Introduction

Background

The concept of lean project management is rapidly gaining popularity around the world in different fields. According to Schaufelberger and Holm (2017), a lean operation involves provision of excellent value to customers using the least amount of resources. Its fundamental principles are creation of maximum value to clients and elimination of waste. When using this concept, a firm should understand what the market needs and then develop unique strategies of providing it in the best way possible. Customer satisfaction is paramount at all times when applying the strategy. Waste elimination is of great essence when applying lean operations in a company (Yang et al. 2017). When a company eliminates wastes, one of the outcomes is that the cost of production will be lowered significantly. The process requires a deep understanding of tasks and a clear communication among all stakeholders involved so that they can understand what is expected of them when undertaking a project. Mistakes have to be eliminated because they are often responsible for unnecessary generation of wastes. The process also shortens the time that it takes to complete a project.

Lean operation is currently applied in the manufacturing industry, the service sector, governmental institutions, and non-profit organisation. Its relevance has been proven in different markets. Dahl (2020) explains that large projects both in the private and public sectors are currently implemented under this concept. It is beneficial to the project owner because of two principles of meeting customers’ expectations and eliminating wastes. The owner or sponsor of the project is assured that all tasks will be completed within a given period as per the expectations and using the predetermined resources. Cases of inflated cost of project and delays in their completion often make project owners to avoid mega projects because of the fear that they can stall. However, lean project management addresses such fears by ensuring that costs are maintained as low as possible. In this paper, the researcher seeks to discuss the application of lean project management in different areas.

Problem Statement

Government entities and private companies have embraced the concept of project management as the best way of undertaking developmental activities. This approach makes it easy to assign specific resources to the activity, set a timeline within which it should be completed, and assign specific individuals or companies with the best skills in that field the task of completing it (Modi, 2017). However, most of the major projects are often completed late and at an inflated cost. The problem is common in government projects that may take several years to complete. One of the most common excuses that contractors often give is the problem of inflation in the economy (Stark, 2019). The problem is that it is always impossible for the project cost to drop when there is a reduction of cost of materials used in the construction.

Whenever a project is completed at a higher cost and at a date later than what was expected, its value would significantly drop. This problem has been affecting large projects both in the public and private sector. The inability to determine the actual cost of a project and its timeline creates uncertainties. Parties involved in the project are not aware of what they should expect once a project is initiated. For a government or a company to approve a given project, some of the primary factors that have to be defined in clear terms are cost and timeline. Lean project management promises to eliminate these uncertainties by making the stakeholders to understand what to expect and how to plan for it.

Cases of unnecessary generation of wastes have been common when undertaking large projects. Salah and Rahim (2018) note that one of the reasons that cause massive waste generation is miscommunication among the relevant stakeholders in the project. When the designer fails to engage the contractor regularly to understand how the plan is being implemented, incidences may arise where a section of the construction has to be destroyed because of the failure to follow specifications. Assigning tasks to individuals who lack the capacity to deliver the desired outcome is another issue that always arises. Such individuals with limited knowledge and experience are likely to make costly mistakes because they do not understand how they can undertake a given activity appropriately. When these undesirable events happen, the additional cost is often transferred to the project sponsor even if the mistake was made by the contractor and designer (Kim, 2017). Lean project management focuses on addressing these concerns. The contractor must understand tasks that have to be completed within a given period, assign experts who will avoid mistakes, and ensure that success is not compromised at all.

Justification for the Study

Lean operation is rapidly gaining popularity because of its relevance in solving problems in project management. Currently, the global community is battling the COVID-19 pandemic that is threatening to cripple the economy of many countries. The rate of hospitalisation in many countries has shot up significantly, and many healthcare institutions are overwhelmed. As such, there is an urgent need for both public and private sector healthcare entities to expand their infrastructure. Hospitals are getting constructed all over the world to help create room for the additional patients who have to be admitted when their condition get worse. Besides the pandemic, the need for private and public sector entities to expand their operations has always remained significantly high. Riis (2017) observes that one of the best ways of knowing whether a company is growing is to determine the amount of space it uses to support its operations. Governments also have the responsibility to regularly repair existing infrastructure (roads, rail, port facilities, housing, and communication infrastructure among others) or build new ones. Cost is always the most important factor that has to be considered in such projects.

This study will discuss how organisations in different areas can apply the concept of lean project management to improve efficiency in their operations. Oke and Aigbavboa (2017) argue that not all companies have been able to apply this concept adequately. It is one thing to popularise lean operations and another to actually implement it in actual activities within a project. Many companies that claim to be using this tool still produce unnecessary wastes in their production because they do not understand how they can apply its principles and pillars. For instance, one of the critical pillars of lean operations is aligning workers skills with their assignments to ensure that only those who are highly qualified handle specific tasks (Rosenfield, 2017). It is only through such alignments that unnecessary generation of waste can be eliminated. The study will discuss each of these principles and primary pillars that have to be embraced when a company or a government department is keen on embracing lean project management. Through this document, they can conduct a comprehensive assessment of their current methods to determine weaknesses that limit their ability to eliminate waste and enhance efficiency in their operations.

