A case study on the events leading to the financial crisis at Chrysler Motors LLC indicated several aspects on the poor performance of Chrysler. In addition to the hard financial situation, in which the 2008 financial crisis played a major, Chrysler had difficulties caused by the lack of appealing and innovative models. In that regard, the present paper will attempt to analyze the financial situation at Chrysler through the application Hard System Method (HSM) to the Chrysler’s case.

HSM method consists of eight stages, a description of which along with the application to Chrysler case can be seen as follows:

System Description

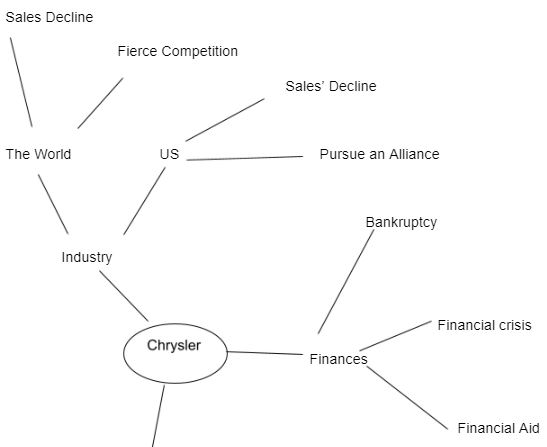

Such stage is concerned with describing the problem and identifying the problem to be solved. In that regard, a description of the current model of operation in Chrysler can be used in this context. The environment for the case at the time can be seen as largely representing US car industry in general. The industry as a whole was in decline for the same period, showing downward trends for all manufacturers. Chrysler was the second in such downward trend in the US, and third in the world, considering that Chrysler is the third largest automobile manufacturer in the US. For Chrysler in particular, the situation can be described through the following facts:

- Bankruptcy.

- Failed leadership.

- Unrealistic business plans.

- Slow reform rates.

Other elements representing the situation in Chrysler LLC can be seen through the following Spray diagram:

Objectives and Constraints

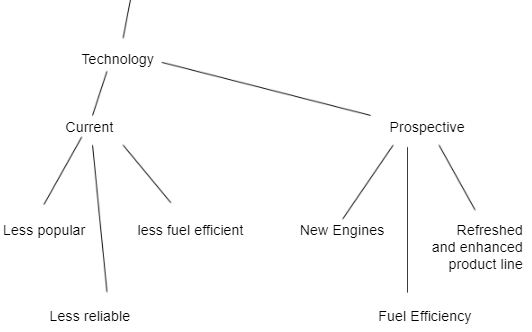

The objectives of Chrysler can be seen through the goals of any business, which is making profit. In that regard, one of the ways to observe the objective of Chrysler can be seen through the position indicated as perspective in the spray model. Accordingly, another objective can be seen through the restoration of the image of the Chrysler brand as one of the leading car manufacturers in the US and in the world. In a more specific way, the latter implies capturing a larger market share along with the goals set by the company to be reached in the short and long term. Such goals include:

- Becoming a quality leader by 2012 (Kleis, 2009).

- New network and a new manufacturing initiatives (Chrysler, 2010).

- Producing “the most fuel efficient, reliable, stylish and safe vehicles across all brands” (Chrysler, 2010).

The main constraints in reaching such objectives can be seen through the challenges faced by Chrysler, one of which is the fierce competition in the Car industry and the position held by Japanese manufacturers. The financial situation of the company that was mentioned in the case is another major contributing constraint to toward reaching the identified objectives. Such situation is concerned with the fact of filing bankruptcy by the company. Another factor can be seen through the collapsed confidence of US consumers in US car makers, a factor that hit all three US car manufacturers, rather than Chrysler alone (Clark, 2009).

Generation of Alternative Routes

The options that can be identified by the US car manufacturer are not plenty. The options can be differentiated based on whether the company will attempt to handle the situation alone, headed by Fiat managers, or team up with other companies. One solution is to adopt the manufacturing model of the Japanese giant Toyota. The elements that can be specifically outlined, in addition to Toyota Production System (TPS), are related to quality control, cost reduction, and environmental efficiency. Another option can be seen through teaming up with other US manufacturers in order to face the decline in US auto industry.

