Introduction

Like many industries in the 21st-century business world, the retail industry is heavily dependent on technology. The main purpose of technology simply put is to make work easier. Retail chains experience a myriad of problems that make it necessary for them to adopt the said technologies to remain competitive in the business world.

Every retail chain aims to ensure the delivery of products to customers from suppliers in their original quality while minimizing the costs associated with warehousing inventory and transportation. For such a goal to be achieved, retailers must ensure a sufficient supply of inventories so that there is enough stock always while keeping the inventories low to reduce carrying costs and to meet the dynamic customer demand. The challenges that retail supply chains experience make it difficult for them to have a lean supply of goods and services. The challenges mainly occur in purchasing or merchandising, store replenishment, and in both purchasing and store replenishment combined.

In purchasing, there is always a lack of clarity between the purchase order placement and receiving of goods or services. Also, there is difficulty in managing inbound purchase order shipments that are less than truckloads in size.

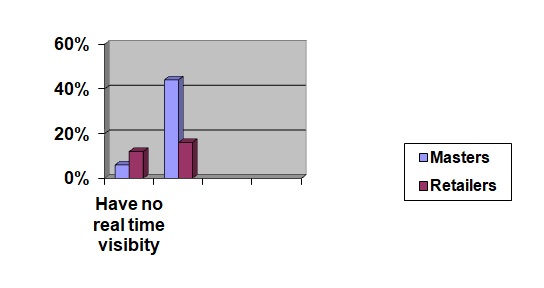

Storage of inventory in numerous locations is for the sole purpose of shortening lead-time back and forth between the store and or customer. Further, more there is always an imbalance of inventory when the same items are stoked at different distribution centers at the same time. The stock imbalances lead to store replenishment from multiple distribution centers that create further ambiguity. Store managers find it difficult to predict customer demand by-product because of the existence of high and low inventory turn ratios. A study carried out by Global Consulting Firm, Accenture found out that most retailers only have inventory visibility only across their internal distribution networks while only a handful could barely manage visibility beyond the extended chain.

The figure below illustrates inventory visibility in retailers and masters who have managed to enhance their visibility in supply chain management.

When both purchasing and store replenishment challenges are combined, the result is high costs brought by the line-haul carriers that deliver goods to multiple centers. There is also the risk of product damage when less than truckload shipment is done.

The above challenges coupled with volatile market conditions and the ever-changing consumer mindsets and trends; put retailers in awkward positions faced with mounting problems and delicate balancing acts in their supply chain management capabilities. Consumer expectations are high while their preferences are dynamic hence retailers have no choice but to harness the abilities of their supply chains to retain customers and generate revenue.

Technology and the Supply Chain management

Retailers have acknowledged the importance of technology in supply chain management and as a result, have increasingly adopted new technologies to stem competition and ensure customer satisfaction and retention. Besides, the adoption of technologies has ensured cost minimization and the efficient flow of inventories from suppliers to customers. There have also been numerous advantages associated with the adoption of these technologies. Technology has ensured smarter customer data and the development of e-shopping. Most expansions made by these businesses have been enabled by technology. Store technologies have enabled better inventory control and reduced errors in stocktaking. It is easier now for businesses to check out customers place orders and manage inventories through the technologies.

One of the most overlooked enablers of these technologies is the internet. Through the internet, these businesses can collect customer information and customers can access remote applications. Internet communication has also emerged as an important source of communication reducing the bulk of internal and external communication with both suppliers and customers.

Research which has been conducted on the effects of technology on the retail industry has shown that supplies and retailers must align product data to ensure that it is efficient consumer response. Since the 1980s, people have come up with different forms of technologies that have made the flow of information between suppliers and retailers to become much faster and easier. The main aim of these technologies is to ensure that the correct orders are made between the supplier and retailers and that the orders take minimal time to reach the retailer. This ensures that the consumer gets the goods in good time that is of good quality and quantity. Because of the collaboration of suppliers and retailers, efficient consumer response (ECR) is achieved.

Technologies Used In the Retail Market

The problems associated with supply chain management systems have given rise to the development of numerous technologies and technological models meant to ease the burden on retail managers and ensure better supply chain management. The technologies include:

Enterprise Resource Planning Systems

Warehouse and distribution center operations have been automated through the ERP technology and it is now easier for supply chain managers to monitor the system as it performs broader tasks more efficiently. The system works through a combination of hardware and software operations that are programmed by system engineers. It comprises fixed machinery and mobile technology. The fixed machinery including cranes and conveyor belts communicate with the mobile devices that relay instructions to operators present in the warehouse. The integration software does overall control while barcode scanners inserted in the equipment help in the identification of containers.

