Introduction

Linn Products Ltd was founded in 1973 by Ivor Tiefenbrun, who had a passion for creating innovative, high-quality audio systems. The company is headquartered in Scotland, and it sells audio systems in a variety of international markets (Linn Products Limited, n.d.). Linn Products’ mission is to create high-quality audio systems that reduce variations in music from recording to at-home playback. In order to fulfill this mission, Linn Products employ various methods to ensure the high quality of their products and introduce innovations that improve the sound. The purpose of this paper is to evaluate the competitive basis, performance measurement methods, and the performance management approach used by Linn Products.

Competitive Basis

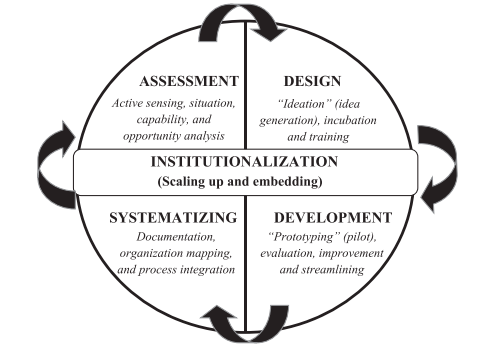

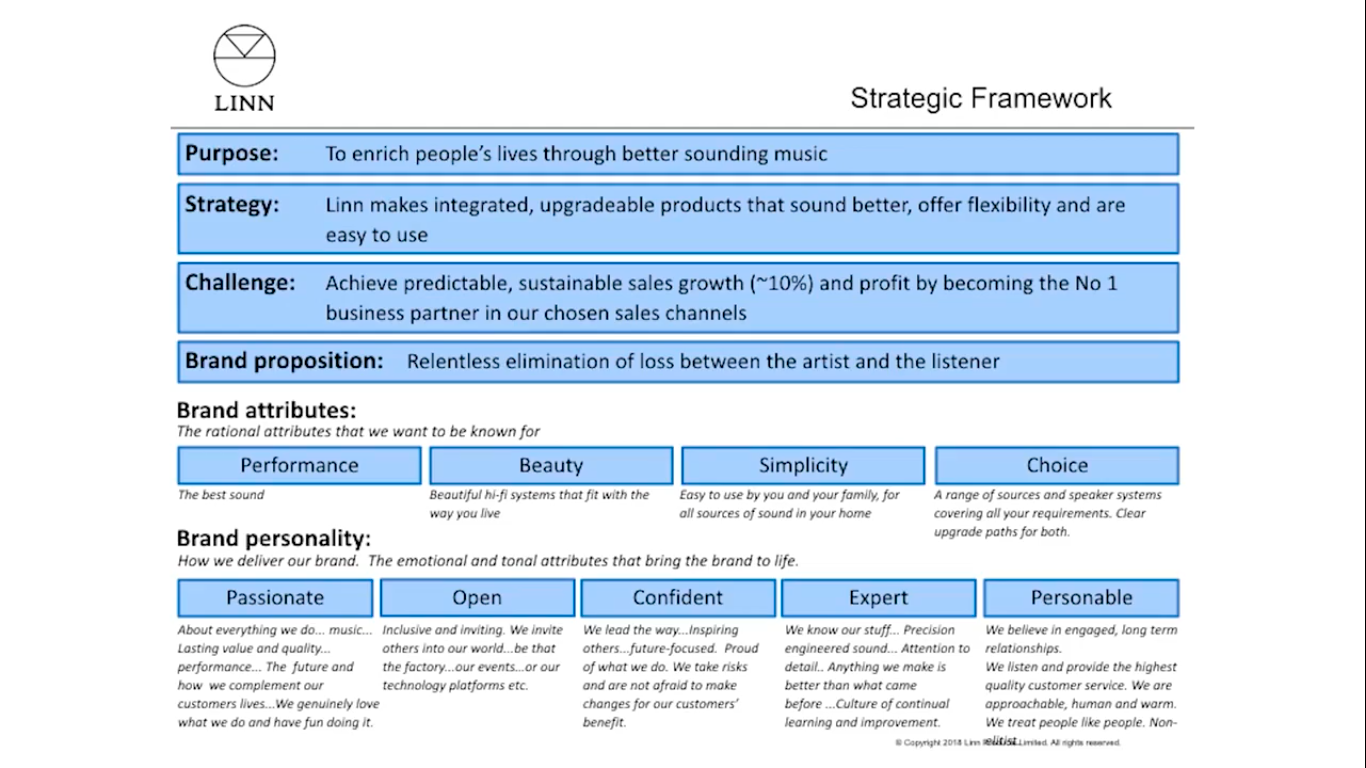

The primary components of Linn’s competitive basis are innovation and quality because Linn Products strive to develop technologies that would elevate customers’ experiences with the company’s audio systems. The focus on innovation as a competitive advantage fits into the theoretical view of hi-tech business development. According to Kamasak (2015), innovation is among the primary drivers of success for most contemporary companies, including those capitalizing on technological progress. However, merely responding to technological advancement is not enough; contemporary businesses should also strive to develop new technologies in order for their products to be popular (Kamasak, 2015). In this context, the emerging concept of corporate social innovation is of particular importance. Herrera (2015) explains that social innovation focused on value creation for stakeholders, and thus it contributes to competitive advantage. Based on the information gathered from the case, product development at Linn Products generally fits into the corporate social innovation process (Figure 1), meaning that the company can use innovation to produce value for customers, thus retaining and improving its competitive position.

