Executive Summary

The business environment has become more complex such that firms cannot handle all aspects of production on their own. The focus of this report will be on the selection of a supplier for Hydrec Ltd., a designer and manufacturer of forecourt petrol dispensers for the European market.

The firm is in the process of merging two manufacturing plants where the Denmark operations are being phased out. The plant in Ireland will remain, and the move means the company has an opportunity to take advantage of new market entrants who have better production equipment and state-of-the-art management systems. Therefore, the suppliers selected will have to reflect these two core characteristics, which are regarded as added value. The approaches to be used in selecting a range of suppliers will be discussed and criteria outlined for assessing the bids. Lastly, added value will be explored, and a negotiation plan developed.

Introduction

Many businesses today have grown in size, which has resulted in more complex operations. These firms tend to find it hard to run all processes on their own and often require the use of third-party services. Suppliers have become an integral part of the supply chain from where manufacturers can source materials. Therefore, an organization has to make critical decisions regarding who among these providers will be contracted. Supplier selection is a crucial procedure because of the implication it has on the success of firms. Choosing the right supplier will help achieve corporate objectives and address challenges such as costs and quality.

The literature on supplier selection is broad and extensive, where scholars debate the best approaches and methods, as well as tools to aid in making these decisions. The choice of any of these frameworks is made by the managers in charge of the process depending on the applicability to the specific context. The case of Hydrec Ltd. is presented in this report to explore these issues related to supplier selection.

Sourcing

Supplier Selection

Supplier selection is a critical process because it plays a vital role in the success of a firm. According to Taherdoost and Brard (2019), supplier selection is a process through which an organization identifies, evaluates, and contracts suppliers. It is an important decision-making issue in the field of supply chain management because of its implications for the competitiveness of a business. The sole purpose of the process, as explained by Mukherjee (2016), is not limited to objectives such as obtaining supplies at the lowest possible costs and at the right time. However, it is a strategic decision that helps in fulfilling long-term goals with minimum risks.

Several approaches can be used to help choose the right suppliers, including the analytical hierarchy process (AHP), the analytic network process (ANP), and the fuzzy analytical hierarchy process (FAHP) (Wang and Tsai, 2018; Wang and Li, 2018; Zhao et al., 2017). For a manufacturer, the decision to apply any of these or other approaches depends on their applicability.

Competitiveness is a major concern in the supplier selection process. However, several other aspects need to be considered as well. In the case of Hydrec Ltd., for example, the main focus is that the new suppliers will need to have better production equipment and state-of-the-art management systems. This is in addition to other elements such as price, delivery time, and quality which have been established by researchers are key factors (Bruno et al., 2016; Abdel-Basset et al., 2018).

While the competitiveness of Hydrec Ltd. remains a priority, the new suppliers will have to meet several criteria which will allow the company to gain the best from any contractual relationships. The approach selected in this case, therefore, is the analytical hierarchy process which has been deployed in several industries and explained by multiple researchers (Wang et al., 2017; Siregar, 2019; Jayant, 2018). The AHP is the approach of choice for Hydrec Ltd. because it is a simple but powerful tool for decision-making.

In manufacturing, the AHP approach has been applied to help solve different challenges depending on the nature of the companies involved. In this case, it will be an effective tool to select the suppliers who meet the new needs of the company. The AHP model described by Wang et al. (2017) involves a selection of multiple criteria and establishing weights for each criterion. The model can be applied for several suppliers and a combined wight or other approaches used to select the most appropriate one. In this case, the weights can be used to help choose several firms that are most likely to offer Hydrec Ltd. the aspects it seeks in a supplier.

Considering that the selected suppliers will be allowed to place their bids, a new strategy to select a winning bid can be the final yardstick. Using the model by Wang et al. (2017), criteria such as manufacturing methods and management systems will be used. Several others, including delivery time, quality, cost, and reliability, will be explored as illustrated in Table 1 in the appendix.

Table 1: Criteria and weights for supplier selection.