Electronic Data Interchange

Electronic Data Interchange is among the technologies used in the retail industry. This technology enables the transmission of data from one computer system to another via a network chain which the organizations involved have made. The information is transmitted from the sender to the recipient in form of a formatted message that represents the financial documents involved. According to analysts, this technology is more efficient than the mere use of emails. The data is strictly transported and interpreted by the computer. Human intervention is minimal, only occurring to correct an error, to ensure that the quality of the information that is being transmitted is good, and only a few other instances.

EDI is used to control the flow of information between two parties either within an organization or between two or more organizations. EDI constitutes the whole system that is used to convey the message. It controls the flow of data, the formats of the data, and the software is that is used to interpret the data. The technology is very strict and ensures that the standards of the business are maintained, which has made it to be a very useful tool in the supply chain. The standards which have been set up by EDI are very flexible and user friendly.

These standards enable the users of the technology to determine how the information will be transmitted between them. The information can be transmitted by the use of emails and modems. To ensure that the information is secure while using the internet, standards have been set to minimize the chances of unauthorized people retrieving information while it is being transmitted. Due to its advantages over the paper system, EDIs have become very common in many retail operators.

Radio Frequency Identification (RFID)

Some experts refer to RFID as the “next-generation bar code”. None line of sight and unique serialization characterize the technology that is expected to revolutionalize supply chain management. Experts further contend that the technology compared to the rest is better and able to enhance shop-floor visibility besides ensuring accountability on the part of managers. Its capabilities enable manufacturers, suppliers, and retailers to collect, organize, distribute, and store information. There is increased efficiency in inventory management, security control, and business processing.

RFID is a wireless technology that employs automated identification and data capture methods in providing solutions to the supply chain questions and providing tentative alternatives to the retailer. It embodies three constituent layers, a chip, a reader, and a computer. The chip is attached to a physical object that is used to identify a product. As opposed to bar codes, the reader allows the user to interrogate the chip through the antennas without actual contact with the product. They do not require the user to engage the product one at a time.

The technology does not also require that the user is within a line of sight to interrogate the chip. The computer contains application software that aids in the management of the equipment and the data collected from the interactions with the gadgets. There are varieties of designs of this technology available in the market with a vast selection of features including varying data storage capacities, varying carrier frequencies, memory sizes, and types as well as product lives and costs.

Despite the positive reviews on capability, some scholars contend that RFID has been slow in its absorption into the market. Many companies have hesitated to invest in the technology owing to different reasons including issues with its tracking system implementations. Other challenges cited include the cost of the technology and its adoption, different standards, and insufficient technology, security, and data sharing problems, and issues with ethics and privacy of the technology.

Other technologies

Other retail technologies have been developed by IBM. They include Enterprise Data Management that is a set of tools with special capabilities able to aggregate, share, synchronize, and manage product information with businesses and their partners. There is also Trading Partner Integration that comes with a collaborative trading partner portal that offers one window through which business partners can access a wide range of functions of the supply chain collaboratively. Technology is especially beneficial as it does away with functional boundaries effectively enabling a consumer-focused chain of supply.

As it were, the efforts made by retailers in partnership with market research scientists have led to the development of a host of application technologies that aim to streamline the supply chain process and hedge against costs involved in this process. The list of these technologies is long down From Enterprise Resource Planning, Transport Management Systems, Warehouse Management Systems as well as Automatic Identification and Data Collection Technologies. The need for a competitive and cost-effective solution continues to motivate the creation of these technologies.

The technologies discussed above have enabled the development of business models on which supply chain management operates. Key among them are the Collaborative Planning, Forecasting, and Replenishment (CPFR) and Vendor Management Inventory (VMI).

Collaborative Planning, Forecasting, and Replenishment (CPFR)

Collaborative planning, forecasting, and replenishment (CPFR) is a model form of technology that is being used in the retail industry. The system is a business model that is enabled by technologies such as ERP. Through this system, cooperation in the acquisition and management of inventory among members is encouraged throughout the supply chain. It is, therefore, necessary for suppliers and retailers to share information amongst them to ensure that consumer satisfaction in the industry has been achieved. This system ensures that there is a continuous supply of goods that are required by the consumers at all times. This, therefore, ensures that the market is always fully stocked with the goods that the consumers need at all times. The system is very efficient in that it cuts the costs of purchase, inventory, warehousing, and transportation of goods by all the trading partners in the industry.

