Bill of Materials (BOM)

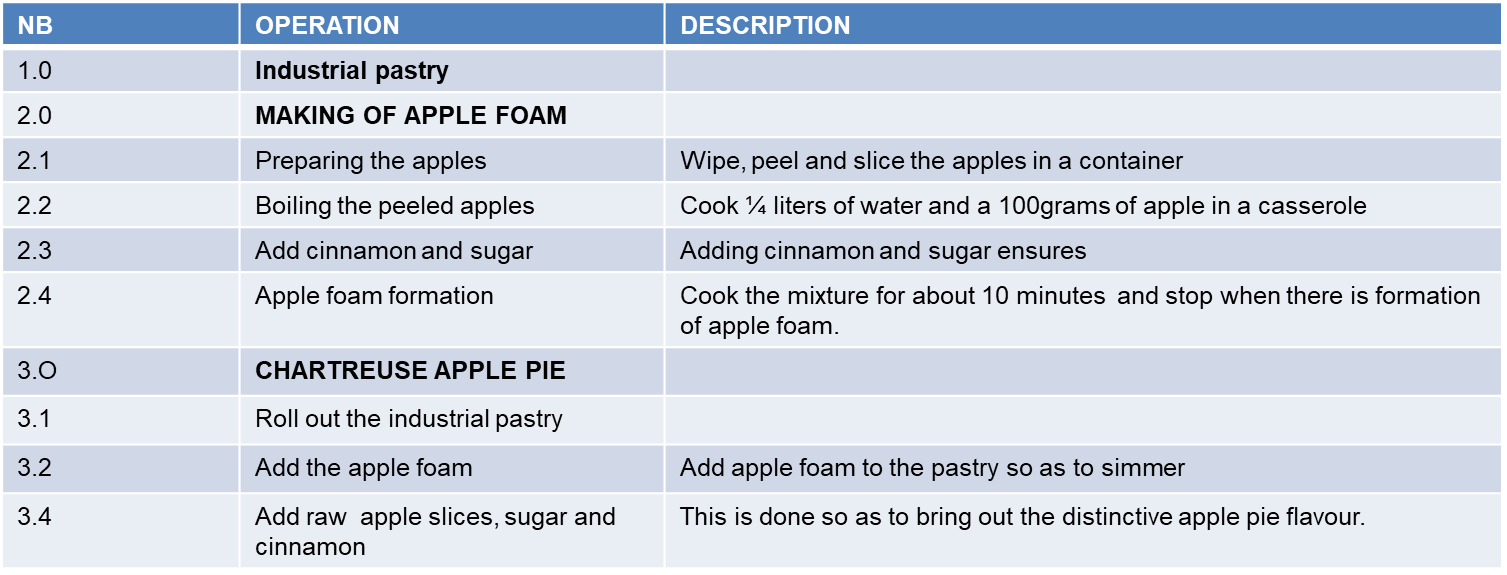

This is a list or complete set of raw materials that are required to complete a certain production process and to give a specified end product (Krajewski & Ritzman 2004). It contains the raw materials and intermediate goods that are required. The complete set of raw materials that are required to make Chartreuse Apple Pie is as follows:

Chartreuse Apple Pie:

- ( add apple slices and cinnamon cooked in an oven at 250 degree Celsius)

- Pastry Plus Apple Foam

- Add butter slices,

- Add cinnamon and eggs and salt sugar.

- Wheat flour Apple.

The above bill of material (BOM) tree shows the process through which chartreuse apple pie is made. White flour is spread on the bank, then add salted slices of butter and egg. Then the mixture is thoroughly mixed while adding flour until it stiffens. It is left to repose for thirty minutes. On the second stage, wipe and peel the apples gently, then slice them. Take the 100 grams of the sliced of apple and a quarter litres of water in a casserole and cook. Add sugar and cinnamon in the casserole while stirring gently. Stop after ten minutes immediately apple foam appears on the casserole.

