Read this paper to get familiar with capacity planning in operations management. Here, you will find capacity planning in operations management examples, shareholders management, factors affecting different types of capacity planning, and capacity planning issues and challenges.

What Is Capacity Planning in Operations Management

Although there are different ways of defining or describing capacity planning, one aspect is common in all the definitions. Capacity planning is globally defined as the ability to deliver something in a specific period of time. The phrase adds different dimensions which cover the skill to hold, receive, store and accommodate in a business (Lam, 2014).3 Nonetheless, it is not only the skill to achieve the aforementioned properties but also the ability to do so. In simple terms, the capacity refers to the amount of output that a business is capable of producing over a specified amount of time.

This includes the amount of time, the constraints on the system that is involved in the production as well as the number of services and tangible goods produced. On the other hand, capacity planning is the ultimate utilization of resources by predicting production requirements (Lam, 2014).3 This is feasible in many areas and departments in a business setting. It may be functional in an organization’s computer network or storage system. In addition, it can be very useful in the human resource department, and the manufacturing department, among other things.

Why Capacity Planning Is Crucial

Every business, regardless of its size and operations, can benefit from capacity planning. Through this strategy, businesses can benefit from numerous financial advantages that accrue from it. Evidently, long term strategic planning is very crucial for the success of any business entity. It is the long term plan that dictates the success and sustainability of any business (Lam, 2014).3 This paper seeks to discuss and prove the benefits of capacity planning in managing an operation.

In managing any operation, the flow of information is very important. Information is one of the success factors that a specific operation can have (Lam, 2014).3 In many cases, project planning fails because of poor communication and inefficient flow of information. To enhance the chances of succeeding in operation, communication cannot be overlooked. In this regard, capacity planning allows the possibility for the analysis and decision-making process. Operation managers are responsible for ensuring the operation at hand is successful.

In order to achieve such a success, one has to take into considerations a lot of other different factors. Communication flow, being one of the factors to consider, constraints that the client-server relationship should also be checked (Kim, Gupta, Urgaonkar, Berman, & Sivasubramaniam, 2014).1 For the success of an operation, the operation manager must have the basic supplies that he or she requires in order to achieve the desired goals. This includes machines, location/working space, and the required skilled labour/human resources, enough time/deadline to complete the work, and enough stock for production (Kim et al., 2014)1.

This means the manager must utilize the available resource in the most effective manner. To achieve good results in operations, one needs to plan ahead of time in order to be sure that all the anticipated risks are covered in the risk management plan. Therefore, capacity planning is one of the most useful strategies. It is one of the greatest elements of a functional business entity (Kim et al., 2014)1. However, implementing or adopting a capacity planning process, one needs to be very careful and prudent in the process.

Effects of Failing to Use Capacity Planning

The capacity planning, when handled with care and prudence, can singlehandedly influence a business’ profits. However, if thoughtful engagement and care are not given to the process, it can be disastrous. When a company or a business does not have a capacity planning strategy, the dangers exposed to its productivity are immense.

Types of Capacity Planning

The capacity planning, just like any other form of planning, involves the four main pillars of planning

- Long term capacity.

- Medium-term capacity.

- Short-term capacity.

The Long-Term Capacity

The long term capacity of any organization or any business entity is highly dependent on other factors. These factors include

- Design capacity.

- Capacity planning.

- Sustainable capacity.

- Effective capacity.

The design capacity refers to the total output that an organization is capable of producing under the utmost ideal working environment. A perfect example of a product that has been thoughtfully designed is the Disney theme park (Liu, Sawik, & Papageorgiou, 2014).2 The Disney theme park has been designed in such a way that every part of the service delivery process offers the maximum customer satisfaction. The company has put in practice particular measures to ensure that the customers experience fun from the moment they pull into the parking until they leave (Liu et al., 2014).2 Here, nothing is a hustle and the employees are always smiling and are ready to offer any kind of assistance.

