The strategic purpose of capacity choices can be immense, influencing all aspects of a business. From an operational management point of view, strategic plans set the conditions under which activities are required to operate. It is therefore highly important to include insight from operating managers in the decision-making process of an organization. Flexibility may be a critical point in capability decision-making, but flexibility is not often a choice, especially in capital-intensive economies. However, where feasible, the versatility allows an enterprise to be adaptable, implying to respond to variations in the marketplace (Stevensons, 2018). It also decreases the reliance on long-term projections to a certain degree to reliably estimate demand. Versatility allows organizations to capitalize on technology and other innovations. In this analysis, Coca-Cola’s flexible production strategy is documented to illustrate flexible schedule management to attain innovative production objectives.

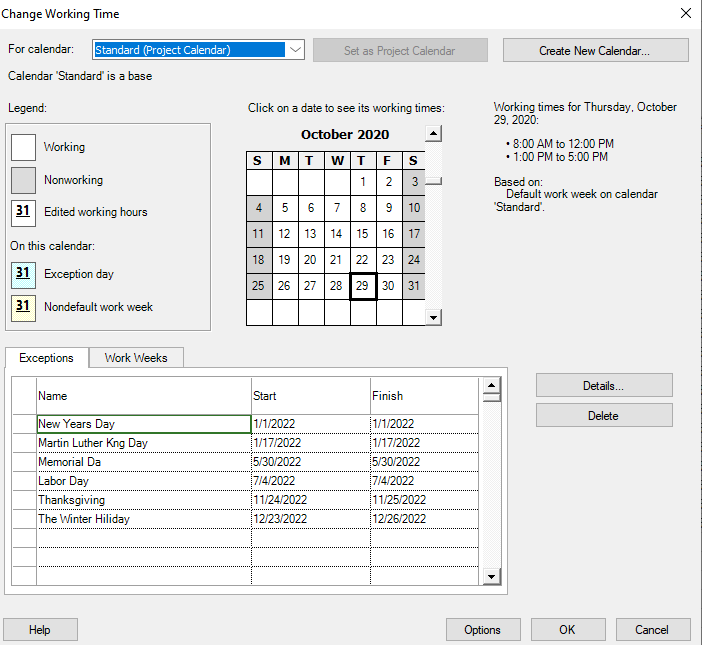

Coca-Cola Co. unveiled intentions to debut a healthy energy drink in 2019. The decision is focused on the consumers’ request for the business to accommodate health-sensitive clients. The drink includes a combination of tropical juices, including pomegranate, grapes, and mango, among other nutritious fruits. The beverage was among the hundreds of fresh previewed drinks in 2019 (Schouten, 2019). Coca-Cola has designed the product to get fresh customers into the energy segment. Hence, the attached project outlines Coca-Cola’s strategy for the production and introduction of the innovative drink for a competitive edge. The linked Microsoft project outlines the 185-day job breakdown layout. The schedule coincides with the production of the product and finishes with the planning of the product launch. The project will begin on 21 February 2022 and finish on Tuesday, 2023. Out of the 185 days, 62 days would be non-working days, allowing a total of 123 working days as shown in Figure 1 below.

The critical path or cumulative working days from start to finish, is 123 days, and the list of tasks to be performed entails R&D product growth, which includes a survey, a series of product requirements, a diet study, and a shelf life. The operations will also involve obtaining fruit suppliers and initial development, which will comprise refurbishment facilities, production checks, quality tests, quality metrics, and quality preparation. Other operations will consist of sales, which will take account of consumer research, product design, and selection of vendors, regulatory enforcement, including completion of FDA approval and registering of trademarks. Finally, the team will plan for the start of the project as outlined in Table 1 below.

Table 1. Project activities and time estimate.