CPFR began to be used in the retail industry in 1995. Since its incorporation into the industry, the technology has been very successful hence more and more trading firms have adapted and incorporated the idea in their operations. This is because it has made the supply of goods in the market to be very efficient and at the same time it has resulted in the reduction of purchase and acquisition of goods.

CPFR has a model that it uses to operate. This model is composed of nine components that have to be followed so that the system becomes effective and efficient in its operation. This model has the laid down procedures that control the way that information, as well as the goods and the services, move. Three rings constitute the model. The first ring is the supplier who in this case is the manufacturer of the goods. He is involved with the production, storage, and supply of the goods or services. The second ring is made up of consumers. In this case, the consumers are the retailers who buy the goods from the suppliers and sell it to the consumers. The third ring is composed of the end consumer. End consumers are the individuals who create the demand for the goods and use them to their satisfaction.

Thus for the technology to be successful, there has to be a form of collaborative management among the partners. The partners should also develop a joint business plan that has to strictly state the goals and objectives that have to be achieved through the collaboration. Other factors that have to be considered include sales forecasting, analysis of demand and supply of the market, and fulfillment of the orders of the customers. Therefore, through strategy and planning, demand and supply management, and market analysis, the technology can be very successful leading to the high efficiency of the supply of goods and services in the market.

Vendor Management Inventory

Vendor Management Inventory (VIM) is a response to the push and pulls of the competitive market forces alongside the need to hedge against costs. It keeps the inventory levels checked and maximizes the product profits. It is a concept that borrows from backward replenishment whereby orders by the supplier are made based on the responses and reactions between the retailer and the customer. It leaves enough room for visibility in the supply chain and ensures that the participants engage in proper product planning and keep inventory levels on a just in time basis. It is very useful in the distribution of packaged products at the distribution and store levels.

Operations management implications of implementing the technologies

The modern-day trend in supply management has been to invest in technology that focuses on the transfer of business information via computers and other electrical devices. This is quite understandable keeping in mind the unpleasant risky and costly history of manual transfer of this information. The employment of these technologies has brought along its implications and drawbacks.

Supplier integration

EDI’s claim of market usage is long overdue given the period that it has been in the market. This however may be pegged to the lack of proper information of the potential users of this technology. Despite the challenges, however, uptake of EDI is high compared to other technologies. It’s one of the most efficient and widely used technologies in the market.

In a research conducted on the application of EDI in practice by a German University, 84.7 % of the companies they interviewed had integrated the technology with their customer base. 41.2 % were free to also engage their suppliers but only after the system had been proven to have worked for the customers. They were also very reluctant to engage third parties such as their bankers and public agencies, especially at the preliminary stages. They were only engaged at the later stages of the implementation of the technology. For instance, those who were found to have engaged these parties were companies that had operated under this technology for two or more years amounting to 40% of the companies interviewed.

The research also included that of all parties incorporated into the system the forwarders seemed to fit in the best in all sectors. Out of the interviewed companies, 32% had engaged they’re forwarded into their EDI system. A remarkable percentage of these companies had engaged public agencies in their system. This can be pegged to the ease associated with EDI in international transactions.

EDI has been in the market for over three decades. During this period it has grown into a self-sustaining application technology that offers tangible benefits. These benefits include the following.

- Fewer costs associated with data entry errors.

- Faster accessibility of information owing to the increased information recycle capacity.

- Reduced documentation and reference to printed documents.

- Fostered commercial relations with the various supply chain players.

- Cheap effective and convenient dissemination of information in electronic form.

- Convenience in the control and management of inventory.

Inventory management

The accentuated role of RFID in the manufacturing sector may be linked to the contemporary dynamics of the market trends as well as the alienated nature of the supply channels in the retail business segment. The market-product history of RFID resembles in great respects that of EDI. It was also a measure aimed at responding to the market drive towards a streamlined supply chain as well as service and order management.

Manufacturers and retailers in search of a fast accurate and reliable way to manage the transportation movement and arrangement of goods inside and outside the warehouse turn to this technology due to the flexibility that it offers. The mainstream RFID tags vary between those with reading and write features and active, passive, and semi-passive varieties. These categorizations are made based on the technology’s ability to drive operating power and convey information to the reader. Active tags are built with miniature batteries that ensure that the tag operates over a wider range of transitions. In effect, they have higher transition speeds and capacities as compared to passive tags. Depending on the customer’s needs and requirements they will choose between the cost and service delivery of both types of tags.