The facility is always clean, and everything is maintained in perfect order. The company consistently improves its services in response to the changing demands and customer changing preferences. This helps the company to retain its customers and attracts new ones (Liu et al., 2014).2 The management understands that processes are very crucial to customers. Capacity planning, on the hand, refers to the ultimate production that equipments can handle under the normal working conditions.

Thirdly, the sustainable capacity refers to the total output that can be achieved considering all other abnormalities, like machine breakdown and the cost of maintenance (Liu et al., 2014).2 Lastly, the effectual capacity is the best or the optimum production level. Through long term capacity methods, one is capable of managing his or her operation effectively. Without this kind of a plan, it is impossible to be prepared for the unforeseen calamities.

The Medium Capacity

The medium capacity plans run from 2 to 3 years. These are capacity plans that are developed to monitor the organization’s output levels in a period of beyond one year.

The Short-Term Capacity

These are plans that run the business on a daily basis. As the saying goes, ‘what gets measured gets done’. This is the guiding principle in the Capacity planning systems. The Capacity planning is very important to many organizations, and this has led to the huge investment in it (Liu et al., 2014).2 Many organizations are spending a significant amount of resources and investing their time on implementing and formulating the Capacity planning. Through the Capacity planning systems, an organization is able to reflect and identify the issues of significance for the business. The success of an organization is effectively assessed through Capacity planning.

However, the trends in Capacity planning have been taking a new turn every other day. For instance, in the 80s, there was a growing demand for a shift from the traditional performance measures to adopt a more responsive strategy (Liu et al., 2014).2 The numerous shortcomings in the conservative performance measures led to the revolutionary overhaul to the new measures that reflect organizations’ competitive nature. Organizations need to control their measurement systems and ensure that they consistently remain relevant in the current competitive business environment.

In order to achieve this, there are different phases involved. The first phase involves identifying the factors that inhibit the transformation of the Capacity planning systems. The second phase includes controlling the evolution of the system. This includes managing the system so that it reflects the organization’s strategies and goals. Nonetheless, it is important to note that the changes in the performance measures will most likely influence changes in the organizational culture, among other changes.

Therefore, as an organization seeks to adopt a new Capacity planning system, these other factors should also be considered. All the same, appropriate and consistent Capacity planning systems are the factor that cannot be compromised under any circumstances.

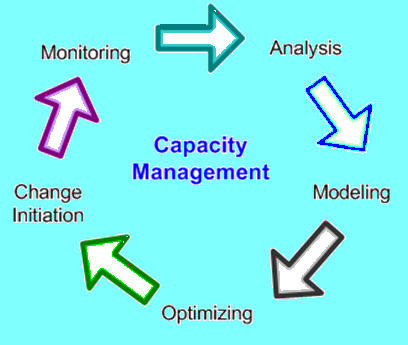

Capacity Management as a Discipline

Capacity management is the study of planning, organizing, motivating and controlling resources in an effort to achieve specific goals. Projects, on the other hand, are specific activities that are bound by the time or schedule. Projects can be either short-term or long-term, but in both cases, they have an end. Projects are run with a limited budgetary allocation; hence, management of such funds is very crucial. In project management, the effective utilization of the limited resources in terms of financial, time and human resources is very crucial. The main challenge of a project is realizing the project’s goals as well as objectives in the midst of the underlying risks.

Industries in Which Capacity Managers Are in High Demand

Currently, the rising demand for a capacity manager is spreading all over the world and in almost all the industries. The ICT Technology industry, for instance, is one of the greatest employers of capacity managers globally. Capacity management in the technology world is becoming a very basic tool of success in the business. Another similar employer of capacity managers globally is the construction industry.

With the growing demand for housing, both domestic and commercial, the services of capacity managers are increasingly needed. The energy industry is also a major user of capacity management skills; hence, it demands a great number of project managers. With the rising demand for energy, more projects meant for energy creation are being rolled out globally. Such projects require a capacity manager to succeed.

The General Role of a Project Manager

The role of a Capacity planning manager is to influence the available resource in order to achieve specific goals. In that light, it is clear that the Capacity planning manager is the leader of a team, and he is responsible for the performance of his team (Lam, 2014).3 The Capacity planning manager plays three significant roles in a project, technical, transactional and transformational roles.

