Abstract

This paper delves into the concept of supply chain management and the use of software in the sector. The effective management of the supply chain, from the production of raw materials to the consumption of finished goods by the end-user, gives the company a competitive advantage. Understanding the supply chain helps the company better manage its inventory, leading to lower operating costs and better customer services.

However, its complex nature leads to the emergence of problems, such as bullwhip effect, coordination breakdown, and stockpiling, among others. To mitigate these problems, the adoption of supply chain management software is necessary. The software helps to coordinate events in the supply chain and allows for the seamless flow of information. This paper explores the various forms of the supply chain, its significance, and the associated problems. It also explains how supply chain management software can be adopted to help solve pertinent problems, such as information delay and the bullwhip effect.

Introduction

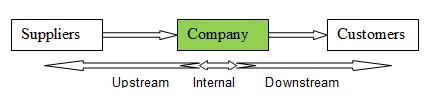

The supply chain constitutes the processes, which goods or services go through to reach the end-user, including the design, manufacture, and delivery stages. Out of this description, we can develop a simple supply chain that is composed of the company, its suppliers, and its customers. I have illustrated this in figure 1 below:

As we can see from figure 1 above, a company has the upstream, internal, and downstream parts of the supply chain. It receives supplies of raw materials from the upstream and channels it finished products to the downstream. In between the downstream, there exists an internal supply chain. We can agree that it is easier to control the internal supply chain than it is for the upstream and downstream points. Internal supply chains normally include aspects, such as receiving raw materials, inventory, manufacturing, distribution, and marketing, among other activities.

In real life, I don’t think such simple supply chains exist. There are many players in the chain, and the company may be in more than one chain. Businesses and companies are part of one or more supply chains and depend on them to thrive. In my opinion, understanding all supply chains is not possible due to the complex processes some raw materials undergo before the final delivery to the company. Therefore, I feel that the main objective of the company should be to evaluate and participate in the most profitable chains so as to gain a competitive advantage over their competitors.

In this regard, supply chain management (SCM) is the actions that a company does to influence the way its supply chain is operated to maximize profits and cut costs, among other desirable effects. From the definition of SCM, I think that the larger the part of the supply chain the company is able to influence, the higher the chances of maximising its margins.

Supply chain management not only takes into consideration traditional logistics, but also incorporates customer service, marketing, finance, and product development into the supply chain. I think the shift from logistics to supply chain management has been influenced by global competition and the need for organizations to remain competitive through pricing.

Components of the Supply Chain

The five major components of the supply chain are production, inventory, location, transportation, and communication. Production should be concerned with manufacturing the products whose demand is high, ascertaining the amount that should be produced, and matching the quantity needed by consumers. Although I think accurate matching of the quantity needed by consumers is difficult, with experience, an organization should be able to realize it.

The inventory is concerned with all the stock related issues along the supply chain. In my opinion, inventory control should ensure the least amount of inventory to minimise the related costs. I think the challenge for most organizations is maintaining the least inventory while meeting customers’ needs and taking care of uncertainties of the supply chain. It is at this point that I think the software for supply chain management should play the biggest role. The software should be programmed in such a way that it ensures the uncertainties along the supply chain are well taken care of, and no excessive stock is piled.

The location is concerned with where the facilities of production or storage are situated. I think organizations that deal with bulky and perishable raw materials should prioritize location to minimize logistical costs. In doing this, the organization should, however, not forget to ensure the location selected offers room for improvement, expansion, or construction of new facilities to cater for an unexpected rise in demand. It is after the locations have been determined that I think the company should then determine the most cost-effective routes for the products to flow through in the supply chain, from the company to the end customer.

The transportation component is concerned with how inventory and goods move from one location to another within the supply chain. From my own observations, most companies consider this to be the most important part of the supply chain. Although I also think transportation is an important aspect of the supply chain due to the amount of time and money it consumes, it should be the main focus. Unfortunately, many managers still think of the supply chain as one and the same thing as logistics. The choice of the mode of transport depends on the nature of goods, urgency, a distance of travel, and cost, among others.

