Abstract

Effective supply chain management of an organisation ensures that the systems for supply chain management reduce various costs that are associated with supplies. Thus, products and services are availed just whenever they are required in a manner that ensures sustainability of the increasing number of products that need to be availed in the market. This role enhances the capacity of an organisation to compete with other organisations in the same industry.

To achieve the objectives of the project, the roles of supply chain in enterprise planning are examined within the context of a hypothetical company: Highchem Medicare. The company manufactures and distributes medical products across the globe. The goal of discussing the roles of supply chain in enterprise planning using this imaginary company is to simulate how the challenges of enterprise planning call for solutions that entail the deployment of supply chain management theoretical paradigms and discourses.

This project paper is divided into three main sections. In the first section, it reviews the literature on both supply chain and enterprise planning. In the second section, it presents a discussion of the challenges that a global organisation faces such as Highchem Medicare. The third section presents the solutions behind the difficulties of establishing the roles of supply chain management in enterprise planning.

Introduction

Enhancing the competitive capacity of an organisation is one of the purposes of enterprise planning. Enterprise planning assists in the identification of the goals and objectives of any venture. These goals may range from planning of product development and the related costs, marketing, management of inventories, sales, manufacturing, procurement, purchases, and even logistics management. All goals of enterprise planning require the inputs of supply chain management. In this sense, supply chain management is an important function in an organisation.

Indeed, according to Ketchen and Hult (2006, p.574), “organisations increasingly find that they must rely on effective supply chains or networks to compete in the global market and networked economy”. Operating efficiently in a digital economy requires a precise and high-speed analysis and synthesis of information. This highlights the relevance and significance of incorporating computer information management systems in the current business operation models together with the integration of supply chain management approaches in enterprise planning. The objective of this project is to examine the role played by supply chain management in enterprise resource planning.

Literature Review

Literature on the roles of supply chain management in an organisation presents supply chain management as an essential aspect for enhancing competitive advantage in a global market that is characterised by excess products and services. Fundamentally, supply chain management entails overseeing the movement of goods and services, finances, and information from the point of production to wholesalers and then to the end consumers. It also involves “coordinating and integrating these flows both within and among companies” (Ketchen & Hult, 2006, p.573). Consequently, supply chain management involves the handling of an immense amount of data. Good gathering and processing of supply chain data to draw important business decisions requires effective tools and systems for information management within an organisation. One of such tools is enterprise resource planning system (ERP).

A system for enterprise planning within an organisation involves various internal and external factors, which influence the operation of an enterprise. Following the PESTLE analysis approach, these factors comprise opinionated, collective, ecological, legal, financial, and technological aspects (Callon, 2006). While these factors are important in the establishment of sustainable supply chain, they are also of great value in an enterprise planning process. They determine the capacity of an organisation to produce services and products, as the major concern of enterprise planning. According to Mellahi, Frynas, and Finlay (2005, p. 103), “enterprise planning systems are part of a firm’s knowledge base or corporate structure whether formally identified and structured or simply executed when the need appeared”. In this context, supply chain management plays key roles in enterprise planning by providing information that is necessary for derivation of survival, thriving, and competitive advantage tactics.

Facing the challenges of survival of an enterprise requires gathering of intelligence on effective and cost cutting strategies for operation. Supply chain information, especially on sustainable supply chains helps to avail this intelligence, which is then utilised in enterprise planning. Faced with modern problems that are associated with production processes and distribution of products, enterprise-planning managers deserve plausible information about the implications of supply chain and logistics strategies on physical and environmental participants.

This requirement is pivotal in helping to resolve the various challenges associated with supply chain management in business environments that are characterised by the changing trends in terms of globalisation together with the concerns of intensive competition. There is also the need for “reliable, flexible, and costs effective business systems that are capable of supporting customer differentiation” (Bullinger, Kuhner & Van Hoof, 2002, p.3533). More than it has been experienced before, the current enterprise planning workers within an organisation encounter a myriad of complex and dynamic enterprise planning challenges that are related to supply chain problems, trends, and developments, which are incredibly hard to predict.

