Introduction to Supply Chain

The world is increasingly getting competitive, and the pressure is mounting on supply chain units of every firm. The need to ensure that products move from the manufacturing plant to the consumer is on the rise as firms increase their production within various industries. According to Lan (131), supply chain has been under focus in determining how successful a firm is within an industry. Li (117) defines supply chain simply as a process where a product is delivered from the manufacturer to the consumer.

On the other hand, Wang (115) defines supply chain as a systematic process of moving finished products from their manufacturing points, to the final consumers. Other scholars have given different definition to supply chain, but the most striking and common factor in their definitions is that supply chain deals with the movement of products from the point of their manufacture to the desired destination where the consumer will access them.

Supply chain is taking a new dimension in the current society. The world has been reduced into a small global village where one can move easily from one place to another. Communication is now easier due to advancement in the field of information and communication technology. This is definitely a positive development that has enhanced this field. However, Lan (58) says that the more this field gets advanced, the more complex it becomes. Li (90) says that shipping in the late 18th century depended on large ships that would take years to reach their destination. These ships would take several months, and at times years, to reach the desired destination.

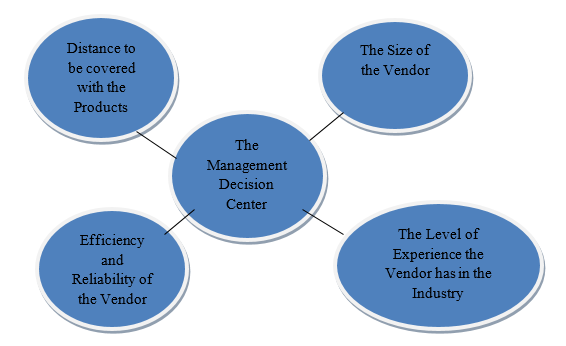

Using an engine propelled ship was, therefore, a massive development that has seen the time for goods delivery reduced. It is important to note, however, that in the current business world, the pressure that exists on supply chain officers, or logistics firms have been increased. Firms are currently under pressure to ensure that goods are delivered on time because any delay comes with some consequences. Time is a factor that has become very important in this field as every firm try to look for every little opportunity to gain competitive advantage over other firms. The following diagram shows some of the important activities in supply chain management.

It is because of this that scholars have been attracted to this field to try and unearth some facts that may enhance effectiveness of players in this field. There has been need to help understand how to deal with the current forces in this industry in order to enhance productivity of firms. Lan (112) says that in this 21st century, firms are doing their best to ensure that their products are always available in the market in order to maintain their customer base.

This means that movement of products from the manufacturing point to the point of sale should be very efficient. This will ensure that there is a continuous supply of the products in the market. The raw materials should also move consistently from their source to the manufacturing plant of this firm. This research focuses on vendor selection in supply chain management in the contemporary world.

Supply Chain History

The history of supply chain can be traced several years ago with the invention of trade. As civilization gained roots in various parts of the world, people became aware of the fact that they were gifted differently. It was becoming apparent that while one was gifted in farming, another was gifted in blacksmithing, pottery, weaving, fishing, masonry or even in the army. It was also becoming apparent that from one’s gift, an individual would produce more than he or she could consume.

A farmer would harvest a lot of produce that were beyond personal consumption. A potter could make several pots, most of which he would not be in a position to use. On the other hand, a soldier would need a pot, farm products, milk and fish to lead a normal life. This meant that there had to be found a way that such a solder could give a specific value to the farmer, fisherman, a potter and a weaver in exchange of their products. This was how trade was incepted.

Upon the inception of trade, the next challenge was to ensure that this final product reaches customers within the right time and when in good shape. At first, trade was done basically on the village basis. A farmer would deliver milk to the customer every evening or every morning with the help of a messenger. Maize would be taken to a simple open air market where willing buyers would come and make purchase of the product. That changed as the societies got to interact.

The use of caravans soon developed as there emerged long distance traders in Asia and parts of Europe. To help in this would be camels which carried goods to the market. As new regions were identified, large ships were developed to help reach these new markets for the product. These ships were propelled using wind energy, and they had their seasons. This changed with the invention of engines. The ships were then fitted with engines that enabled then travel faster, and without depending on wind for its movement.