On the other hand, product quality is also crucial to the competitive success of Linn Products since the company is famous for its focus on quality improvement. The information in the case study suggests that Linn Products uses total quality management in order to reduce variation in product quality and prevent errors. The eight key components of total quality management evident in Linn Products are leadership, customer focus, process management, employee involvement, systemic analysis, continuous improvement, informed decision-making, and positive supplier relationships (Goetsch & Davis, 2014). Therefore, the strategies used by the company help to make quality part of its competitive basis.

Value Stream Framework

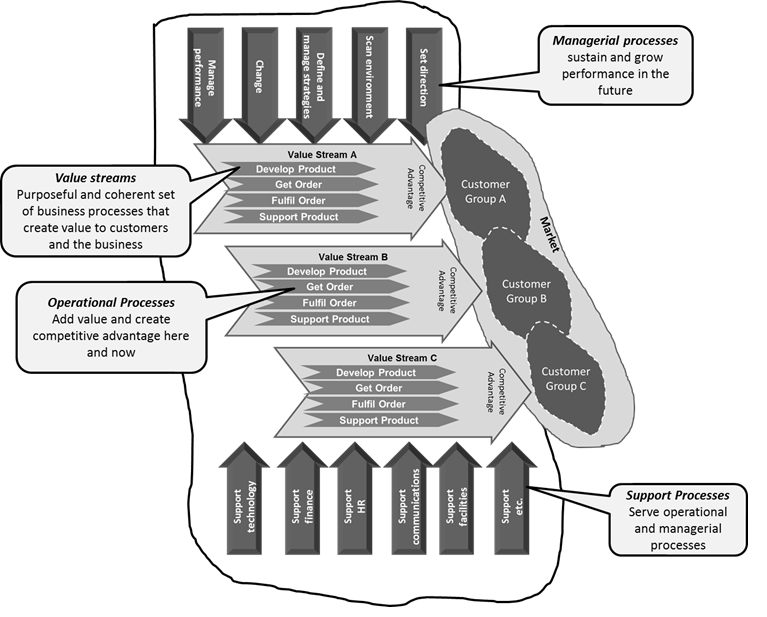

A value stream framework helps to understand how a company creates value for customers through its operations. As seen in Figure 2, the managerial processes in place at Linn are concerned with defining the company’s strategic goals. Based on these goals, products and services for various customer groups are developed, thus creating value for customers through innovation, quality, and service. For example, the product development stage creates value for customers by designing products with innovative features that would contribute to the customers’ experiences.

The manufacturing process also generates value by applying low-waste production methods and leveraging quality management (Bilge et al., 2016; Mintchell 2012). Team leaders and managers support the design and manufacturing processes. The support processes in place at Linn Products involve communication, guidelines, organizational culture management, task support, and other components. These features of the company add value by helping operators to build high-quality products efficiently. Hence, both the managerial and operational processes in place at Linn Products support the creation of value for customers.

