Abstract

The Coca-Cola Company is a very large multinational company, should employ a number of well-stated frameworks of action as it contracts to supply cola liquid in the Olympic Games in London. The company should in this case consider its upstreams and decide on what quantities of raw materials will be sufficient to reach the required production levels. Generally, the company should pursue improving its logistic and supply chains in enhancing efficiency in the provision of its commodities

Introduction

The Coca-Cola Company is one of the largest multinational corporations majoring in the production of soft drinks needs to address the management of its supply, so as to enhance its prosperity. Based on this aspect, therefore, the company will face the problem of meeting the global market requirements; whose links with their potential supply bases should be well managed. In the current highly technological trends, the company must employ viable market inventories; both in its logistics and supply chain options (Garrison et al., 2007).

The global acceptance of the commodity to its global markets influences its supply chain, whereby an appropriate design for the supply design has to be invented. In the contemporary current society today, the company needs to employ a sophisticated model of its production and distribution strategies which will lead to the acquirement of a stable and reliable market worldwide. On this basis, therefore, the company should ensure that; its operations and planning systems are advanced and the management of the company’s real-time inventions and processes (Haag et al., 2006)

On this basis, therefore, as the Coca-Cola Company plans to supply canned cola at the London Olympic Games, it has to incorporate a highly sophisticated logistic and supply chain process which must be well developed in the wider concept of the global context. This paper will present various processes involved in the analysis towards the development of a supply chain design, which will ensure an effective and sufficient supply of canned cola by the Coca-Cola company in the year 2012 London Olympic Games (Haag et al., 2006).

Supply chain performance

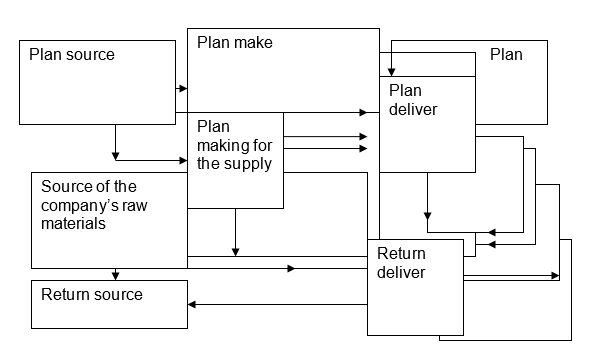

The supply chain that follows is meant to measure the Coca-Cola company’s efficiency and its performance of its subsequent supply chain gearing to defining the correct supply chain operation model reference; as the company plans to supply its canned cola to the London Olympics games (Haag et al., 2006).

The Coca-Cola company should pursue appropriate metrics that will enhance an appropriate operation of its supply chain; through employing various process perspectives like the location of the material to be supplied should be near the market so as to meet efficiency in logistics. This will also ensure that the company minimizes its time wastage towards meeting the prospected dates, for the commodity supply to the markets and the general market expenditures (Garrison et al., 2007)

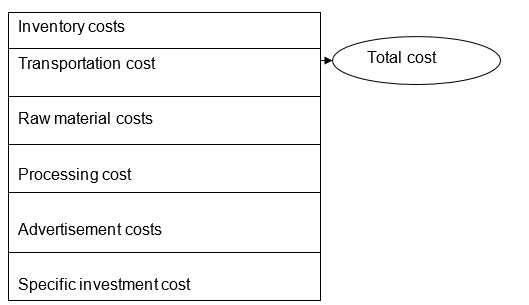

In absolute terms, the company should ensure its cost metric definitions are clarified and not exceeding the company’s expected returns from the supply chain. Generally, the total cost product line should put into consideration various factors some of which are presented in the following cost line structure (Haag et al., 2006)

The following chart shows the estimated costs which must be considered in the process of planning for the supply chain.

This is a model developed to determine the typical resources utilized in the marketing of the commodity. The supply chain model the Coca-Cola company will pursue towards the supply of the canned cola to London Olympic Games; should be of the right magnitude to meet the desired market levels. Team designs should be engineered so as to ensure that meet various market requirement so as not to lose popularity of the commodity in the market (Bosanko and Braeutigam, 2000)

Product demand model.

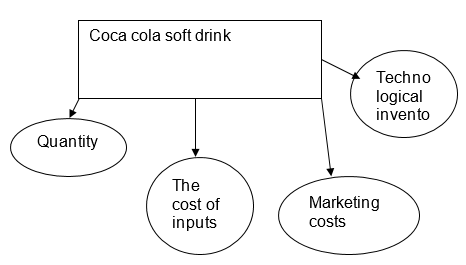

The product should also be properly engineered so as to ensure that, it meets all the expected standards as it paves its way to the market. In this respect, therefore, the coca cola company should organize a very detailed plan on the various engineering methods of the cola liquid it plans to supply to the market; so as to ensure that it meets the expectations of the customers (Garrison et al., 2007)

The chart below shows the general overview of the aspects that need to be engineered.