Supply chain in the 21st century is completely different from that which was practiced before. Technology has completely transformed supply chain in various fronts. The current society is very sensitive of time that products take before reaching their destination. As mentioned earlier, the world has been reduced into a small global village where products manufactured in London would find its market in New York City, Sydney or in Cape Town in South Africa. There are some products that are highly perishable, but manufactured miles away from the market. A case in point is flowers that are harvested in East Africa but have their major markets in Paris, France.

Cargo ships would be used to ensure that this product reaches the market in time. According to Wang (92), in this 21st century, supply chain has become one of the major determinants of competitive advantage of a firm. The development of containerization has characterized the modern supply chain as firms struggle to standardize their products. Use of containers does not only help in easing transport process, but also in protecting goods on transit. Modern technology in information and communication has enhanced this sector a great deal. As Lan (92) puts it, in the modern days, supply chain is getting computerized and every movement of goods is monitored closely with the help of modern technological tools.

Supply Chain Optimization

Efficiency has become a defining factor in every department of a firm. Supply chain optimization refers to the process of improving the performance in the supply chain of a firm with an aim of increasing profitability and reducing costs as much as possible. According to Lan (119), in the past, it would be common to find cases where over ten percent of products on transit are damaged. Most suppliers were forced to deal with such losses and some would always consider this as a normal incident that cannot be avoided once goods are on transit. However, this is changing as the world experiences changes in various fields, especially in the field of technology.

The need to optimize supply chain processes has seen players in this industry struggle to come up with strategies though which they can minimize costs and maximize all the benefits that come from this industry. This means that management must understand the possible causes of threats and how these threats can be countered.

Supply chain optimization can take two main forms depending on the level of analysis that is taken. The first level of analysis can be a simple approach where a firm determines ways through which it can minimize all wastages or any form of breakage on the goods on transit. This strategy is appropriate for small firms where supply chain is very simple and uses few tools that can easily be accounted for. The second strategy can be a complex mathematical model that uses computers to generate a methodology of maximizing the profits of the firm as may be desired. Irrespective of the approach taken to realize optimization, the bottom-line if that the process should result into increased productivity of the firm as costs of production are minimized to the lowest level possible.

According to Wang (83), supply chain optimization is “the process of delivering products to the customers at the lowest costs possible in an attempt to maximize profitability of a firm. According to this scholar, supply chain managers are concerned with the best way to maximize profitability of the firm by lowering logistical costs. This is a situation where they are forced to formulate a way of delivering products within the shortest time possible and ensuring that the products are safe when they reach the market.

This involves increasing efficiency of every single section of the supply chain. According to Li (94), this involves “maximizing gross margin return on inventory.” This scholar says that supply chain will be focused on maintenance of the product right from the manufacturing point to the finale sale point. It involves ensuring that value of the product is maintained right from the point of production to the point where the product is delivered to the consumer.

A number of firms have come up with various techniques in value chain optimization. A section of the firms have preferred the use of best fit model in ensuring safety of the products in the market. In this model, the firms apply safety stock rules. In this strategy, the firm maintains safety of the product along all the channels that it may follow from the manufacturing plant to the final place in the market where it shall be delivered to the customers. Other firms have considered the use of stochastic techniques in their bid to ensure optimization of the supply chain.

In this strategy, Wang (67) says that “There is calculation of the most desirable level of inventory per article in each of the individual stores for the retail customers, while trading off the costs of inventories against the expected sales.” The result of this is an optimized level of inventory that is known to as the model stock. Coming up with a model stock is a complex process that in itself requires optimization. It requires a distribution requirements planning system that would enable the planner to develop a lean process that would meet the expectations of the stakeholders.

Supply Chain with solids

In the current competitive business environment, firms are coming up with various strategies to ensure that their supply chain is efficient so that they can achieve maximum productivity out of their internal operations. With tools such as Total Quality Management and Six Sigma, firms have come out strongly to improve their services and ensure that they are in a position to offer value to their customers at the least cost possible.