Pillars of Value Propositions

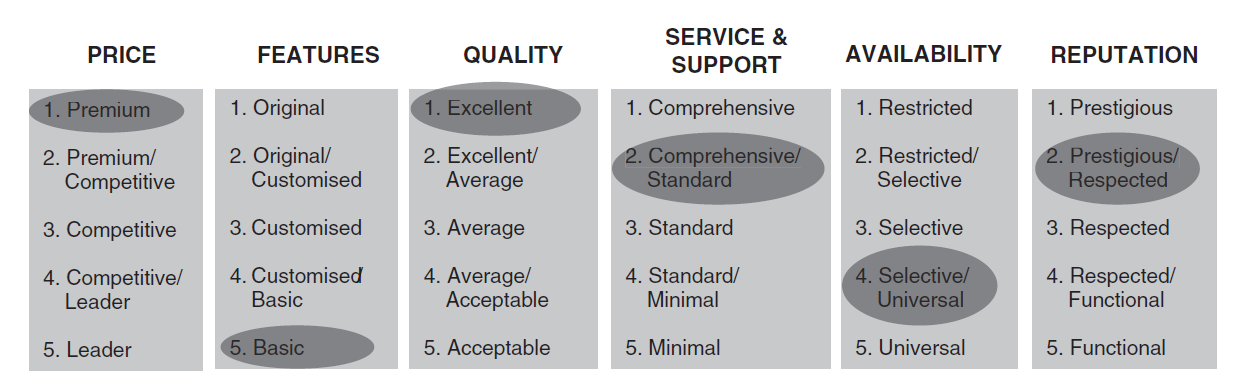

The value proposition is essential for a company to attract customers and earn a larger market share (Payne & Frow 2014). According to Kaňovská and Tomášková (2014), market orientation is particularly necessary for the high-tech industry because products have to respond to customers’ needs and wants. Through market orientation, companies can create a value proposition for different customer segments (Payne, Frow & Eggert 2017). The value proposition is typically based on the company’s positioning in the six key value areas (Figure 3). These include price, features, quality, service and support, availability, and reputation (Frow et al., 2014; Londhe, 2014).

Linn Products’ prices are in the premium section, which adds to their value by creating a feeling of exclusivity and luxury. The features of Linn Products’ audio systems are rather basic due to the low potential for customization, but the products’ excellent quality contributes to customers’ experience (Frow et al., 2014). The service and support offered by Linn Products are comprehensive/standard, meaning that the company provides an adequate level of support for the price. Lastly, the selective/universal availability of Linn Products’ audio systems, coupled with the company’s prestigious/respected reputation, creates value by appealing to the customers’ desire for luxury and uniqueness. Altogether, Linn Products’ value proposition based on these six pillars attracts high-income customers who value quality above all and for whom Linn Products’ audio systems are also a demonstration of status.

Value Matrix

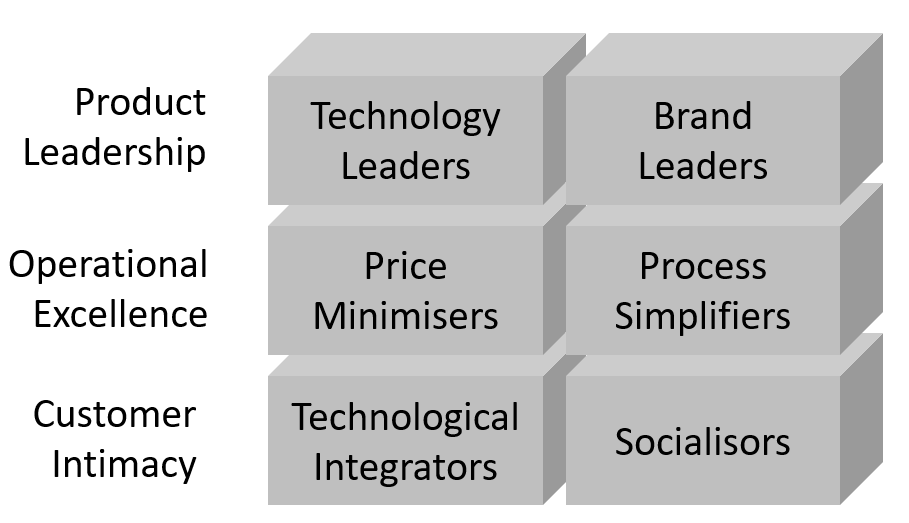

According to Biloshapka, Osiyevskyy, and Meyer (2016), the value matrix can help companies to evaluate their approach to value generation and establish a certain position in the market that would attract customers. It can also help to determine whether or not a company responds to customers’ needs in accordance with its business model (Kolkowska et al., 2017). As evident from Figure 4, the value matrix consists of three indicators with two options in each: product leadership, operational excellence, and customer intimacy. Concerning product leadership, Linn is a brand leader since the value of its products comes from their high price, quality, and the brand’s reputation rather than from product features. This is also the company’s main area of focus, as these features distinguish Linn Products from competitors and form the foundation of its business model.

