Executive Summary

An analysis of the layout design of the TC furniture manufacturing company shows the need for a model that can be used to create the best layout design for modeling the processes used to make timber products, which in turn can enable the company to be competitive in the market. Fixed and flexible layout designs have been discussed in the paper with a specialised focus on the use of the CRAFT, BLOCKPLAN, and the Graph theory modeling techniques to produce different layout designs, which could enable business organisations to make good decision on the best modelling technique and the best layout design to implement. Such decisions are critical in enabling company become competitive in the market. It is however, recommended that further studies should be conducted to determine how different analytical techniques can be combined to design a layout that optimises the resources available to improve the performance timber manufacturing plants.

Introduction

The use of formal methods to create a design layout of a furniture production line for the purpose of improving the productivity of TC furniture manufacturing company raises the question of the effectiveness of the strategy. This study focuses on analysing the use of flexible and fixed layouts strategies, using different formal methods to produce an effective plant layout design, which provides an effective performance optimisation process (Pinto Wilsten & Shayan, 2007). According to Aurich, Fuchs and Wagenknecht (2006), a good plant layout provides direct and indirect benefits to optimise the use of available resources and maximise plant operations. The case study case by Pinto Wilsten & Shayan (2007) shows that different layout design techniques can be used to maximise existing spaces in the manufacturing plant to produce good quality furniture. Using formal methods increases the productivity of plants by reducing the production lifecycle, the number of bottlenecks in a plant, the work in progress, and the material handling time (Aurich, Fuchs, & Wagenknecht, 2006). The underlying formal methods examined in this paper include CRAFT, AHP, and the Graph Theory (Pinto Wilsten & Shayan, 2007).

Results on the problems associated with the flow of materials within a plant include the use of obstructive and less cost effective methods of allocating and finishing products. Some of the solutions include the use of inspection sections to enhance the flow of materials by decreasing the plant layout and reducing the distance the materials flow within the plant to increase productivity. In this case, tests conducted using different models based on different parameters show the significance and effectiveness of using formal methods to solve plant layout problems. The goal is to achieve efficient use of space, minimal financial investments, minimum material handling costs, and minimum throughput time. Typically, the analysis of the flow of materials underpins the development of the strategy for minimum material travel distances within the manufacturing plant based on the use of fixed path material handling method. The minimum flow material distance when combined with the fixed path handling method provides the basis for developing a strategy for making the best decisions on handling shortcuts in material handling procedures (Banerjee & Zhou, 1995). A focus on the area or the distance materials travel within a plant in the manufacturing process based on the minimum product travel method is the right method to use. In this case, the right method is arrived at when other methods have failed.

Conceptual Framework

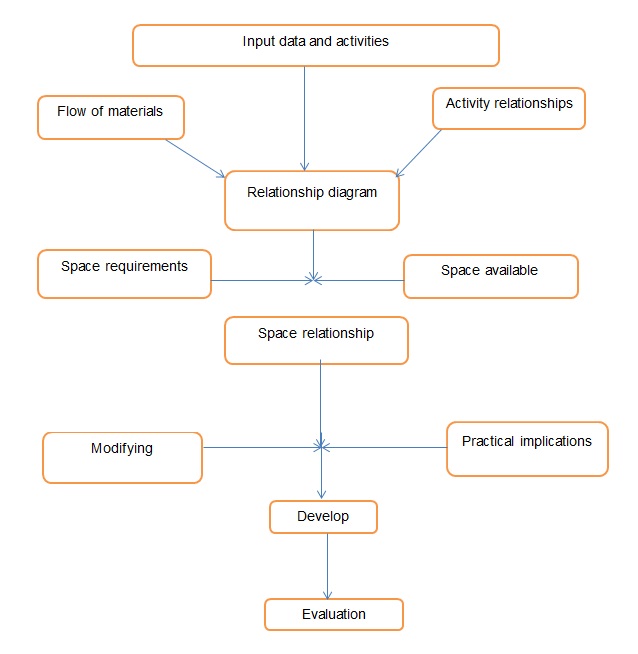

An analysis of the best techniques to use to design the best layout is conceptualised in diagram one below (Pinto Wilsten & Shayan, 2007). In this case, the process consists of input data and the activities that are performed based on the use of different methods to produce a layout design for the production of 9 different styles of chairs, and 3 and 2 seaters respectively (Chae & Peters, 2006). The inputs consist of the demand for products based on the rate of flow of materials per month. In this case the flow of materials, which is an important element of the formal design process, is integrated into the framework to determine the best layout design and the best method to use to generate an efficient design. In this case, activity relationships and the flow of materials help to create an optimal relationship diagram based on space requirements and the available space (Banerjee & Zhou, 1995). In this case, the space relationship diagram shows the relationship between different space layouts, and the point at which alternative designs are considered to determine the best method as mentioned in the body of the paper. Once the relationships have been established, alternative design methods are evaluated and the correct design method is used, as conceptualised in diagram one below.

