Why is Coca-Cola operations management an essential topic for a case study? A big company like Coca-Cola depends on how well the operation management is organized. In this analysis, discover Coca-Cola operation management, supply chain, and other processes.

Introduction

Operations management is a critical aspect of business operations because it influences the quality of goods and services offered to customers. Based on its importance, manufacturing and service industries use the concept to boost their productivity, competitive advantages, and maintain good levels of customer service (Bamford and Forrester 2010). Developing a good production system is central to effective operations management. It is also beneficial to both customers and organizations that serve them because of improved product/service quality and enhanced efficiencies (Johnston, Clark and Schulver 2012).

Therefore, understanding the in-built mechanisms of such systems makes it is easier to comprehend their areas of weaknesses and strengths, which could be leveraged for purposes of developing strong competitive advantages (Bamford and Forrester 2010; Johnston, Clark and Schulver 2012).

This paper contains a review of the operational management practices of Coca Cola. Particularly, emphasis is made to review the company’s supply chain management system because of its robustness, long years of implementation, and sophistication (Slack 2016). The document is structured in seven key sections that discuss the company’s supply chain, asset management system, key operations in the production model, critical analysis of operations, and the adoption of a lean approach in operations management. One key feature of Coca Cola’s operations management process is its supply chain management model, which is discussed below.

Coca-Cola Supply Chain

Some observers deem Coca Cola’s supply chain as that which follows a generic model of product flow because of the traditional roles played by its key players in availing the company’s products from the parent company to consumers around the world (Barnes 2018; Slack 2016).

Key actors in the firm’s supply chain system include manufacturers, suppliers, distributors, and end customers. The company’s supply chain works by selling a trademarked syrup to bottlers around the world who then convert it to soft drinks that are purchasable by consumers. The bottlers control different territories or markets in their respective jurisdictions but the anchor agent is located in the United States (US) – Coca Cola refreshments (Barnes 2018). The bottler’s responsibility in the value chain is to distribute and merchandise the company’s products to retail outlets who later sell them to the end-user.

Coca Cola’s supply chain is also characterized by distribution efficiency and integrated solution practices that have allowed goods to be sent from a dispatch point to warehouses where deliveries are done in bulk to retailers who later sell them to consumers. The Atlanta-based firm also uses the economic order quantity model and the First-in-First-out Methods (FIFO) for inventory control (Ivanov, Tsipoulanidis and Schönberger 2016).

The company’s management has adopted these models because it endears them to minimize holding costs. Therefore, the supply chain management process works by allowing distributors to order quantities that minimize ordering, shortage, and holding costs (Ivanov, Tsipoulanidis and Schönberger 2016). Therefore, suppliers typically set a predetermined ordering amount, which has to be monitored. If it falls to a certain level, it triggers the need to order more products.

This supply chain feature is complemented by Coca Cola’s adoption of the FIFO inventory model, which outlines the need to sell goods bought first, as opposed to the most recent purchases (Johnston, Clark and Schulver 2012). The adoption of this technique largely dominates Coca Cola’s supply chain system but it is dependent on how well resources in the production system are managed. Consequently, it is vital to understand how key resources in Coca Cola’s production system are managed.

Assets Management in the Production

Coca Cola’s upstream activities do not involve the main players because of the firm grip that the parent company has on the formula for producing the original syrup concentrate, which is later sold to bottlers (Ivanov, Tsipoulanidis and Schönberger 2016). Stated differently, the exact ingredients used by the company to develop the syrup remains a top-secret and, as such, there is little information known about the cost of developing it – sugars (sucrose and corn syrup) are perhaps the only known ingredient of the Coca Cola brand (Ivanov, Tsipoulanidis and Schönberger 2016). Coca Cola monitors the price of the syrup across different global markets using a sophisticated array of tools. Their functionalities will not form part of the scope of this study; instead, an in-depth discussion of the company’s key operations of the production system will be provided.