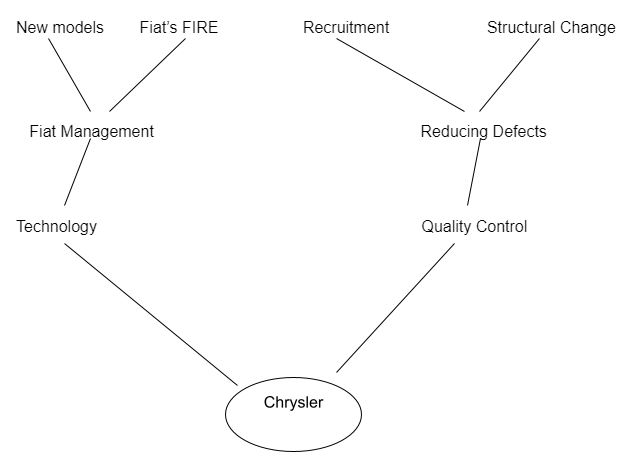

Such possibility includes cooperation with GM and/or Ford through research and development (R&D) initiatives. Finally, the last option can be seen through the company’s individual initiatives headed by Fiat management. The purpose of teaming with Fiat was initially established to be in utilising Fiat’s technology. In that regard, Chrysler might as well focus individually on quality management through initiatives such as establishing new internal standards for quality, new HR recruitment policies, and new supplier relationships (Matsubara and Pourmohammadi, 2009).

Formulating Measures of Performance

Such stage is concerned with establishing measureable metrics that will indicate that the company achieved the established goals. For auto manufacturing industry, it can be stated that the metrics will be largely general. One element that can be used as metric is related to financial performance, including aspects such as sales, revenues, expenditures, etc. A comparative analysis of the financial statement of the company might provide an indication of the company’s performance, especially considering that one of the company’s areas of problems was related to financial performance. Accordingly, the numbers achieved by competitors can be used as metrics as well, in terms of car sales, developments in productions, etc. An example of the latter can be seen through suing the figures of the main competitors and the leaders of the market, e.g. Toyota. Thus, the metrics can be seen through the following:

- The number of engineer-related defects.

- The sales of cars in US and the world.

- Revenues.

- A measurement of customers’ satisfaction.

- The number of energy efficient cars produced.

Modelling

The modelling stage is directly connected to the previous stage of performance indicators, where it tells how the outcomes can be tested for the established indicators. A potential model to test the outcomes of the proposed alternatives can be seen through establishing a program targeted at a specific period, during which the performance of the company will be measured. Annual reports, customers’ surveys, and quality monitoring programs can be seen as suitable models for any of the alternative options that the company might consider in the current situation. Accordingly, an important criterion can be seen in each model that will be the cost of implementing each alternative. Thus, a feasibility study can be seen important in such aspect.

Taking quality monitoring programs as an example of models that will test the likely outcomes, it can be stated that such model will investigate whether the performance measurement established, e.g. a specific goal represented as a percentage of defects, is reached. Customer surveys, on the other hand, will investigate such performance measurement as customer satisfaction is reached. Accordingly, sales figures can be seen as the ultimate model of testing the outcomes of the alternative options. In the light of an overall decline in sales, such model can be specifically useful.

Evaluation

The evaluation stage refers to the assessment process, in which each of the alternatives is evaluated against all performance measures. Considering the option of adopting Toyota’s model, it can be stated that the likely outcomes will be reducing costs and improving the relationships between the company and suppliers and as well as the company’s improving the efficiency of the company’s inventory system. Accordingly, those aspects can be evaluated. For the route in which the company will team up with GM, forming a unified R&D department, the expected outcome can be seen through building models which can utilise common platforms between cars. Such method was implemented in Volkswagen Group, where different car brands shared common components through a system of platforms (Kubes and Radler, 2002).

Accordingly, the likely outcomes will be reducing costs, improving quality, and differentiating products for both companies. Thus, the likely outcome will be increasing the revenues through decreasing costs, although the factor of energy efficiency might not be evaluated through such route. For the last option, which is focusing on quality control system within the Fiat alliance, the likely outcome can be seen through reducing defects, and increasing the customers’ satisfaction level, and subsequently increasing sales.

Recommended Route

It can be stated that no single route from the proposed alternatives will satisfy the all performance measurements. It can be stated that targeting quality within the Fiat alliance can be seen as the most satisfying to the performance measures, and at the same time the most feasible. Such factor can be explained through the fact that Chrysler is already under Fiat’s management which will be responsible for one of the performance measurement energy efficiency. Thus, it can be expected that targeting quality is recommend as the most feasible option that focuses on performance measurement and addresses the objectives established in the model.