The conceptual framework shows the relationship between the outcomes of the processes and activities for each process using different design methods. In this case, the conceptual framework provides the basis for the technical analysis of the design layout methods. The flow of materials in each specific design provides the best analytical results of each method and the advantages associated with each method. The ultimate goal is to optimise the performance of the layout design.

Technical Analysis

In this case the section consists of an analysis of different computerised methods that have been used in the layout design to produce layouts with different advantages and disadvantages and that are appropriate for the production of furniture. The methods to be analysed in this case include CRAFT (Computerised Relative Allocation of Facility Techniques), ALDEP (Automated Layout Design Program), and BLOCKPLAN.

CRAFT

An analysis of the use of CRAFT shows that the technique operates on the principles of the minimisation of cost when moving resources and is expressed as a linear function of the distance moved by the materials in the plant. The layout allows for 11 operations to be done per product, but does not allow for the sequential movement of materials. According to Chae and Peters (2006), the program can be used to design layouts that are updates of the best existing layout based on calculations, which use adjacent and split areas of the same size (Fu & Kaku, 1997). The input requirements for the method include configuring the initial layout of the furniture manufacturing plant. The sizes of the departments and the arrangement of the elements used in the departments provide the basis for defining the matrix, which shows the movement of materials in terms of man hours, days, years, and weeks. The interdepartmental movement of materials and the space occupied per unit area provides the parameters that can be used to calculate the cost of the total movement of materials in the plant layout (Morrison, 1996). The procedure has to be repeated to attain a point without cost savings. The system does not provide an optimum solution in terms of minimising cost and distances moved in the plant (Pinto Wilsten & Shayan, 2007). The critical advantage with the layout design method is that it allows the users to fix permanent locations based on the fixed layout design method. The shape of the inputs can be varied and it consumes minimal computer time, is mathematically effective, and can be used to design the layout of offices and furniture manufacturing plants (Pinto Wilsten & Shayan, 2007). In addition, it is possible to check previous interactions and to provide accurate cost saving printouts (Morrison, 1996).

The main disadvantages with the method is that it can only be effective if an initial layout of the required layout design is available to enable the system provide the required layout. In addition to that, the leaner model used in the design provides a straight line movement of materials, which is not the case when applied practically. In this case, it is possible to interchange different departments and the inputs have to be carefully structured accordingly. The model allows for only 40 departments to be factored into the layout design, which can be used in the layout. It is possible to take into account undesirable relationships.

ALDEP (Automated Layout Design program)

According to Pinto Wilsten and Shayan (2007). The Automated Layout Design program is used when activities are the main elements of focus in the design of the layout. In this case, the manufacturing system is designed based on constantly varying conditions, which prohibit the collection and use of accurate data. Here, related activities play a significant role in decision making. This method requires the designer to collect and use related activities, which are close to the desired activities and have the required size and category (Ratnasingam & Wagner, 2009). It is critical for the interconnected elements to be selected and added until a specific number is reached. It has been shown that the method can accommodate an analysis of up to 63 departments in a layout, which have different layouts. In this case, it is possible to restrict the type of layout design.

The design operates on a number of requirements, which specify the width and length of the floor, the scale of the printout design, the number of departmental preferences, and the number of layouts to be generated. In this context, it is important for the designer to know in advance the layout of the building when setting up the layout design.

Genetic Algorithms

According to Ratnasingam and Wagner (2009) and Yang and Peters (1998), this method is based on the use of potential solutions called a population, which relies on encoding parameters lying between 30 and 60 individuals. Different approaches to problem solving have been proposed using this method. Space layout is a critical optimisation component that can be achieved based on the use of the algorithm by considering the flow of materials and isolated spaces when different sources of raw material and final products are considered (Yang & Peters, 1998). In this case, a pre-existing layout, the flexibility of the design, and the material handling procedures are critical in the design. Closeness and distance ratios are critical in the layout design. Changes in the location of the products and the materials that are used in the production process are critical elements, which significant contribute to the design process (Yang & Peters, 1998).

This is a layout design method that operates on an encoding technique, which relies on an initialisation procedure to solve the design layout problem. In this case, the strategy consists of a number of elements, which include the creation, evaluation function, the selection of parents who are concerned with the reproduction of new elements, genetic operators, and the termination of the layout design. The underlying aim is to optimise the costs of handling materials to solve the space and logistical problems. The method relies on the use of input data from users for presenting solutions graphically and provides alternatives that optimise available resources. Optimal solutions in this case are limited by the amount of space available, but some suboptimal solutions have been developed to address layout problems that are more complex (Chae & Peters, 2006). Different solutions have been proposed when using the method, but the optimal solution is a layout that contains elements, which increase in number as the number of layouts increase with the number of facilities in each block increase.