To resolve the above problems, deployment of sustainable supply chain strategies in enterprise planning is inevitable. This means that the current and future enterprise planners will have to understand various suitability issues that are articulated to an enterprise business operational environment. One of the issues is addressing the need for competitive advantage. Through the adoption of sustainable supply chain strategies, an enterprise can develop long-term plans for taking strategic actions that are aimed at increasing and/or improving an enterprise’s competitive advantage.

For instance, McNurlin, Spraque, and Bui (2005) observe that enterprises can plan, set their budgets, and use or implement various information systems strategically. This endeavour is important since “information systems and information technology investments can be a source of competitive advantage” (Callon, 2006, p.47). In the deployment of such investments in an enterprise, data, which upon its analysis and synthesis through the information technology systems helps in informing appropriate enterprise planning decisions, is required. For an organisation seeking survival and capacity to thrive, such data can be extracted from supply chain and logistics management information database.

Modern approaches to enterprise planning entail the development of strategies for cutting costs in a bid to enhance the capacity of an organisation to compete strongly in the highly competitive global market environment. Through effective supply chains practices, enterprises can plan for implementation of strategies, thus ensuring a reduction of inventory levels such as tracking of inventories. A traditional approach of supply chain management to tracking inventories involves the use of paper work. Unfortunately, tracking supplies using paper files is an immense hindrance to the creation of effective supply chains because it “is much more difficult to keep track of inventory and similar data files using paper work” (Leclerc, 2012, p.68). A more effective way is the creation and embracement of technology in maintaining supply data through mechanisms such as holding it in the soft form.

Over the last two decades, many organisations have strategically focused on programmes for the creation of sustainable supply chains as part of their enterprise planning efforts. This role is a transformative process that is meant to outline various comprehensive road maps for detailing the various approaches that are implementable to ensure that business partners remain committed to achieving green technology in supply chains. In this context, Aronsson and Brodin (2006, p. 395) assert, “for an organisation to be actively engaged in building a sustainable supply chain, it starts with the right supply chain strategy, which will be inclusive of customer service levels, financial results, operation costs, and environmental targets”. Enterprise planning approaches initiate with simple, but also significant practices to optimise supply chain decisions. The beginning point is ensuring that inventories are availed at the right places, at the right time, and in the appropriate quantities.

Linking customers and interest groups to the enterprise planning strategies call for the creation of a means of collaboration between customers and other people on a single page. In this context, Ketchen and Hult (2006, p.574) reckon, “Supplier B and Supplier C can even collaborate on their separate processes to increase working operations with Company A”. This implies that effective collaboration and communication, as means of acquiring feedback on enterprises’ plans and strategies of success, cannot be achieved without deployment of technology.

Indeed, real time communication, as a strategy that is enhanced through the deployment of technology in a supply chain, can increase the chances of having an accurate enterprise supply plan that is capable of preventing inefficiency and/or waste of resources in the distribution channels. The claim here is that enterprise planning needs collaboration with technology experts who can invent new strategies for waste minimisation. Such an effort entails consolidation of technology tools such as software in the supply chains.

The marketing theory provides incredible justification for the importance of supply chain management in enterprise planning. There are several decisive factors, which help in determining the nature of the business environment. They include demand and supply together with general environment within which an organisation operates. These factors help in the determination of the appropriate competitive advantage that an organisation can adopt for long-term success (Bullinger, Kuhner & Van Hoof, 2002; Chopra & Meindl, 2004). Supply side factors include employees, competitors, and suppliers. An enterprise seeking to have an effective enterprise plan must organise its long-term tactics together with cost effective strategies to meet the capabilities of employees to deliver its products in a socially responsible manner. This must be done in a manner that offsets the capabilities of the competing supplier in the same industry, especially those dealing with substitute commodities.

Modern business environment is characterised by competition among organisations in terms of who is able to engineer the best strategies that will ensure that his/her enterprise planning strategies satisfies all stakeholder and interest groups. One of the competitive strategies is to ensure that organisations manufacture and distribute environmentally friendly products. This case encompasses a major concern in the current approaches to chain supply management. From the perceptive of demand of products and services, customers are becoming concerned about the impacts of product in terms of costs such as social costs that are likely to be created by the nature of goods and services supplied to them.

