Executive Summary

Efficiency is a strong competition tool in businesses. It reduces the cost of production and leads to more satisfied customers. On the other hand, satisfied customers are an increased business to an organization. When pondering of a system that can point out areas of inefficiency, Motorola Company in 1981 innovated a system called Six Sigma. Six sigma is a management tool which approaches management from a scientific angle. It analyses an entire organization’s processes and by creating relationships and data analysis, the area with a deficit is recognized. The next step is to define the problem then come up with a number of alternatives to improve the system. The end result is a full efficient business.

Project Overview

The project is aimed at implementing a six sigma management method in company A. it will analyze the processes that must be undergone to see the project success. Efficiency in a business has numerous benefits to the business. It gives a business competitive advantage; to attain efficiency, there is need to ensure that all business processes are adequately addressed. In 1981, Motorola- a leading phone manufacturing company in United States of America developed a management tool that aims at attaining efficiency in business processes.

Despite that the project had been innovated to be used in the company; it has spread too much business in United States and other places in the world. It has also been incorporated in management syllabus. The system is called six sigma. When a company implements a six sigma procedure, it ensure that there is efficiency in all processes in a business it uses scientific methods like data analysis to make decisions in a certain area. The process aims at attaining specialization in areas of interest in a way that the end result will give an overall efficiency in an organization. It creates special infrastructure and labels the users of such processes as “Belts”.

There are “green belts” and “black belts” among others. After developing a certain route of efficiency, it lays down steps that must be followed to all people who are working in a particular area. The steps are regarded as the path of efficiency. The path minimizes wastes in all aspects as it aims at realizing the areas of defect. Improvement of a prevailing procedure follows after that has been attained. The management tool analyses any derivative from perfection and offer management with an overview of the areas that they need to look into for a full efficiency. This paper looks into the process involved in a six sigma implementation. It will discuss the management tool from its inception all the way to final implementation of a hypothetical manufacturing company.

Project Scope

The management system assumes that if a company has more than 3.4 defects, then they said company has a problem that need to be addressed. The method acknowledges that there is no 100% efficiency level; however it is of the option that the highest attainable efficiency should be attained. It is of the opinion that there are some areas in an organization which can be improved to attain full efficiency. It works with the following objectives in mind

- Ensuring customer satisfaction – this is attained through continuous improvement of processes in addition there is the customer care that they receive from staff and should guarantee satisfaction.

- Defect- failing to deliver what the customer wants the management tool ensures that there is complete satisfaction of customers by quality products free from defects.

- Process- internal procedures need to be looked at to ensure that there is efficiency in production processes

Project charter

Company A is a manufacturing company which deals with packing of human food. It is located in a busy town in United States of America. The target customers are both local and international customers. To reach its customers, the company has online internet and marketing services where a customer can order and pay for goods. There after when the deal is sealed, the company arranges for transportation of goods to the customer.

The management has been faced with an issue where there has been increased cost of production, increased customer complaints, and reduced sales. After consultation, it was decided that there is need to have a management tool that can cure the situation. The final result was that a six sigma management tool should be introduced. The following is the process that the management will use in implementation.

Work breakdown procedure

The initial stage of a six sigma if for management to agree and understand the need to develop a six sigma management tool; when the decision has been reached it requires them to understand the prevailing condition. The first step in making a decision to implement six sigma management systems is defining the challenge that calls for a attention. They are involved in asking which areas require the change. Why is the change important? Generally to have a job well-done, it is of great importance that the people involved starting from the beginning. Decision making is not an exemption. In this stage, a good context of the problem is grasped.

It is only after getting the correct understanding of the problem that he/she can make a good decision. Concerns of customers are noted, the trade of profit is analyzed. Since company A has been operating well then there has been an almost immediate change, it means there is a place where there are defects. These defects maybe in processing course, in advertising, pricing or even distribution, it is the tapes of management to realize where.

The next stage is for the management to gather all relevant data and facts. It is from the facts and data that he develops various alternatives of choices that can be used to solve the problem at hand. Customers who have complained may be called to give more details, production targets reviewed compare the company with other companies in the same industry, consider data from published and unpublished sources. The statistics will also be the ones that will support the final decision.