Using BLOCKPLAN

BLOCKPLAN provides the next formal methods option that can be used in the layout design of the furniture production line. In this case, the program provides interactive features for the users in designing a multistory layout. Typically, the design layout is illustrated in the diagram below.

This layout planning technique allows for a design that focuses on the placement of each activity in the design (Yang & Peters, 1998). The diagram shows the relationship between different elements in the design and consists of product quality and quantity, timing data and how the elements relate to the space requirements in the design, the relationship between activities, and the link to the relationship diagram (Bowen & Hinchey, 1999). In this case the availability of space, space requirements, tentative plans, evaluations, and the plan section are critical in the design. The plan provides a layout, which shows the relationship between different points in the layout design.

The above method is less productive and has been modified to provide the layout shown below.

The formal methods used in this case vary depending on a variety of reasons. Here the importance of using computerised formal methods provides the basis for the argument on the best strategy to adopt and to identify if the strategy can work, based on the advantages and disadvantages of the methods.

Evaluation

The best layout design based on the different modelling techniques to design the most efficient furniture layout are critical improve the productivity of the TC furniture manufacturing company. The strategy is to optimise the available space based on different layout design methods and enable the manufacturing company to operate with optimal space capacity to reduce the costs associated with inefficient use of space. Technically, the approaches used to accommodate the layout plans can either be flexible or fixed layout plans. In this case, a layout design based on the graph theory shows that the method can be used effectively to produce a design that integrates the flexible and fixed layout designs based on the distance moved by the materials and the products for optimal utilisation of resources. The layout decisions that can be achieved based on different design and modeling techniques include flexible and fixed design methods.

Typically, it includes the number of centers needed within a manufacturing space, the amount of space and capacity requirements, the location of the production points, and the layout configurations. The modelling techniques used to achieve different designs for optimal space needs include CARFT, ALDEP, and genetic algorithms and provide different outputs to obtain the best output. An evaluation of the methods shows that the methods have failed to integrate the concept of product demand variations. That is because CRAFT focuses on minimising cost depending on the distance moved between the elements in the production line, and relies on adjustments done on the initial layout to optimise resources (Chae & Peters, 2006). The ALDEP method is limited to the activities that are done on the products and lacks the capability to collect accurate data in doing calculations. It relies on the movement of interrelated activities within the manufacturing plant. On the other hand, the genetic algorithms method provides the manufacturers with the ability to optimise available space and depends on the closeness of different production points in the manufacturing plant. However, the methods provide the flexibility to the flow of material handling costs despite the changes that are experienced in product demand.

Strategy Analysis

The strategy is a combination of the flexible and fixed design layout methods. The reason for combining both methods is to create a hybrid layout design, which integrates the advantages of both methods into the new method. The strategic issue is to provide a good layout to improve productivity in terms of the material and product flow, minimisation of the total area occupied by the plant, and minimisation of the adjacency distance to ensure the systematic flow of materials and products. In this case, it is important for the layout to be made is such a way to ensure an increase in the quality of the products, reduction of hazards to workers, improved communication and interactions in the plant, improved flow of materials, improved utilisation of materials, and optimal use of available space. Each of the strategic approaches provides different benefits to the layout design of the plant manufacturing activities. Analytically, the approaches to use include the fixed or flexible layout design plans, which are the only available design methods that can be used in the design of the plat layout plan.

Typically, the fixed approach provides benefits include the least movement of materials within the manufacturing facility, low handling costs of equipment, a production process, which allows for maximum flexibility, and the possibility of ensuring efficient utilisation of employees by assigning them specific areas, which require their specialised skills to ensure continuity of work. On the other hand, the flexible layout approach allows for economical movement of materials and employees within the manufacturing plant, it allows for flexible volume and accommodates a variety of processes, it allows for the grouping of processes and resources according to the function to be done, and the movement of resources and products depends on the

Strategy key elements

The critical elements to seek for justify the use of improved plant layout methods and include minimum time for material handling, shorter material distance movement at each time the movement is required, elimination of the unnecessary need to backtrack and sidetrack the movement of materials, less effort required in the use of labour, improved location of employees within the layout of the facility, increased output per man hour, low number of accidents, and the possibility of increasing the wages required for the employees. It is possible, by using the optimal material handling method to reduce and eliminate incidents of fire and less inspection time. However, some of the problems experienced when using different material handling methods include picking the wrong type and amount of materials, necessitating the need for the right type of design layout. An accurate identification, with the right condition and the right time is one of the elements that define the layout design of the facility.

