Introduction

The fundamental issues revealed about the safety of the radioactive materials when the fissile storage site was surveyed include handling procedures, transportation, and safe storage (Ahn 1999). Evidence points out that there was a critical need to remediate the plant by removing the “two (standard) four cubic meter steel skips containing fissile materials from the discovered site (Williams 2000). In addition, the presence of two waste dumps that had collapsed into a ditch required attention as the second one had already been broken and spilling with some of the spilled bottles that required repackaging. Because there was no indication of ‘criticality’, the bottles required resealing and repackaging, despite there being no clue on the substance stored in the containers (Williams 2000). The unfolding events and the strategic measures to ensure the material fissile material maintained the sub-’criticality’ level when being handled and relocated for storage are discussed as follows.

Scope statement

The scope of the study was to investigate the ‘criticality’ requirements for the removal, transportation, and disposal of fissile materials and determine how such handling could be kept safe.

Statement of the problem

From the above case study, a survey of the storage of fissile materials revealed the distinct problem of handling the fissile materials to prevent unintended critical incursion in the handling, transpiration, and storage of the fissile materials. The central problem is embodied in the statements:

…The entire contents of this second site are uncertain but it is obvious that there are eight 210 liter drums, one drum having broken open, spilling two, 15 cm diameter, 4-litre plastic bottles both labeled as 1 kg/L plutonium nitrate.

Objective

The main objective was to empty the two dump sites of fissile materials by safely handling the containers based on a ‘criticality’ competence framework of the empty yard measuring 12 meters long and 10 meters deep in a concrete enclosure topped with a razor wire (Williams 2000). The objective was achieved by conducting an analysis of the ‘criticality’ of the situation based on the critical accident conditions that were likely to arise and the necessary procedures to empty each dump site of the fissile material to prepare the new site for the storage of the new materials.

Model

The presence of strong indications that the ‘criticality’ or the likelihood of the neutron flux increasing to the ‘criticality’ level was not possible, enabling the formulation of a model that was used in this study, which focused on an analysis on how to prevent the neutrons reaching the ‘criticality’ level by ensuring that the fissile material were safely handled (Greene 2000).

Geometries

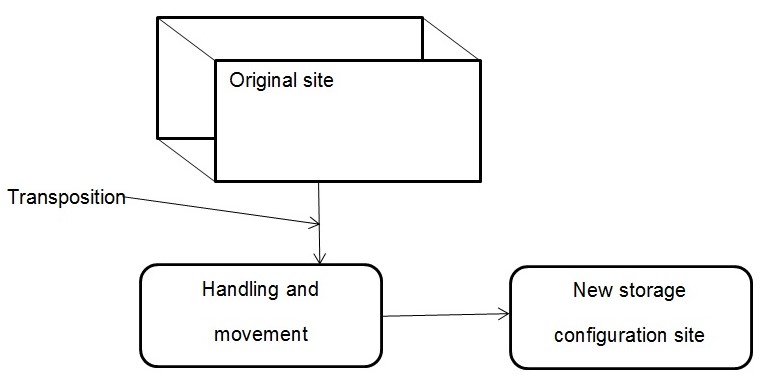

The ‘criticality’ analysis was based on a model that was used to provide solutions to the problem of removing, transporting, and storing the fissile materials. Here the model was based on a ‘criticality’ safety review of the fissile material when in storage, transportation, or relocation. The key process indicators include the key physical processes that influenced the outcome of the model development and implementation processes. In addition, the problem statement showed the need for a model that could be used to address the movement of the fissile materials from the discovered location consisting of a sunken site of a depth of 2 meters that was caused by the earth’s movement covering a width of 4 metres and breadth of 8 meters to the new location as shown in figure 1 below.

The argument by Goans, Holloway, Berger and Ricks (2001) provides the framework for establishing the model that was used to show how the emptied fissile material was transported to a safer site for storage with the storage site consisting of an arrangement of containers in a configuration that meets the standard storage requirement. The success of the operation relied on the successful transportation of each drum to the storage site using the best recommended practises (Ahn 1999).