With the above table, the sourcing team will use their judgment to estimate the weights for each of the primary and secondary criteria. The rationale for the selection of these criteria is that there is not a single criterion that can be used to make a supplier selection decision due to the level of complexity involved. Many scholars have expressed that the newer methodologies, including the AHP, are multi-criteria where the selection will consider several alternative suppliers and conflicting incommensurable measures (Zhao et al., 2017). The most important factors for Hydrec Ltd. include quality measures, new manufacturing methods, and management systems.

It can be expected, therefore, that a more critical approach to weighting these elements is taken as they could be the key deciding factors. As will be discussed in a later section, these will also comprise a few of the items considered as adding value when choosing between the multiple bids.

Determining the weights using AHP is critical because the ranking of the suppliers depends on this procedure. The process has been described by Wang et al. (2017), who proposes that a hierarchical structure is first established by recursively decomposing the decision problem.

A pairwise comparison matrix is then constructed to show the relative importance of the criteria by including both the single-level and total level sorting. Lastly, a judgment matrix can be procured, and quantitative methods such as geometric means used to determine the weight vectors. However, simpler alternatives can be used by the sourcing team at Hydrec Ltd., where procurement analysts can use their expertise to estimate the weights for each primary and secondary criteria. The most important point is that the team should place more weight on those criteria considered critical. After the weighting, a new tabulation for all suppliers can be constructed, as illustrated in Table 2 below.

Table 2: A judgment matrix.

As shown in Table 2 above, the number of suppliers selected is represented by ‘n,’ and the criteria included in the table are for the secondary ones, which have been simplified and assessed individually. Ranking of the suppliers can be done according to the specific weights or a further quantitative assessment conducted to establish the ranks. However, it is important to notice that some suppliers will rank higher in some criteria and lower on others. This explains the decision to use the criteria in a descending order depending on the level of importance. The use of primary criteria can be easier and utilized to make the initial selection. The secondary criteria can be used for further screening where those who score higher are preferred.

From a theoretical perspective, it should be noted that the selection procedure determined the competency of the suppliers. According to Bals et al. (2019), purchasing and supply management (PSM) helps increase the competitiveness of a business. This is because between 60% and 80% of the overall organizational costs are external to the firm, which means payments to suppliers (Bals et al., 2019). The competencies can extend beyond offering quality and quantity at lower costs to include aspects such as sustainability and ethics. Managing the supply chain offers multiple challenges, some of which have legal implications. Compliance and disclosure are highlighted by Nolan and Bott (2018) as major legal implications. The sourcing team may need to include these as additional selection criteria or as part of the criteria for assessing bids, as will be discussed in the section below.

Criteria for Assessing Bids

Transparency in the assessment of bids from the selected suppliers will be key. It is argued that the company will be operating and sourcing within the EU and, therefore, bound by the EU’s procurement directives. According to Halonen (2016), these directives include transparency and open electronic access to invitations to tender and contract notices. While these mostly apply in public procurement, their inclusion as part of the criteria for assessing bids will help boost legal compliance ratings. However, the company will still be looking to maximize the benefits emanating from any contractual relationship.

The agency theory can be used to explain this argument because, from an economic perspective, an agency relationship is an optimizing issue that involves the use of both legal and organizational solutions (Chrisidu-Budnik and Przedanska, 2015). Therefore, the bid will be assessed and selected to secure the best return on investment while at the same time achieving legal compliance.

It is argued that the AHP approach was strictly a qualification criterion where all suppliers meeting set standards can be allowed to contest for contracts. Using AHP can, however, be extended to cover bid assessment based on the assumption that the pricing for the materials will be a known variable. The AHP model illustrated by Wang et al. (2017) mentions costs and prices, quality, and delivery times as the primary performance factors.

Therefore, their inclusion in the matrix with proper weighting can eliminate the need for further analysis. This is because further screening will mean including other criteria, most of which have already been featured in the matrix. However, the AHP process, in this case, has been used to qualify suppliers for consideration. The assessment of the bids offers the company an opportunity to further examine the most economically beneficial contracts because each contract could reveal new items not featured in the AHP. It becomes critical to evaluate individual bids to reveal them.