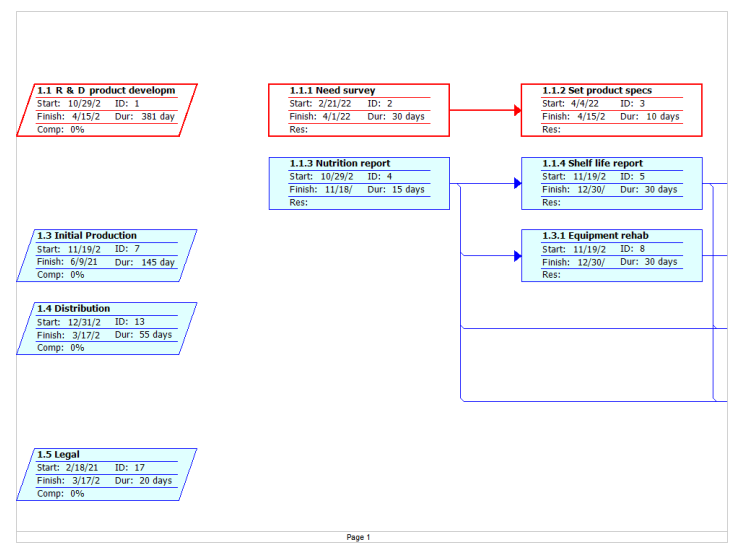

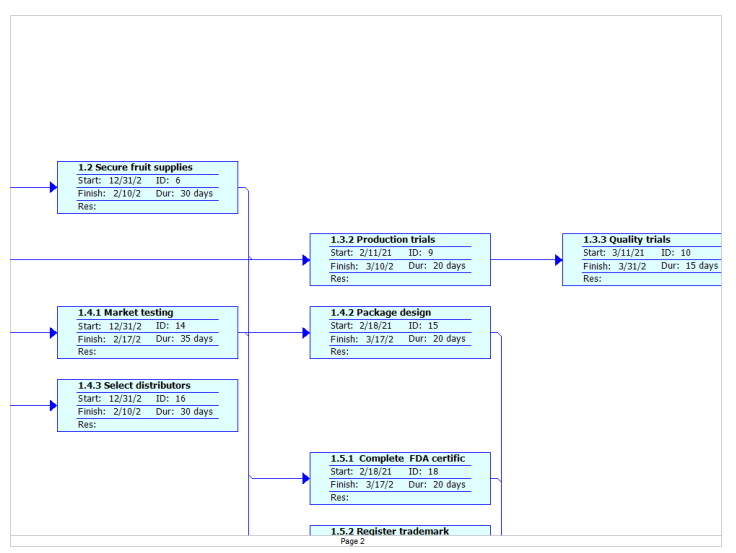

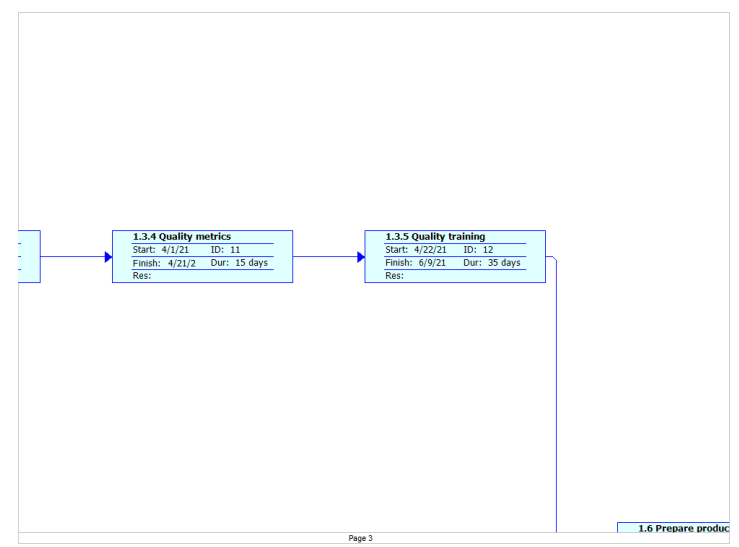

The time estimates above were arrived at based on the amount and projected completion time of each activity. The activities are mainly proposed for the development of the new innovative beverage for Coca-Cola. Slack time refers to intervals occurring on activities accomplished before their deadline. A network PER diagram is as shown in the screenshots below exported from MS Project. Projects are an important tool for creating value in any enterprise. Running a company with a shortage of concepts and no clear work plans can contribute to the loss. Regardless of the scale or complexity of the project, a schedule plan identifies when each task has to be completed, what has been done, and the order in which tasks need to be accomplished (Stevenson, 2018). In the current market climate, all companies should be capable of handling and scheduling tight budgets, resource shortages, as well as the most recent trends in innovation.

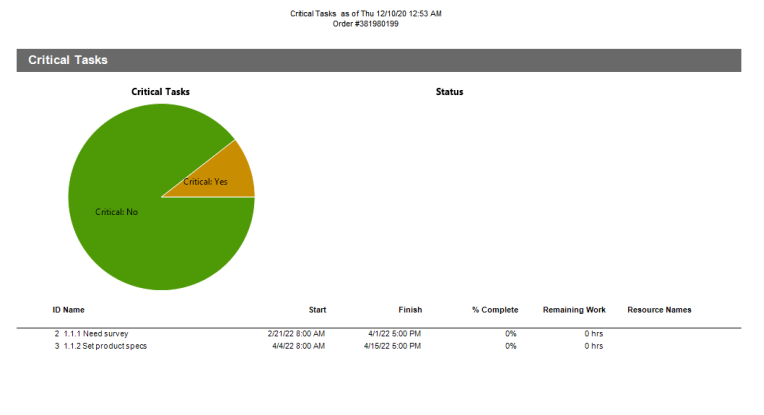

The network diagram above illustrates the plan of activities from product development in 1.1 to product preparation in 1.6. The diagram is imported from MS Project developed for this assignment. The diagram clearly illustrates the process of activities from the design phase to the manufacturing phase that will allow Coca-Cola to produce the beverage for the market. Figure 5 below illustrates the critical tasks. It is vital to be mindful of when time lags in the task, as this time will be used to reorganize the timeline to facilitate the vital route.

