The provided video revolves around ZARA, a giant international corporation that works in multiple areas in the world. There are about 32 countries where clients can find the company’s products and benefit from their high quality. Inditex, the owner of ZARA and other successful franchises, was founded in Spain and opened the first store in 1970. At the moment, it owns 20 manufacturing and distribution facilities, which proves the importance of the brand and the opportunities for its further evolution. There are also multiple specialists and employees working for the company in different areas, which means that there is a need for an effective management system that will be able to align the cooperation between various departments and ensure the use of practical strategies in the sphere of supply chain management.

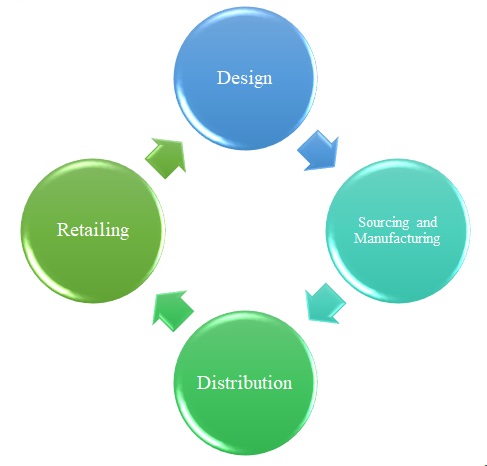

The complexity of the brand’s functioning and its development introduces the need for better quality management and control. At the same time, Zara should be able to produce, distribute, deliver, and sell goods in the most effective ways. For this reason, the company employs the four-step business system consisting of the following elements: design, sourcing and manufacturing, distribution, and retailing:

The observation of the given model guarantees the effective distribution of resources and the ability to monitor all phases of the supply chain, which is vital regarding the company’s size. The case presented in the video also emphasizes the brand’s desire to continue its expansion, which means that there is a demand for further improvement to generate a competitive advantage and overcome rivals in attractive regions.

The phase of design is the first important aspect of Zara’s supply chain. Correctly realizing the importance of this aspect for the successful distribution of clothes and their sales, the company establishes a developed system of data collection and processing. Every store provides information about units that are demanded by clients and that are popular among them. At the same time, they report about unpopular products or elements of clothes that are not present in shops and might be attractive to clients. This information is vital for further decision making and planning as they demonstrate the success of the current collection and the need for future change. Through personal communication, store managers offer their recommendations and share data about the shop’s functioning to plan the next actions. Zara has three solutions that impact its chain management: the company might take out an item from the collection if sales are low, it can make some changes and keep their style but make clothes from different fabrics, or introduce a completely new item. The solution is made resting on discussion with designers and a team of 200 people working in three major departments: women’s clothes, men’s clothes, children’s clothes. In such a way, Zara emphasizes the continuity of the process as the creation of new items starts immediately after the start of sales of already existing ones, and designers, using data from real clients, plan new collections that would meet new demands.

The sourcing and manufacturing phase of the supply chain of Zara is also given significant attention by the company. The manufacturing facilities are mainly concentrated in Europe as 80-90% of plants can be found in this area. It helps to simplify logistics and guarantee that needed materials will be delivered in time. Out of this 90%, 65% are produced in Spain as the brand was created here. However, fabrics arrive from Italy, France, and other locations, which sophisticates the supply chain management and introduces the need for effective solutions. Zara cuts about 35 million meters of cloth, for this reason, it tries to minimize waste by planning cuts and marking pieces. It guarantees that the material will be used wisely, and the company will follow the sustainable model. The company has to deliver these pieces to different workshops where 11000 employees working on small assembly lines will make various items. The workshops are owned by independent companies, which is vital for planning supply chain management. All garments should be returned to the plant where the cutting was done for quality control and the transportation to distribution areas.

The distribution phase is critically important for the company’s work as it has to manage thousands of items and ensure that they are delivered to proper locations in-time. Zara has a distribution center with two basic areas for hanging and folding clothes. It uses a carousel specially created for the brand to guarantee that all products are transported and automatically directed to boxes that will travel to shops located in various areas. The distribution system is based on mail and the PDA system used to make orders. The barcode on every item shows its destination point, which helps to improve the effectiveness of product management and avoid confusion. Another vital part of the distribution is the provision of shops with items they need at the moment as they can be sold out. The company sends orders four times per week to ensure a wide pool of goods in every shop. It uses the services of independent subcontractors to deliver cargoes either by trucks or by planes as there are distant locations, and two days are needed to provide them with demanded products. The brand also uses a special system processing information about products provided by shops every day to plan future deliveries and logistics needs. This approach guarantees that the company manages and distributes all items effectively and does not have delays.

The final stage of the supply chain is retailing. The company uses a unique model that guarantees its popularity among clients and its ability to sell goods. Zara does not employ public advertising practices; instead, it focuses on displaying its products in its shops and attracting clients by design and well-decorated windows. To guarantee that the given strategy works, the company has a prototype store in its headquarters, which is used to plan future changes in the interior and organize goods in the ways that are most convenient for clients. The team of designers considers feedback from customers in different areas and offer new styles every week. Solutions used in the prototype are sent to shops in different regions for them to follow this pattern and create a unique and recognizable image of the brand. The coordination team consisting of specialists select music, design elements, and windows’ styles because of the critical importance of the environment and design which attracts clients. Every shop-window demonstrates the newest clothes and parts of a new collection that will be attractive to clients. In this way, Zara manages to popularize its goods among clients and attains higher sales.