In terms of operational excellence, Linn Products focuses on process simplification, which is reflected in its production process. Finally, the customer intimacy of Linn Products falls into the “socializers” category due to the focus on fulfilling customers’ needs. Marr and Gray (2012) explain that socializers’ strategic objective is to “build confidence and trust in the customers,” while the operational objective is the “sensitive fulfillment of customers’ needs supported by careful delivery, reliability, and honesty” (p. 36). This description fits Linn Products’ business model and reflects its value proposition.

Performance Measurement

Agile and Traditional Enterprises

The distinction between agile and traditional enterprises is critical because it highlights the company’s capabilities in terms of projects and processes. Traditional enterprises apply the management approach that is focused on fulfilling clearly defined objectives, controlling processes, and determining the flow of responsibility and accountability throughout the organization (Cummins 2017). Traditional enterprises usually operate through linear processes and focus on the reduction of risks while maintaining a clear organizational order (Cummins 2017; Rigby, Sutherland & Takeuchi 2016). These characteristics of traditional enterprises make them rather inflexible, which affects success in the contemporary fast-paced business environment.

Agile enterprises, on the contrary, focus more on individuals and their capacities rather than on processes (Cummins 2017). These enterprises are more flexible in their operations and use fast decision-making to set a strategic course (Cummins 2017; Ragin-Skorecka 2014). Projects in agile enterprises adapt to changes in strategy or focus of the business, making this type of enterprise more successful in dynamic conditions (Ahimbisibwe, Cavana & Daellenbach 2015). As a result of their flexibility, agile enterprises are more sustainable and can fulfill the changing needs of customers better than their traditional, plan-based counterparts. Agile enterprises also benefit from higher levels of employee satisfaction and innovation (Ragin-Skorecka 2014; Rigby, Sutherland & Takeuchi 2016). Linn Products is an agile enterprise because it is adaptable in terms of operations, focuses on individuals rather than processes and plans, and has a flexible strategy with a limited outlook of one to three years.

Employee engagement is crucial for agile enterprises because it has an important influence on the factors that enable agile organizations to succeed. First of all, employee engagement is necessary to achieve buy-in in the context of a changing strategy (Moreira 2017). Secondly, employee engagement correlates positively with performance, thus allowing to fulfill projects quicker and more efficiently (Patary 2014). Thirdly, employee engagement adds to the company’s flexibility because committed workers who know the company well can share decision-making and use their skills to drive the completion of the company’s objectives (Moreira 2017). Lastly, employees who are motivated and invested in the company are less likely to leave, meaning that over time, they will develop excellent product knowledge, leading to better performance results (Moreira 2017). These factors make employee engagement particularly important to the success of agile enterprises, including Linn Products.

Balanced Scorecard, KPIs, and Value Stream

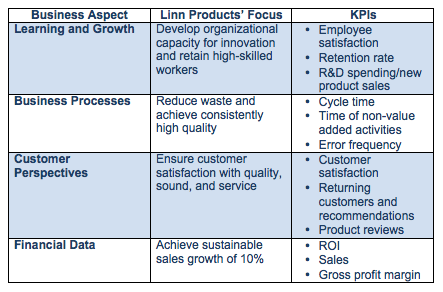

A balanced scorecard is a useful tool for analyzing the company’s objectives to produce measurable performance indicators (Hoque 2014; Perkins, Grey & Remmers 2014). Based on the traditional approach, a balanced scorecard determines the company’s focus and key performance indicators (KPIs) in four key business aspects: learning and growth, business processes, customer perspectives, and financial data (Perkins, Grey & Remmers 2014). For the present analysis, Linn Products’ strategic framework was used to determine focus areas in each business aspect (Figure 5).

The results of the analysis using the balanced scorecard are shown in Table 1. The identified KPIs align closely with Linn’s value stream. In learning and growth, Linn’s KPIs include employee satisfaction, retention rate, and the ratio of R&D spending to new product sales. The first two KPIs are necessary for ensuring that the company’s employees use their skills and knowledge to design and manufacture high-quality products. The latter KPI is considered to be a measure of corporate innovation, which also adds to the value-added during design and production processes (Aase et al., 2018). Business process KPIs focus on quality and waste reduction, which are pivotal aspects of Linn’s value stream. Cycle time and time of non-value-added activities are proposed for measuring waste (Kelchner 2019; Pieńkowski 2014).

Customer-related KPIs relate to the value stream as they represent the factual value of the end product to customers. KPIs such as customer satisfaction, returning customers, and product reviews reflect the customers’ experience with Linn’s products, whereas the share of new customers who were introduced to Linn by recommendation identifies the effectiveness of the value stream in attracting new customers. Lastly, financial KPIs are required to understand whether the current value stream is sufficient to leverage the company’s profits and market share.