For instance, if there is a time lag in a role not situated on the critical path, funds may be transferred from such activity to assignments that are positioned on the critical path, thus improving the most important task. It is also essential to keep track of the pattern in the time allotted for each role. If the pattern is declining, it may mean the project is lasting longer than anticipated. Crashing an activity on the critical part will affect the completion of other tasks leading to a longer completion time.

Schedule control is a strategy that involves the development of policy and documents to create, build, coordinate, and monitor deadlines and assets for the execution of the project. The logistical advantage of the control of the plan is that it can track and maintain the schedule during the project. The scheduling process starts with tasks that are required to be completed in compliance with the specifications of the stakeholders.

Schedule Control entails design work that increases efficiency and brings progress and deals with aspects including managing risk and stakeholder engagement (Stevenson, 2018). A project Plan is a methodology that shows what task should be completed, which asset of the company would conduct the project, and the period duration in which the task should be conducted. The project plan should represent the bulk of work relating to the completion of the job on time. Without a detailed plan, the project leader would not be able to convey the expenses and services that are essential to the project.

Some applications help project managers to monitor project plans, personnel, expenditures, and associated assets in real-time. In the current task, the Microsoft Project program is used to design a plan for Coca-Cola’s product innovation. The project plan should be revised and interpreted by peers relevant to the mission that keeps participants well aware of the general status of the project. Initial development, which includes five activities, is the task with the largest amount of slack. The project is susceptible to the slowest operations, including R&D product creation and initial manufacturing. Two sensible achievements comprise the creation of R&D goods and the filing of trademarks. The objectives represent the beginning and the end of the whole initiative, thus are crucial to the completion of the program. The Gantt map’s network facilitates the counter-checking of potential editing operations, unlike the Gantt chart, which is restricted to the illustrated results.

Providing innovative goods and services in demand and within the expenditure can increasingly measure the effectiveness or failure of businesses. In the current project, R&D is defined as the most delayed operation of the project. Companies frequently allocate time to such analytical initiatives to make developments that may help to create innovative goods or business approaches or to enhance current processes and products. These practices belong to the research and development (R&D) category. R&D is an essential means of ensuring the future development and sustaining the related commodity on the market. There is a misunderstanding that R&D is the realm of high technology or medical companies. In reality, most developed consumer products firms commit a large part of their capital to design innovative model versions or upgrading current prototypes.

While most other businesses are permitted to invest less in research, sectors such as healthcare, electronics, or high-tech companies spend considerably on the quality of their items. Coca-Cola engages in detailed research, which happens as research results are used for the manufacture of particular items, such as the stated beverage. The design and creation of prototypes and procedures are also a function of this process. At this stage, there is a crucial distinction between construction and engineering or production. Design is research that produces the necessary information and models for production and transforms these into prototypes. Technology is the application of these designs and research to create consumer goods.

Based on the above needs five steps were employed in developing the current schedule. Project Management is often fascinating on how things work best. As a consequence, the project scheduling falls into the planning process of any project. The first phase included identifying the tasks. This method allows the project team to utilize the Work Breakdown Framework (WBS) and the Implementation Graph to set up and begin the activities necessary for execution on schedule, thus guaranteeing that they are knowledgeable of the tasks to be integrated into the plan.

Second, a series activity was used to establish the connection between the tasks. The next step entails the ordering of activities and the recognition of constraints. Estimation was used to enable the project team to identify the activities and responsibilities in the task breakdown structure; the next phase was to select time management to finish the project.. The method included estimating activities to accomplish, how to do them, and the extent the project needs to be completed.

Next, it was important to decide the dependencies. Projects are often not easy. A task cannot begin before the one in the progress is done. This is termed job dependence. As a consequence, the new timeline required an analysis of these related projects.

The last phase included the deployment of capital to fulfill the scheduled plan. It requires resources that are needed to accomplish the delegated activities on schedule. In particular, getting the tools and their schedule assignments was regarded. Since the timeframe was formulated, it was important to seek input from the project leader and to make the necessary improvements needed. It was essential to estimate the project schedule before continuing with the implementation of the plan. When the project is in development, a regular comparison between the expected and the real dates is possible. Here the objectives of the project were essential to help set a timeline after the conclusion of the process.

References

Schouten, R. (2019). Coca-Cola’s year of innovation. Foodbusinessnews. Web.

Stevenson, W. (2018). Operations Management. Thirteenth edition. McGraw-Hill.