The suggested ‘criticality’ assessment method involved the use of design reviews that could enable the assessment person to create a documentation of new processes, near misses that happened when handling the fissile materials, and other issues such as aging that was detected in the process of transpiring and storing the fissile materials (Oversby 1997). The results of the survey showed that:

Figure 1: ‘criticality’ assessment

The standard assessment results of the survey of the ‘criticality’ safety of the fissile storage were detailed on table 1.

As part of the strategy to move the fissile materials, it was important to identify the components and the materials that were present in the environment where the fissile material was moved to and later stored.

The components were fissile materials storage components made from HEU Uranyl Nitrate (consisting of tubes whose measurements were not indicated), 4 meters long steel skips containers with a chemical composition of carbon steel, two dozen 210 litre drums of wash-water and/or mixed oils, rows of drums arranged in 3×8 rows, metallic plutonium wastes in oil, and wash-water poisoned with boric acid. Other materials were concrete, and plutonium nitrate with a concentration of 1 kg/l, and 1 kg/L of highly-enriched uranyl oxyfluoride (Pain, de Oliveira, Goddard & Umpleby 2001).

The suggested model for this study factored the physical interactions with the environment that allowed for the use of spheres and cylinders because the area for any ‘criticality’ was not known. Here, the different timescale of events and the key physical processes were important in influencing the outcome of the model. However, it was important to develop confidence in the stakeholders by conducting peer reviews, verification, and other validation on available data (Liu, Bellamy & Shuler 2007).

Fissile material

The fissile material handling, transportation, and storage as per the case study existed in the form of an aqueous solution of HEU Uranyl Nitrate (Highly Enriched Uranium) substance, which is 18% of Uranium belonging to the 235U isotope that was subject to transient movement (Williams 2000). Before transportation, the material was analysed to determine the possibility of reactions occurring in the aqueous dilution medium created by the presence of natural uranyl nitrate hydrate (NUNH) that consists of 238 U isotopes. However, no further reactions were discovered within the old storage environment (Rechard, Sanchez & Trellue 2003). Despite the absence of any reactions, it is crucial to note that the transportation of the fissile material should be done in accordance with the standard requirements certified for packaging fissile materials. In addition, it was important to ensure that fissile material was transported using the right procedures and standards.

From the study it was possible to conclude that there was a low concentration of 18% 235U isotope and a high concentration of 238U isotope, which was over 90% based on an aqueous delusion solution of natural uranyl nitrate hydrate (NUNH). On the other hand, it was evident from the study that the fissile material could be used further for other useful purposes (Yapıcı 2003).

The transportation and storage of the fissile material was done in such a way to prevent ‘criticality’ depending on the mass and degree of enrichment of the fissile material in the environments such as when using tanks to transfer the materials (Williams, 2000).

‘Criticality’ of accident conditions

The HEU Uranyl Nitrate (Highly Enriched Uranium Nitrate), which was the material in question to be transported and stored in the appropriate storage facility, was subjected to the ‘criticality’ analysis procedure used for handling and storing fissile materials (Valentine & Mihalczo, 1996). Here, the movement of enriched materials requires ‘criticality’ detection and response due to the consideration of the application of regulations and standards for ‘criticality’ incident and safety.

Situation summary: There was no indication of fissile material activity in the storage area and the results showed that the highly enriched uranium was fresh and could be used for different purposes. In this case, the highly enriched uranyl nitrates solution measured ~85 wt% 235U. Here, the fissile material was fresh and the packaging material was able to control the emission of neutrons to below the ‘criticality’ value, which is less than unity.

Process description

The process description provides the methodology for the assessment of the current storage, transportation, storage, and handling by the consignor of the fissile materials (consignment) from the source to the destination. In addition, it provides information about the credible states of the fissile material that was discovered and required to be transported to the new destination. Typically, the factors that could affect the ‘criticality’ of the process include:

- The mass, shape of container, density of the fissile materials and the volume have significant impact on the processing of the handling of the fissile material by the consignor.

- The level of enrichment and concentration

- The nature of moderation, reflection of neutrons, and absorption of the neutrons to ensure the K value is below the ‘criticality’ value of unity.