Evidence if the strategy will work or won’t work

An analysis of the key elements of the strategy and the outstanding benefits gained from the use of a combination of both the flexible and fixed layout design shows that the strategy can work. That also depends on the modelling techniques used to achieve the goal of designing a layout that ensures optimal use of space, improved system performance, effective resource utilisation, cost effectiveness, and an effective use and movement of components to make the layout an effective design. It is critical to note that the hybrid strategy can work effectively because it focuses on product and process layouts. In this case, evidence of focusing on the product and process is shown in the ability to determine labour and machine requirements, minimum time is required to conduct inspections on products and processes, and allows for effective handling of materials. That is because the CRAFT method allows the designer to fix some locations and other locations to be flexible. In addition to that, the technique allows for the ability to vary the shape of inputs when making the layout design, and allows for a cost effective layout design.

Industry Analysis

The need to produce high quality furniture has compelled the furniture manufacturing companies such as TC to evaluate different plant layout designs and design models to ensure that the company produces the best layout design to enable the company to optimise the cost, space, employees, and other resources resulting in improved performance and productivity of the firm. In this case, different firms are looking for the best methods to optimise the use of available resources to become competitive in the market based on gaining a significant market share is the underpinning reason for the companies operating in the furniture producing industry to seek for methods that can be used to optimise the productivity and performance of the firms. The problem with many of the furniture producing firms is related the total areas available for each of the firms to carry out their production activities, and the flow of resources within the layout, including the materials used to make the products and the flow of the products into the areas, which are easily accessed by customers. Each strategy provides advantages and disadvantages for each method used to create the most competitive layout design.

SWOT analysis

A SWOT analysis provides us with a clear description and organisation of the strengths, weaknesses, opportunities, and threats in the furniture manufacturing industry using fixed method and flexible layouts based on different modelling techniques as shown in the table below.

Issues to address

The main issues to address are the adjacency distances, which can be achieved, the adjacency percentage that can be achieved, and the best layout design to optimise the performance of the layout design in terms of the product and process flow of materials, and the best modelling technique that can be used to achieve the best layout design.

Recommendations to improve stagey

It is recommended that the best method in this case is to integrate both types of layouts designs to optimise the benefits gained by using the fixed and flexible layout designs in the design of the hybrid layout to achieve optimal plant performance. Different layout modelling techniques can be used to design layouts with different product and process movements. However, by evaluating different modelling techniques, it is possible to identify the best method that is suitable for the best hybrid layout design techniques.

Conclusion

In conclusion, it has been established that the efficient movement of materials and products and the processes involved underscore the need to create a layout design for the timber manufacturing company to ensure optimal plant performance of the furniture manufacturing plant. Optimal performance enables the plant to optimise performance, increase productivity, and reduce wastes by using available space efficiently of cost effectively. In this case, different layout design modelling techniques provide different layout outputs, which when evaluated enable designers to settle on the use of a hybrid layout design that integrates the best elements of the fixed and flexible layout designs. In this case, a combination of the modelling techniques could also produce the best modeling technique that can be used to create the best layout design that could make the production process efficient and the company competitive in the furniture manufacturing market.

References

Aurich, J. C., Fuchs, C., & Wagenknecht, C. (2006). Life cycle oriented design of technical Product-Service Systems. Journal of Cleaner Production, 14(17), 1480-1494.

Banerjee, P., & Zhou, Y. (1995). Facilities Layout Design Optimization with Single Loop Material Flow Path Configuration, International Journal of Production Research, 33 (1), 183-204.

Bowen, J. P., & Hinchey, M. G. (1999). High-integrity system specification and design. Heidelberg: Springer.

Chae, J., & Peters, B. A. (2006). A simulated annealing algorithm based on a closed loop layout for facility layout design in flexible manufacturing systems. International journal of production research, 44(13), 2561-2572.

Fu, M. C., & Kaku, B. K. (1997). Minimizing work-in-process and material handling in the facilities layout problem. IIE transactions, 29 (1), 29-36.Lynn, C. M.

Morrison, K. R. (1996). Plant Layout Selection Process for the Fifth Generation Corvette, Computers and Industrial Engineering, 31 (1-2), 67-70.

Pinto Wilsten, J., & Shayan, E. (2007). Layout design of a furniture production line using formal methods. Journal of Industrial and Systems Engineering, 1(1), 81-96.

Ratnasingam, J., & Wagner, K. (2009). Green manufacturing practices among wooden furniture manufacturers in Malaysia. European Journal of Wood and Wood Products, 67(4), 485-486.

Yang, T., & Peters, B. A. (1998). Flexible machine layout design for dynamic and uncertain production environments. European Journal of Operational Research, 108(1), 49-64.