Workflow

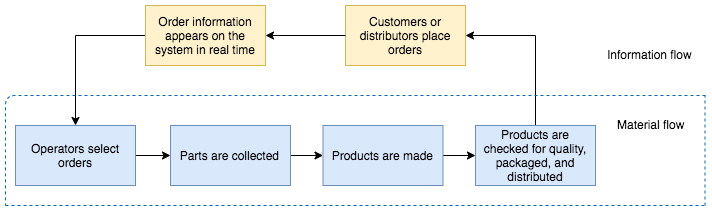

Due to the production process in place at Linn Products, the workflow in terms of product manufacturing is fairly simple. As pictured in Figure 6, product assembly is a single process step due to the single-build production design. The information flow includes customers or distributors placing orders for Linn Products. Then, the material flow begins with operators selecting orders to work on, receiving the required parts, and assembling products. The final stage of the material workflow includes quality assurance and packaging, after which orders are delivered to customers. The information on cycle, process, and wait times were not included in the figure because they were not provided in the case study.

The value stream follows the material workflow since each step adds to the value of a product. First, operators who select orders contribute their skills and product knowledge to ensure high quality. Second, reliable parts and materials are used for improved sound and durability. Third, the assembly is carried out by a single operator, reducing the risk of errors and resulting in hand-built products. Lastly, quality assurance and packaging add value by promoting quality and setting the design of the finished and packaged product.

Operations Consistency

Consistency of daily, weekly, and monthly operations at Linn Products is achieved through three different strategies. Firstly, the use of total quality management and the just-in-time approach to production contributed to reduced process variations and increased project control (Chen 2015). Secondly, the single-build structure of manufacturing processes provides opportunities for standardizing processes. As explained by Husby and Hamilton (2018), standardization impacts consistency by creating a stable environment and defining process steps. With one operator creating a product from start to finish, there is a reduced risk of inconsistency because they create a standardized environment and have full control over the product’s quality. Finally, consistency relies on effective organizational support and the lack of product customization, which enable workers to complete projects more quickly and effectively (Scholtz & Maher 2014). Due to these strategies, Linn Products can maintain high operational consistency, which contributes to its value stream.

Visual Management Techniques

Visual management refers to the management approach that “helps teams and individuals to be self-going in terms of having a better understanding of their own role and contribution within the larger frame of the project” (Tjell & Bosch-Sijtsema 2015). Specific techniques in visual management involve communication boards, schedules, process maps, and other tools that could help employees to visualize processes or strategies (Bateman, Philip & Warrender 2016). Based on the case study video, Linn Products use a limited range of visual management techniques. For example, the company presents the key strategic documents, such as the strategic framework and strategy wheel, in visual form. This assists the employees in understanding and memorizing Linn Products’ goals, objectives, and values. Additionally, some operational documentation, such as meetings schedule and KPI tables, is also represented visually. Improving the use of visual management techniques in manufacturing could help the company to improve the processes and productivity of employees.

Performance Management

Dynamic and Operational Capabilities

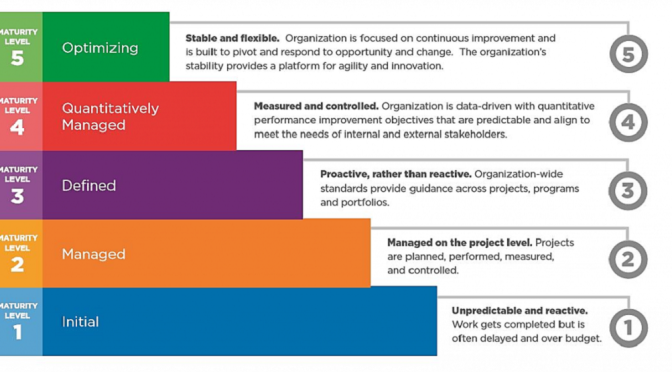

The interplay of dynamic (adaptive) and operational capabilities has a strong effect on company performance and thus constitutes a significant part of performance management. Operational capabilities are defined as routines that enable companies to sustain and improve performance (Inan & Bititci 2015). These include strategic capability, product leadership capability, customer intimacy capability, operational excellence capability. Based on the capability maturity model (Figure 7), Linn Products have well-developed operational capabilities in most of these areas.