Research Aim, Objectives, and Questions

Lean project management is a field of study that has attracted the attention of many scholars over the recent past. As such, it is essential to specify the specific area of investigation that a researcher seeks to focus on to define data that should be collected. Hunt (2018) explains that defining aims of the study makes it easy to determine the kind of information needed when collecting data from both secondary and primary sources. The primary aim of this study is to analyse the application of lean project management in different areas. The following are the specific objectives that have to be realised through collection and analysis of data from primary and secondary sources:

- To determine the level of popularity of lean project management in different sectors of the economy

- To determine how well various stakeholders understand the concept of lean project management

- To discuss the level of application of lean project management in different sectors

- To identify and discuss benefits of lean project management in different organisations

- To discuss challenges that different organisations face when trying to implement lean project management

The researcher had to develop a list of question that facilitated the collection of both primary and secondary data. The following research questions were developed based on the above research objectives:

- What is the level of popularity of lean project management in different sectors of the economy?

- How well do various stakeholders understand the concept of lean project management?

- What is the level of application of lean project management in different sectors within the local economy?

- What are the benefits of lean project management in different organisations?

- What are the challenges that different organisations face when trying to implement lean project management?

Literature Review

The chapter focuses on reviewing literature to understand what other scholars have found out with respect to the application of lean project management in different areas. According to Oakland and Marosszeky (2017), lean operation in project management is a field that has attracted the attention of many scholars who are keen on understanding how efficiency can be improved. Reviewing what these scholars have found out helps in identifying existing knowledge gaps.

Understanding the Concept of Lean Management

It is necessary to start the review by understanding the concept of lean management. According to Kumar and Basu (2017), lean management primarily focuses on elimination of wastes in the production process. It strives at achieving project excellence through five main principles, which have to be observed in a systematic manner. The first step is to define customer value. This step involves understanding what customers need from the company. There is always the need to ensure that there is a continuous improvement of value for customers. Comparing what rival firms are offering and determining how well satisfied customers are may help in determining the expected value. The second step is to measure the capability of the company to meet these needs. Kerzner (2018) explains that internal assessment helps in identifying possible weaknesses and developing effective ways of addressing them. This process entails coming up with a proper plan on how to meet the expectations of customers in the best way possible.

The third step involves creating flow and eliminating wastes. At this stage, the team will be aware of customers’ expectations and the ability of a firm to achieve them using the available resources. At this stage, the team will put in place a system meant to achieve the desired goals using the available resources. Efficiency is given priority as the team is expected to eliminate all forms of waste in the process. The fourth stage requires improvement and innovation as the team moves towards meeting customers’ expectations (Kerpchar, Protzman and Mayzell, 2015). It requires regular reviews to understand weaknesses in the current system and developing new ways of fighting identified weaknesses. The last stage towards achieving project excellence is control and sustained performance process. The assumption is that at this stage, the team should have achieved a proper rhythm of operation that avoids wastes at all stages of production and emphasises the need for excellence. The team must then pursue perfection at every stage of the production process. Figure 2.1 below summarises the concept of lean management based on the above five principles.

Application of Lean Project Management

Lean project management can be applied in different contexts, from manufacturing to service industry. In the current competitive business environment, there is pressure for companies to deliver greater results using fewer resources. Kerzner (2018) explains that to achieve such a great efficiency, it is important for a firm to embrace concepts and practices that helps in eliminating wastes while at the same time improving productivity. Lean management grew from the manufacturing industry as shown in figure 2.2 below. The ability of a firm to charge competitive prices for its products depends on how efficiently the production process is. When the production cost is maintained as low as possible, then a company can afford to charge a lower price without compromising on its profitability. Companies had to embrace innovative ways that enabled them to maximise the use of limited resources to achieve the set targets.

Lean project management targets 8 main processes and production stages where wastes are likely to be generated. The first one is elimination of defects in the production process. Rosenfield (2017) explains that whether a firm is operating in the car industry, food industry, electronics, or in cosmetics, defective products often have to be eliminated from the process line so that they do not find their way to the market. A phone that has a defect in its battery system may become explosive. Similarly, a car with a problem with its breaking system can easily cause an accident if it reaches the market. When defects are identified and eliminated, the cost is transferred to the company. The concept of lean project management promotes the need to eliminate any form of waste at every stage of production (Salah and Rahim, 2018). Quality assurance team must identify specific factors responsible for waste generation, and then find ways of eliminating them.

Overproduction is another factor that is always associated with an increase in the overall cost of production. Riis (2017) observes that when embracing lean production concept, the marketing department must maintain constant communication will all the other departments, especially the production unit, finance department, and the logistics unit to ensure that what is needed in the market within a given period is what is released. Overproduction forces the management to expand its storage capacity, which inflates the overall cost of production. Another major challenge that often arises is damage arising from constant handling of finished goods in the warehouse. Pilferage is also a concern when a company regularly overproduces products, which then have to be stored for long. When a company is producing perishable products, it may be forced to sell the excess products at lower prices or face the risk of throwing them away. Such incidences not only lead to increase in the cost of production but also results into unnecessary wastes and theft. Producing just enough good needed in the market helps in cutting the cost of operation.

Targeting non-utilised talent is another major concept when one is keen on embracing lean production within a company. According to Salah and Rahim (2018), cases where one’s skills are mismatched with their talents is one of the most common practices in underperforming companies. Such cases arise when one is forced to fill a vacancy that is not aligned to their training. Lean management encourages project managers and departmental heads to identify special skills and competencies of their subordinates. Tasks should then be assigned to them based on these identified skills. As Kerzner (2018) observes, people tend to perform optimally when they are assigned tasks aligned to their skills. They get greater motivation when they put to practice something that they have learned over a given period. It also eliminates unnecessary mistakes often associated with guesswork.