Coca-Cola’s Key Operations in the Production

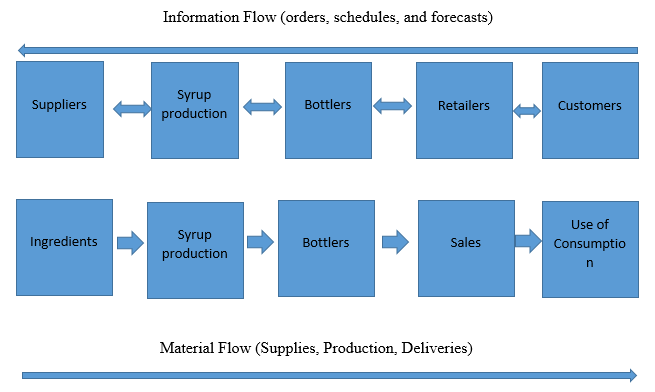

Key operations in Coca Cola’s production system are categorized into two segments: material and information flow. Information flow integrates different aspects of production and supply chain management, such as orders, schedules, and forecasts. Key players in this segment of the production system include suppliers, manufacturers, assemblers, retailers, and customers. Alternatively, the second section of the production flow matrix (material flow) is characterized by the interaction of supplies, production, and deliveries components of the supply chain management system. Ingredients used in the production of the Coca Cola syrup, its production, bottling, sale, and consumption characterize its key components. These two segments of the company’s production system are highlighted in figure 1 below.

The downstream segment of Coca Cola’s production system is based on the franchised model of product distribution. The framework allows bottlers who manage different territories to have sole distribution rights over their markets. The company’s anchor bottler in Atlanta controls this supply model by giving some distributors minority shares in some of the company’s key subsidiaries, such as Coca Cola Amatil and Coca Cola Hellenic Bottling provider (CHBP) (Slack 2016; Barnes 2018). However, fully independent bottlers provide almost 50% of the total volume of the product sold in major markets (Ivanov, Tsipoulanidis and Schönberger 2016).

Aside from product development, the parent company in Atlanta also has the mandate of marketing the Coca Cola brand on behalf of its bottlers, thereby leaving them adequate room and opportunity to focus on improving the distribution aspect of the production system.

The commoditized aspect of Coca Cola’s production system has had a significant impact on its development because it informs the rigor in its distribution system, which has seen the parent company partner with major world bottlers to distribute its products (Slack 2016; Barnes 2018). Although the bottlers are known to have some degree of autonomy over their operations, most of their operational plans are dictated by the parent company in Georgia. For example, their customer relationship procedures and feedback on questions that interrogate their operations are influenced by the parent company (Ivanov, Tsipoulanidis and Schönberger 2016).

Therefore, most areas where bottlers have the freedom to change their operational management practices include redesigning their distribution roles, fleet controls, and credit line development procedures (among others) (Barnes 2018). It is also important to mention that despite the existence of a global production chain system, local and regional bottlers have their unique supply chain systems, which are customized to their market standards.

Lastly, selling the company’s concentrate is a prerogative of Coca Cola’s subsidiary – the Coca Cola Export Company, which keeps a catalog of its major distributors around the world (Ivanov, Tsipoulanidis and Schönberger 2016). These relationships are developed through partnerships with third-party agents around the world who produce the beverage and sell it to different regional markets around the world.

Coca-Cola’s Critical Analysis

In this section of the report, a critical analysis of Coca Cola’s key operations is provided. As mentioned in this document, most activities undertaken by the major distributors are moderated by the parent company in Atlanta. The justification for adopting this approach to management is to standardize the company’s operations and make room for the centralization of its majority strategic decisions. These advantages have been evidenced through the emergence of a regional headquarter to oversee most of the company’s distributors’ practices in each major market (Ivanov, Tsipoulanidis and Schönberger 2016).

Despite the oversight, retailers are still accountable to a regional head of operations management that is also answerable to the parent company. Therefore, Coca Cola’s production system is manned in a top-down hierarchical structure that allocates a lot of power at the top of the hierarchy. Slack, Chambers and Johnson (2007), say the main advantage associated with this distribution system is the ease of making and implementing decisions. Additionally, it is easier for the parent company to align key operational goals of the production system with the overall corporate objectives of the company.

Although these advantages have facilitated the efficient implementation of Coca Cola’s production plans, they have also stifled change in the overall distribution structure because top management has to approve changes before they are implemented (Slack 2016; Barnes 2018). Sometimes, the approval process takes a long time, thereby negating the potential benefits of implementing the changes in the first place. This problem is relevant to the need to make timely adjustments to the production system.