- The level of interaction with other materials

- Factoring the level of enrichment of the highly enriched uranium (~85 wt% 235U)

- Factoring the possibility of producing Uranium oxide for military use

- Factoring the possibility of producing uranium hexafluoride from the highly enriched Uranium 235

- High-enriched uranyl nitrate solutions (U-235 concentration from 20-700 g/L)

- Design considerations of the storage of the fissile material

- Presence and absorption of neutrons

- The mass of fissile materials to be transferred should be accounted for

- The volume of each of the storage drums should be known

- Absorption and reflection of neutron materials

- Materials for the moderation and absorption of neutrons

The parametric assessment of the elements listed above were based on three universal categories recognised and used to analyse the factors related to the handling, transportation, and storage of fissile material as indicated in the case study. The factors were converted to a scale of normal, contingency, ‘criticality’, and control as detailed below.

Normal

- Requires a critical concentration of the fissile solution

- Use of boric acid for the wash water absorption for absorption

- The distance between the drums containing the fissile materials kept to standard.

- The Uranium is highly enriched up to 85 wt% 235U

- Concrete is used as a reflector and the water jacket through the tubes

Contingency

The contingency parameter was defined by the following elements:

- The critical mass in not applicable here

- Leaks led to the emptying of tubes carrying boric acid

- All tubes were used as tubes instead of boric acid

- Water can be used in the tubes instead of boric acid

- It is important to factor the fissile material for the reflector on the concrete floor

Control

- The fissile tubes should be maintained at the recommended standard to ensure that the Uranium-235 remains below the critical value.

- ‘criticality’ accident measures not evident

- The fissile tubes should be handled as per the recommended regulations and standards for the safe handling of the fissile tubes without causing any damages.

- The skip water should be emptied before the process begins

- The carries should be made of steel to minimise the rate of scattering neutrons.

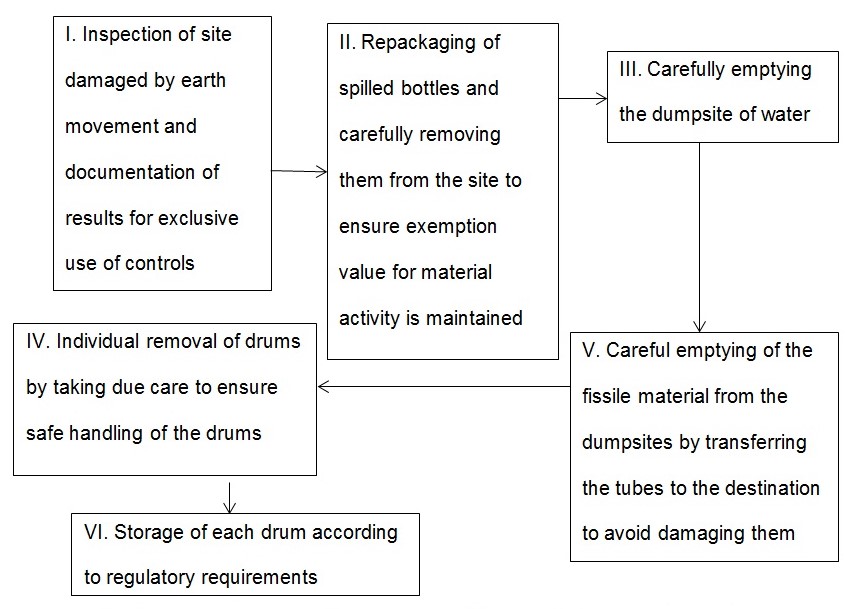

The flow description provides a conceptual framework for emptying each dump site of the drums, resealing and transferring the contents to the empty yard for safe storage both by road and by hand.

Description of the process

A report was generated based on the inspection process could generate a report detailing the extent of the damage caused by the movement of the earth to ensure safe handling, removal of water, and fissile materials from the two standard four cubic meter steel skips. In addition, the removal of the skips enabled the team responsible for identifying the best procedures to use to safely handle the fissile materials (Übeyli & Acır 2007).

The next step was to repackage the spilled bottles to ensure no further spilling occurred. The repackaging enabled the team to process the handling of the fissile materials according to the standard recommendations to ensure that the highly-enriched uranyl nitrate solutions was safe.