Transportation is another area of concern that has to be considered in lean production. Many companies spend more than is necessary because of their inability to have an effective transport system. The management of a company has to determine whether it is necessary to have internal transport system or source for these services from specific providers (Schaufelberger and Holm, 2017). It depends on how often the company uses transport services, the level of sophistication needed during transportation, the availability of employees to undertake such tasks, and associated costs. Careful planning and assessment of the various available options can help the management to make the right decision.

Inventory management is also essential when embracing the concept of lean production. Once goods leave the production plant of a company, they have to be handled with care during the entire transit process till they reach the final customer (Salah and Rahim, 2018). A product such as milk is not only highly perishable but also delicate and requires proper handling. As the company speeds the process of making it available to customers in the market within the shortest time possible, it must remember that spillage is a possible threat that has to be observed. Any form of contamination of the product can shorten the lifespan even further. Managing the inventory is, therefore, an essential part of operation that has to be handled with care. Eliminating breakages, pilferage, and spillage of products once they have been manufactured and during the entire process of availing it to customers is critical in lowering the overall cost of production. Extra-processing and motion are the other factors that a company, government entity, and non-governmental organisations should not be ignored when they are keen on cutting its cost of operation.

The principles and practices discussed above can be applied in different areas of operation. In the manufacturing sector, companies have realised that the only way of maintaining low cost of production is to embrace lean production concepts. It helps to identify and eliminate wastes while at the same time promoting efficiency. In the service delivery sector, this concept has also proven to be very effective. For instance, service sector companies have learned the significance of matching skills of their employees with tasks assigned to them. Doing so helps to avoid unnecessary mistakes because one is fully aware of what is expected of them and how to achieve the desired goals. Yang et al. (2017) note that lean production has also gained popularity in the public sector. Government departments are using it to lower cost of their operations, eliminate wastes, and enhance efficiency. Incidences where governments outsource services from specialised companies are becoming common because of the understanding brought about by this concept (Salah and Rahim, 2018). Non-profit making organisations are also using lean management practices to ensure that they are more responsible for donations they receive. They understand the fact that it can help them achieve more using their limited resources.

On-Time On-Budget Mantra

The fundamental mantra for lean project management is on-time on-budget delivery. This mantra emphasises two main factors that often define the ability of a project to deliver the desired value. First, there is need to deliver projects within the set timeline. Delay in major projects has always been blamed on cost inflation. Issues such as theft, wastage, and the need to redo some activities often arise when a project is not delivered within the planned time. When the delivery is delayed, another problem that would arise is that the expected value or benefits would not be available at the expected time. If it is the construction of a road, those who were to benefit from it may have to wait for a longer period than was expected to start enjoying it. Rosenfield (2017) believes that delaying a project often diminishes the expected value of a project. A company may be forced to get into unexpected expenditure when delays arise. For instance, when the construction of a warehouse takes longer than was expected, the affected company may be forced to rent a facility to sustain its operations during the period before the project can be completed.

The mantra encourages completion of projects within the original budget. One of the biggest challenges that companies, governmental institutions, and non-profit companies face in mega projects is the upward adjustment of the planned cost of a project. According to Dahl (2020), many of these projects often experience over 30% increment on the initial cost. One of the primary factors that often lead to cost inflation is unnecessary wastage during the process of implementation. The contractor may fail to ensure that materials used in the construction process are kept carefully for future use. Another challenge that may emerge is pilferage. Cases where employees steal some of the materials from construction sites are often common. Wrong designs or ineffective implementation of the right design may bring about the need to demolish a section of the construction, leading to loss of time and resources. All these wastages and thefts leads to the increase in the overall cost of production that the owner has to meet. Lean management eliminates possibilities of wastage and damage that may result into inflation of the operation cost.

Toyota’s Lean Production Approach

Toyota Motor Corporation is one of the companies that have perfected the concept of lean production. When it started manufacturing cars, Rosenfield (2017) argues that this Japanese company faced stiff competition from American and European car manufacturers. The competitors already had a strong brand in the industry and enjoyed benefits of economies of scale. The company had to decide whether it would focus on production of high quality highly priced cars or low-cost cars targeting the masses. The low cost car market appeared more lucrative, especially within the Asian market that has a large population of the middle class. The management realised that they had to make a radical shift from traditional approaches of producing cars to ensure that they lowered the cost. It has to embrace unique ways of producing cars that would enable it make its products highly affordable to masses.