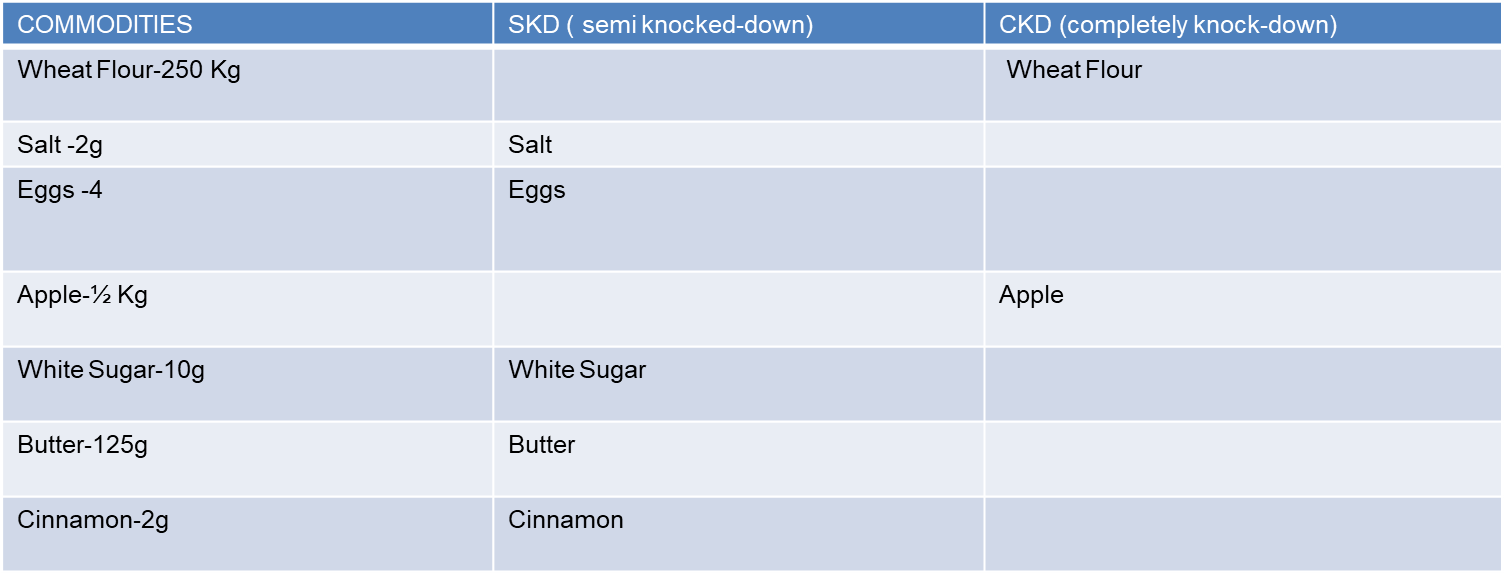

The Bill of Materials in a Tabular Format

- SKD- Semi knock-down: These are incomplete items that are important in the production process since without them, the production will be incomplete. In our case these are salt, eggs, white sugar, butter and cinnamon.

- CKD- Completely knockdown: These are elements that are very detrimental in the production process. They form the basis of manufacturing any product. In our case these are wheat flour and apples.

Master Production Schedule (MPS)

This is a schedule set forth to ensure that there are no shortages in the market or wastage in terms of excessive production. This is done by partnering with suppliers to distribute in advance before the stock ends, delivering goods on time to customers and predicting their demand.

MPS is linked to the appropriate manufacturing plan where it indicates the time and amount of the product needed. Thus MPS greatly and directly affects the profitability of a business entity. Master production schedule software are created in accordance with the manufacturers demand and as such are structure to be effective in different cases (Reid & Sanders 2002).

One major weakness of master program schedule is that the programmers do not include every aspect of production. This can cause delays in updating the supplier on the appropriate time to supply goods. However this can be rectified with time. The company can therefore foresee future shortages and expedite costs. Its major advantage is that it can be aligned with the business plan and therefore avoid last minute rush and inefficient allocation of resources