Carefully emptying the dump site of water was done to control the neutron absorption within the sub-’criticality’ level for safe handling by ensuring that the ratio of neutron generation was lower than the rate of neutron absorption. The process was to ensure the neuron leakage reached a k-effective value less than unity to reduce ‘criticality’. Here, the neutron emissions from the waste packages were kept sub-critical despite the destruction of the physical environment where the materials were discovered. It is important to note that the ‘criticality’ was safely achieved by the use of water, a reflector, and concrete (Mihalczo, Mullens, Mattingly & Valentine 2000).

Carefully emptying the water from the dump site was done in accordance with the standard requirements to ensure that the ‘criticality’ reached was less than unity and that that the heat and energy released when the water was removed was controllable. Barriers were engineered to the radionuclides to avoid damaging them because of the safety issues arising because of the neutrons being released.

The removal of the drums was done carefully and in accordance with the regulatory requirements and standards by the consignor removing the packages from the source to the destination.

Emptying the fissile material required observation of standard requirements for the movement of fissile materials to avoid ‘criticality’ incidents from happening. Here, the boric acid tubes were removed and replaced with boric acid to ensure that the tubes were properly mounted to make them stable. The fissile material was repackaged as per the safety regulations and standards while ensuring that the setting package limits were met. In addition, the interim storage and transportation was conducted according to the transport requirements of the low specific activity and surface contained objects. In addition, the emptied package were dealt with in accordance with the regulations for disposing of the radioactive packages and marked as per the UN requirements for disposing of packaging materials.

‘Criticality’ Assessment Methodology

Single parameter method

The study would not use the single parameter limit to establish the sub-’criticality’ limit of the fissile materials as it was not easy to evaluate the level of ‘criticality’ because of lack of information on the ‘criticality’ parameters that could be used in the model.

Other methods

However, different methods for ‘criticality’ assessment have been developed to screen the waste packaging procedures to establish the ability to meet the criteria for ‘criticality’ safety requirements for the transportation and disposal of the fissile materials into the new site under the Disposal System Safety Case (DSSC). In addition, the ‘criticality’ safety assessment involved indicative fissile limits that were in compliance with the IAEA Transport Regulations. Research and calculations showed that the highly enriched uranium limits of indicative ‘criticality’ were 105 g and 150 g of U-235 that is equivalent to 3 boxes of 500 liters drums. However, the equivalent limits of the lower screening level (LSL) were 160 g and 175 g for the packaged fissile materials. However, it was crucial to note that the materials were being transported using the indicative ‘criticality’ limits that were more restrictive and compliant with the IAEA Transport Regulations to be adhered to by the consignor (Nicolaou & Tsagas 2006).

For instance, the package requirements for the highly enriched uranium

(HEU) consisting of <0.1kg-Be and <1kg graphite was recommended to have a screening value that is of a lower level of U-235 + 1.6 × (Pu-239 +Pu-241) = 160 g. However, for <0.1kg-Be and <1kg graphite high polythene content, the lower screening level should be U-235 + 1.6 × (239Pu +Pu-241) = 165 g (Talamo 2006). On the other hand, for both <0.1kg-Be<1kg graphite and <0.1kg-Be<1kg graphite with high polythene content, the U-235 + 1.6 × (Pu-239+ Pu-241) = 1400 g for the upper screening level. It is important to note that the ‘criticality’ safety requirements have to be met when the consignor transports the drums through road and handles the drums using carts and by hand (Mason, Smith, Turland & Jackson 2012).

Demonstration of safety

Because suitable ‘criticality’ safety requirements and limits were established for the packaging and transportation of the packages, it was important to show evidence that no ‘criticality’ incident could occur if the fissile material was accidentally exposed to events such as fire, flooding or any other impact when being handled or transported. However, the resultant arrangement of the packages when being transported was based on the geometry adopted for the transportation and disposal tasks. In addition, it was important to conduct a generic assessment of the geometry or conceptual design of the destination site before starting the process (Choi, Ko & Yang 2001).

As per the movement, handling, and disposal of the fissile packages, it was important to use geometry that factored the diffusion of neutrons when the fissile packages were being transported because the fissile materials behaved according to Fick’s law, where neutrons move from higher density to lower density regions. It is important to note the relationship existing between the bucking geometry and the neutron multiplication distribution in the fissile material storage drums was important to establish. However, to establish the sub-critical limits, the geometry of the fissile tubes had to be calculated to get the values necessary to reach the geometry buckling value.