The price will be the major criterion for assessing the bids from suppliers. However, it will not be the only framework considering the legal implications, as explained by Chrisidu-Budnik and Przedanska (2017), who warn against its excessive use. Hydrec is allowed to use cost accounting for this purpose because the end products will be priced as a function of these costs. Even though the company does not use cost-based pricing, it is argued that it will not sell below the production costs. Higher procurement costs will ultimately reflect on the sales and, therefore, the right supplier should offer materials at affordable costs.

The cost accounting approach works best when the entire production process, which includes materials purchased from suppliers, is examined to establish the unit costs of the dispensers. As a company that has been in the European market for some time, the merger should help achieve cost efficiencies as opposed to undermining them. Therefore, the cheapest alternative will become preferable based on the notion that the bids come from those suppliers selected using the AHP approach discussed previously.

Due to the need to explore individual bids, as explained earlier, another major criterion will be an evaluation of the tender documents. By definition, these are written applications for contracts which a company must review to decide who is the most qualified for the specific tender. According to Ozyurek and Erdal (2018), an evaluation of these forms reveals which suppliers meet the economic, financial, technical, and professional thresholds.

These thresholds are set by the company to act as the basis for decision-making. The tender evaluation includes the costs as part of the financial and economic thresholds. The economic and financial benefits, however, go beyond the pricing proposed by the supplier. Other factors to consider include discounts for bulk buying, after-sales services, delivery arrangements and the costs involved, and other services that might have and financial and economic implications. In essence, therefore, tender evaluation considers the whole package offered and the benefits that the firm gains from the contractual relationship.

In addition to the economic and financial thresholds, a company seeking a contractual relationship with a supplier will need to examine the technical and professional capabilities. These aspects have been labeled by Ozyurek and Erdal (2018) as non-price factors. Their significance is based on the fact that professional and technical competence will determine the quality and success of the contractual engagement. A supplier with a higher-skilled labor force can be trusted to deliver better quality materials. The professionalism in the manner in which the supplier handles the tender presentation and relationships with the company can also be key deciding factors.

Another key consideration is the ability to align the supplier practices with the strategic management of the firm. As mentioned earlier, the company hopes to take the opportunity to select a new supplier with new methods and state-of-the-art management systems. It can be argued that the firm seeks to revolutionize its manufacturing plants to reflect the changes in technology. This is a strategic decision, and, therefore, the assessment of the bids should also be a means to establish the possibility of a supplier aligning their practices with the strategic requirements of Hydrec. Additionally, the ability to establish long-term relationships based on mutual benefits and consideration for legal and environmental compliance can be assessed and used as a bid selection criteria.

Added Value

In many cases, the sourcing team will find similar bids in almost all aspects, in which case other criteria may be needed to decide the winning bid. As such, the concept of added value is considered a perfect approach. The idea of using added value strategy has been described by Renganath and Suresh (2016), where both resource-based and transactional theories for strategic supplier selection are combined.

These researchers explain that the suppliers chosen are based on a self-organizing feature map (SOFM), which accounts for both direct and indirect variables. The nature of the supplier, new production methods, sustainability concerns, strategic relationships, and management systems can all be considered an added value. However, the fact that they have already been included in the AHP model means that additional factors will need to be considered. The added value strategy proposed by Renganath and Suresh (2016) used 84 value-added attributes, some of which have also been used in the AHP process. Therefore, a closer examination of additional features may become a necessity.

The items that can be considered added value include trust, customer orientation, responsiveness, customization of products and services, cooperation, and commitment of resources. Trust is critical because an untrustworthy supplier may increase the risks involved in a contractual relationship. Additionally, a trusting relationship could be the beginning of a lasting strategic engagement for the mutual benefit of both parties. The commitment to resources can be manifested in many ways. For example, Hydrec is keen to adopt new methodologies and management systems which could mean the company needs to undertake research and development. A supplier with an effective research and development (R&D) investment may have been selected, but the ability to commit the research materials and equipment to aid Hydrec in its product development efforts can become a critical added value.

Negotiation Plan

A negotiation plan is a critical tool that can help guide the negotiations with a supplier. In this case, the plan outlined below considers the fact that the supplier is based in the United States. The legal and commercial implications of sourcing internationally are taken into account. The available information hints that the supplier can offer products that meet specifications and within the desired timeframe. In this case, the general assumption is that the quality and issues such as production methodologies and management systems are included in this assessment and that they all meet the desires of Hydrec.