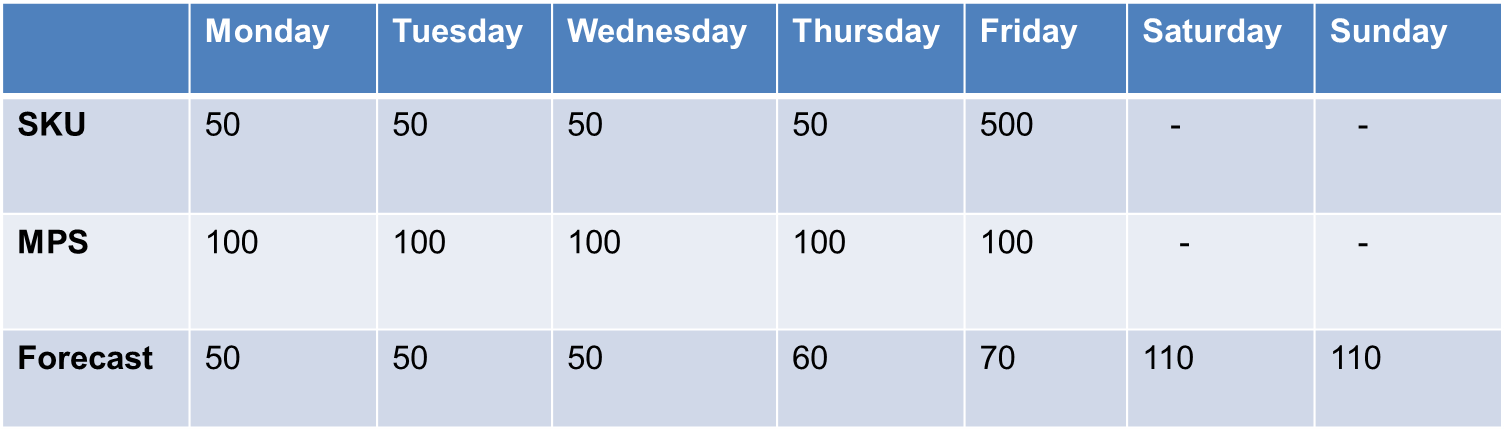

Since our maximum production is 100 pies from Monday to Friday and our demand has already been forecast to vary starting from 50 on Monday to 110 on Sunday, we shall maintain the current production schedule and the market shall consume it all before the expiry date. The current production schedule is efficient avoiding shortages and ineffientallocation of resources.

Stock-Keeping Unit (SKU)

SKU is a code (usually alphanumeric,)in a stores’ catalogue that helps to identify each unique and distinct product or service that had been purchased or can be purchased by a business firm (Krajewski & Ritzman 2004). The stock is usually assigned a unique machine-readable bar code which helps to track in the inventory. This makes it possible for a company to systematically track and monitor the movement of its inventory or product. SKU is mostly associated with physical items. SKU is very important especially during stock taking which is done on-line.

A n efficient data design should have identifiers that are meaningless. This provides for flexibility because the codes can overflow to numbers and characters allotted to them. This will reduce conflicts with a new character for another product. In respect to this the code helps the supplier to detect when EOQ is reached. This is because an accurate count of inventory is kept. This ensures that there is a steady supply that can last from Monday to Sunday.

In APP there is an inventory of 50 on Monday and this can easily be tracked all the way to Friday. In this case, management uses SKU to allocate the resources to be used in a day so as to avoid loss through spoilage. Therefore, resources are used as efficient lyas possible. Their weekly stock is used adequately before the next order.

Push Manufacturing Process

This is a situation where the end-consumers do not request the product to be developed. Therefore there is stability with minimal demand fluctuations (Reid & Sanders 2002). In such a situation, manufacturing is done based on history of orders and APP has been able to forecast its market for Chartreuse Apple Pie.

In this type of manufacturing, manufacture resource plan works with the firms orders where master production schedule is controlled by exogenous factors. Therefore, the manufacturing system seems to defy any demand. Even though this happens it does not limit work in progress and it becomes a push system. The push manufacturing process is most suitable for stable products with a long -life and not perishable.

Therefore vigorous promotion of the product will increase its sales in case demand fluctuates. It uses advertisement avenues such as space and electronic media. It introduces discount days or ‘buy one get one free’ promotions when demand fluctuates.

The shortcoming of APP is that at times inventory exceeds demand in the market. This might lead to spoils and ultimately losses. At times the market forecast tends to drift away or excess demand might arise. This can lead to customer dissatisfaction hence loss of goodwill. In our case, the push manufacturing process works to our advantage since the weekly focused demand falls under the maximum number of pies that we make. As such excess demand will easily be met. However, a drop in the real demand and forecasted demand means that we are probably going to record a loss. This is coupled with the Food and Drug Administration’s new regulations.

Inbound Logistics

Logistics can be defined as the management of the flow and movement of various production aspects. These includes goods, services and people from the point of production to the marketplace. This also includes the administration of the workforce in the production process. Thus, inbound logistics is the management of goods that are arriving at one’s business premises.

Inbound logistics ensure that raw materials are allocated adequately, damaged and spoiled goods are recorded appropriately, order for replenishing goods are made, procurement procedure are in accordance with the company’s policies and disposal logistics are taken care of (Monk & Wagner 2007). Tracking of goods can be made more efficient when using bar codes since the overhead count shall be kept in check such that it does not exceed a certain level.