There are various methods of collecting data; they include researching, brainstorming, and experimentation. It is the manager’s duty to choose the right method to adopt because different problems call for different methods. When adequate data has been collected, then the company has a base to make the right decision. The following was what the management realized;

- Production has sometimes been delayed because of lack of raw materials

- There has been a lot of waste of food stuffs

- Customers are complaining of system/ Company A’s system failures

- Local customers are complaining that they are taking long before they are served

- There has been an increased payment to local council of pollution tax

- Employees are not motivated; some look for unreasonable explanations not to attend their duties

- There is a 10% reduction in sales

Depending on the problem, the people to be consulted differ. However, an effective manager should ensure that he/ she consults those who matter and those who know. Consultation assists in making a more informed decision and assists in generating more alternatives of choice. Their opinions and viewpoints should be considered in the final decision making, but the manager should always keep in mind that it is his/her responsibility to come up with the right decision. After taking time and pondering over the issues; time taken depends on the urgency of the decision, he/she chooses and implements the best alternative.

At the initial stage a lot of support of the decision is required to ensure that the whole organization or the departments concerned have adopted it effectively. It is not always that a decision made bring the expected results; thus feedback from the people on the ground and the general performance of the business should be sorted, so as areas that need improvement are recognized. In-case an area that needs improvement has been recognized, it should be addressed appropriately.

Certainly a decision to have a six sigma tool of management will change a number of things in an organization; the following are some of things that the management of six sigma should expect in the organization;

- Organizational structure; this is the way an organization set up is, it may be affected by the change about to come

- Addition/removal of another department; some departments may prove unworthy and as the source of inefficiency, they may be script. On the other had, there may be need to develop a monitoring department which will be mandated with the task of overseeing the entire process

- removing procedural barriers to experimentation and change; these may be bureaucratic processes, some employees may be sucked, some deployed in other department, and an additional employees may be required

These are processes that involve top management to be fully involved and understand the trend and effect of the process.

When all is set the next step is moved.

Communication Stage

Company’s A management understood the situation, the next step is communication among all stake holders. This is important since the company will be able to understand first hand information. The following are the stakeholders who require to be consulted;

- Customers (both local and international) an interview should be arranged between the company and the customer; it involves those who have companioned and the loyalists. For international customer they can be called or communication conducted via the internet.

- Creditors, they are the lenders of capital; they ensure that a business has adequate supply of goods and services and payment made later. When a business is not performing well, they will be affected since they peg their success on the business. Alternatively, one of the areas realized when understanding the question is that there has been a delayed supply of goods (raw materials). A discussion is set with them to realize the areas that may have resulted in a problem.

- Employees, they are the people on the ground; they are involved in producing of good and offering services to the customers. They are important in the process since they will directly be affected by the system. Other stake holders will get the net effect but real actions are with the employees.

- Stake holders like shareholders may be consulted. There are times that shareholders have crucial information that can assist in devising means to improve services. Their views should be considered.

This early employee’s sensitization may start where they are explained of the changes that are likely to occur in the organization. Before a company adopt a new system of doing things, there is need to appreciate that the new way can only succeed if the employees are positive about the change. This calls for a gradual process of implementing the change. The organizational culture is one of the factors that can affect the change negatively or positively. The change agents should understand this well before implementing the change program.

In this stage there is full understanding of the need for a six sigma implementation. The following are the things that should be left defined;

- The nature of the problem that is to be solved

- Have an implementation team which will pioneer the entire process – the team can be outsourced or from internal

- Create a team charter, project charter, and shareholders analysis

- It is in the same stage that the company should draw and interpolate SIPCO (Suppliers, Inputs, Process, Outputs, and Customers).

When developing a SIPCO Chart, it is necessary to follow the following sequence of activities;

- Develop an appropriate method where employees and stake holders can give information on various areas in the process.

- Make a high level process chart or process map. This should involve all the key areas that are undertaken in the department/area of review.

- On the specific review area, identify and record the Outputs of this Process.

- Identify the market segment and target customers who are directly affected by this area. Customers are not limited to external customer but internal customer equally important

- Identify the Suppliers of the Inputs used in the area of review. This may be other departments in the same company or an outsider (Taylor, 2008).

Measure

This is the third state which is more time consuming; this is because the management need to device measurement to be used to gauge the performance of the entire organization. This is though in departmental parameters. This stage the management with the assistance of departmental head should devise minimal standards required to be set for an appropriate implementation. This happens after understanding the potential of a certain process. It is appreciated that it may not be possible to get a 100% outcome out of the projects/process in an organization; however there is a minimal level that the system should not go.

