Introduction

A unique contribution of procurement management in the automotive industry is its perspective. The case of supply chain and logistics allows saying that the organizations within this industry adopt a systems orientation to plant location, transportation, warehousing, inventory, and movement and handling processes. These logistics and procurement management processes are designed as a coordinated system and linked with the other elements of marketing management (Hanson 1999). Thus, procurement management has brought a change in concept. The gap between traffic and marketing philosophy is painfully evident in many companies’ distribution tools; little has been done to relate transportation methods and services to the aims of the distribution in support of marketing management The case of the automotive industry shows that procurement management encompassed by these terms are concerned with the movement and storage of raw materials and products to implement marketing strategies and tactics and satisfy the ends consumer. They concentrate on coordinating supply and demand and developing place, time, and possession possibilities.

Case Analysis

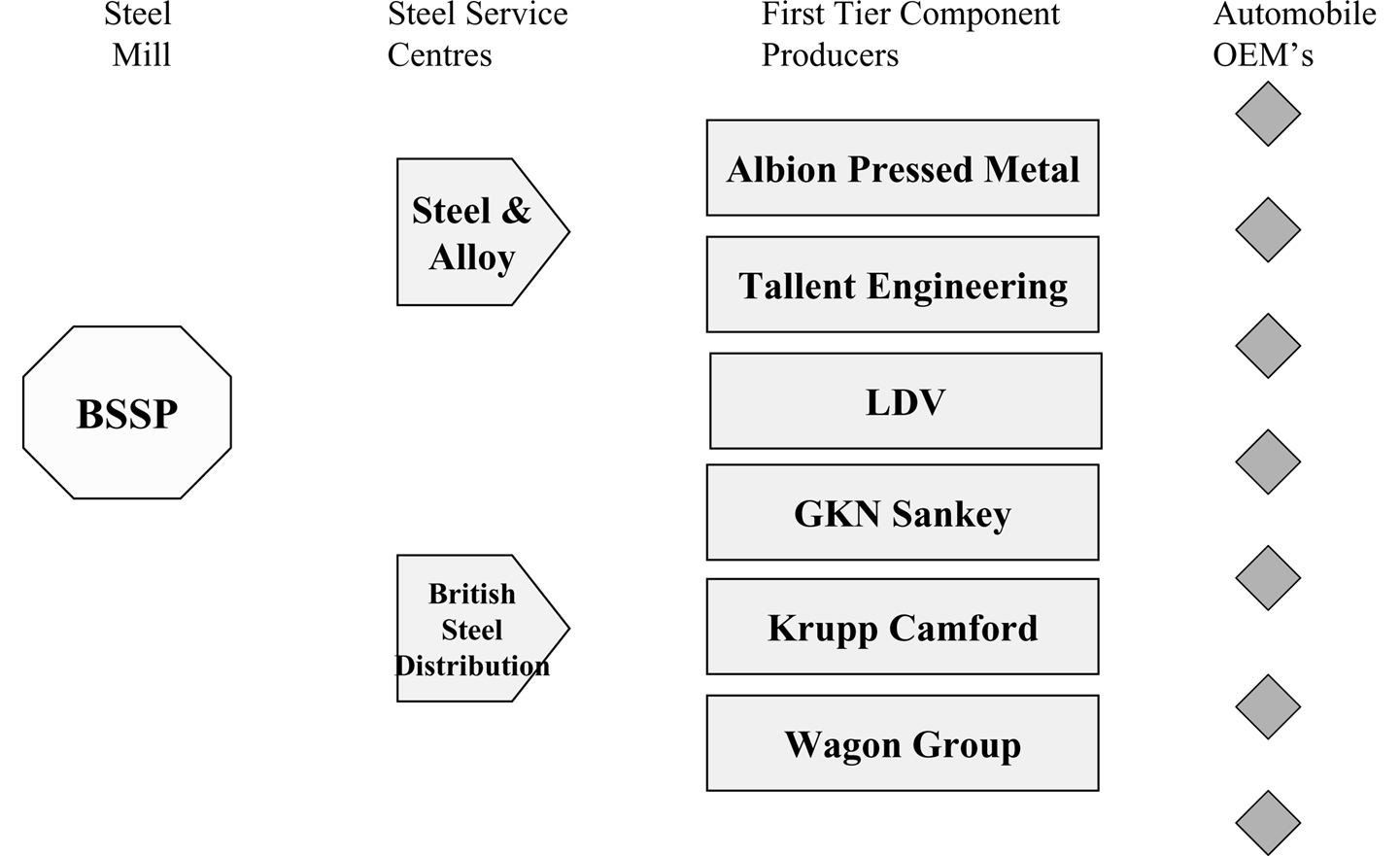

The case of the automotive industry shows that it has a complex supply chain consisting of multiple chains and marketing channels. In contrast to other industries, information and raw materials handling are two main factors of success. These issues suggest that procurement management is involved in long-range planning. The location of distribution processes and activities is a capital-budgeting problem. Automobile manufacturing, production, packaging, information, costs are influenced by procurement management processes. The basic job of procurement management is to make products available so as to support the demand-creation activities of the automobile manufacture (Cohen and Roussel 2004).

The main activities and stages of car manufacturing are receiving warehousing, assembly line, and shipping. For car manufactures, the complexity of the processes and the diversity of operations show the various areas of procurements management (Baudin, 2005). Given so diversified a group of processes and varying company situations, there is no ideal model of organization for procurements management. The procurements management arrangements must be based on the nature of the company and its resources. However, some rules may be established. The basic factors concern the following processes: (1) whether and how to group procurements management activities within a single chain; (2) the level of executive responsibilities of the chief procurements management officer; (3) the processes that should be included; and (4) the functional area to which procurements management should be attached (Jamison, 2003).

Assembly material planning is one of the most important stages of management because it stipulates costs and the quality of the end product. Assembly material planning consists of the followings stages: planning/sequencing, components scheduling, pre=production planning, and vehicle scheduling. Effectively organizing assembly material planning activities is a difficult task, because it involves such technical matters as transportation rates, materials handling, scheduling movements, and laying out warehouses (Jamison, 2003). Thus, it has general coordination of manufacturing, marketing, and purchasing functions. Procurement management does not lie exclusively within the jurisdiction of any one of these divisions; it is affected by and affects all of them (Christopher, 2005).

