Introduction

A supply chain is the total of all the stages involved in delivering a product to a client or customer. Traditional supply chains are mainly static in nature this is because they are based on long-term relationships between business partners. Modern supply chains are considered virtual in state, as they are internet or computer network applications. In these applications, software programs known as agents are responsible for putting the supply chain together. This approach to supply chain formation has established itself as a means that introduces flexibility, dynamism and intelligence to supply chains.

When an order is placed, its constraints are obtained and then configured in one class of agents. A series of negotiations involving this and other classes of agents is triggered. In the end, a supply chain is formed either with or without any compromise from the agents involved. One of the problems that affect a supply chains is the bullwhip effect, which arises from changes in demand of a product. One of its consequences is increased inventory levels.

The inconsistencies in demand attract piling of stock by agents in the supply chain as a measure to counter the effect. Another consequence of the bullwhip effect is agility reduction in the supply chain. The third consequence of the bullwhip effect is a decrease in customer service levels. The inconsistencies in demand can result in a stock-out, which renders an organization unable to meet new customer needs, and thus deteriorated customer service levels. These consequences put together can amount to huge losses for a manufacturing enterprise.

Discussion

Walsh and Wellman believe that automation is the answer to improving the task of designing a supply chain (1). The ideal model to base a supply chain on should include certain issues. Before we look at these issues, it is imperative to know who an agent is in a supply chain. An agent is a computer entity that handles one or more tasks within the supply chain. One of the issues to be assimilated in the model is resource contention between agents.

A scarcity of a particular resource may arise especially if more than one agent requires it. The model should be able to resolve this conflict by ensuring that the agents involved in the conflict do not operate jointly in the supply chain. Another sub-issue arises from this, which touches on the value of an agent. To address it the model has to look at value from a three dimensional perspective. The first dimension is the monitory cost of the agent, that is, is it justifiable?. The second dimension is time taken by the agent to accomplish a particular task. The third dimension is quality, that is, the quality of work done by the agent. The second main issue the model should weigh is hierarchical subtask decomposition. Hierarchical subtask decomposition is a property that enables the agents in a supply chain to accomplish tasks that are complex in nature.

This is because agents are designed to specialize on different tasks of the supply chain. When a task is complex, an agent breaks it down into segments and then distributes them to other agents who in turn might repeat the process again until the task is done. Another issue to be looked at is uncertainty, which is the direct eventuality of intended or unintended failures in the supply chain. For instance, an agent might opt to de-commit to take hold of a better deal elsewhere.

The effect of such like failures and others is the disruption of the supply chain, which can be costly to an enterprise. The final issue to be assimilated in the model is decentralization of the agents. Decentralization within the supply chain means assigning all the agents with decision-making privileges. Thus, no one agent has all the necessary information to carry out or control the supply chain on its own. In such a context, it is useful for the model to come up with a strategic interaction scheme.

Supply Chain Management (SCM) deals with the planning and coordination of supply chain activities beginning with procurement of raw materials to delivery of finished products (Al-zu’bi, 106). The knowledge of SCM is important in maximizing the profits of an organization. Effective management of the supply chain is important in enhancing the timely and cost effective meeting of consumer demands. Thus, it is important in giving a manufacturing enterprise the competitive edge needed over its rivals. As market conditions change by the day, traditional supply chains that are mainly static in nature are not sufficient to fulfill business transactions.

Thus, there is a need for more flexible and dynamic supply chains that are able to link a customer to a supplier depending on the product wanted. With the internet has come E-business, which is a way of executing business processes with the aid of internet technology (Al-zu’bi, 106). An enterprise that successfully adopts E-business opens for itself a door leading to among other things improved supply chain efficiency. The increase in efficiency is because of

- using intelligent supply chains,

- a reduced supply chain time cycle and

- the strong loyalty that is exhibited by customers.

Six processes are captured within the activities and infrastructure for Electronic Supply Chain Management (ESCM) (Al-zu’bi, 106). The first is E planning where collaborative planning is emphasized in order to develop a single and shared forecast for suppliers and consumers. The forecast is of demand and the corresponding supply plan to support it. The forecast should be updated on a regular basis based on the information shared over the internet. The second is E-replenishment, which touches on the incorporated manufacturing and distribution process. Replenishment information is very useful in a number of ways:

- reducing the level of inventory

- elimination of stocking points and

- increasing the rate of replenishment.