Computer simulations

Computer simulations provide the best alternatives for the detailed verification and validation of models by evaluating them for consistency with physical equations when in the models are being developed and used. However, it is not possible or it is difficult to conduct code verification and validation but the results that show consistency are adequate to show the reliability of the models that have been used to show how to assess the ‘criticality’ of handling and disposing of fissile materials. Typically, computer code can be verified and validated to determine the accuracy of the results obtained by running the code using the input values from the model. In addition, the computer code provides the ability to calculate the accurate values of keff to verify that the results are accurate and lead to the correct sub-’criticality’ level of the fissile material to ensure no accident happens.

Results

Single parameter limits

The results showed the importance of maintaining the sub-’criticality’ level when handling, transporting and disposing of the fissile material to ensure that no ‘criticality’ incident happens. However, it is possible for the sub-’criticality’ to be maintained if human error is avoided during the process. Typically, it implies that certain limits have to be imposed such as keeping the nuclear chain reaction low. For this study, the packages have to be designed with the right measurements and the distance between the drums have to be maintained at the minimum to avoid increasing the concentration of neutrons that could lead to a ‘criticality’ incident. The measurements for the ‘criticality’ of the drum used to store the fissile material are shown in figure 2 below.

Reflectors thickness

The dimensions of the container in figure 2 are in centimetres. The container consists of the reflector solution that was used to absorb the neutrons and reduce the ‘criticality’ to the sub-’criticality’ level to ensure that no ‘criticality’ incident happened in handling of the fissile material. Here, the diameter of the cylinder is 29.16 cm, the volume of the solution was 5% of the critical value, which is 28.9 liters, and the mass was 5% of the critical value, which is 37kgU -/U=27kg. On the other hand, the lower limit of the diameter of the container was 5% of the critical value-cylinder diameter, which was 26.2cm. On other hand, the cold trap, center-to-center separation was 110 cm with a 2.5 cm reflector making some slight difference with the measurements shown on figure 2.

It was important to keep the keff value at 0.8996 to ensure that the transportation of the fissile material was safe under the Individual (single) package geometry. However, when the keff value exceeds a value of 0.9017, the ‘criticality’ level is reached and the condition in no longer safe. On the other hand, when transporting an array of drums of fissile materials as in the case being analysed, the keff value of 0.9019 must be used under normal conditions to ensure sub-’criticality’ conditions are maintained and no ‘criticality’ incident happens.

Reflectors thickness

From figure 2 above, the buckling conversion method of calculations provides specific answers on the thickness of the reflector. However, there are other methods such as the Monte Carlo computer code that can be used to calculate the thickness of the reflectors. In practice, what was established shows the thickness to be 29.16 cm while the value obtained by calculating the thickness using the buckling conversion method was 31.47 cm. On the other hand, the diameter of the tube is 29.16 cm as shown.

Ultimate sub-critical limit

The sub-critical limit was important to ensure that the activity of neutrons do not reach the ‘criticality’ level to cause an accident. However, the input code used for the analysis of the sub-’criticality’ level using the MCNP program had to be verified to ensure that accurate values were generated in calculating the sub-’criticality’ level.

Distance between fissile materials

The distance between fissile materials was important because it affects the ‘criticality’ of the fissile material. Typically, when the tubes are closer to each other, the keff value increases and when the distance between the drums with the fissile material are moved closer, the keff value increases and the relationship is based on the inverse square law. Here, the distance between the drums has to be kept as far apart as possible to keep the ‘criticality’ level is low.

Removing process

It was important to follow the standard requirements for removing and handling the fissile material to ensure no accident occurs. The fissile material had to be controlled using neutron absorbers to ensure sub-’criticality’ was maintained.

Upset conditions

The geometry, which is based on an array of drums, should be used to handle and arrange the tubes as recommended.

Suggestions

According to the findings of the study, it was crucial to devise the best method to handle the fissile material when not in the neuron absorption medium to control the rate of neutron emissions to avoid causing human accidents. In addition, safety regulations need to be observed to ensure the new storage area provides adequate protection from the neutrons being emitted to avoid the ‘criticality’ that could lead to human accidents.