Procurement management pays special attention to materials planning and new product development. Information sharing is the main and the most important component of this activity (Murphy and Wood 2005). Decentralization of suppliers tends to be the practice in companies with the following operating characteristics: a large number of small shipments are made, production facilities are decentralized and widespread markets exist, the products transported and stored are mixed and shipments cannot be consolidated, and different geographic areas require different services. Procurement management can be organized differently for various segments of an organization. For example, the manufacturer of widely diversified products may have centralized distribution for one division and a decentralized plan for another (Jamison, 2003). Coordination of procurement management requires a perspective that takes into account the properties of products, markets, and logistical process; the breakdown of lines among carriers and methods of movement and handling; and the development of integrated systems that utilize many procurement management modes in order to lower costs (Christopher, 2005). Even if all these factors are considered, though, managerial and organizational limits often prevent the reduction of costs, for the authority of a distribution manager extends only to activities undertaken after products are made (Stroh, 2006).

The case of car manufacturing shows that the elements of a procurement management system include market segments, manufacturing, distribution to wholesaling and retailing points, and transportation and storage links. The system’s structure is affected by the predictability of product flows through the system, the distances between points, and the bulk and perishability of commodities. In essence, the same elements affecting such marketing areas as advertising, personal selling, and products affect physical distribution decisions. For the automotive industry, plant and warehouse location, competition, markets, transportation facilities, service requirements, the location and size of customers, product characteristics, distribution requirements, inventory forces, and production requirements establish the frame for procurement management systems. While demand-creating forces attempt to make sales and develop markets, procurement management is concerned with developing the supporting logistical system that will move and position products to permit the most profitable development of markets (Monczka et al 2005). Thus, the issues of both production and markets shape the design of the procurement management system. The interrelationship of production activities with market patterns, coupled with company resources, will establish guidelines for choosing particular forms of inventory, transportation, distribution, and handling activities (Christopher, 2005).