Implementation

The implementation of the selected alternative can be seen through the following spray diagram, which will depict the processes involved in such alternative.

It can be seen that the implementation will be concerned with two paths; one is currently established in the vision of the company, while the other is based on the proposed option. Combining both is expected to lead to the objectives established by the current model, and will likely to influence the established performance measurement.

It can be concluded that the hard system method allowed portraying the current situation faced by Chrysler Group LLC as well as the options that should be taken by the company to change such situation. In that regard, the hard system method as well as its stages took the assumptions that the main objectives in the case and the problematic points are clearly defined and can be solved using quantifiable measures.

The Use of Hard Systems

The use of hard systems can be justified as a method that will enable the company to assess its current position and reach its established objectives. Nevertheless, in case there are factors which are not easily quantified, then a soft system approach can be implemented. In that regard, it can be stated that the usage of hard system method in the case of Chrysler is largely of a limited applicability, specifically in terms of clarifying the situation. It can be stated that there might be many factors causing the problem in the case of Chrysler which cannot be quantified. An example of such factors can be seen through the strategic leadership of the company and their ideology. Such statement can be supported through the rejection of US companies in general to adopt manufacturing models of more successful competitors, especially if those models proved to be efficient and companies are facing crises; the reaction to “the constant evolutionary challenges faced in the automotive industry has brought GM, along with Chrysler and Ford, to their precarious situation today; and while they have made great strides to improve quality and production efficiency, they still bring continual excuses of why they do not need to (or cannot) restructure and become leaner, more advanced automobile production companies” (Matsubara and Pourmohammadi, 2009).

Such aspects as the aforementioned can be measured qualitatively, rather than quantitatively, and thus, using hard system method might make the problem limited, focusing only on those aspects that can be solved quantitatively, and which results can be quantified as well, e.g. number of defects, the number of sales, etc. The weaknesses of the hard system method, in the context of the Chrysler case study are mainly related to that the hard system assumes knowledge of the where the company is at, while in the present case such situation is unclear. Comparing the software and the hardware system methods, LogFrame tool can be used. The results of the analysis can be seen in the following table.

Conclusion

Considering the fact that the situation in Chrysler involves several ambiguous and unknown factors, the soft system method can be recommended to be used, specifically in the aspect of analyzing and identifying the current situation of the company (Bate, 1999). In that regard, one of the tools that can be recommended to be used is the SWOT (strengths, weaknesses, threats, and opportunities) analysis. SWOT analysis is based on an analysis of the internal and the external environment, in the company and the industry respectively (Bate, 1999).

Thus, it can be stated that such soft system method is more representative of the situation of the company, and provides a better opportunity to clarify its situation. The threats and the opportunities in the industry can be seen through an external analysis. The tools that might aid in such analysis might include PEST analysis and Michael Porter’s five forces, two tools both of which are devoted to describe an industry and its competitiveness, in order to outline the threats and the opportunities that the company might utilise (Bate, 1999).

As for the strengths and weakness of the company, they are related to an analysis of the internal environment. Accordingly, implementing different combination of the results of the SWOT analysis might help clarifying the situation in the company. For example, the results of the analysis can be helpful to outline the strengths of the company that might utilise the opportunities of the environment or avoid its threats.

Thus, it can be stated that utilising soft system method might help reduce the ambiguity surrounding the facts and the events causing the financial situation in Chrysler Group LLC. Accordingly, it can be concluded that such approach is better suited to such task than hard system method, utilising different tools and methods that might help clarifying the situation.

References

BATE, T. 1999. Approaches to Management Development: the domain of information management Wolverhampton Business School Management Research Centre. Web.

CHRYSLER. 2010. Our Company Overview. Chrysler Group LLC. Web.

CLARK, A. 2009. Obama threatens US car industry with bankruptcy. Guardian News and Media Limited. Web.

KLEIS, M. 2009. Chrysler sets goal to be quality leader by 2012. Left Lane. Web.

KUBES, Z. J. & RADLER, G. 2002. Globalizing Volkswagen: Creating Excellence on All Fronts. International Institute for Management. Web.

MATSUBARA, K. T. & POURMOHAMMADI, H. 2009. International Review of Business Research Papers. The Automotive Industry Supply Chain: The Evolution Of Quality And Supplier Relationships, 5, 90-97.