal cutting theory. New York, NY: Industrial Press Inc.

Grant, R. M., 2005. Contemporary strategy analysis. Oxford, UK: Wiley-Blackwell.

Heikkilä J. 2000. Developing Demand Chain Management: Case Study on the Fast Growing Cellular Networks Industry, Dissertation. Department of Industrial Engineering and Management, Helsinki University of Technology.

Houldcroft, P. T., 1990. Which Process? A Guide to the Selection of Welding and Related Processes. England. Woodhead Publishing.

Krajewski, L., Wei, J.C. and Tang, L-L. (2005), “Responding to schedule changes in build-toorder supply chains”, Journal of Operations Management,Vol. 23, pp.452-69.

Lawrence, R.D. et al., 2001. Personalization of supermarket product recommendations, Data Mining and Knowledge Discovery. 5(1), pp.11–32.

Martin, J. W., 2007. Lean six sigma for supply chain management: the 10-step solution process. New York, NY: McGraw-Hill Professional.

Patentgenius. Library., 1976. Steel container making process. [online Electronic Source] Kleinhans, Siegfried. Web.

Rayport J. F. and Sviokla J. J.,1995. Exploiting the virtual value chain, Harvard Business Review. Vol. 73,No. 6, pp. 75–85.

Sarwar, B. et al., 2000. Analysis of recommendation algorithms for e-Commerce, InProceedings of the Second ACM Conference on Electronic Commerce. Minneapolis, Minnesota, USA. Pp. 158–167.

Schafer, J.B., Konstan, J.A. & Riedl, J., 1999. Recommender systems in e-commerce, In Proceedings of the First ACM Conference on Electronic Commerce, Denver, Pp.158-166.

Schmenner, R.W. and Tatikonda, M.V. (2005), “Manufacturing process flexibility revisited”, International Journal of Operations & Production Management, Vol. 25 No. 12, pp. 1183-9.

Slats, P. A. et al.,1995. Logistic chain modelling. European Journal of Operational Research, Vol. 87, No. 1, pp. 1–20.

Stalk, G. Jr. & Hout, T. M., 1990. Competing Against Time. How Time-based Competition is Reshaping Global Markets. London. The Free Press.

Vickery, S., Calantone, R. and Dro¨ge, C. (1999), “Supply chain flexibility: an empirical study”, Journal of Supply Chain Management, Vol. 35 No. 3, pp. 16-24.

Wu, Y. H., Chen, Y. C., & Chen, A., 2001. Enabling personalized recommendation on the web based on user interests and behaviours. In Proceedings of the 11th International Workshop on Research Issues in Data Engineering. Heidelberg, Germany. Pp.17–24.