McKinnon, Cullinane, Whiteing, and Browne (2010, p. 27) add that customers also “increasingly recognise the value of supply chain services and quality as are less likely to select products and services only on price”. It is through thinking or appreciation of the roles of supply chain management in enterprise planning from these dimensions that has seen corporations such as Dell and Apple outperform other organisations in terms of adoption of effective enterprise plans.

Body of the Project

Project Context

Increased market share for an organisation opens it to various challenges that are attributed to the needs to avail products and services in geographically disjointed markets both quickly and in the right magnitude to satisfy consumer demand. Organisations operating in the provision of medical products and services in the global market such as Highchem Medicare face a myriad of challenges in the continued effort to resolve supply chain problems, customer issues, and complaints with urgency. Indeed, this major problem may hinder the success efforts of any company operating in any industry. “In a fiercely competitive environment, business strategy not only determines success, but also it governs business survival” (Nah, Lau, & Kuang, 2001, p.285). Hence, adopting the appropriate enterprise planning strategies is incredibly important in the effort to put in place mechanisms of responding and ensuring ardent reaction to market place demand. Otherwise, an organisation will perish.

Due to the increasing number of customers that global business enterprise such as Highchem Medicare has to attend, problems such as quick location of the customer and determination of the frequency of purchases for each customer are experienced. Amid these problems, the enterprise plan has to ensure accurate and timely forecasting of market demand. Consequently, making decisions on market targeting proves problematic.

Enterprises suffer from being unable to forecast their production precisely. This problem is even more significant by noting that making target marketing decision in good time results in good decisions for “helping to determine which of the business practices can be altered to increase customer numbers” (Nah, Lau, & Kuang, 2001, p.286). Upon using the enterprise planning approaches, incorporating information management systems, which are highly dependent on the interaction of human decision makers (department heads and general managers) with segregated information systems running on different computers, pose major challenges to the development of an effective enterprise plan.

Under the above approaches to enterprise planning, location of past records, which involve customer communication, is hard to access. It results in slowed resolution of customer disputes. In effecting the transactions between suppliers and the organisation, holding information on different computers makes it difficult to prepare all documents relating to specific transactions as dictated by an established enterprise plan. This challenge forms a major hindrance to the attainment of the strategic plan of a company. “Every minute that a staff spends on editing or otherwise generating paper work is an extra minute he or she is being less productive than is ideal” (Head, 2005, p.65). Therefore, a solution is necessary to enhance speedy preparation of documents ranging from invoices, shipping labels, purchase orders, receipts, and customer communications to preparation of manufacturing plans based on the customer demands as part of concerns of enterprise planning.

Seeking Solutions to Problems of Enterprise Planning

Establishing a solution, which ensures an organisation archives an effective enterprise plan, which is able to deliver on the concerns of enterprise planning in an organisation, requires consideration of the roles of supply chain management in an enterprise developed in the literature review. In fact, developing an effective enterprise plan requires the use of information management systems to integrate supply chain functions and data to arrive at a comprehensive decision on an appropriate survival strategy, competitive approach, and thriving tactic for an organisation. This suggests that any information management system, which integrates various functions of supply chain, also plays critical roles in enhancing enterprise planning.

Enterprises experiencing challenges of enterprise planning such as Highchem Medicare require integration of the information management systems to enhance rapid decision-making. Indeed, rapid decision-making is required for organisations having a large number of stakeholders whose contribution in the organisation influences the activities of the whole organisation. Solutions to supply chain problems, which again affect the enterprise planning, are achievable in different ways. The first solution may entail designing a decision support system. The second option involves designing and implementing a transaction processing systems. Finally, the third option involves designing and implementing MIS that integrates these two systems. The choice of either system is based on the analysis of each of the MIS system’s capacity to integrate optimally the functions of supply chain and channelling this accruing information to enterprise planning.

Decision support system has the strength of helping in making various decisions based on the analysis of supply chain data and statistical projections. Transaction processing system has the strength of “providing a way of collecting processes, storing, displaying, modifying, or cancelling transactions” (Shields, 2001, p.9). The decision support systems create an opportunity for improvement of quality of the decisions made by organisation managers as opposed to replacement of the managers. Via transaction processing systems, an organisation gains an opportunity to permit multiple transactions to occur simultaneously. In addition, through transaction processing system, data collected by the system can be “stored in databases, which can then be used to produce reports such as billing, wages, inventory, summaries, manufacturing schedules, or check registers” (Fryling 2010, p.327). These are the main issues addressed in enterprise planning. The two systems share common threats in that security of the systems is a big issue of concern.