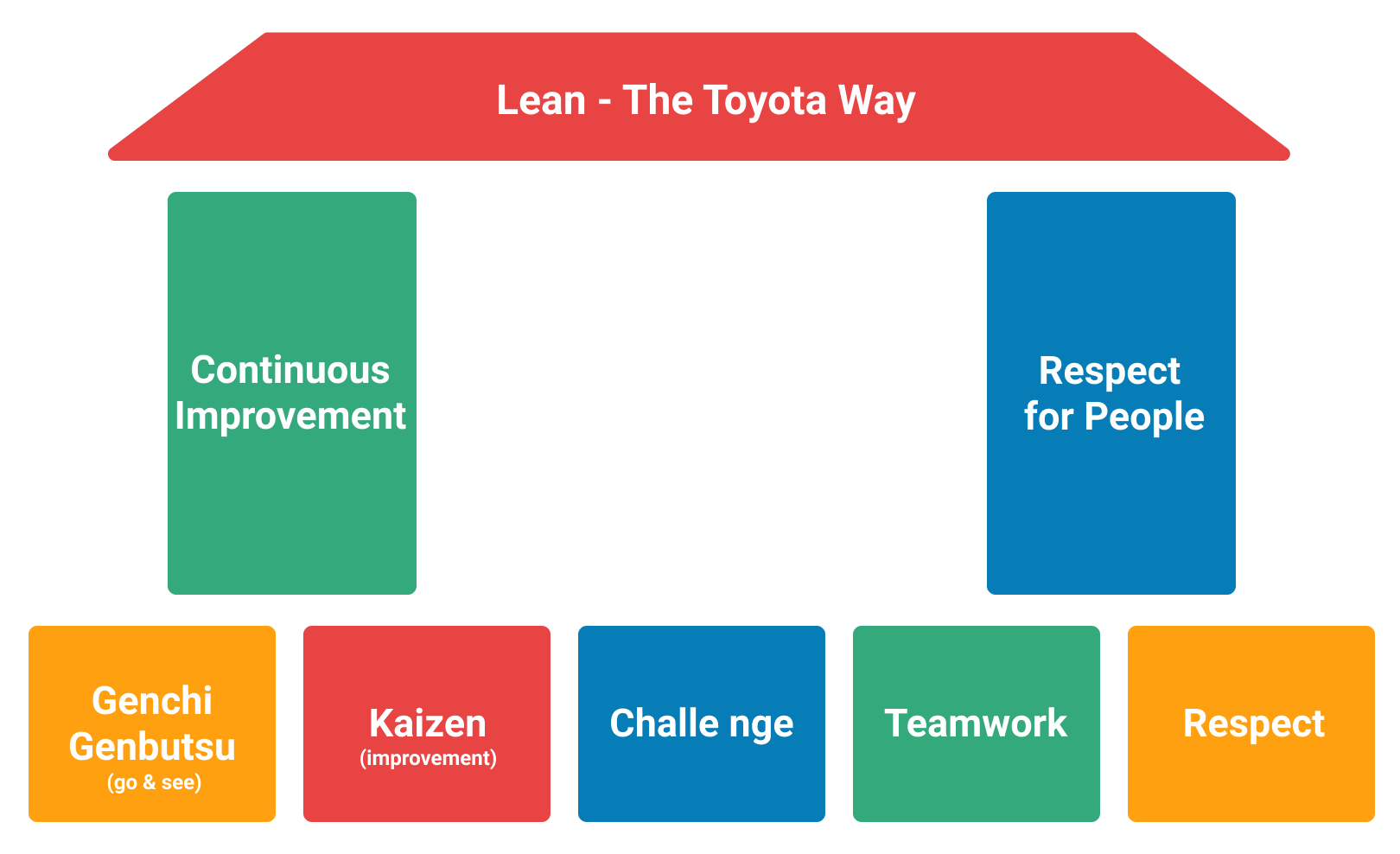

The initial concept that the company embraced focused on two primary pillars which were respect for people and continuous improvement. The company realised that when its employees feel respected, they tend to perform well than when they feel oppressed (Salah and Rahim, 2018). As such, it introduced a new culture where its workers could easily contact their superiors so that issues that affect their work can be addressed. Ideas of junior employees would be taken into consideration when creating new concepts of operation. This strategy helped in promoting creativity and innovativeness among workers. Implementing new policies also became easier as all workers felt that their ideas formed part of these policies. The company also promoted teamwork among employees. The management made employees to realise that the overall success of the company depends on the individual output of every employee. Assisting a colleague who is struggling to accomplish a given tasks is essential in enhancing the overall success of a department. Instead of promoting rivalry among workers, the management created a system for collaboration (Schaufelberger and Holm, 2017). It helped in enhancing unity and productivity of workers. Cases of wastage and damages reduced significantly because of these initiatives.

Continuous improvement was another factor that the management of Toyota focused on to help improve efficiency. The management realised that it could lower the overall cost and improve efficiency by maintaining a culture of continuous improvement. One of the main factors that helped in promoting improvement was the idea of observing best practices around the world to understand its own weaknesses. It made an effort to compare its mode of operations with other firms around the world, including those that were not operating in the car manufacturing industry (Salah and Rahim, 2018). Best practices were embraced and helped in defining new policies and operational practices within the firm.

The company also embraced challenge as a way of promoting continuous improvement. The challenge was taken at different levels within the company. The first one was at the employees’ level. Employees were encouraged to challenge their own capabilities by striving to deliver better output every time they undertook a given task. The strategy helped in promoting creativity and innovativeness among these workers. The second was at the departmental level (Rosenfield, 2017). The management would set new manageable milestones every time the previous ones were realised. A clear path and relevant resources would be provided to help the department realise these new expectations. The entire organisation would also have its own new challenges meant to improve its capacity to deliver improved performance. The goal of the company has been to deliver better products to its customers at affordable price. Figure 2.3 below identifies the pillars and foundation of lean management and operation at Toyota.