In my opinion, the information part of the supply chain is the most important aspect. It is concerned with the amount of data that is available, collected, or shared across the supply chain. I can argue that the incorrect and unreliable flow of information in a supply chain can be the most harmful issue to the company. I think the main reason companies are adopting supply chain management software is to streamline the flow of information along the supply chain.

All these decisions reflect the effectiveness and capability of the supply chain. From the details, we can conclude that the competitive advantage of a company is greatly reliant on the effectiveness of the supply chain. Therefore, I feel that the most successful company in this century will be the one that is able to best understand and improve its supply chain.

Significance of Supply Chain Management

Supply chain management (SCM) is an important aspect of any organization, as it improves the efficiency of its operations, which leads to customer satisfaction and financial success. Customer satisfaction, in my opinion, should be the main goal of improving supply chain management. A satisfied customer is the one who keeps the supply chain in operation. I don’t think a supply chain can even exist without the end-user customer.

Most scholars can agree with me that an effective supply chain management is one that furnishes the business with valuable information that can help it diagnose any problems and provide relevant solutions to maintain customer satisfaction. It can be argued that the main aim of SCM is to give the business a competitive advantage over its competitors by streamlining the supply chain, which leads to reduced costs and prices.

SCM versus Logistics

Logistics involve the management of material and information flow in the supply chain. According to my observations, most managers consider logistics as the main part of the supply chain and neglect other components. Logistics are just a part of the supply chain management strategy, and involve planning, implementing, and ensuring the efficient and effective flow and storage of goods and services, as well as pertinent information along the supply chain, from the point of production to the point of consumption in the best way that meets the customers’ demands.

The consumer is the most important part of the supply chain; therefore, I am of the opinion that most companies should try to build a close relationship with their clients when considering improving their supply chain. I also think managing the entire supply chain is important and can lead to greater gains.

Types of Supply Chains

Supply chains are dependent on the nature of the company. Although companies should strive to minimize inventory costs, I don’t think it is practically possible to cut these overheads in totality without risking customer dissatisfaction. Cutting these costs lead to the scarcity of the stock needed to cater for uncertainty in customer demands, which I think can be more costly in the long run. Examples of supply chains include: integrated make to stock, continuous replenishment, build to order, and channel assembly.

Integrated Make to Stock Chain

The integrated make to stock supply chain model is concerned with actively tracking customers’ demands to ensure the production process, efficiently replenishes the inventory to match the demand for finished goods. To achieve this, I think the organization must invest in the information system to ensure efficient flow of information. In my opinion, the use of modern information technology and supply management software is vital in these types of supply chains.

For instance, Starbucks Coffee uses Oracle’s automated information system for the management of its supply chain to coordinate the suppliers of coffee beans according to the demand for the beverage. I think the major success of Starbucks Coffee can be attributed to some extent to its use of the SCM software in managing supplies in all its outlets. The main aim for Starbucks Coffee incorporating the use of the software is probably to help it in realizing a well-timed and appropriate flow of information in relation to goods, customer demand, store capacity, and logistical issues, among others.

Continuous Replenishment Model

This model is adopted to ensure that there is a constant replenishment of the inventory by ensuring a close working relationship among suppliers and intermediate partners. Although constant replenishment, in my opinion, cannot be guaranteed in normal business situations, this model is aimed at minimising extreme fluctuations in the inventory level.

We can, however, argue that supply chain of this nature can be disrupted if the logistics involved are complex and costly. One would probably agree with me that, supply chain of this nature can be difficult to coordinate where there is no information flow between the production and service points. In my opinion, this type of supply chain can best operate in fields such as the supply of medicine, where there the demand pattern is a little constant and predictable.