The third is E-procurement, which touches on the use of the Web to accomplish key procurement procedures. For Web-based procurement some documents are made available online such as shipping notices, contracts etc. The fourth is E-Collaboration, where collaboration among multiple companies involved in developing a product is emphasized. This is done to make the launching of the product into the market a success as well as reduce the time it takes to reach its intended market. The fifth is E-Logistics, where Web-based technology is made use of to enhance warehouse and transportation procedures. The sixth is E-B2B Exchange, where the use of B2B exchanges to play the role e-supplies is emphasized. E-supplies offer an alternative to traditional supply chains.

According to Walsh and Wellman, multi-agent system (MAS) technology is well situated to develop robust models for the process of creating a supply chain (1). The models form the basis of what is known as Multi-Agent-Based Supply Chain Management systems. According to Kovalchuk, multi-agent approach is adopted because it among other things introduces flexibility into the system architecture (2). Kovalchuk goes on further and states that, agent technology has established itself as a popular tool for designing SCM systems that are distributed in nature (2)

. The reason for this as given by him is that they advance further the management of links – contained in the supply chain – making it more adaptable and dynamic (2). Multi-agent-based SCM systems have two main advantages. The first is that they response to disturbances and changes is quick this is because they are enabled to do their own decision-making. The second is that they allow tasks to be studied individually as wells as with respect to each other. In multi-agent-based SCM systems, agents have to demonstrate four important characteristics (Moyaux et al, 7).

The first characteristic is autonomy, which implies that the agents are able to carry out their duties without intervention either direct or indirect from humans or other sources. Additionally, it implies that the agents should have within themselves a mechanism to control their actions as well as their internal state. The second characteristic is social ability which implies the need for the agents to interact amongst themselves and if need be to do so with human beings. The interaction is most of the times achieved using any of the Agent Communication Languages (ACLs).

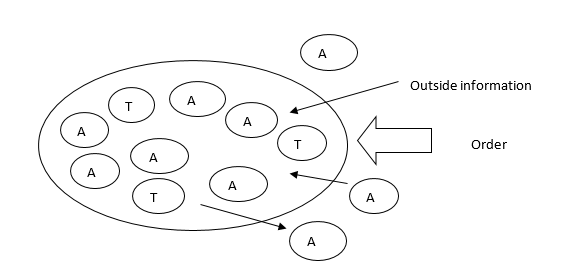

ACL is a language of computer, which has its own distinct language rules, semantics, pragmatics and it is the base upon which communication among software means is planned self-sufficient of one another. Two examples of ACL are KQML, FIPA ACL, the fist in full is Knowledge Query and Manipulation Language, and the second is Foundation for Intelligent Physical Agents / Agent Communication Language. The third characteristic is reactivity, which implies that the agents should be sensitive to their environment and respond satisfactorily to changes in it. The agent’s environment captures the physical world, a group of other agents or a user of multi-agent based technology. The fourth characteristic that should be exhibited by agents is pro-activeness, which implies that the agents demonstrate that they are initiative-driven. The figure below gives a conceptual framework for multi-agents in managing a supply chain

The outermost layer captures the ACL, which means communication services are emerge from this point. The communication services offered allow an exchange of messages between agents that are from two sources. The first source is domain-dependent and relays in its messages communicative acts whereas the second is domain-independent and relays in its messages content specifications. After this layer and to the inside of the framework we have the conversational coordination layer.

The conversations can define different agent-to-agent interactions. For instance, the aim of a given interaction can be a request for or a submission of information or simply a response to a certain event. The innermost layer is action and behavior and contains five features. The features are organization models, decision-making, behavior planning, behavior execution and domain specific solvers. Here, general models of action along with behavior are presented as well as obligations and interdictions associated with the agents.