Lean Six-Sigma

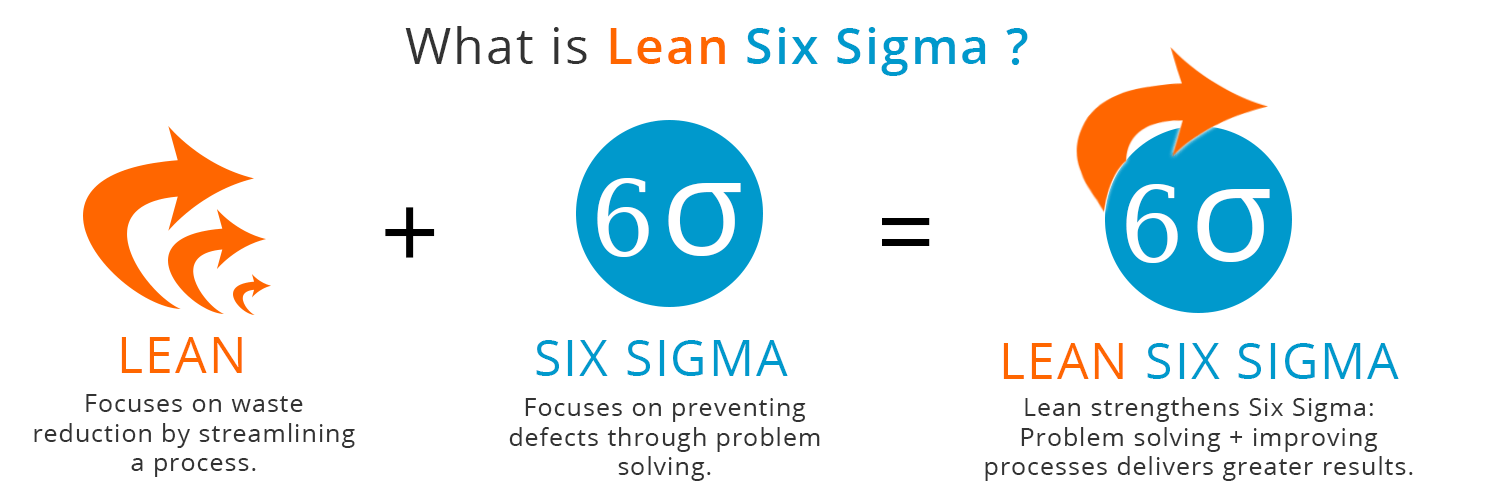

Lean six-sigma is a powerful tool that that integrates both six-sigma and lean management methodologies to create a powerful business transformation tool. Six-sigma is a commonly used tool that helps to reduce wastage. As such in figure 2.4 below, this tool aims at preventing defects in a product. It also promotes problem solving within an organisation to ensure that there is a smooth operation. Six-sigma has widely been used in large corporations to help manage wastage, especially in the manufacturing sector. On the other hand, lean management emphasises the elimination of all forms of waste (Voehl and Harrington, 2016). This tool encourages streamlining of production processes within a company. It creates an environment where managers can work easily with their subordinate to identify weaknesses within a system and develop an effective mechanism of addressing it.

Combining the two models results into having a lean six-sigma. This multifaceted tool tightens the strategy of managing wastes and improving efficiency through careful planning and problem-solving strategies. When using this tool, Hunt (2018) explains that a company must understand specific issues that limit the ability of a firm to deliver excellence. Its precision starts with a thorough investigation of the current system. The internal investigation is meant to identify both strengths and weaknesses. The team then focuses on solving weaknesses that may compromise effective service delivery. It also requires reviewing emerging best practices within the industry and how a firm can embrace them to achieve specific goals and objectives. This tool can be applied in different industries to achieve desired goals.

Benefits of Lean Project management

Lean project management has numerous benefits to corporate entities, governmental institutions, and non-profit organisations if it is applied in the right way. According to Stark (2019), the growing popularity of this concept in the construction, manufacturing, air travel, automotive, and numerous other industries is a clear testament of its effectiveness in lowering operations costs and enhancing the overall productivity. It is a major improvement of tools such as total quality management (TQM) and six-sigma among others. It is necessary to discuss these benefits to help in defining why it is essential for one to embrace it.

As evident in the discussion above, one of the greatest benefits of lean project management is the reduction of waste. One of the biggest concerns when undertaking both large and small projects is the unnecessary production of wastes. Carelessness is known to be one of the major factors that often lead to mass production of wastes. Actions such as taking wrong measurements, delay in undertaking a given task, and such other related mistakes may lead to mass production of wastes. Lean project management helps in eliminating this problem by investigating all the potential causes of waste production (Dahl, 2020). When these sources are identified, the management has to find a way of eliminating them as a way of enhancing efficiency in the production process.

Reduced lead-time is another benefit of using lean project management. According to Modi (2017), when a company manages a project under lean concept, it must follow specific guidelines at all stages of operation. One of the requirements is that workers must be assigned tasks based on their skills and experience (Stark, 2019). It strongly discourages cases where tasks are assigned based on one’s availability or desires of the project manager. This skill-based approach of assigning tasks eliminates cases of delay that may arise from mistakes of employees. Lean project management also promotes the use of just-in-time (JIT) approach of making production materials available for the company. It means that cases where activities are stopped because of delayed delivery of raw materials are eliminated.

Less rework is another major benefit that is associated with lean project management. One of the undesirable practices when managing a project is the need to redo an activity that had been done by someone else. Such incidences often arise when tasks are assigned to individuals who lack the right skills or experience. Redoing a work may also be necessitated by poor communication among stakeholders. When the team fails to implement the original design as expected by the owner, the team may be forced to undo and redo sections of the project. Employing lean project management eliminates such events. First, it ensures that there is an effective communication among stakeholders. It also ensures that an efficient communication system is maintained throughout the lifespan of the project. The implementing team should be aware of what is expected of them at every stage of the project. On the other hand, the designer and project owner should be aware of every activity that is undertaken in the project.