Build to Order Supply Chain Model

In the build to order model, company produces a good when an order is placed, rather than for purposes of storing it in the form of inventory. In my opinion, this type of a model can best work when supported with smooth and efficient flow of information along the supply chain. I think a breakdown in communication in this type of a chain can be detrimental to the company than in the chains discussed earlier.

In my opinion, Dell Computer Company is able to utilize this model due to its experience in the field of computer technology and the varied demands on specifications by its customer. Assembling a computer before an order has been registered can lead to higher costs in labor and inventory for dell. I am inclined to think that this type of a model will also demand keen management and monitoring of raw materials and the efficient and timely delivery of the required materials along the supply chain.

Channel Assembly

This type of supply chain is a slight modification of the build to order model. I think this type of model is effective in the manufacturer of complex products, which require other components to function. I can give an example a car which several companies may produce different parts, which are then channelled to an assembler; the assembler may then deliver the car to a painter. I can argue that in this type of supply chain, proper coordination between parties involved is essential and as a result, constant communication must be maintained along the chain.

Global Supply Chains

Global supply chains involve partners from different countries in a single supply chain. In my opinion, global supply chains are becoming more of the same to local supply chains due to the advancement in technology. I think companies are engaging in international supply chain to increase their customers, cut costs, expand technology know-how and enhance brand awareness. The global supply chains are complex and longer than domestic ones, and have a lot of uncertainty and problems, though I feel that these problems and uncertainties are on the decline due to the improvement in cargo handling and information technology.

You will agree with me that pirates in international waters offer a significant risk, obstacles and uncertainty in the logistics of the global supply chains. I think language barrier is declining in significance as an obstacle to global supply chains. Fitting trading software with language translation capability is a novel idea that is breaking this barrier. You may differ with me, but I feel the main challenge is political uncertainty that surrounds the global supply chains that poses the greatest threat.

Supply Chain Problems

Long and complex supply chains are likely to develop problems that can lead to the collapse of the company. One feels that collapse of the supply chains can be attributed to the failure of most companies. Forecasted demand can be altered by several external factors, such as competition, weather conditions, technological changes, and customer confidence levels. Hold-ups also transpire owing to equipment breakdown and traffic hitches. I am of the opinion that these internal holdups are the major causes of delays in the supply chain. As I pointed out earlier communication and flow of information is vital in a supply chain as the breakdown can lead to failure of many companies. In my opinion, this can result from miscommunication, delay in communication or both. I think an efficient supply chain should enable quick inventory turnover.

The Bullwhip Effect

The bullwhip effect occurs when customers demand more goods than they need or can handle. I agree with argument that this is the most significant problem in the supply chain. This occurs when there are promotions and can lead to stockpiling, leading to high inventory costs. Sharing of information is one of the measures companies use in dealing with the bullwhip effect. Use of EDI, extranets, and software for supply management can also help in the sharing of information to mitigate the negative impacts of the bullwhip effect. Therefore, one can argue that poor communication can lead to adverse bullwhip effect which can lead to failure of many companies.

Supply Chain Management Software

Supply chain management software is used by companies to track and monitor the flow of goods and services in their supply chain. The development of SCM software, according to me, is a major breakthrough to proper management of supply chains. Software dealers and developers, including i2, Oracle, and SAP, have already come up with intricate software for purposes of SCP. Despite these developments, I feel that companies should invest in developing their own software that is customised to meet their demands and operation procedures. It can be argued that most companies are adopting supply chain software so as to induce synergies, improvements, and savings.

Types of Supply Chain Management Software

There are many types of event management software in the market that are designed to capture data to produce information in the forms of reports, which are used in the evaluation of the company’s supply chain. In my opinion, despite the presence of much software, companies should hire experts to develop supply chain software that are customized to their operations for the best results. This software should have optical character recognition features to read the serial numbers of products.