The company should in this case consider its upstreams and decide on what quantities of raw materials will be sufficient to reach the required production levels. The source of the raw material should be considered. In this case, where the Coca-Cola Company uses different raw materials in its production process, it is thus necessary to determine and define the sources of such raw materials. Labor on the other hand will be considered and its right sources are, considered so as to create efficiency in the production process. The following table shows the various inputs and their expected prices.

It should also be noted that the sources of both the raw materials and human resources will be from the European community so as to enhance the lack of inconveniences in the productions. In this case, most of these raw materials and labor resources will be chosen according to their prices; and any other costs to be incurred in their acquirement (Haag et al., 2006).

Considering the down streams of the company also, it has to be noted that the company has to maintain its other supply chains on to of preparing to supply to the London Olympic Games. This will involve, various strategies meant to expand the level of production and also to carry out a detailed survey of the market conditions, for the commodity produced (Garrison et al., 2007).

More precisely, the company should acquire the necessary statistics that will ensure that the correct number of the expected total commodities required to be supplied are well defined. This will ensure that the company acquires such data from the previous statistics of the prior Olympic Games. In this respect, therefore, the Coca-Cola company should carry out a survey on the previous attendance to the Olympic games and try to examine and predict for any variation in such numbers, which will enable the company to approximate the amounts of cola that it has to produce so as to sustain the market conditions in the Olympic games (Garrison et al., 2007).

For instance, a detailed survey of all required cola liquid cans to the Olympics games will help the company approximate the right amount of raw materials it will employ in the production process, so as not to go loses incase of overproduction or to underproduce leading to deficiencies on the consumption of the cola liquid I the London Olympic games (Bosanko and Braeutigam, 2000).

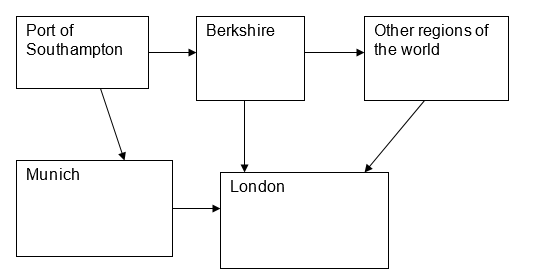

The production centers should be well linked to Munich city in Germany which is the entire European distribution center which will help in determining the appropriate mode of transport of the commodity to the Munich depot.

The model above shows various distribution channels that the caned cola should follow as it paves its way to the London Olympic Games. As shown the product will first be collected at the port of Southampton which is the national collection center of the Coca-Cola products (Garrison et al., 2007)

The products then are transported to the regional distribution center at Berkshire. The products will also be transported from Southampton to Munich city, which is the European distribution center for the Coca-Cola products. The products are then transported to London at the Olympic Games which will ensure that it reaches the intended, markets afterward. The rest of the Coca-Cola products are distributed to the rest of the world in the already established supply channels (Haag et al., 2006).

Europe is one of the major markets for the Coca-Cola company products will mean that there are already well-established channels; for the Coca-Cola products as the market, situations are already set (Bosanko and Braeutigam, 2000).

The company should ensure connectivity to the market conditions which may in the process of adjusting to expand its production level lead to any inconvenience.

In this perspective therefore the company should apply an improved network of communication which will provide an important link to the market globally (Haag et al., 2006).

To be able to meet the required market target, the company should develop specific policies that will govern the financial resources, manufacturing process and a continuous constant supply of its commodities to the already established customers on top of the supplies it intends to make to the London Olympic Games.

In this perspective, therefore, various team members will be employed to perform various functions towards achieving the requirements for the supply of the commodities desired (Garrison et al., 2007)

In this case, the Coca-Cola company will involve the following identities to perform the stated task.

Summary of the supply chain design for the Coca-Cola company

The Coca-Cola Company is a very large multinational company that should employ a number of well-stated frameworks of action as it contracts to supply cola liquid in the Olympic Games in London. The framework of activities as stated above will ensure that the company beats up any challenge that might crop up as it plans to supply its commodities to the London Olympic games as the plan is well detailed and all the strategies well organized ensuring efficiency in the supply of the company’s commodities (Bosanko and Braeutigam, 2000)

Generally, the company should ensure that it incorporates various strategies and modes meant to establish a constant and continuous supply of its commodities to the Olympic Games as planned.

Reference list

Bosanko, D. and Braeutigam R., 2000. Managing Business Supplies. 2nd Edition. New York: Wiley Publishers.

Garrison J., Noreen, E. and Brewer P., 2007. Supply Management Strategies for a Prosperous Business. 5th edition. New York: McGraw-Hill/Irwin Press.

Haag, S., Cummings, M. & McCubbrey, D., 2006. Management Information Systems for the Information Age. (3rd Edition). Canada: McGraw Hill Ryerson Press.