Financial saving is another benefit that is associated with lean project management. Many companies are currently under tight financial pressure because of the need to expand, conduct research, and ensure that they deliver superior products at competitive prices. As such, they cannot afford to deal with unnecessary inflation of the cost of major projects (Voehl and Harrington, 2016). The fundamental principle of lean production is to ensure that activities are conducted based on the predetermined budget. Identify potential sources of wastes and eliminating them is one of the best ways of keeping projects’ costs as low as possible. Using experts to undertake specific responsibilities also enhances efficiency, lowering the operation cost.

The lean concept also enhances understanding of processes in project management. Success of a given project depends on how well stakeholders involve understand the primary goal that should be achieved and their role in achieving the set objectives. Yang et al. (2017) argue that it not just about completing tasks assigned to an individual or a team. It is also critical for one to understand how their individual action would help realise the goal in the project. This understanding creates commitment as everyone will have the anticipation to facilitate the realisation of the primary goal. Lean project management requires the project manager to explain these goals to project members, including all the beneficiaries. Tasks should then be defined to ensure that every stakeholder understands what is expected of them and the interrelationship of tasks. This strategy makes it easy to have a smooth production process based on a mutual corporation among all stakeholders.

Methodology

Project management is a widely research topic because of its relevance in both public and private sector operations. In this study, it was particularly important to achieve research objectives using both primary and secondary data sources. In this chapter, the focus is to discuss the method that was used to collect and analyse data from primary sources. It helps in explaining how the study reached a specific conclusion.

Research Methodology

Research methodology helps in defining the approach that one should take to analyse primary data collected from respondents. Trueman (2016) explains that the chosen methodology should help to achieve research goals and objectives. In this study, the researcher seeks to analyse the application of lean project management in different sectors of the economy. The most appropriate research design for the study is qualitative method. This approach was considered appropriate in understanding the level of popularity of lean project management among local companies and in government entities. It was also possible to understand views of respondents about the level of relevance of this tool in enhancing operations within a given organisation.

Data Collection

Primary data had to be collected from a sample of respondents. The researcher had to collect primary data to achieve the objectives of the study. It also helped in confirming or challenging information obtained from secondary sources.

Sampling

Project management has become a common practice in both public and private entities irrespective of their sizes. As such, data could be collected from a wide range of people working for the government or in local companies. It was not possible to collect data from the entire population because of the limited time available for the study. Having a small manageable sample was essential, as Philippopoulos-Mihalopoulos (2017) advises. As such, the researcher identified 50 people who helped in collecting the needed data about the application of lean project management in different areas. Simple random sampling was used to identify those who took part in the investigation. The researcher sampled employees from both governmental and non-governmental institutions.

Tools for Collecting Data

It was necessary to develop a tool that would harmonise the process of collecting primary data from participants. The researcher developed a questionnaire to facilitate the process. In a quantitative research, respondents have to answer questions in a structured format. Nunkoo (2018) explains that using structured questions makes it possible to collect data that can be coded for the purpose of statistical analysis. Using a Likert scale, it was possible to determine the level of popularity of this management tool in different organisations based on the experienced of participants in the study.

Approach Used to Collect Data

When a sample had been identified and data collection tool developed, the next stage was to conduct the actual collection of data from them. The researcher contacted the management of individual organisations that were identified to help facilitate this research. After getting the approval from the management, contacts of a few employees were obtained. The researcher called these participants and informed them about the intended investigation. Their role in the study was also explained to ensure that they understood what was expected of them. The researcher then e-mailed questionnaires to each of them, with a detailed explanation on how they were required to respond to the questions. They were advised to take seven days to answer these questions and then e-mail back filled questionnaires.

Data Analysis

The last stage was to process raw data that was obtained from the sample respondents. According to Klugman and Lamb (2019), when raw data is obtained from participants, it is the primary responsibility of a researcher to process it using the predetermined design to ensure that it fully responds to the aim and objectives of the study. As explained above, the researcher used quantitative methods to process primary data. It was the most desirable approach of processing data in a way that would help achieve the aim. Using Excel spreadsheet, data was analysed statistically and the outcome presented in graphs and charts. It made it easy to explain the popularity of lean project management and how well it is applied in different organisations in the country.

Research Constraints and Ethical Consideration

It is important to appreciate the fact that when conducting this study, the researcher encountered some challenges worth discussing at this stage. The researcher had the intention of meeting all the respondents and conducting face-to-face interviews. However, the current corona virus pandemic made it impossible to collect data from these participants through that approach. The contagious nature of the virus has forced the government to limit interaction of people as much as possible. The world has moved to the online platform to facilitate social interactions. As such, the researcher used these online platforms to facilitate regular communication with participants. Instead of conducting face-to-face interviews, the researcher used survey to facilitate the study. Questionnaires had to be e-mailed to the participants. They answered all the questions and e-mailed it back to the researcher.

The researcher had to observe ethical requirements when collecting data. According to Sirakaya-Turk et al. (2017), it is important for the identity of participants to be hidden from third parties as a way of protecting them from those who may find their views on a topic unacceptable. As such, each of them was assigned numbers for identification instead of using their actual names. Consent was received from each of the participants before starting the investigations. As an academic project, it was essential to complete all the research and to prepare the final document within the time provided by the school. All forms of academic malpractices such as plagiarism was avoided at every stage of writing the document.