One of the models put forward is the work of Chen et al and is a negotiation-based MAS (Chen et al, 1). One of the terminology adopted by the framework is Supply Chain Management Systems (SCMS). This is the system, which takes on the roll of the overall manager of the supply chain. Another of the terminologies used in this framework is functional agents, which describes agents that are heterogeneous in nature and that are the means of accomplishing various functionalities of the SCM. The first class of functional agents as classified by the framework provides information about the system, which are known as information agents.

The second class of functional agents is linked to certain objects and each of them is specialized in accomplishing a distinct task. Negotiation is another terminology used in the framework and it describes the corporation that exists between the functional agents. The negotiation process is implemented within a system protocol with information on the product being handled and rules for interaction between functional the agents. The language that is used for the negotiation activity is a form of Agent Communication Language (ACL). One of the issues that functional agents negotiate about is the due date of an order.

Another issue likely to be negotiated about is the quantity to be produced of a certain product. Negotiation performatives is another terminology used in the framework and it is used to describe features that are used to develop the necessary and extra protocols for the system. Now, a basic feature of this framework is that it allows an existing functional agent to depart from the system and new functional agents to join and stay as well. Another basic feature of the framework is that the negotiation process is only between the functional agents. The framework presents the supply chain as negotiation processes that are automated in full or partially (Chan et al, 2).

When an order is placed for a given product, a buyer agent captures it. Now, the buyer agent consults with the information agents, which is an effort aimed at identifying potential seller agents. A negotiation process gets underway between the buyer agent and the seller agents identified. The end-result of this negotiation process is for the buyer agent to come up with one seller agent who will meet its interests satisfactorily.

The seller agent can perform its duties in one of two ways. In the first, it does a comprehensive search of the information agent to identify able manufacturing agents. In the second, the seller agent can post a request to be responded to by the manufacturing agents. Thus, these continual processes of negotiations result in a virtual supply chain that begins with retailer agents and ends with provider agents. All of these agents are possibly contained in the internet or a large-scale network of specific parties or partners.

One of the problems that these model deals with is the evaluation of offers available in a supply chain. Information agents convey information on these offers. The information is input in the agents though application of certain constraints. The following is an example of how this model can be used to deal with this problem. Consider a number of companies interrelated through a supply chain. These are represented as functional agents who negotiate with each other through a pair-wise negotiation protocol. Of these let a company C have the following production schedule

Now, T is the represents the period and D represents the quantity to be delivered to a customer.

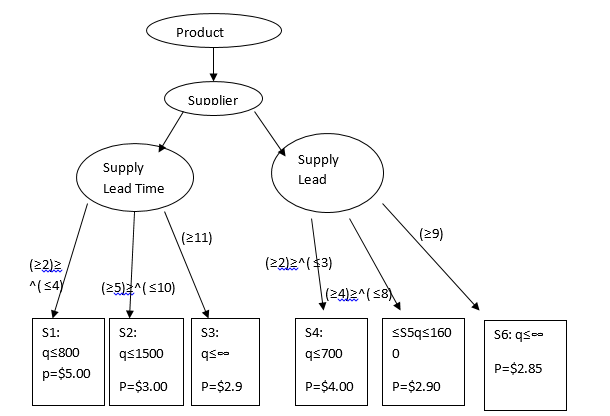

The first constraint is that agent C needs these quantities over different periods. Also linked to company C is companies W and Z who are represented by agents W and Z respectively. The first conversation is among C, W and Z and is triggered when agent C posts a CFP that is a call for proposal. W and Z respond to C’s CFP with their own proposals that are in the form of constraints. A typical response by W would resemble the following algorithm

(if ((supply W X) ^ ( 2≤supply_lead_time ≤ 4)) ( (quantity ≤800) Ù ( unit_price X 5)))

(if ((supply W X) ^ ( 5≤supply_lead_time ≤ 10)) ((quantity ≤1500)^ (unit_price X 3.00)))

(if ((supply W X) ^ (supply_lead_time ≥ 11)) (unit_price X2.95))

The interpretation of this response algorithm is that W is only capable of supplying 800 units of a commodity in period of two days at a cost of $ 5 per unit.