Furthermore, the top-down production model adopted by Coca Cola has made it less responsive to local market dynamics because of the overwhelming power wielded by the parent company in Atlanta in approving decisions. Additionally, the parent company may not be versant with supply chain challenges that affect local and regional markets. However, they hold the power to approve or disapprove changes that could be made to address some of these challenges. This process requires a review of critical areas of assessment that need attention.

Areas that need Attention

Based on a comprehensive analysis of Coca Cola’s production system outlined above, the organization’s delivery system may fail when there is a poor material flow transition from the bottlers to the retailers (salespeople). This challenge may emerge because of the difficulty in achieving desired sales targets purely based on a bottler’s input in the supply chain process. Marketing efforts could also distort outcomes by influencing demand and customer buying preferences (Bamford and Forrester 2010; Johnston, Clark and Schulver 2012).

For example, competitor activities could influence such outcomes. Therefore, extra marketing efforts need to be made to popularize the brand before further consumer engagement can be done. This recommendation is premised on the basic marketing theory, which presupposes that companies need to position their products in the market in a manner, which suggests to customers that buying them would be beneficial to their lives (Ivanov, Tsipoulanidis and Schönberger 2016).

Companies have used such information to redesign their products or change existing ones. The goal is to align the company’s production system with key operational measures. The transition between retailers and customers in the information flow segment of the production system is another area that may need further attention. This is because there is no proper framework for exploiting customer feedback, which would enable retailers to adjust their operational processes accordingly. However, as discussed in the section below, the adoption of a lean approach could improve productivity.

Lean Approach & Coca-Cola

The lean approach to supply chain management operates on the premise that the movement of products or services in a company’s value chain should happen expeditiously and efficiently. This statement implies that the system should use the least amount of time, effort, and resources to make it viable (Kerber and Dreckshage 2017). The goal is to maintain a smooth and balanced flow of items on the production system. Many organizations that adopt this model have logical and disciplined processes of managing their production systems (Kerber and Dreckshage 2017). The whole premise of the model is to create the highest value for the customer.

Stated differently, it stipulates that a company’s supply chain management system should be designed and implemented in a way that maximizing customer value above all other considerations is of importance. Therefore, its systems and tools are designed to identify areas of wastage that do not add value to customers and consequently eliminate them for purposes of improving efficiency. Stevenson (2009) defines the value stream as a model that involves the process of designing and ordering goods and services through the identification of critical tenets of the entire value chain process.

The lean approach has different tools for influencing supply chain management systems. Particularly, these tools are integral to Coca Cola’s supply chain management system because of their capabilities in developing process mapping outcomes that are instrumental in identifying areas of wastage. The lean approach, through its value stream analytical capabilities, can also help supply chain managers to identify the most important and critical areas of operations management that require support.

The most important aspects of these tools (to the assessment of Coca Cola’s supply chain systems) lie in their capability to evaluate and chart broad supply chain processes for purposes of understanding critical areas of improvement. For example, some researchers point out that corporations, which have adopted these techniques, have benefitted from tightly controlled automation and production flow processes that have improved their efficiencies and profitability (Slack, Chambers and Johnson 2007).

The lean approach could also improve Coca Cola’s productivity through improved lead times and profitability. Increased productivity could be achieved through a reduction in wastages and inefficiencies that exist between the bottler and retailer phases of the supply chain management system. Coupled with the high quality of the company’s products, it makes for a more efficient and profitable company. Studies have shown that companies that have such kinds of management practices are more sustainable than conventional companies are because of their low wastages and adaptability to future business challenges (Slack, Brandon-Jones and Johnston 2013; Greasley 2013; Slack, Chambers and Johnson 2007).

Extent that the Lean Approach could improve the Production System

The basic premise of the application of the lean approach is the existence of three categories of processes that characterize supply chain management. The first one is processes that create value for the customer (Kerber and Dreckshage 2017). For example, timely distribution is a critical tenet of Coca Cola’s production system that creates value for customers. Similar processes are often targeted by the adoption of a lean approach for maximum value creation.

The second category of activities that characterize the supply chain system is integral to the overall health of the ecosystem but do not add direct value to customers. For example, administrative activities associated with management functions are integral to the functionality of the supply chain management process but add no direct value to customers. The last category of supply chain activities outlines those that create no value at all. Typically, they are referred to as wasteful activities that are often targeted for elimination or improvement (Kerber and Dreckshage 2017).