The attachment of tags that do not require individual product attention makes the processing of product data much faster and less tedious. Suppliers may receive shipments from different suppliers at once without the need for actual individual supplier identification.

The relevance to retailers and suppliers who engage in the process of branding (packing picking and transporting) experience the first-hand benefits of this technology. These come in the form of faster and easier service to a diverse supply chain. The products are easily queued in the order of their exit depending on the inventory system.

Queuing theory

The main idea behind queuing theory is the waiting in a line that everyone and everything experiences in life. It can be in a hospital, airport, or supermarket. Queuing problems come because of waiting line situations. Queuing is characterized at any time by several physical entities referred to as the arrivals who are attempting to receive a service from limited facilities referred to as the servers. Like in all areas that experience queuing problems, inventory, management also does experience its queuing problems.

The application of the queuing theory and its relationship with technology can be explained through three major areas of operations management. They include:

The inventory capacity trade-off

Companies may indulge in the overuse of capacity that automatically leads to congestion and high lead-time and high inventories. The only way companies have to beat the above predicament is to have excess capacity effectively leading to an inventory capacity trade-off.

Traditionally, inventory management involved the full stocking of stores so that customers can be supplied with the goods that customers may want. New thinking however has it that the stock should be kept low and customers can be served more effectively with a little bit of waiting. The retailer, therefore, is regarded as a queuing point rather than a stocking point. The success of the retail technologies is pegged on the ability of the retail managers to eliminate all waste to ensure continuous improvement and maximum participation. Implementation of the technologies to ensure a good queuing system also needs disciplined implementation participation of all suppliers and a major restructuring of the production floor. Queuing fastens the customer response as by reducing lead-time hence leading to market power for the business. All the above is meant to achieve the Just in Time phenomenon. Queuing discourages retail chains from taking up large inventories and other contingencies to meet unforeseen surges in demand.

Impact of disruptions and capacity utilization on lead-time

Many companies are advocating for the fast cycle strategy to beat the challenges associated with retail chain management. There is an important element between time in the system and inventory. High inventory is almost a sure way of having a long lead-time. Lead-time is composed of two parts namely the waiting time and the processing time.

Here queuing theory applies through Little’s law. The law combines the most basic operations management performance measures and transforms them into one formula. The number of customers in the system that is also the same as the average inventory is combined with the time the units spend in the system that is equal to the lead-time. Lead-time here is effectively lessened.

Lot Sizing and Lead times

Balancing ordering costs are inventory holding costs that have traditionally been the focus of operations management. However, a lot of sizing on lead-time has become the focus. Sometimes the facilities of production will be used to do set-ups. Lot size determines the setup time and because small lot sizes lead to larger portions of set up time, the utilization of the facilities in terms of capacity will increase.

All the above applications of queuing theory won’t be possible were it not for the availability of supply chain technology. Retail chain managers have found it easy to manage inventories through technologies that enable queuing.

Capacity management

VMI takes the burden of costs involved in the forecast and creation of purchase orders from the retailer and casts such a burden on the supplier. The services of EDI are employed in the communication of information. Retailers submit their reflections reactions and requests through EDI to the vendor who creates a database that is used in the creation of orders. The data provides a history of fill levels and reorder levels that are used in the forecast of the appropriate orders.

Upon preparation, the vendor sends a notice to the retailer before supplying the product to allow for any revision depending on the market situation. He will then after sending the goods to the retailer with an invoice depending on the agreed terms of payment. This process creates a smooth flow of information and ensures that there is harmony for goods produced and supplied. In effect, the participants of the supply chain can ensure that they manage and keep within the limits of their capacities.

Broader business challenges to successfully implementing technologies to improve retail supply chains

The adoption of these retail technologies has enabled retail chains to expand operations across borders owing to easier logistics management and better coordination. I.T has become a powerful tool of management in retail supply and chain management. Additionally, the technologies have enabled the retailers in strategic positioning in both domestic and international markets through the formation of strategic retailer networks. Their competitive advantage is better than those who have not yet installed such technologies. That is on the brighter side though. Several challenges come along with the acquisition and use of these technologies. The challenges mainly affect the operation management aspect of the retailers hence hindering the full benefits of the intended goals.