Introducing changes and ship release influence all activities in logistics management. The fundamental activities performed by a procurement management system are concentration and dispersion. These processes can be performed several times in the distribution of the end product as products are assembled and stored and bulk is broken. In many car companies, terminals are located at points to balance market demands with the movement and shipment size. These structures are dictated by movement-and-handling processes (Leenders et al 2005). Thus, the major decisions in designing a procurement management system involve: (1) the number and geographical location of plants; (2) the number, size, and geographical location of warehouses; and (3) transportation and handling possibilities. Up to the point of processing, the location of raw materials and accumulation of volume shipments are the most important factors in designing geographical. Beyond this point, customer needs and purchasing habits (largely dispersion) take on increasing importance (Cohen and Roussel 2004).

Set-Up of the Procurement Management Department

The main idea of the Procurement Management Department is that a procurement management system should be developed with flexibility and an awareness of future market changes. Changes in supply, raw materials, or movement-and-storage possibilities can force alterations. Investments in plants and warehouses introduce investment “lumpiness” and rigidities. innovations in the market and other environmental changes can greatly affect the value of such fixed investments. Among the issues that will be considered are the following:

- The geographical location of raw materials;

- The geographical location of markets;

- The characteristics of products and product lines;

- The uniqueness of demand and customer-ordering patterns;

- The channels of distribution;

- Human resource factors and resources;

- Costs of logistics activities such as warehousing and transportation;

- The geographical location of manufacturing and assembly plants (Bacal, 1996).