A major weakness of the transaction processing system is that the appropriateness of the system is overly dependent on the accurateness of the information maintained in the databases. On the other hand, the decision support system is slower in helping to arrive at a decision because it interacts with human decision makers. Considering the systems’ strengths and opportunities, an organisation seeking to use information systems and technology as a competitive advantage needs to take advantage of the strengths and opportunities of both designs. Integrated information management system has this capability.

ERP (Enterprise Resource Planning) is one of the types of integrated information systems commonly used in supply chain management, and for that matter in enterprise planning, upon considering the roles of supply chain management in enterprise planning. In a complex organisation that has huge amounts of data for every specialised department, arriving at a comprehensive enterprise plan requires information sharing between departments. For Highchem Medicare, this role includes arrangement, making of enquiries and design, production, human supply, promotion, procurement, investment, acquisition, and register control among others. ERP comprises the single important system that has all these departments together while still maintaining separate optimised systems for each department.

Implementation of Integrated Information System to provide Information Input to Enterprise Planning from Supply Chain

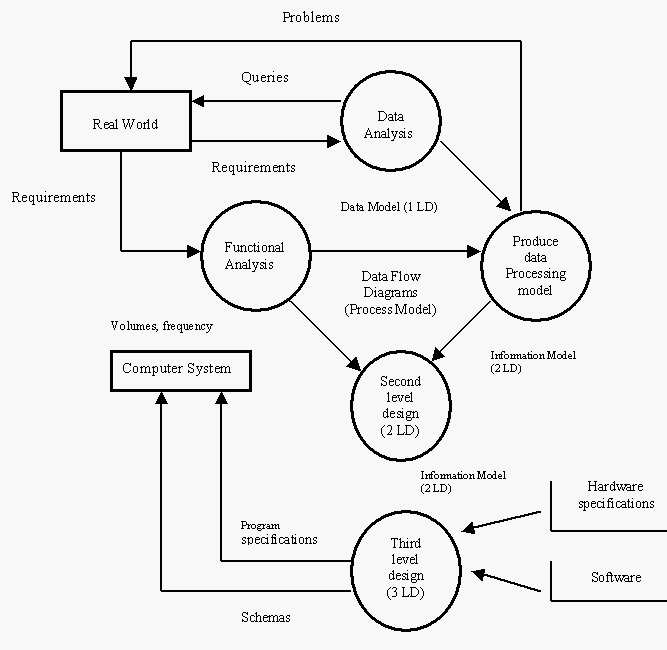

Implementation of integrated information system in an organisation that seeks to use supply chain information to develop effective enterprise planning is important. ERP enables an organisation to integrate all its production and management function in a manner that decisions are quick to make and respond to concerns of all stakeholders of an organisation in real time. Fig. 1 below shows a schematic diagram of modelling an ERP version, which can help to integrate supply chain functions and hence provide decision constructs to enterprise planning.

The implementation of the solution of an ERP system involves the construction of the system and introducing it to an organisation. This encompasses the construction of both software and hardware. However, although construction of the system in an organisation is viable, development of new information management systems is always susceptible to bugs, thus leading to system failures soon after implementation (Turban, Volonino, McLean, & Wetherbe, 2008). This situation poses a big challenge to information security. Most organisations resort to the alternative of acquiring customised hardware and software from manufactures who produce tested information management systems. This option is preferred to save the time required for a new MIS to be operational in the organisation with optimal reliability, availability, and dependability.

Bidding encompasses the first step in sourcing hardware, software, or equipment in an organisation. Bidders are selected using different approaches such as ‘low price bidder’ approach or ‘the best quality provider’ approach. Irrespective of the approach utilised, organisations need to ensure that the integrated system software supplied meets functionality requirements. In the context of integration of supply chain information to provide reliable enterprise planning information, an integrated information system such as the ERP should support the integration of external and internal management information throughout Highchem Medicare.