Changes in organizational structure

Adoption of new technologies requires a change in the organizational structure of a company. Because of the automation of tasks, some people may be laid off while others may be required to undergo training to operate these systems. This also touches on the planning-related challenges that these firms have to undergo. Training and reengineering are required since the planning process is technology-oriented. Considering that not all companies in the supply chain will be wired the same way, planning across different firms becomes a little difficult. Processes that are not in sync therefore may lead to red tape.

In cases where all players in the supply chain have adopted technology, the uniformity of system architecture may be called to question. Failure of standardization of all the systems – which is the case more often than not leads to planning failures or supply hiccups that may extend the lead-time effectively beating the purpose of using technology.

Cost

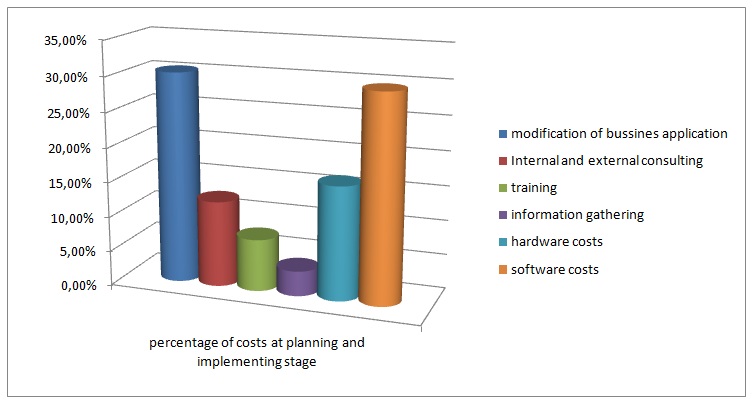

Implementing new technological applications requires quite a bit of investment from firms. While implementing technology is not the main driver of high costs, it takes quite a chunk of the companies’ expenditure. This makes it difficult for firms with little capital to implement relevant technological changes. This also affects firms with enough capital by making them reluctant to adopt these technologies despite the obvious benefits that accrue to such an undertaking. Research that sought to establish the place of EDI, technology in the modern market established the following outcome:

Most of these costs are incurred in training personnel who handles the equipment and also the manpower needed for the maintenance of the networks.

Chart representing the initial cost ratios of setting up an EDI system.

The majority of these costs are fixed costs that imply, apart from the daily costs of sending a message, the size of the company determines the efficiency of the technological method adopted. For instance, a company with a large message transfer volume will be able to cover their fixed costs while one with a lower volume will struggle to cover them.

Loss of clientele

There are also other costs such as the loss of orders. Some retailers, customers, and suppliers value the interpersonal value of the first-hand communication that occurs between the parties. This, therefore, means that the implementation of these technologies leads to distrust by these clients.

Security concerns

The harmony of systems and the centralization of control pose security challenges. The implementation of these technologies poses a threat to the company’s secrets and makes a business more vulnerable. It, therefore, becomes quite difficult to build the trust of the parties in the supply chain to cooperate and surrender their information.

Fear of loss of control

The implementation also faces the challenge of resistance from market forces that recommend that each party maintains control over their information and decision-making processes. Parties, therefore, are reluctant to embrace these technologies for fear of loss of control.

Employee skepticism

Like in all other sectors, the onset of technology causes a ripple of fear to the employees who will be substituted by the technology. The intermediaries who under normal circumstances would mediate the communication between the parties in the supply chain will oppose the adoption of this technology. This makes the implementation difficult since their skepticism bars the progress of the implementation plan.

Rigidity

The diversity of supply chains also poses the problem of adjusting to the default technology to suit the demand of the chain. This leads to heavy costs that more often are incurred by individual retailers. Should the retailer choose to alter the sales or supply channel, these costs will be written off as fixed costs that depreciate the individual’s capital base.

Privacy and Security

These technologies have the potential to compromise customer security. While they are designed to ensure customer anonymity, there is the potential of identification through electronic means of the customer who may be carrying such items. Though managers have grappled with warnings to exonerate themselves in case such a scenario comes up, it is still not enough. In the end, it seems such complications are inevitable.

Challenges posed by the rapidly evolving shopper and consumer expectations placed on retail operations

The changing preferences, tastes, and demands of the modern-day customer present a great challenge to the retailer in ensuring convenience and security in the face of the ever-changing retail technology. There lies an even greater challenge that rests in the form of maintaining a sustainable differentiation of their products while keeping in line with the quality standards required of the industry.