Analysis and Discussion

When data has been collected from sampled respondents, the next step is to analyse it in a way that answers research question. According to Bertrand and Hughes (2017), the process of analysing primary data requires an understanding of the primary research questions arising directly from the aim and objectives of the study. As stated in the previous chapter, statistical analysis of data was considered appropriate in answering research question and meeting the aim of the study. This chapter presents findings made in the study.

Analysis of Primary Data

The analysis of primary data helped in understanding the application of lean project management in different sectors within the local economy. The graphs and charts helps in understanding specific issues of interest about the application of lean operations in organisations where sampled respondents work.

What is the level of popularity of lean project management in different sectors of the economy?

The first question focused on determining the popularity of lean project management. The researcher asked participants how popular they feel the concept is within their organisation. Figure 4.1 below shows that overwhelming majority (70%) of the respondents feel that lean project management is highly popular. Many organisations are popularising this concept as a way of fighting waste generation and improving efficiency in their operation. Another 22% of them supported the same view, stating that the concept is popular in their organisation. Only two percent stated that it is unpopular, while another 6% stated that they were not sure about the popularity. It is important to explain that the 2% of the respondents who had a contrary opinion about the popularity of this concept explained that they had had undesirable experience in its implementation within their firm. They explained that they were subjected to immense pressure in an effort to eliminate waste, reduce time within which the project was delivered, and to enhance the overall quality of the project. As such, the researcher concluded that lean project management has gained massive popularity even though its implementation poses some challenges.

How well do various stakeholders understand the concept of lean project management?

The second question focused on determining how well various stakeholders understand the concept of lean project management. Effective implementation of this concept heavily relies on how those who are in position of power understand it. Respondents were asked to state how they feel various stakeholders especially their immediate supervisors understand the concept. Figure 4.2 below shows that the majority of the respondents stated that their immediate superiors are either uninformed (48%) or highly uninformed (11%). They explained that having basic knowledge about lean project management is not enough for a person in authority to implement it.

One should understand its primary pillars, basic principles, and how it should be applied. According to them, their immediate supervisors lacked knowledge on how to implement the strategy, especially on major projects. Another 10% stated that they were not sure about the issue. 20% of the participants felt that their immediate superiors are properly informed about lean operations. They stated that their experiences with these supervisors demonstrate their knowledge of its application. As Voehl and Harrington (2016) observe, managers and supervisors should have a proper understanding of how this concept should be applied in an organizational context to avoid negative experiences. It was evident that the response that each of the participants provided was based on the experiences that they had during its implementation.

What is the level of application of lean project management in different sectors within the local economy?

This question focused on determining the level of application of lean project management in different sectors within the local economy. Participants were selected from different sectors of the economy. They were requested to state how often their organisation applies the concept in managing projects or in normal operations. Figure 4.3 below shows the response that was obtained from the participants. The most important observation made from the data was that none of the participants stated that their organisation has never embraced the concept of lean operations. It shows that despite the varying level of knowledge that different stakeholders have towards it, organisations across the country are committed to applying this concept as a way of eliminating wastes and improving efficiency.

The majority of the respondents stated that their organisations often apply (36%) or occasionally apply (40%) the concept of lean operations to improve efficiency. It means that 76% of these participants feel that there is some form of application of this concept to facilitate operations in the firm. Another 22% stated that their organisations rarely apply the concept. Even if the application is low, the fact that there is some form of application once in a while demonstrates commitment of those entities to use lean operations as a means of enhancing their operations. It is important to note that the majority of those who stated that their organisations often or very often apply this tool are in the private sector. The trend can be explained by stiff competition that makes it necessary for these organisations to find ways of cutting cost of operation. They consider this tool as a means of producing goods or services more efficiently to enable them charge competitive prices without compromising their ability to make profits.

What are the benefits of lean project management in different organisations?

It was essential for the researcher to determine major benefits of lean project management based on the experience and knowledge of participants. Each one was asked to identify single-most important benefit of applying this concept in an organisational setting. Figure 4.4 below shows the pattern of response. The majority of the respondents (50%) stated that elimination of material waste is the most important benefit of using this concept. Its emphasis on efficiency and allocation of tasks based on skills and experience of employees significantly reduces material waste in the production process. Another 22% explained that using this concept eliminates time wastage. Everything is done to precision without using trial and error approach. It makes projects to be completed within the schedule.

Improved coordination is another benefit of this concept, as was noted by 14% of the respondents. The responsibility of every stakeholder within the project is defined in clear terms. It makes it easy for them to know how to coordinate their activities more efficiency. Communication among team members can easily flow. Top managers also find it easy to monitor the progress that is made. 8% of the respondents identified enhanced task allocation as another benefit of lean project management. Instead of haphazard approach to assigning tasks, lean management emphasises the need to start by defining task requirements, then assessing capabilities of workers to meet the requirements before assigning each one of them responsibilities. 6% of the respondents felt that lean project management makes team members and employees in general more responsible. Everyone is assigned specific tasks and they are aware that they cannot blame anyone for their failures. As such, they have to remain committed to register the expected performance.

What are the challenges that different organisations face when trying to implement lean project management?