An MIS system for supply chain management needs to have various modules. It should have modules for management of manufacturing functions, service and sales, modules for management of customer relationships, inventory controls, production planning, forecasting, and procurement. The system also requires other modules that “facilitate the flow of information between all business functions inside the boundaries of the organisation while managing the connections to outside stakeholders” (Yusuf, Gunasekaran & Abthorpe, 2004, p.77). ERP is an expensive MIS in the short run. Hence, organisations seeking to use the system in enterprise planning need to cut on the costs of hardware. In this effort, compatibility for ERP system software with the hardware supporting Windows NT, UNIX, mainframe, and other windows is important.

Implementation of any new methodologies of doing work, including the use of integrated information management systems such as ERP, involves change. This underlines the importance of change management in an organisation seeking to link supply chain management functions with the enterprise planning through an MIS system. Change management entails the alteration of the processes that employees utilise to conduct the business of the organisation. Many operations executed in an organisation without an MIS system involve employees working manually or with interventions from computers.

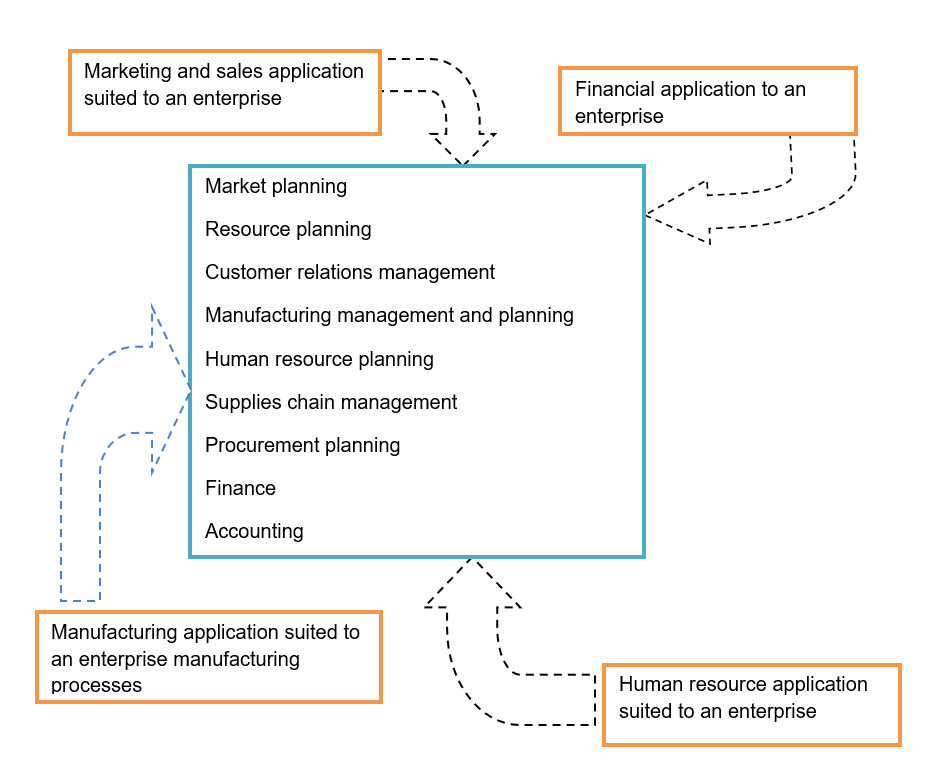

Implementation of an MIS systems leads to integration and automation of supply chain functions and enterprise planning functions throughout an organisation. Implementing this change requires retraining of employees on the use of a new system. This helps them to “share common data and practices across the entire enterprise and produce and access information in a real-time environment” (Nah, Lau, & Kuang, 2001, p.285). In some situations, an enterprise does not have a technical team to facilitate the implementation of the MIS. Available options include hiring third vendors to evaluate the customisation needs for an organisation to suit its needs. Fig. 2 below shows these customisation requirements for a system integrating supply chain function with enterprise planning.

Examination of the above-proposed areas of customisation for an MIS system evidences that ERP’s scope involves significant alterations of practices in an organisation together with working processes. Consequently, incomplete understanding of various processes before the implementation is initiated may lead to failure of an MIS project. Insufficient understanding of the operation of MIS systems used in integrating the function of supply chain management and enterprise planning may truncate into the failure of an organisation to make effective or even weak enterprise planning decisions because decision-making is a function of input from the supply chain management information.