For example in company A, the packaging department has a capacity of packing 20,000 packages in a day. However, this is dependent on other processes before it reaches to packing a minimum can be set on that. Number of packages to be packed in a day to the minimum are 17,500, when such a target is not attained then there is a cut back to realize where is the inefficiency, are the packaging department not working as expected? Are they getting enough supplies from the other parties? All this will cut back to where a problem originates from.

In terms of service there is a stipulated time that a customer should be served. In this case there is need to give the rotation time. For example, the company receptionist should ensure that she is up to date with the occurrences in the organization so that at any one point she can have a solution to all issues at her level. Those issues which she can’t solve should be escalated to the appropriate person. Here the set turnover time can be set as three minutes.

After the set target has been made, the next step is to evaluate the level of deviation that the services or goods have. Key areas that have defects are identified and given a weight. There are areas that level of deviation is dependent with the level of efficiency in a prior process. All these should be identified. Areas with the highest deviation should be given an immediate attention. Being objective is important in this stage because it is the stage that a direction is shaped and if not gotten well the entire process will not be a success.

Analyze

This is the fourth stage where the data collected are analyzed. The most important thing is to understand the deviation level, the relationship between deviations and the areas that require immediate attention. Inefficiency in one area leads to inefficiency in another area, thus the source area should be interpolated and problem addressed directly. There are different ways of analyzing data which can be used they include;

- Z-test- this is based on normal probability distribution and its used for judging the significance of several statistical measure, particularly the mean of a sample. The same test is used for judging the difference between mean of two different samples.

- T-test- this is based on t distribution and considered appropriate for judging significance of the difference between mean of two samples. The relevant test statistic ‘’t” is calculated from sample data then compared with its probable value based on t distribution read from “t” statistical tables.

- The chi-square- this is based on chi-square distribution and is used for comparing sample variances to a theoretical population variance

- F-test- this is based on f- distribution and is used to compare the values of two independent samples. This test is also used in context of analyzing the variances called “ANOVAs”. ANOVAs are used for judging significance of more than two samples means one at a time. After it has been calculated it is compared with probable values in the f-ratio tables

After testing the data, then an in depth data understanding for implementation is done it follows the following steps;

Understanding data will involve going through the data collected again and getting the general flow of the data. The management should note the kind of impression that the data seem to give. This though will not shape my conclusion but will focus it in a certain direction. At this point those data that are to the extreme are noted.

The next step is realizing any relationship among data. At this point critical thinking will be used to derive meaning of the data and pattern. The wide secondary collected for an insight understanding of industry trends will be reviewed to assist in making an informed conclusion. A review of the aim of the research will be done and conclusion made.

Correlation co-efficient is also calculated to ensure that an understanding of the entire situation has been grasped.

During this period there is need to have well defined Cause and Effect diagram, Regression analysis, and Flow diagrams.

The gap can then be analyzed in financial terms; areas of high inefficiency should be well understood. Correlation co-efficiency gives the level that one process affects the other. It shows which the direction that the problem is following.

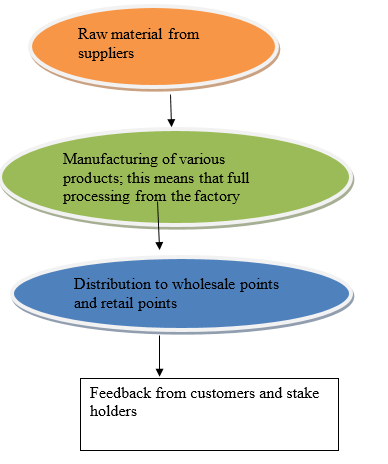

The following is a sample cause effect diagram;

For a process to be completed, there are always a set of processes which have taken place before the end point. This is what is defined by a cause effect diagram. In this case one process leads to another and thus inefficiency in a preceding one leads to inefficiency in a later one. Using the diagram is beneficial since it cuts back and as it looks for the main cause of a problem. For example in a manufacturing process, the start point is always raw material supply. This is done by trusted suppliers; if they fail to supply; then the packaging department will have no task to do. Analysis may start from packaging then traced backwards.

Improve

Now the management/implementation team understands the problem at hand, has a well defined picture of what is going on in an organization, understand departments with inefficiencies and the financial implications of the gaps. The next step is to devise a number of possible solutions to be implemented. Here staffs should be fully included. Alternatives are derived and the best alternative among the many is considered. It is important to follow a scientific managerial decision making process. Managerial decision-making is the process through which managers arrive at the alternative solution to a given challenge facing an organization.

The success of an organization is dependent on the quality of decision made by its manager. One of the major attributes that make a good manager stand out is his or her decisiveness. The quality of decisions made will directly be reflected in the performance of his or her organization.