Lan (39) says that best practice in supply chain management is the best way to ensure that costs are minimized while maximizing productivity. When dealing with solids, it is important that the products rive in good shape. According to Dam (86), dealing with the solids in supply chain can be the simplest of the efforts in supply chain, and it can also be the most complex.

According to Li (68), supply chain management can be very complex when dealing with irregular shape bulky solid substances. Unlike the liquid or gas that would easily assume the shape of the container, solid products will have to be given a container that can accommodate their shape. Solid substance can develop stress in its transportation if it happens to be not only bulky and irregular shaped, but also heavy.

Dam (134) says that containerization was a concept borne out of the need to standardize solid products in a way that will make their transportation easier. According to this scholar, transportation of solid products was initially considered as an easy process as compared to transporting either gases or liquid products. However, with the invention of airtight containers, transporting of liquid and gas has become very easy.

Lan (84) says that what is now complex is to come up with ways through which the solid raw materials can be managed during their transportation. It is a fact that the best way of managing logistics of the solid products is through standardization. By developing standards for the products, it becomes easier to pack them in a container for their safe transportation. The product, when properly arranged in the transport channel, will reach the market within the desired time and in good shape.

Vendor selection in supply chain

Vendor selection is a very important process that would have massive impact on a firm. It would always determine success or failure of a firm, depending on the approach taken to select an appropriate vendor. Firms have a capacity to select a vendor that is most appropriately positioned to meet its needs within the market. It is important to note that vendor selection can take a simple approach of determining the supplier that is appropriate for the firm, or a more complex approach that involves mathematical models. These models are used to rank the best suppliers with the capacity to meet expectations of the firm. The diagram below shows some of the factors that a firm would need to consider when selecting an appropriate vendor.

When selecting an appropriate vendor to use, it is important to consider a number of factors that are relevant within the field. Some of the factors that management should consider when selecting appropriate vendor is the size of the vendor. When the vendor is large, it may be appropriate to consider it because of the ability to offer a variety of what is needed. This is because of the challenges that a firm may face in dealing with small scale vendors who are coming into the industry for the first time. Another important factor that will always determine the choice of vendor in supply chain is the level of experience of the vendor in the industry.

When selecting a vendor, a firm will always consider the risks that may be encountered as a result of dealing with a new and inexperienced vendor in the industry. As Lan (37) says, movement of products from one place to another is always associated with a number of risks. Some of the risks may deal a serious blow to a firm if appropriate care is not taken. When selecting the appropriate vendor to engage, it is important to consider using the strategy that would offer maximum security.

The efficiency of the internal structures of the vendor will help determine how best security can be guaranteed when one decides to use a given vendor. If a vendor has well equipped logistical facilities that it uses to deliver its products to its customers, then it should be considered when selecting the appropriate vendor for each industry.

If the vendor lacks this, then it may be prudent to consider selecting a different vendor that ranks higher. Efficiency and reliability of a vendor forms another important aspect to consider when determining the appropriate vendor to select. According to Dam (97), a firm should always come up with a simple mathematical model that can help it rank vendors based on different facets. The vendor that ranks highest, especially in efficiency and reliability, should be considered. This is to ensure that the firm is assured of product delivery in time. This will help eliminate cases where some vendors fail to deliver the products resulting in massive inconvenience to the customers. Another factor will be the distance that should be covered in order to reach the desired market with the product.

When transporting goods it is a fact that there are incidents that would lead to breakage, especially if the distance is long. The more goods are handled the more they can easily break. When choosing the right vendor, it is important to consider the distance factor. All these effort should be focused in selecting of a vendor in the supply chain that would offer maximum satisfaction. This will help a firm manage the market competition that firms are currently struggling with.

Works Cited

Dam, Jespersen. Supply Chain Management: In Theory and Practice. Copenhagen: Business School Press, 2005. Print.

Lan, Yi-chen. Global Integrated Supply Chain Systems. Hershey: Idea Group Publishers, 2006. Print.

Li, Ling. Supply Chain Management: Concepts, Techniques, and Practices Enhancing the Value Through Collaboration. Hackensack: World Scientific, 2007. Print.

Wang, William. Supply Chain Management: Issues in the New Era of Collaboration and Competition. Norwood Mass: Books24x7. 2007. Print.