It is important to appreciate the fact that every new concept comes with challenges that may affect the overall experience of the stakeholders involved. The researcher wanted to determine if participants have experienced some of these challenges during its application. Figure 4.5 below shows their response to the question. Close to half of the respondents (48%) stated that they have had dissatisfying experience with the implementation of the concept. Another 14% were highly dissatisfied. It means that a majority of the participants (62%) felt that the current approach of implementation at their respective organisations is dissatisfying. They stated that lack of proper understanding on how it should be applied is the major challenge. cases arise where they are subjected to undue pressure just to meet certain goals. 24% of the participants stated that they are satisfied while another 6% explained that they are highly satisfied. These respondents explained that their organisations have a proper understanding of the concept of lean project management. Additional 8% of the participants stated that their experience can be defined as neutral.

The analysis of the primary data shows that the biggest challenge that organisations face in the implementation of lean management is the limited knowledge that stakeholders have about it. In some organisations, there is an effort to implement the concept but they lack proper understanding about it. As such, they end up subjecting their employees to unnecessary pressure to meet unrealistic targets. Some stakeholders are afraid of embracing this concept because of the demanding nature of implementation. It also requires a firm to regularly train its employees to ensure that their skills meet requirements of their assignments.

Conclusion

The application of lean project management has become popular in different sectors of the economy around the world. Findings made in this study shows that lean operation has been embraced as the best way of eliminating wastes and enhancing product and service quality in the current competitive business environment. This tool has proven to be effective because it emphasises the need to align task requirement with skills and experience of employees. It promotes the practice of continuous improvement both in private and public entities. As shown in the discussion, an organisation can achieve such levels of improvement by conducting regular analysis of the current methods with the aim of identifying potential weaknesses then formulating ways of addressing them. Every time a milestone is made, a new one should be set based on the realities that a company faces. When applied appropriately, lean project management helps in lowering the overall cost of operation, enhancing efficiency in a project, and ensuring that activities are completed within the schedule.

The study shows that despite the obvious benefits of lean project management, its implementation is sometimes affected by some challenges. The main challenge that was identified was the limited knowledge that some stakeholders have in terms of its implementation. Lean operations require managers to allocate tasks to employees based on their capabilities to avoid mistakes in the implementation process. It also encourages continuous improvement in operation. However, some managers end up making unrealistic demands from their employees, believing it is the best way of achieving efficiency. They fail to understand the underpinning principles and primary pillars of this concept. The study strongly recommends improved awareness creation about this concept as a way of ensuring that its implementation does not face challenges. Those in management positions need to understand what it takes to operate in a lean system. Empowering employees through regular training is another important ways of enhancing the application of this concept. It helps in ensuring that workers have the capacity to undertake roles assigned to them. The more changes emerge in the market, the more the training should be maintained. It is also critical to create and maintain an effective communication system within a firm that can support its implementation.

Reference List

Bertrand, I. and Hughes, P. (2017) Media research methods: audiences, institutions, texts. London: Palgrave.

Dahl, J. (2020) Leading lean: ensuring success and developing a framework for leadership. Sebastopol, CA: O’Reilly Media.

Handbook of research methods for tourism and hospitality management. Northampton, MA: Edward Elgar Publishing.

Hunt, J. A. (2018) PMI-ACP project management institute agile certified practitioner exam study guide. Indianapolis, IN: Wiley.

Kerpchar, J., Protzman, C. and Mayzell, G. (2015) Leveraging lean in the emergency department: creating a cost effective standardized, high-quality, patient-focused operation. Boca Raton, FL: CRC Press.

Kerzner, H. (2018) Project management best practices: achieving global excellence. Hoboken, NJ: Wiley.

Kim, Y. (2017) Activity based costing for construction companies. Chichester: Wiley Blackwell.

Klugman, C. and Lamb, G. (2019) Research methods in health humanities. New York, NY: Oxford University Press.

Kumar, P. and Basu, C. (2017) A handbook for construction project planning and scheduling. New Delhi: Copal Publishing Group.

Modi, J. (2017) Essentials of operations management. Delhi: PHI Learning Private Limited.

Nunkoo, R. (ed.) (2018) Oakland, J. and Marosszeky, M. (2017) Total construction management: lean quality in construction project delivery. London: Routledge.

Oke, A. and Aigbavboa, C. (2017) Sustainable value management for construction projects. Cham: Springer.

Philippopoulos-Mihalopoulos, A. (eds.) (2017) Research methods in environmental law: a handbook. Cheltenham: Edward Elgar Publishing Limited.

Riis, J. (2017) Project management: a multi-perspective leadership framework. London: Emerald Publishing Limited.

Rosenfield, J. (2017) Lean game development: apply lean frameworks to the process of game development. Berkeley, CA: Apress.

Salah, S. and Rahim, A. (2018) An integrated company-wide management system: combining lean six sigma with process improvement. Cham: Springer.

Schaufelberger, J. and Holm, L. (2017) Management of construction projects: a constructor’s perspective. London: Routledge.

Sirakaya-Turk, E, et al. (2017) Research methods for leisure, recreation and tourism. Wallingford: CABI.

Stark, J. (ed.) (2019) Product lifecycle management: the case studies. Cham: Springer.

Trueman, L. (2016) Research methods for the biosciences. Oxford: Oxford University Press.

Voehl, F. and Harrington, J. (2016) Change management: manage the change or it will manage you. London: CRC Press.

Yang, L., et al. (2017) Additive manufacturing of metals: the technology, materials, design and production. Cham: Springer International Publishing.