With the help of SKU, inbound logistics is simplified because every item bought or sold is recorded. Inbound logistic board ensures that resources are allocated adequately to each stage of production so as not to experience delays and wastage.

It also ensures that each and every machine (for example the oven ) is serviced so as to counter delays that may result from break- downs of such machine. Inbound logistics in APP helps in ensuring that goods that arrive first are utilized first in production in order to reduce spoilage of the perishable goods like apple and eggs (first in, first out policy) (Monk & Wagner 2007).

Weekly MRP/Purchasing Plan

Manufacturing Resource Plan (MRP) is defined as a software based planning tool that promotes the effectiveness of all resources in a manufacturing unit (Waldner 1992). It updates the suppliers on what parts need to be supplied, how many and when they are required through a link database. It is the best inventory management system. MRP can also be conducted manually.

It is effective in managing materials in a manufacturing firm, maintaining possible materials and low levels of products in the store. It helps in the planning of the manufacturing activities. It uses Bill of Material (BOM) therefore ensuring that each and every part of inventory is available before being replenished. Firms that do not use proper MRP/Purchasing plan risk losses as a result of poor stock keeping. These losses include:

- Delays in delivering contract obligations to supply products on time due to inadequate quantities purchased.

- Abuse of resources and funds especially when the company purchases stock that it does not need therefore straining its budget.

- Loss of customers caused by delays in the production due to lack of raw materials.

In light of the above losses, effectiveness and efficiency of a manufacturing company is paramount in maintaining a profit making record and goodwill in the market. This can be achieved through three major steps in the preparation of an MRP schedule. These are exploding, netting and offsetting.

Exploding uses the Bill Of Material to ensure that all the components and their numbers are taken care of. Finally offsetting occurs when the order is sent in between the lead time period ensuring that the company is not short of supplies (Reid & Sanders 2002).

The major shortcoming of this system is the inability to ensure the integrity of data. This problem arises especially if there is error in inventory data in the Bill of Material. This translates into a false output. This can undermine the accuracy of cycle-count adjustments and can arise from scraps not counted, damages not reordered, count error caused by suppliers and system issues. This inaccuracy can be corrected by using bar code scanners and implementing pull systems.

Coordinating MRP/Purchasing plan with Bill of Material and Stock-Keeping Unit is of much importance to the company since it notifies the supplier when there is need to replenish. Our weekly manufacturing plan is as follows:

- Wheat flour –once weekly.

- Eggs –twice weekly.

- Apple –once weekly.

- Cinnamon –twice weekly.

- Butter – once weekly.

Sales Forecast

Changes in MPS/SKU and MPS/Purchasing Plan

The Master Production Schedule should increase the number of supplies from once a week to twice a week for eggs and three times a week for cream. In effect, we shall decrease the total number of inventory from 50 on Monday to 30 which will be replenished again on Thursday. This will spur demand due to the increase in number of supplies that we will be receiving.

Stock keeping-unit shall expand in order to accommodate the new products that will be supplied to track the efficiency of the commodities (Reid & Sanders 2002). The older purchasing plan will cease to be operational since we will have two purchases in between the week. This is on Mondays and Thursdays. The supply for eggs shall be three times a week on Mondays, Wednesdays and Fridays. This is summarized as follows:

- Wheat flour –twice weekly

- Eggs –thrice weekly

- Apple –twice weekly

- Cinnamon –thrice weekly

- Butter – twice weekly

Operation Costs

The change in Food and Drug Administration’s policies providing that no pastry should be made locally means that wheat flour, butter, salt and eggs will not be purchased. Instead an industrial pastry of 250 grams will be bought. This affects the Bill of Materials, master production schedule and manufacturing resource plan.

The regulation that requires pastry to be made industrially will affect the master production schedule. There will be no making of pastry whose ingredients include wheat flour, butter, eggs, and salt. This shall increase the overall operating costs because of the extra cost introduced for purchasing industrial pastry.

At the same time, the manufacturing resources plan will change. This is brought about by the fact that pastry will be bought. Therefore the new MRP will be:

- Apple –once weekly.

- Cinnamon –twice weekly.

References

Krajewski, L & Ritzman, L 2004, Operations management, Prentice-Hall, New Jersey.

Monk, E & Wagner, B 2007, Concepts in enterprise resource planning, Course Technology Cengage Learning, Chicago.

Reid, RD & Sanders, NR 2002, Operations management, John Wiley & Sons, Chichester.

Waldner, J 1992, CIM: principles of computer integrated manufacturing, John Wiley & Sons, Chichester.