Conclusion

In conclusion, it was established that the process of handling the highly enriched uranyl nitrates solution (wt ~85 wt% 235U) for safe disposal in the new site should be conducted with serious considerations on the handling procedures to ensure controlled emission of neutrons below ‘criticality’ that could otherwise lead to incidents such as fire and other human health effects. In addition, the safe handling within the sub-’criticality’ domain should be ensured especially when being handled by human beings. It is also important for the consignor to conduct an analysis of the drum that was discovered dumped in the second filed without any documentation. In addition, it is important for the stakeholder to use different modeling methods such as those used to model complex systems to evaluate the model that was used against the new model to establish the level of accuracy and reliability of the model. The use of water to reduce the rate of neutrons bombards to minimise the probability of neurons increasing out of control. Factors such as loose coupling, the diameter of the spheres used to hold the fissile material and the water, the effects of changing the diameters of the drums to use, and simulation of the environment should be accounted for.

References

Ahn, J 1999, ‘criticality’ safety assessment for a conceptual high-level-waste repository in water-saturated geologic media. Nuclear technology, vol. 3, no. 26, pp. 303-318.

Choi, H, Ko, W I & Yang, M S 2001, ‘Economic analysis on direct use of spent pressurized water reactor fuel in CANDU reactors-I: DUPIC fuel fabrication cost’, Nuclear technology, vol. 2, no. 34, pp.110-129.

Goans, R E, Holloway, E C, Berger, M E & Ricks, R C 2001, ‘Early dose assessment in ‘criticality’ accidents’, Health physics, vol. 4, no. 88, pp. 446-449.

Greene, S 2000, Reactor-based plutonium disposition: Opportunities, options, and issues, Wiley & Sons, New York.

Liu, Y, Bellamy, S & Shuler, J 2007, ‘Life cycle management of radioactive materials packaging’, Packaging, Transport, Storage & Security of Radioactive Material, vol. 4, no. 18, pp. 219-225.

Mason, R M, Smith, P N, Turland, B D & Jackson, C P 2012, ‘The consequences of hypothetical post-closure ‘criticality’, Mineralogical Magazine, vol. 8, no. 76, pp. 3155-3163.

Mihalczo, J T, Mullens, J A, Mattingly, J K. & Valentine, T E 2000, ‘Physical description of nuclear materials identification system (NMIS) signatures’, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, vol. 2, no. 450, pp. 531-555

Nicolaou, G & Tsagas, N 2006, ‘Criticality safety of spent nuclear fuel assemblies from the transmutation of minor actinides in fast reactors’, Annals of Nuclear Energy, vol. 4, no. 33, pp. 305-309.

Oversby, V M 1997, ‘criticality’ in a repository for spent fuel: lessons from Oklo. Cambridge University Press, London.

Pain, C C de Oliveira, C R E, Goddard, A J H & Umpleby, A P 2001, ‘Transient ‘criticality’ in fissile solutions-compressibility effects’, Nuclear science and engineering, vol. 1, no. 138, pp. 78-95.

Rechard, R P, Sanchez, L C & Trellue, H R 2003, ‘Consideration of nuclear ‘criticality’ when directly disposing highly enriched spent nuclear fuel in unsaturated tuff-I: Nuclear ‘criticality’ constraints’, Nuclear technology, vol. 2, no. 144, pp. 201-221.

Talamo, A 2006, ‘Managing the reactivity excess of the gas turbine-modular helium reactor by burnable poison and control rods’, Annals of Nuclear Energy, vol. 1, no. 33, pp. 84-98.

Übeyli, M & Acır, A 2007, ‘Utilization of thorium in a high power density hybrid reactor with innovative coolants’, Energy conversion and management, vol. 2, no. 44, pp. 576-582.

Valentine, T E & Mihalczo, J T1996, MCNP-DSP: ‘A neutron and gamma ray Monte carlo calculation of source-driven noise-measured parameters’, Annals of Nuclear Energy, vol. 16, no. 23, pp. 1271-1287.

Williams, M M R 2000, ‘The effect of random geometry on the criticality of a multiplying system’, Annals of Nuclear Energy, vol. 2, no. 27, pp. 143-168.

Yapıcı, H 2003, ‘Study of fissile fuel breeding concept for the force-free helical reactor’, Fusion engineering and design, vol. 4, no. 65, pp. 599-609.