The company’s strategic, product leadership, and operational excellence capabilities are developed at the optimizing level, which is highlighted by its focus on continuous improvement, flexibility, and stability. These capabilities enable the company to focus on the optimization of performance while meeting KPIs set for various business aspects. However, Linn’s capability for customer intimacy is underdeveloped, placing it at Level 2 of the capability maturity model. This means that the company interacts with customers on the project level but does not form close and stable relationships with its customers because products are sold through specialized retailers instead and not directly to customers. Developing this capability would enable Linn Products to increase customer loyalty and achieve higher levels of customer trust.

Dynamic capabilities are different from operational capabilities since they reflect “the firm’s ability to integrate, build, and reconfigure internal and external competencies to address rapidly changing environments” (Inan & Bititci 2015, p. 314). In the contemporary business environment, dynamic capabilities are of great importance since they determine whether or not a company can adapt to changes in the market quickly (Wilden & Gudergan 2015). There are three types of adaptive capabilities, including dynamic capability, ambidexterity and learning capability, and organizational culture. The dynamic capability of Linn Products is at the highest level due to its optimized and flexible production processes, as well as its adaptable strategy. Focusing on the near future as part of strategic planning enables Linn Products to respond to market changes fast without losing progress.

Meanwhile, ambidexterity and learning capability are somewhat underdeveloped and remain at Level 3 or 4. The company has a proactive approach to staff learning and training and uses regular reviews and appraisals to promote organizational learning. Lastly, the organizational culture of Linn Products is rather strong and developed to Level 5. The organizational hierarchy and management style allows for stability and flexibility while assisting the company in capitalizing on employee engagement. This has a positive effect on performance since the company’s culture translates into experience, excellence, and employee loyalty.

Overall, the interplay of dynamic and operational capabilities at Linn Products provides a stable foundation for performance management. On the one hand, the company possesses excellent operational capabilities, which allow setting and achieving high KPIs for manufacturing and manage performance based on strategic indicators. On the other hand, the dynamic capabilities of Linn Products allow it to maintain flexibility in terms of strategy and organizational culture, which is required to remain adaptable in the current business environment. Dynamic capabilities also affect performance management by influencing employee engagement through organizational culture. Linn’s well-developed dynamic capability is also important because it makes the company’s performance management strategy adapt to changes in the organization or the market. While improving individual capabilities would benefit the company, the existing condition of Linn Product creates a favorable environment for successful performance management by setting strategic goals, monitoring KPIs, and using staff training and education.

Analysis of Performance Measurement/Management Practices

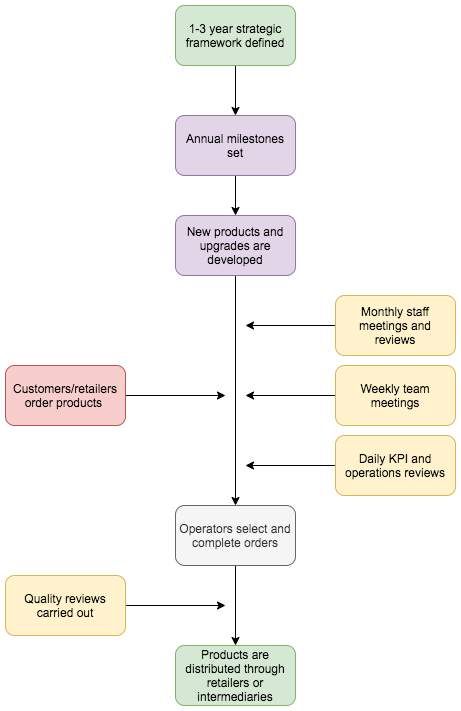

Process Flow Map

Figure 8 presents the process flow map of Linn Products that can be used for analyzing the company’s performance measurement and management practices. The map is rather simplistic because of the linear nature of Linn’s operations. This structure allows the company to evaluate performance management and measurement practices more quickly. In the figure, the key performance management and measurement processes are highlighted in yellow. These include monthly staff meetings and reviews, weekly team meetings, daily KPI and operations reviews, and quality control. The integrated nature of appraisals helps the company to monitor and manage performance in real-time, thus reducing the possible negative effect of underperforming on the company’s success.

Monthly staff meetings and reviews are particularly important for the analysis of performance measurement and management practices since they provide managers with information regarding the effectiveness of performance metrics and management approaches. According to Buckingham and Goodall (2014), managers play a vital role in evaluating performance management systems and strategies because they can notice whether or not the approaches utilized in the company are, in fact, effective. Based on the information gathered from quality control, KPIs monitoring, and weekly team meetings, managers can assess the effectiveness of their performance management strategy and alter it in accordance with the results.