The manager might not be in a position to know all of the tasks in a project, but he or she must get involved even in the technical part to supervise and ensure that all is running smoothly. In the transactional function, the Capacity planning manager is responsible for ensuring the project workflows as intended. Transactional activities include management controls and reporting functions.

Lastly, the transformational function is the leadership aspect of capacity planning. This being the only way through which a company can anticipate the future and prepare for unforeseen eventualities, it is important to initiate such a plan. A business’ success is measured and maintained by its ability to satisfy the market and to meet the demand. The capacity planning helps in creating a clear procedure of dealing with unforeseen calamities.

Capacity Planning Issues and Challenges

The discrepancy

The problem is the fact that IT projects are mainly automated, hence, it is easier to work on them. Such projects do not suffer the challenges faced by other manual projects in terms of personality issues and divergent views from team members.

Ways of Acquiring Additional Resources

It is possible that, in the course of the project, there could be a lack of sufficient support. In the event of such an unprecedented occasion, the capacity planning manager has to look at various available options (Lam, 2014).3 One way is through including sufficient contingency resources on the onset of the project. The capacity managers should perform risk management procedures before the projects proceed further. This includes reviewing the past experiences in other projects. The reviewing of the project portfolio may help to find out the possible risks expected.

Dealing with Changing Requirements

Changing requirements involve changes in the cost of a project. This may cause an increase in the cost or decrease in the latter. When the budget is increased due to the changes in the requirements, the cost and resources allocated for the project must also be adjusted (Lam, 2014).3

Shareholders Management

Sometimes the shareholders might be interested in getting involved in the project. This is not prohibited, but it can also compromise the project, especially where expertise is not sufficient on the shareholders part. Therefore, shareholders can be allowed to participate but only as passive participants. In cases where a shareholder is an expert in the field, more roles can be allocated to him or her.

When the Scope Has Been Altered or Changed

When the scope of a project has been completely or partly changed, the best cause of action is to close the current project and start it as a fresh one. This allows the project manager to change the strategies laid before, since they may not work in the current changes. A new module, in essence, is a new project altogether.

The Conflict between Two Key Capacity Planning Project Members

When a conflict between two key members in the project arises, it is paramount to try amicable ways of resolving the issue. First would be identifying the point of conflict and the divergent resolves. With this, it becomes easier to deal with the situation. It is also important to keep the conflict contained between the two in order to avoid a split between the team members.

Reconciling Capacity Planning with Demand

The main purpose of capacity planning is to support or enhance an organization’s competitive plan. Capacity planning enables a company or an organization to respond effectively to customers’ needs. Sometimes the demand for a product may exceed its supply, and this may be distressing for a company. However, with a proper capacity planning procedure, the company is able to identify the best ways to mitigate the problem and to satisfy the customers (Lam, 2014).

It is important to have a capacity planning procedure because it is easy to lose an unsatisfied customer. The capacity planning is important because it ensures that there is no chance for customer’s dissatisfaction (Lam, 2014). Inadequate capacity planning can cause the company to make loses, hence causing the company to lose money. Capacity planning affects a number of factors in the production of goods. It affects the operating cost, the initial cost, competitiveness, and management.

References

- From Hybrid Plan: a capacity planning technique for projecting storage requirements in hybrid storage systems, by Kim, Y., Gupta, A., Urgaonkar, B., Berman, P., & Sivasubramaniam, A. (2014). The Journal of Supercomputing, 67(1), 277-303.

- From Corrigendum to ‘Multiobjective Optimization of Production, Distribution and Capacity Planning of Global Supply Chains in the Process Industry’. Omega: by Liu, S., Sawik, T., & Papageorgiou, L. G. (2014). The International Journal of Management Science, 44(1), 149. Reprinted with permission.

- From Computer capacity planning: theory and practice. By Lam, S. F., & Chan, K. H. (2014). Elsevier. Reprinted with permission.