Supply Chain Management

Firstly, the paper presents the concept and main purpose of the supply chain. Supply chain management is the organization, planning, control, and regulation of the flow of goods, starting with the receipt of orders and purchasing raw materials to ensure the production of goods, including the optimal cost of resources for the final consumer (Koberg 1087). This strategy aims to obtain a measurable aggregate economic effect, namely reducing costs and meeting the demand for final products.

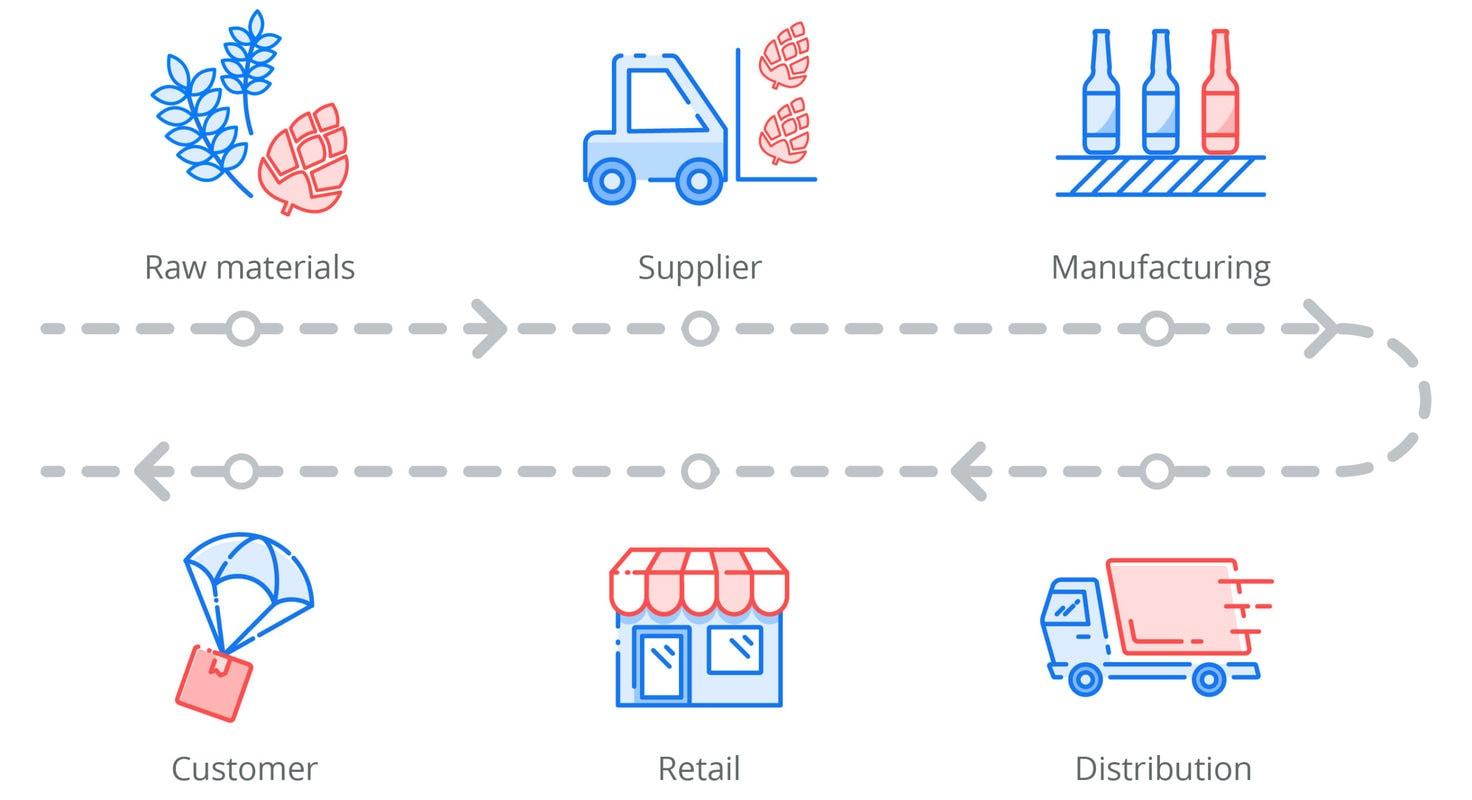

The image contains a description of supply chains affecting a number of activities, including procurement, inventory management, product lifecycle management, transportation management, order management, and more.

Supply Chain Models

Next, the paper presents the main models of supply chain management. The continuous flow model is suitable for manufacturers of the same goods; this model allows them to establish stable contacts with partners and sell low-cost products thanks to the same production technology. The fast chain model is suitable for manufacturers who create perishable goods. Entrepreneurs use the chain to forecast demand for specific goods accurately. The agile model is used to make urgent orders; it is popular among entrepreneurs because of the combination of quality and efficiency in a short period of time (Koberg 1085). The universal chain is the supply chain operating model because its purpose is to standardize processes and results.