After the alternative has been chosen, then there is support from all corners, these will involve management offering direct support to departments in attaining their new set goals. Many are the times that need for frequent meeting at departmental level or the entire company is important to discuss any issue that might have cropped up during the implementation. Time frames are important in this stage to ensure that attainability of the new goals set is possible. There are times that a short time evaluation for example weekly recording can be made to measure progress of the project.

At this level there is use of Force field diagram, Stakeholder Definition, and FAME to explain progress.

The above diagram shows a sample of Force field diagram which gives a picture of the trends that happens in an organization. The right hand side shows forces against change while the left hand shows forces for change. Whichever the situation, there should be an overall change for the better if a Six Sigma is operating well.

Control

The last stage is control of the implemented project. When controlling there is an already set path through which processes should follow. They should start from somewhere heading to another area. When under control, there is need to have a well defined personnel’s who have been recognized to have a certain efficiency level in an area, they should be empowered to conduct their duties. If there was a department that was scrapped, then any effects as a result should be understood and addressed effectively. Project management plans are developed to ensure that the project sustainability has been attained.

Though it is the final stage, it carries a lot of weight since it oversees that every process in the organization has been fully upgraded. It is not a onetime process but is a continuous one. Feedback is of importance and considered for further decision making. The following are some of the tools for this work quality control process charts, control charts, and standardization practices.

Time and again there may be possibility that the company devises better ways of doing things and this should not be locked out by the system. There is no most efficient system but it is unique to a particular organization and industry. All managerial departments should actively participate in this process for example, the human resource department is given the mandate of ensuring that adequate employees are available at all times in the organization; it has both quantitative and qualitative aspects. Qualitative means the right number of employees and qualitative means employees with right skills.

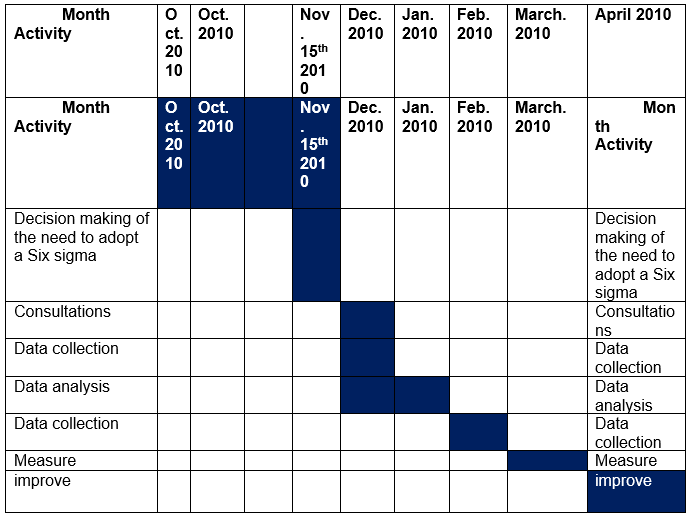

Gantt chart

The chart below shows a sequence of activities with their time frames,

Control though given a time frame is a continuous process.

Recommendation and Conclusion

Efficiency in an organization is attained when all defective procedures are recognized and remedy for them sought. To know the weak link in a system, there is need to undertake a thorough audit on all processes taking place. It is worth noting that there are some processes which are so crucial in an organization that when they have a certain level of inefficiency, then it spreads to an entire organization. In a manufacturing plant, the processes start from acquisition of raw material to the end customer. Six sigma is a management tool that assists managers to systematically audit their processes to ensure that all defective areas have been recognized and remedies derived.

Implementation of a six sigma takes a number of steps; the first step in making a decision to implement six sigma management systems is defining the challenge that calls for an attention. They are involved in asking which areas require the change. After the management has understood the situation, the next step is communication among all stake holders. This is important since the company will be able to understand first hand information.

This is the third state which is more time consuming this is because the management need to device measurement to be used to gauge the performance of the entire organization. After gauging performance, the next most important thing is to understand the deviation level, the relationship between deviations and the areas that require immediate attention. The next step is to devise a number of possible solutions to be implemented.

Here staffs should be fully included. Alternatives are derived and the best alternative among the many is considered. It is important to follow a scientific managerial decision making process. The last stage is control of the implemented project. When controlling there is an already set path through which processes should follow. They should start from somewhere heading to another area. When under control, there is need to have a well defined personnel’s who have been recognized to have a certain efficiency level in an area, they should be empowered to conduct their duties.