In such a way, Zara uses a simple and effective supply chain consisting of four major elements. It designs items resting on information acquired from clients and provided by shop managers on a daily basis. Later, this information is used to order fabrics and create goods. The distribution presupposes using facilities and equipment to manage products and sent them to shops using independent contractors. Finally, sales are handled by attracting clients with a unique design. The model has proven its effectiveness as it helped the brand to evolve and become one of the recognizable companies with loyal clients in different regions of the world. The focus on promotion via its own shops also demands the creation of a unique design that considers clients’ preferences and their demands for the interior and the quality of offered products. The model employed by Zara also presupposes the continuous process of improvement and design, which is needed to remain competitive in the modern market.

However, there are also some ways of how supply chain management can be improved. The positive change is usually added to the most important aspects, such as distribution, retail, sourcing, and sales management. Additionally, today much attention is devoted to much attention and lean management as the ways to reduce waste and increase the effectiveness of resource management. Strategies of this sort are viewed as a beneficial way to remain a competitive player in the market and acquire benefits. For Zara, the following methods can also be employed as they will help the company to generate new services and become more powerful in a long-term perspective. The following recommendations are provided regarding the existing complexities and challenges the company face. As it operates in different regions distribution and shipment practices and retailing should be improved, to avoid delays and ensure a sufficient supply.

The first recommendation is related to the distribution aspect. Zara works with independent subcontractors responsible for the delivery of products to destination points and transportation. For this reason, it is vital to improve contract and rate management. It presupposes adding rates for various modes of transportation and carriers to a database. The given solution will help to enhance the calculation of costs and structure the information about groups that can be viewed as beneficial partners. In the future, the choice of the firm for transportation can also depend on the facts from this database as it will allow the enhanced effectiveness of shipment and delivery. The brand can also employ route optimization technologies to plan deliveries and guarantee that carrying loads will be selected appropriately and shops will acquire demanded items in time. Finally, Zara can create its own warehouses in the most attractive regions to improve supply to shops with a high sales level.

The manufacturing and distribution process can also be improved by using automation. At the moment, Zara uses only a specific carousel to implement technologies and attain better outcomes. However, today, the use of automation and robotic technologies is one of the ways to reconsider the approach to this aspect. Warehouse management can be enhanced by using robots responsible for the evaluation of the quality of goods, their checks, and the selection of items for delivery in particular shops. Automation can also be used to support the PDA system and manage items more effectively. Zara also critically depends on the supply of fabrics, which means that cooperation with suppliers should be improved. It can be achieved by using software for planning supplies and demand, as in numerous cases, the delays or poor planning means the ineffective management of supplies. For this reason, automation of distribution and warehousing, along with the use of IT technologies to plan procurements, is a key to the achievement of success in the future.

Retail procedures can also be improved. Zara is focused on using information from clients to create new goods and sell them. This element can be transformed by using IT technologies and client-oriented applications, providing people with an opportunity to rate specific clothes online and propose their views on how these elements can be improved in the future. It will boost the effectiveness of data collection, and Zara will be informed about the recent change in the demand. It will also increase clients’ devotion levels and demonstrate to them that the brand is interested in their clients’ visions. Moreover, it will enhance supply chain management as a better understanding of the demand will result in more effective procurement, distribution, and transportation.

At the moment, Zara is also concerned about waste management as it uses a significant amount of fabrics. For this reason, it uses a specific cutting technique to minimize waste and ensure the increased effectiveness of this procedure. Thus, the company also creates bags from recyclable materials to create a sustainable image of the company. The given incentive can be supported, and Zara can use better fabric processing by using automation and computers to plan cuts. Moreover, remnants of fabrics can be used to create small items or pieces that will be sold to clients who want to support green incentives. Zara can also start cooperating with suppliers providing materials from recycled materials to contribute to the improvement of the brand’s image and attract new clients.

Finally, the company can benefit from the integration of the major aspects of lean management. The system presupposes the creation of a special flow and performance metrics to outline problematic areas and introduce a positive change. By utilizing the given practice, companies expect the increased effectiveness of supply chain management attained by reducing delays, problems emerging on different stages, and reconsideration of the approach to traditionally vital elements, such as sales management and cooperation with suppliers.

Altogether, Zara can be viewed as a successful company operating in different regions of the world. Its success comes from the practical model that is created regarding the prior goals of the company and its current focus. The brand focuses on distribution, manufacturing, design, and retailing as the major components of its supply chain. At the moment, the framework demonstrates good results; however, it can be improved by introducing some changes. Automation and the use of IT can help to manage distribution, procurements, and cooperation with partners from transportation companies. Additionally, specific applications can help to collect data provided by clients more effectively. Finally, improved waste management and lean practices can contribute to the minimization of spending and gradual improvement of the company’s image, which will also attract new clients. In such a way, the improvement in supply chains and their management will help Zara to hold leading positions and continue its evolution and the planned expansion.