Short-Term and Long-Term Results

The company’s top-level strategic framework is based on a specific 1-3 year challenge set for development, which reflects the desired long-term results. Employees receive comprehensive information about the company’s strategic goals, which helps to increase engagement levels and promote productivity. Additionally, the management sets company milestones on an annual basis. The annual strategy roadmap also determines the objectives for products, manufacturing, IT, sales, and marketing. Hence, long-term results are managed by completing the annual strategy roadmap and milestones, as well as by producing integrated performance reviews regularly.

Milestones and roadmaps are widely used in performance management as they allow determining the effectiveness of performance management systems while also tracking company progress (Mensah & George 2015). Failure to reach a certain milestone indicates an area of weakness in the company that can be addressed using effective performance management approaches. Milestones are also useful for managing long-term results since they increase employee motivation and help to achieve buy-in (Mensah & George 2015). Thus, the company’s approach to managing long-term results is in line with performance management theory.

Besides large-scale evaluation and goal-setting activity, the company also has daily processes in place for managing short-term results on individual projects. In the production department, meetings are held every day to discuss operational goals and performance. There are also daily operations meetings for team leaders, which involve reviewing KPIs from the previous day. KPIs are tailored to the business model and the needs of Linn Products and cover finance, purchasing, orders, customers, and other areas of business operations. The use of KPIs in performance management helps to track performance and identify areas for improvement (Bhatti, Awan & Razaq 2014). At the same time, team leader meetings also support joined-up thinking, thus enabling the company to find solutions to problems in performance fast. This assists the company in monitoring and adjusting performance to get excellent short-term results.

Conclusion

In conclusion, Linn Products presents a good example of applied performance management in the high-tech industry sector. The company’s value proposition to customers is supported by the stream of operations, which allows workers to create high-quality products that elevate the customers’ experience with music. The use of performance measurement systems, including KPI monitoring, assists the company in maintaining excellent performance levels and satisfy customers’ needs and demands through low-waste, controlled operations. Performance management used by Linn Products relies both on these measurement systems and on the company’s capabilities.

The interplay of operational and dynamic capabilities enables Linn Products to fulfill strategic goals effectively and adjust the performance using the input of both managers and operators. Finally, the application of integrated reviews, joined-up thinking, and milestones supports performance management by highlighting areas that require improvement and providing the opportunity to tailor a performance to the company’s strategic needs. Although some improvement in individual aspects of performance management could benefit Linn Products, the company’s current approach allows it to fulfill strategic goals in a sustainable and flexible way.

Reference List

Aase, G, Swaminathan, S, Brown, S & Roth, E. 2018. How to take the measure of innovation. Web.

Ahimbisibwe, A, Cavana, RY & Daellenbach, U 2015. ‘A contingency fit model of critical success factors for software development projects: a comparison of agile and traditional plan-based methodologies,’ Journal of Enterprise Information Management, vol. 28, no. 1, pp. 7-33.

Bateman, N, Philp, L & Warrender, H 2016, ‘Visual management and shop floor teams–development, implementation and use,’ International Journal of Production Research, vol. 54, no. 24, pp. 7345-7358.

Bhatti, MI, Awan, HM & Razaq, Z 2014, ‘The key performance indicators (KPIs) and their impact on overall organizational performance,’ Quality & Quantity, vol. 48, no. 6, pp. 3127-3143.

Bilge, P, Badurdeen, F, Seliger, G & Jawahir, IS 2016, ‘A novel manufacturing architecture for sustainable value creation,’ CIRP Annals, vol. 65, no. 1, pp. 455-458.

Biloshapka, V, Osiyevskyy, O & Meyer, M 2016, ‘The value matrix: a tool for assessing the future of a business model,’ Strategy & Leadership, vol. 44, no. 4, pp. 41-48.

Bitici, US. 2015, Managing business performance: the science and the art, John Wiley & Sons, Chichester, UK.

Buckingham, M & Goodall, A. 2015, ‘Reinventing performance management,’ Harvard Business Review, vol. 93, no. 4, pp. 40-50.

Chen, Z. 2015, ‘The relationships among JIT, TQM and production operations performance: an empirical study from Chinese manufacturing firms,’ Business Process Management Journal, vol. 21, no. 5, pp. 1015-1039.

Cummins, FA. 2017, Building the agile enterprise: with capabilities, collaborations and values. Morgan Kaufmann, Cambridge, MA.