The five elements of supply chain management

In fact, there are many types of supply chain management systems, but the supply chain operating model is best for explanation and demonstration. The model consists of five elements; we will discuss each component in detail.

Planning

Planning includes supply and demand management. This is an important first step because it determines the further actions of the company. If you do not plan demand and supply correctly, then the following stages of the chain will be inefficient and create losses for the business.

Specific planning activities include the following requirements.

The planning element includes balancing resources according to requirements and establishing further communication throughout the chain. At the planning stage, the parties also agree on basic rules to determine the effectiveness of the chain at a particular stage and its possible modification. For example, harmonized rules govern transportation, property, or compliance with the law to ensure that authorities do not seize a consignment of goods as illegal (Kache 14).

Sourcing

The next stage is sourcing. The importance of this step is that the choice of infrastructure sources or suppliers can seriously affect the result. That is, inferior quality raw materials and unscrupulous suppliers can lead to losses even at a lower cost of their services. Business losses can be manifested in a lack of raw materials, poor quality, and higher cost of processing raw materials, which will subsequently affect the increase in the total price of goods.

Legal issues are also a critical component of this stage. Such as determining the details of work with suppliers, terms of delivery, losses in case of untimely delivery of raw materials, or transportation of the finished product (Koberg 1087). Also, an important point is a payment. Usually, payments are received after checking the quality and quantity of the ordered goods.

Production

Next, we will consider the third and basic element of the supply chain. The production step involves the transformation of raw materials into finished goods. The stage of manufacturing the product includes the development of manufacturing technologies and the actual process of change of raw elements into the finished product, design, and packaging. The manufacture of goods is characterized by the involvement of a large number of employees, so checking their qualifications and ability to perform the work is mandatory. After the release of finished products at this stage is the inspection and transportation of goods. The transit itself should be carried out according to the route that was laid at the previous step (Koberg 1089).

Delivery

Delivery of goods is the final stage, after which the goods are with customers. Delivery means not only transportation of goods to the future owner. The process includes order management, resolving issues, and finding premises for storing consignments of goods and, ultimately, transportation (Kuldeep 880). At this stage, the goods are also checked for export and import. Great importance is attached to the supervision of the storage of goods, namely the observance of specific conditions for maintaining the quality of goods. Storage conditions specified by the manufacturer may be specific requirements for lighting, temperature, or freezing of goods. Accordingly, if the conditions are not met during storage and transportation, the cargo will be damaged. The last component of the delivery phase is ordering from customers and invoicing, after which customers become the owners of the goods.

Return of goods

Return of goods is not a mandatory element of the supply chain; return occurs if provided by the terms of the signed contracts. Therefore, the buyer cannot return the goods without good reason. According to the concluded agreements, there are certain conditions of return, such as defective products, improper appearance after transportation, and defective boxes or containers (Kuldeep 880).

When returning goods, it is necessary to make a list of faulty items and calculate their cost, including the cost of delivery and possibly sending a new batch. In order not to receive huge losses, the business owner must, when concluding a contract with suppliers of raw materials, prescribe the possibility of compensation for poor quality raw materials. Similarly, with transport companies, it is necessary to indicate the compensation for damages for non-compliance with the terms of delivery.

The importance of the supply chain for business

Lastly, I propose to assess the benefits and importance of supply chain management. The most crucial advantage is reducing the total cost of goods due to stable relationships with suppliers, which reduces the time to search for raw materials. Established links with the transport company, employees, and long-term employment contracts allow you to respond quickly to customer orders and work more efficiently. A well-established supply chain facilitates the rapid fulfillment of orders that consumers value (Kache 30). It is essential for the customer to receive a quality product as soon as possible due to all factors, the business owner’s profit and competitiveness in the market increase. Therefore, in today’s world, more and more companies use supply management.

References

Kache, Florian. “Challenges and Opportunities of Digital Information at the Intersection of Big Data Analytics and Supply Chain Management”. International Journal of Operations & Production Management, vol. 37, no.1, 2017, pp. 10-36.

Koberg, Esteban. “A Systematic Review of Sustainable Supply Chain Management in Global Supply Chains”. Journal of Cleaner Production, vol. 207, no. 10, 2019, pp. 1084-1098.

Kuldeep, Lamba. “Big Data in Operations and Supply Chain Management: Current Trends and Future Perspectives”. The Management of Operations, vol. 28, no. 11, 2017, pp. 877-890.

Kuldeep, Lamba. “Big Data in Operations and Supply Chain Management: Current Trends and Future Perspectives”. The Management of Operations, vol. 28, no. 11, 2017, pp. 877-890.

Stages of Supply Chain Management, Unleashed, n.d. Web.

The benefits of using supply chain management, PngKit, n.d. Web.