Inventory tracking by the software involves reading the barcodes at the various points of the supply chain. I feel that inventory tracking is the most crucial part of the supply chain that the software can simplify. At various delivery points, merchandise is scanned using barcode readers, as well as wand detectors, after which it is stockpiled. Barcodes readers, which can read a variety of formats, such as code 39, UPC, interleaved 2 of 5, and code 128, are available in the market. Barcode readers can be seen in use in many stores and supermarket and I can’t help to wonder how the attendants would handle customers without the technology.

Some supply chain management software come with Radio frequency identification (RFID) features fitted to them to enhance their performance and capabilities. The advantage of RFID is that information can be obtained from long distances and stored or transferred in a dynamic format. However, RFID devices have incompatibility issues with the current supply chain management software. I would advise that it is important to insist on the supply chain software fitted with RFID features and to enquire on the compatibility with your computer system before buying the software.

Significances of Supply Chain Management Software

Supply chain management software is developed to assist managers in managing and cutting production overheads, reducing lead time, decreasing shortfalls and preventing excessive inventory, and cutting down transport costs. For me, the best software should be tailor made for the business to exploit the full benefits of automation. The advancement in technology is changing how supply management is conducted at a rapid pace.

The use of electronic data interchange (EDI) and other technologies, such as XML/EDI, have simplified supply chain management. As opposed to enterprise resource planning (ERP) software, which is limited to inbound oriented operations and functions, supply chain management software incorporates both the intra and inter-organizational processes. I would advise that the software a firm buys should be able to connect with the internet, Bluetooth, and other connectivity technologies to enhance its capability.

Conclusion

The success of an organization is influenced by the efficiency with which raw materials, finished goods, information, and money flow into, within, and out of the organization. This flow of material and information is known as supply chain. In my opinion, the supply chain forms the backbone of a company’s success. A simple supply chain has a few players, including the company, its suppliers, and its customers.

However, in the real situation, I don’t expect simple supply chains to exist; most of them involve complex logistics among numerous stakeholders. The existence of many partners in a supply chain leads to a multifaceted relationship that requires careful management for the company to be successful. Complex supply chains have many related problems, such as the bullwhip effect and coordination problems between the different partners.

The breakdown of the supply chain of a company can lead to delays and customer dissatisfaction. To improve the capability of the software, I agree to the opinion of some other researchers that it should be integrated with emails and the internet to allow for the sharing of information to resolve the main problems encountered in the supply chain.

References

Buxmann, P, Ahsen, A, Diaz, L & Wolf, K 2004, ‘Usage and evaluation of supply chain management software: results of an empirical study in the European automotive industry’, Info Systems Journal, vol. 14, no.7, pp. 295–309.

Datta, S, Granger, C, Graham, D, Sagar, N, Doody, P, Slone, R & Hilmola, O 2008, ‘Forecasting and risk analysis in supply chain management’, Working Paper, Engineering Systems Division, Forum for Supply Chain Innovation, Massachusetts Institute of Technology, Boston, MA, pp.13 -25.

Du, S, Lu, T, Zhao, L, Xu, B, Guo, X & Yang, H 2012, ‘Towards an analysis of software supply chain risk management’, Proceedings of the World Congress on Engineering and Computer Science, vol. I, San Francisco, CA, pp. 211-235.

Ertek, G & Eryılmaz, E 2008, ‘The bullwhip effect in supply chain: reflections after a decade’, CELS 2008, Sabancı University, Jonkoping, Sweden. (Presented by Emre Eryılmaz).

Gelderman, J & Weele, A 2005, ‘Purchasing portfolio models: a critique and update’, The Journal of Supply Chain Management, vol. 14, no. 3, pp. 19-28.

Young, B, Das, B, Case, K, Rahimifard, S, Anumba, C & Bouchlaghem, D 2007, ‘A Review of Approaches to Supply Chain Communications: From Manufacturing to Construction’, Journal of Information Technology in Construction, vol. 12, no. 3, pp.73- 102.

Information Technology One-Stop Portal. 2012, Starbucks Coffee and Information Technology, Web.