To the consumer, the most important of these is convenience and connectivity of life solutions that make the daily experience of shopping and making product choices more easily bearable and even enjoyable. This leaves the retailer in the middle position, connecting the interested parties in the sales transaction such as banks and government agencies with the needs of the consumer.

While consumer expectations have hit an all-time high their confidence on the other hand is at an all-time low. Retail managers are finding it difficult to manage the demand of consumers especially considering there are numerous options available in the market for the consumer hence constantly changing their preferences. Retailers have somehow turned their focus on new markets with explicit use of the available power of their supply chains to stay competitive in the market.

The dynamism that characterizes consumer demand and preference has made consumer demand unpredictable hence complicating the process of retailers delivering high customer services and in-stock rates. Retailers have therefore adopted high standards of customer service as the prime tool to retain the seemingly untouchable customer. Over 30% of retailers consider value added services to be one of the surest ways of creating and retaining customers.

Retail pricing is another victim of the increasingly demanding consumer. Retailers have resulted in price cuts to entice customers for their products to boost sales. This has resulted in rising costs that retailers have to manage carefully lest they go under.

The rapid changes in fashion and preferences brought about by demographics and unique lifestyles have created a problem for retailers. As a result, retailers cannot effectively identify a product, reap its benefits, and at the same time grow its opportunities.

Conclusion

The retail arena continues to suffer the influence of modern technological solutions as well as the onset of e-commerce. This influence continues to sway the formulation of the sales inventory and marketing strategies that are adopted. The advantages that are associated with this venture are undeniably numerous. They enhance information exchange among the different participants of the supply chain. They ease the flow of control within and outside the business.

They also provide economical and reliable solutions for the monitoring of business activities at the convenience of an office. They offer alternative solutions to the enhancement of interpersonal relations and ensure that there is harmony in the business environment. All these accrue to all players in the industry and the participants of the supply chain in equal measures. The nature of the modern market leaves little room for non-compliance with these technologies even as the above-mentioned challenges continue to persist.

Retail firms that want to remain in business and maintain a competitive advantage over their competitors have no choice but to adopt the technology. As said earlier, technology enables these retailers to make easy expansion forays into new markets thanks to the element of flexibility, easier management, and better coordination.

One aspect they need to bear in mind however is the rapid changes that are associated with technology. New forms and versions of retail management applications are developed every other time. It’s imperative therefore for retail managers to ensure they have installed technologies that can be upgraded with ease.

Since the ultimate goal of adopting these technologies is to balance inventories with demand Vis avis lead time, it’s not too late for these retail chains to start thinking of venturing to the online selling platform. This way, customers will be served easily and many challenges associated with inventory management will be avoided. Firms will also drastically cut costs and shopping for customers will be more personalized.

Retail technology is a relatively old phenomenon in the industry. In other parts like Africa however, the uptake of the technologies is a little slow. This is against a backdrop of growth in IT in these regions. Its fertile ground for retailers with expansion plans.

Works cited/ Bibliography

Henry, S., Electronic Transactions – An Introduction to EDI in the Retail Industry, Electronic Markets, 11, 1994, p. 15.

Henry, S, and Jorg, M., Application of EDI in practice. Nd, Web.

International Labour Organization. Social and labor implications of the increased use of advanced retail technologies. (2006), 10-46.

Jan, S., The Role and Emerging Landscape of Data Pools in the Retail and Consumer Goods Industries, Journal of science and technology,1 (1), 2007, p. 1.

Louis, C., From EDI to RFID: Evolving Standards in Manufacturing Business Solutions, Cincom 2010. Web.

Samuel, F., Enabling Intelligent B-to-B eCommerce Supply Chain Management Using RFID and the EPC Network: A Case Study in the Retail Industry. 1998.

Sheffi, Y., RFID, and the innovation cycle. International Journal of Logistics Management 15, 1 (2004), 1-10.

Siegel, G, and Shim, K.J., Operations Management.Nd (1999), 41-50.

Sparks L., and Wagner, B. A. Retail exchanges: A research agenda. Supply Chain Management, 8, 1 (2003), 17-25.

Srivastava, B., Critical Management Issues for Implementing RFID in Supply Chain Management, International Journal of Manufacturing Technology and Management, Volume 21, (2010), 3-15.

Subramanian, C., and Shaw, M. J., The effects of process characteristics on the value of B2B e-procurement. Information Technology and Management, 5, 1-2 (2004) 161-180.

Swartz, J., Changing retail trends, new technologies, and the supply chain. Technology in Society 22 (2000), 123-132.