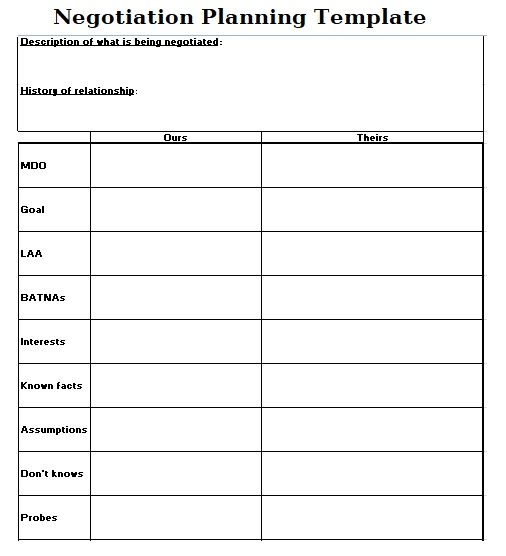

However, it is important to highlight that the sourcing team will be using the best alternative to a negotiated agreement (BATNA) to increase their bargaining power. Attractive BATNA or a walkaway option not only increases the bargaining power but also helps determine a zone of the possible agreement by considering the attractiveness of BATNAs from both parties (Sebenius, 2017). The plan outlines the object of negotiation, assumptions, goals, known facts, interests, and probes. The negotiation plan template will be presented in the appendix.

Object of Negotiation

This section can be used to offer a background to the item being negotiated. In this case, Hydrec seeks to source pumping assembly, and there is a supplier in the United States who can offer them to specification and within the required timeframe. Using the AHP process, it is assumed that the primary performance factors are acceptable and that the other criteria have ranked this supplier among the best. Without details of the products, this section can be very brief.

Assumptions

As mentioned above, the main assumption is that the supplier meets the AHP criteria outlined above for all the assessment criteria. Most importantly, however, Hydrec sought a supplier with a state-of-the-art management system and new production methodologies. It is assumed that the United States supplier meets these requirements as well. Additionally, the supplier meets several items classified as an added value to Hydrec. Lastly, it is assumed that the supplier will be in a position to ship the products to the plant in Ireland or that the two parties will reach a delivery agreement that will be mutually favorable. In other words, the delivery arrangements are such that the contract will remain the most economically and financially beneficial to Hydrec.

Goals

The primary goal is to get the best terms possible from the negotiation. Considering the distance between the supplier and Hydrec, transport becomes a major cost issue and where the negotiation will place greater emphasis. Hydrec understands that the materials being sources are rare, and only a few global suppliers are available. Therefore, getting the best deal from this supplier becomes the primary goal of the sourcing team. Additionally, the team hopes to get favorable prices and delivery arrangements.

Key Negotiation Items

The key negotiation items include the price of the supplies. The most favorable prices will be within the BATNAs of Hydrec. Higher prices than acceptable will lead to the team walking away from the negotiation. Second, quality assurance will be negotiated because this is a major supplier selection criterion. The team will negotiate on how they can verify the quality before shipping to help reduce risks and extreme costs of returning goods. Third, delivery agreements will be negotiated to pursue an obligation for the supplier to cover the shipping costs. The best alternative will be shared costs which will fall within the BATNAs of Hydrec. Lastly, the team will pursue a provision that the supplier handles all legal issues exporting according to the United States laws. Hydrec will handle all import legal concerns based on EU laws.

Legal Considerations

The legal implications for sourcing internationally will be discussed during the negotiation. Import and export duties and other forms of taxation are the major concerns. The negotiators will focus on all trade agreements that make commerce possible between the two countries and how each of the agreements affects the contractual relationships between Hydrec and the supplier. Environmental regulations and any other law addressing pollution and sustainability will be a major consideration in the negotiation.