Conclusion

Successful production and service organisations integrate in their operations a department that is principally dedicated to engaging in supply chain management. The department takes charge of providing oversight to materials, finances, and any other information as it moves from the manufacturer towards the wholesaler, from the wholesaler to the retailer, and then to the target consumer. Supply chain administration entails ensuring synchronisation and incorporation of all such movements to and between various businesses.

The overall aim of the supply chain within an organisation is to ensure that there is limited accumulation of inventories. It also ensures that the costs associated with urgent replenishments are mitigated in the effort to ensure that an organisation runs both smoothly and effectively for optimal profitability. For this to happen all the time, development of an effective enterprise plan is important. This implies that information used in the enterprise planning process is drawn from supply chain database.

Based on the above assertion, the project highlighted the importance of integration of supply chain management within enterprise planning decision constructs to enhance competitive advantage of an organisation, its survival, and prosperity. These three aspects define the purpose of enterprise planning. Depending on the available supply chain information, an organisation such as the hypothetical organisation, Highchem Medicare, discussed in the paper can examine assets, which are either accessible or even out of hand, in its bid to manufacture commodities and services.

Determination of the above resources requires the availability of information on inventories, sales, and marketing, manufacturing capacity, finances, planning, and procurements among others. This information is available in supply chain management databases for an organisation. Hence, the project suggests that enterprise planning is impossible without supply chain management information. Consequently, for effective development of enterprise plans, supply chain information integration systems are required in any organisation handling massive amount of supply chain data. Many types of supply chain integration information systems are available for procurement by an organisation. However, the project proposed ERP as an effective tool for integrating supply chain information to provide reliable and adequate information for enterprise planning in an organisation.

Reference List

Aronsson, H., & Brodin, M. (2006). The environmental impact of changing logistics structures. The International Journal of Logistics Management, 17(3), 394–415.

Bullinger, J., Kuhner, M., & Van Hoof, A. (2002). Analysing supply chain performance using a balanced measurement method. International Journal of Production Research, 40(15), 3533–3543.

Callon, J. (2006). Competitive advantage through information technology. New York, NY: McGraw-Hill Higher education.

Chopra, S., & Meindl, P. (2004). Supply chain management: Strategy, planning, and operation. Upper Saddle River, NJ: Prentice Hall.

Fryling, M. (2010). Estimating the impact of enterprise resource planning project management decisions on post-implementation maintenance costs: a case study using simulation modelling. Enterprise Information Systems, 4(4), 391–421.

Head, S. (2005). The New Ruthless Economy: Work and Power in the Digital Age. Oxford: Oxford UP.

Ketchen, G., & Hult, T. (2006). Bringing organisational theory and supply chain management: The case of the best supply chains. Journal of operations management, 25(2), 573-580.

Leclerc, Y. (2012). Sustainability and the Supply Chain: How to Reduce Cost and Save the Environment. Manufacturing business technology, 2(1), 67-71.

McKinnon, A., Cullinane, S., Whiteing, A., & Browne, M. (2010). Green logistics: Improving the environmental sustainability of logistics. London: Kogan Page.

McNurlin, B., Spraque, R., & Bui, T. (2005). Information system s management in practice. New Jersey, NJ: Pretnice Hall.

Mellahi, K., Frynas, G., & Finlay, P. (2005). Global Strategic Management. New York, NY: Oxford University Press.

Nah, F., Lau, J., & Kuang, J. (2001). Critical factors for successful implementation of enterprise systems. Business Process Management Journal, 7(3), 285-296.

Shields, M. (2001). E–Business and ERP: Rapid Implementation and Project Planning. New York, NY: John Wiley and Sons, Inc.

Turban, E., Volonino, L., McLean, E., & Wetherbe, J. (2008). Information Technology for Management, Transforming Organisations in the Digital Economy. New York, NY: John Wiley & Sons, Inc.

Yusuf, A., Gunasekaran, Y., & Abthorpe, M. (2004). Enterprise Information Systems Project Implementation: A Case Study of ERP in Rolls-Royce. International Journal of Production Economics, 87(3), 75-81.