The lean supply chain approach could be used to address the challenges of Coca Cola’s production system by improving the responsiveness of the supply chain model to external forces. To recap, the two challenges associated with the company’s production system involve gaps in materials flow transition from bottlers to retailers (salespeople) and a possible gap between retailers and customers. The lean production system could address these challenges by making the production process more efficient by eliminating waste, unevenness in operations, and overburdening of supply chain assets. For example, there is low information flow from suppliers to customers in Coca Cola’s production system.

Therefore, little input is generated from customer feedback as players in the top levels of the production system wield a lot of power and control over the entire system. If the information flow model is overburdened at the top, the lean supply chain system could help to alleviate the problem by redistributing power across the entire value chain system so that the input obtained from every stage of the process is factored into the overall design process.

The above-mentioned recommendation stems from studies, which have shown that the lean management system is less of a tool for managing organizational assets and more of a business philosophy that needs to be reflected across all stages of the value chain (Bamford and Forrester 2010; Johnston, Clark and Schulver 2012; Slack, Chambers and Johnson 2007; Patton et al. 2011). Therefore, when it is overburdened at the top, there is poor management of supply chain assets, which needs to be examined.

The best outcomes will only emerge when employee buy-in is secured across all levels of leadership in the organization. For example, when a specific area of improvement to the company’s supply chain management is identified, a meeting that involves all key stakeholders should be organized and their input considered in the development of the final decision. Thereafter, all players should adopt a common ground and implement its recommendations.

This approach to management reduces the possibility of conflict and disagreements among different actors in the value chain process because a consensus would have been built during the brainstorming phase. Consequently, team buy-in could be realized and efficiencies developed. At the same time, this management consultative framework would ensure there is an equal distribution of power across different cadres of the supply chain process.

The lean production system also portends significant advantages to materials flow processes in Coca Cola’s production system because one of the main problems affecting the model is the gap in materials flow transition from bottlers to retailers. When these challenges are solved through the adoption of lean management, it will be easy for the main players in the supply chain management system to free up more time to improve other areas of engagement.

The lean approach could also help mainstream Coca Cola’s supply management system by allowing it to better respond to market fluctuations. This will result in improved integration of supply chain processes between retailers and bottlers. Additionally, better lead times could be achieved in the supply phase involving the two parties. Broadly, these findings suggest that the lean production system could improve Coca Cola’s operational efficiency by avoiding wastages and making the overall production system efficient. By doing so, the company’s resources would be working in synchrony to maximize value and reduce costs. Therefore, by maximizing productivity, Coca Cola should be able to navigate existing supply management requirements and mitigate associated risks.

Conclusion

A review of the operational management practices of Coca Cola has been provided in this report. Particularly, an emphasis has been made to review the company’s supply chain management system, as one of the most expansive and tested in the global food and beverage industry. As highlighted in this document, the company’s production system is simple because it involves the development of one formula for syrup development by the Atlanta-based parent company, which is later sold to bottlers around the world. These distributors are accountable for selling the product in different territories around the globe and by so doing control vast territories of the market on behalf of the parent company. The lean approach could be a useful tool for managing inefficacies associated with the production chain because it fosters resource mobilization for purposes of improving productivity.

References

Bamford, DR and Forrester, PL 2010. Essential guide to operations management: concepts and case notes. John Wiley, London.

Barnes, D 2018. Operations management. Macmillan International Higher Education, London.

Greasley, A 2013. Operations management. 3rd edn. John Wiley, London.

Ivanov, D, Tsipoulanidis, A and Schönberger, J 2016. Global supply chain and operations management: a decision-oriented introduction to the creation of value. Springer, New York, NY.

Johnston, R, Clark, G and Schulver, M 2012. Service operations management: improving service delivery. 4th edn. Pearson, New York, NY.

Kerber, B and Dreckshage, BJ 2017. Lean supply chain management essentials: a framework for materials managers. CRC Press, New York, NY.

Patton, S, Clegg, B, Hsuan, J and Pilkington, A 2011. Operations management. McGraw Hill. London.

Slack, E. 2016. Coca-Cola. Web.

Slack, N, Brandon-Jones, A and Johnston, R 2013. Operations management. 7th edn. Pearson, New York, NY.

Slack, N, Chambers, S and Johnson, R 2007. Operations management. 5th edn. Prentice Hall, London.

Stevenson, WJ 2009. Operations management. 10th edn. McGraw-Hill Irwin, London.