A similar but independent offer from Z can be captured in the algorithm

(if ((supply Z X) ^ ( 2≤supply_lead_time ≤ 3)) ( (quantity ≤&00) ^ ( unit_price X 4.90)))

(if ((supply Z X) ^ ( 4≤supply_lead_time ≤ 8)) ( (quantity ≤1600) ^ ( unit_price X 2.90)))

(if ((supply ZX) ^ (supply_lead_time ≥ 9)) (unit_price X2.85))

The interpretation of this response algorithm is that Z is only capable of supplying 700 units of a commodity in period of two days at a cost of $ 4.90 per unit.

Agent C responds to these two offers by making a search tree in figure 3 below. If the search tree does not determine which of the two offers from W and Z is satisfactory it pursues other options. One of the options is for agent C to compromise its constraints through reconfiguring its master schedule. Another option is to request either W or Z to compromise their constraints. A third option would be for Agent C to maneuver between both offers.

Another of the models put forward is the work of Al-zu’bi and is known as E-SCM model (AL-zu’bi, 108). The model makes use of an MAS to create a supply chain in the context of a network that is Task dependent. Below is conceptual framework of the E-SCM model that is proposed by Al-zu’bi.

The framework also uses the concept of functional agents that represent self-interested companies. A feature of the framework is that the negotiation process is only between the functional agents. The framework presents the supply chain as negotiation processes that are automated either in full or partially. The ACL languages proposed for the model are KMQL and KIF (that stands for Knowledge Interchange format). The both of this are combined with the first being used as a format for messages and designing a protocol for message handling. The protocol is designed to support sharing of knowledge between agents during run-time.

The second language (KIF) is used for knowledge exchanging amongst heterogeneous programs. Agents in the framework are classified according to their tasks. These model is designed to change accordingly to fit in the existing environment. In the framework, a manager agent can be perceived as a facility and the relationships between agents perceived as links. In effect, a supply chain can be conceptualized as a network of these facilities. A facility is capable of breaking down a process to smaller sub-processes, which are to be handled by other facilities.

Recommendation

Considering the level of research that has taken place in recent times in the field of multi-agent-based SCMs and considering that more needs to be done. It will be useful for research community in the field to apply the concept of knowledge integration. Knowledge integration enables the fitting together of different ideas into a single structure that is coherent. By achieving knowledge, integration an individual or organization is able to, first, make use of available knowledge to formulate solutions to address various problems or challenges that they are facing during growth. Secondly, knowledge integration helps to expose underlying assumptions and inconsistencies through reconciling conflicting ideas.

Thirdly, knowledge integration helps an individual or organization to identify areas with incoherence, uncertainty and in disagreement; it does his through synthesizing different perspectives. Finally, by weaving different ideas together knowledge integration achieves a whole that is better than the total of its part. Thus, researchers are able to create a system that is more practical and cost effective.

The proposals put forward by the researchers should be assimilated to everyday life since they have been tried and found to be significant improvements. The results obtained from the experiments done serve as strong evidence that these methodologies do improve the practice of multi-agent-based SCMs.

Conclusion

The above models form the basis of dynamic flexible and cost effective supply chains, which are needed today because of changes in market conditions. As stated above they give an enterprise the competitive edge needed over its rivals. Thus, companies should take advantage of the opportunities offered by these models and other multi-agent based models. It is also important to note that a lot of emphasis is laid on the recommendations made above to guarantee development of more robust models in the future.

Works Cited

AL-zu’bi, Haitham. Applying Electronic Supply Chain Management Using Multi-Agent System. 2010: 106 -113.

Chen, Ye, Peng Yun, Finin Tim, Labrou, Yannis, Cost, Scott, ChuBill. YaoJian.

SunRongming and Wilhelm Bob. A negotiation-based Multi-agent System for Supply Chain Management. University of North Carolina, n.d.

Kovalchuk, Yevgeniya. A Multi-Agent Decision Support System for Supply Chain Management. University of Essex, 2009.

Moyaux, Thierry, Chaid-draa Brahim and D’Amours Sophie. Supply Chain Management and Multiagent Systems: An Overview. Canada, Qubec, n.d.

Walsh, William and Wellman Michael. Modelling Supply Chain Formation in Multiagent Systems, USA: University of Michigan, 2000.