Conclusion

Sourcing is a critical business function among firms because it can have massive implications for financial and economic outcomes. The focus of this report was to help Hydrec, and its sourcing team select suppliers and assess bids, as well as explore other items considered to be of added value. The concept of supplier selection has been explained in detail. The use of the AHP approach has been recommended for Hydrec because it is both a simple and practical tool for the sourcing team. The criteria for assessing bids include price and tender evaluation, which are based on the economic, financial, technical, and professional thresholds.

Added value items include trust, the commitment of resources, cooperation, and alignment with the strategic objectives of Hydrec. Lastly, a negotiation plan has been outlined, which highlights the objective and progression of the negotiation, as well as the key items of negotiation. The plan also establishes the major legal issues to be considered when undertaking the negotiation. The legal issues include taxation, trade laws, and environmental and or sustainability regulations.

Reference List

Abdel-Basset, M. et al. (2018) ‘A hybrid approach of neutrosophic sets and DEMATEL method for developing supplier selection criteria’, Design Automation for Embedded Systems, 22, pp. 257-278.

Bals, L. et al. (2019) ‘Purchasing and supply management (PSM) competencies: current and future requirements’, Journal of Purchasing and Supply Management, 25(5), pp. 1-42.

Bruno, G. et al. (2016) ‘Applying supplier selection methodologies in a multi-stakeholder environment: a case study and a critical assessment’, Expert Systems with Applications, 43, pp. 271-285.

Chrisidu-Budnik, A. and Przedanska, J. (2017) ‘The agency theory approach to the public procurement system’, Wroclaw Review of Law, Administration & Economics, 7(1), pp. 154-165.

Halonen, K. (2016) ‘Disclosure rules in EU public procurement: balancing between competition and transparency’, Journal of Public Procurement, 16(4), pp. 528-553.

Jayant, A. (2018) ‘An analytical hierarchy process (AHP) based approach for supplier selection: an automotive industry case study’, International Journal of Latest Technology in Engineering, Management & Applied Science, 7(1), pp. 102-114.

Mukherjee, K. (2016) ‘Supplier selection criteria and methods: past, present and future’, International Journal of Operational Research, 27(1/2), pp. 356-373.

Nolan, J. and Bott, G. (2018) ‘Global supply chains and human rights: spotlight on forced labour and modern slavery practices’, Australian Journal of Human Rights, 24(1), pp. 44-69.

Ozyurek, I. and Erdal, M. (2018) ‘Assessment of qualification criteria described in public procurement law code 4734 in construction works by analytic hierarchy process (AHP)’, Journal of Science, 31(2), pp. 437-454.

Renganath, K. and Suresh, M. (2016) ‘Supplier selection using fuzzy MCDM techniques: a literature review’, 2016 IEEE International Conference on Computational Intelligence and Computing Research (ICCIC), The Institute of Electrical and Electronics Engineers, Chennai, India, 17-17 December. Bengaluru: IEEE Explore, pp. 1-6.

Sebenius, J. (2017) ‘BATNAs in negotiation: common errors and three kinds of “no”‘, Negotiation Journal, 32(2), pp. 89-99.

Siregar, I. (2019) ‘Supplier selection by using analytical hierarchy process (AHP) and techniques for order presence methods with similarities to ideal solutions (TOPSIS)’, Journal of Physics: Conference Series, 1339, pp. 1-5.

Taherdoost, H. and Brard, A. (2019) ‘Analyzing the process of supplier selection criteria and methods’, Procedia Manufacturing, 32, pp. 1024-1034.

Wang, R. and Li, Y. (2018) ‘A novel approach for green supplier selection under a q-rung othorpair fuzzy environment’, Symmetry, 10(12), pp. 1-28.

Wang, T. and Tsai, S. (2018) ‘Solar pannel supplier selection for the photovoltaic system design by using fuzzy multi-criteria decision making (MCDM) approaches’, Energies, 11(8), pp. 1-22.

Wang, T. et al. (2017) ‘Integrated supplier selection framework in a resilient construction supply chain: an approach via analytic hierarchy process (AHP) and grey relational analysis (GRA)’, Sustainability, 9(2), pp. 1-26.

Zhao, J. et al. (2017) ‘An extended VIKOR method using intuitionistic fuzzy sets and combination weights for supplier selection’, Symmetry, 9(9), pp. 1-16.

Appendix