Edvardsson, B, Klaus, P, Payne, A & Frow, P 2014, ‘Developing superior value propositions: a strategic marketing imperative,’ Journal of Service Management, vol. 25, no. 2, pp. 213-227.

Frow, P, McColl-Kennedy, JR, Hilton, T, Davidson, A, Payne, A & Brozovic, D 2014, ‘Value propositions: a service ecosystems perspective,’ Marketing Theory, vol. 14, no. 3, pp. 327-351.

Goetsch, DL & Davis, S 2014, Quality management for organizational excellence: introduction to total quality, 7th edn, Pearson Education Ltd, Harlow, UK.

Herrera, MEB 2015, ‘Creating competitive advantage by institutionalizing corporate social innovation,’ Journal of Business Research, vol. 68, no. 7, pp. 1468-1474.

Hoque, Z 2014, ‘20 years of studies on the balanced scorecard: trends, accomplishments, gaps and opportunities for future research,’ The British Accounting Review, vol. 46, no. 1, pp. 33-59.

Husby, PC & Hamilton, J. 2018, Make your business a lean business: how to create enduring market leadership, CRC Press, Boca Raton, FL.

Inan, GG & Bititci, US. 2015, ‘Understanding organizational capabilities and dynamic capabilities in the context of micro enterprises: a research agenda,’ Procedia-Social and Behavioral Sciences, vol. 210, 310-319.

Kamasak, R. 2015, ‘Determinants of innovation performance: a resource-based study,’ Procedia-Social and Behavioral Sciences, vol. 195, pp. 1330-1337.

Kaňovská, L & Tomášková, E 2014, ‘Market orientation and strategic behaviour at high-tech companies,’ Economics and Management, vol. 17, no. 4, pp. 86-100.

Klechner, L. 2019. Typical lean manufacturing measurements. Web.

Kolkowska, E, Nöu, AA, Sjölinder, M & Scandurra, I 2017, ‘To capture the diverse needs of welfare technology stakeholders–evaluation of a value matrix,’ in International conference on human aspects of IT for the aged population, Vancouver Convention Center, Vancouver, pp. 404-419.

Linn Products Limited n.d. Find a shop. Web.

Londhe, BR 2014, ‘Marketing mix for next generation marketing,’ Procedia Economics and Finance, vol. 11, 335-340.

Mintchell, G 2012, ‘Creating value in manufacturing,’ Automation World, Web.

Marr, B & Gray, D 2012, Strategic performance management, 2nd edn, Routledge, Abingdon, UK.

Mensah, W & George, BP 2015, ‘Performance management in the public sector: an action-research based case study in Ghana,’ Journal of Applied Economics & Business Research, vol. 52, pp. 97-111.

Moreira, ME. 2017. The agile enterprise. Apress, Berkeley, CA.

Nath, S. 2016. Building capability with CMMI. Web.

Patary, CL. 2014. ‘Gamifying agile projects to drive employee engagement and increase performance,’ PM World Journal, vol. 3, no. 11, pp. 1-18.

Payne, A Frow, P & Eggert, A. 2017. ‘The customer value proposition: evolution, development, and application in marketing,’ Journal of the Academy of Marketing Science, vol. 45, no. 4, pp.467-489.

Perkins, M, Grey, A & Remmers, H. 2014. ‘What do we really mean by “Balanced Scorecard”?’ International Journal of Productivity and Performance Management, vol. 632, pp. 148-169.

Pieńkowski, M. 2014. ‘Waste measurement techniques for Lean companies,’ International Journal of Lean Thinking, vol. 5, no. 1, pp. 11-24.

Ragin‐Skorecka, K. 2016. ‘Agile enterprise: a human factors perspective,’ Human Factors and Ergonomics in Manufacturing & Service Industries, vol. 26, no. 1, pp. 5-15.

Rigby, DK, Sutherland, J & Takeuchi, H. 2016. ‘Embracing agile,’ Harvard Business Review, vol. 94, no. 5, pp. 40-50.

Scholtz, CR & Maher, ST. 2014. ‘Tips for the creation and application of effective operating procedures,’ Process Safety Progress, vol. 33, no. 4, pp. 350-354.

Tjell, J & Bosch-Sijtsema, PM. 2015. ‘Visual management in mid-sized construction design projects,’ Procedia Economics and Finance, vol. 21, pp. 193-200.

Wilden, R & Gudergan, SP. 2015. ‘The impact of dynamic capabilities on operational marketing and technological capabilities: investigating the role of environmental turbulence,’ Journal of the Academy of Marketing Science, vol. 43, no. 2, pp. 181-199.