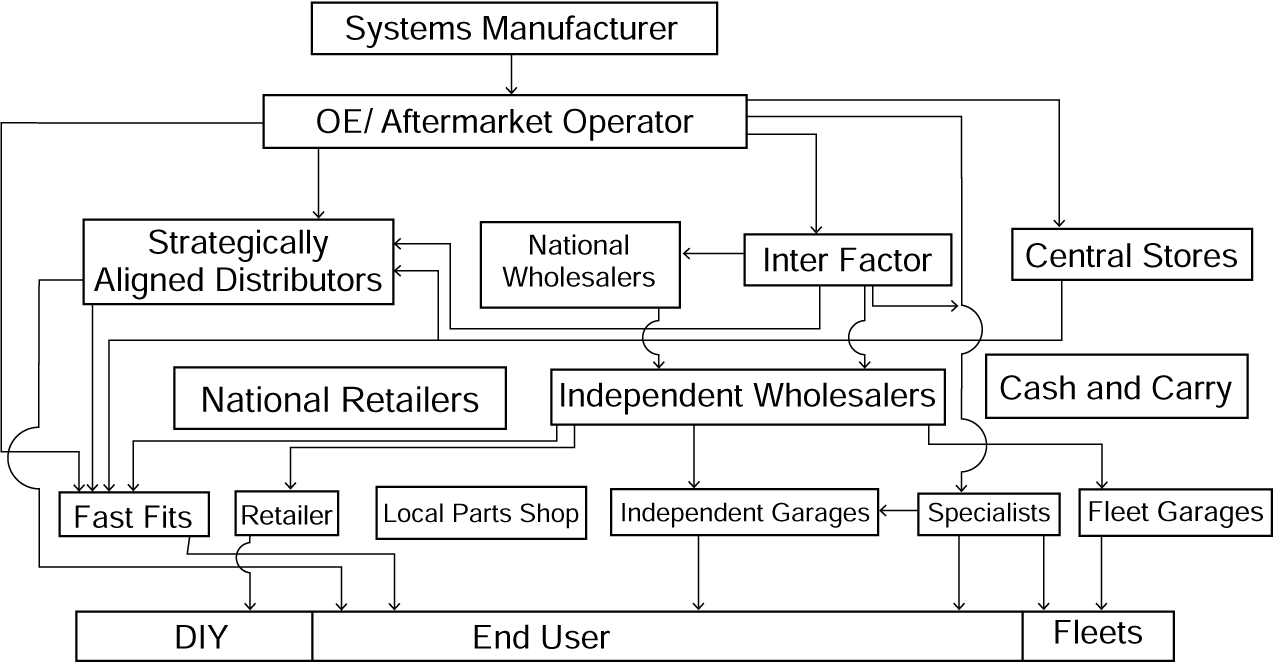

Third-Party Logistics providers in each region will take into account the issues that the costs of procurement management include the location of a company in the distribution channels in relation to customers, the geographic location of markets, and the location and operation of distribution centers, as well as the characteristics of services, including their value and weight. These factors concern aspects of space barriers. The basic geographical location decision is to find the location that maximizes profits for the company. In France, the Lyon area is considered the core of the automobile industry as it has an entire supply chain and allows automakers to save costs and time on delivery. Located in this area, the Procurement Management Department will have multiple product lines, factories, specialized divisions, widespread markets, and therefore a complex procurement management system. In an integrated organization that serves multiple markets with wide product lines, the unity of products on market segments demands different networks and functions (Naylor 2002). In this situation, a direct link exists between channels of distribution and physical distribution. The assembly and bulk-breaking activities of procurement management must be related to markets, product lines, and the channels of distribution that connect them. Procurement management links channel elements to one another and to the markets (Cohen and Roussel 2004).

In order to ensure an effective supply chain, the procurement management department should diversify its main channels. The main plants are located in Lyon, so it will be easier to control the supply of parts. The raw materials will come from North France (iron ore) and from the South (resins and plastics). For procurement management must not only reduce the total costs of distribution but also do so within the constraints of meeting market needs and competition. Services include such considerations as frequency and reliability of supply, order time, availability, and stock-outs. Procurement management and logistics costs will include inventory obsolescence, insurance, handling and taxes, warehousing, order handling, packing, breaking bulk, and company and common-carrier transportation. The size and scope of a market are significant. Warehousing facilities will be clustered by market potentials (Stroh, 2005). It is suggested that the automotive industry in Lyon requires different distribution policies. Designing procurement management systems to meet market needs is a dynamic problem, for continuous changes in markets, activities, and processes bring about new procurement management techniques and patterns. Competition and pressures to reduce costs are crucial. The development and location of a procurement management center itself is a commitment (Cohen and Roussel 2004).

For the automotive industry with the geographic center in Lyon (France), Third Party Logistics providers are the connecting link among plants and warehouses and end consumers. Product uniqueness affects procurement management activities. If the markets for products are highly competitive, then procurement management demands are great because of product substitution, the necessity of offering adequate stocks and prompt delivery, and competitive pricing. The price characteristics of products should also be considered. Changes in product lines and such features as packaging, color, size, style, and variety place a heavy burden on the procurement management system. Now more cars have to be handled with lower volume per item and higher costs of storage, inventory, and handling. In this situation, transportation and handling costs, distant locations, and time are barriers to the development of markets. Through procurement management, costs are reduced and time and geographic barriers are hurdled, thereby enabling companies to cultivate additional markets profitably. Procurement management costs have, in fact, forced firms to withdraw from the previously served market (Simchi-Levi et al 2005).

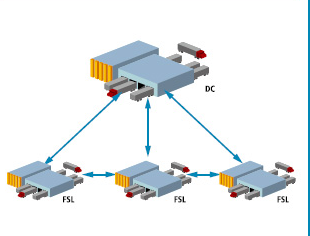

For the Third Party Logistics providers, difficult policy issues confront management in selecting warehouse locations. These questions require the assessment of investments in inventories and distribution centers against customer services and opportunities. Though procurement management decisions are greatly affected by warehouse locations, warehouses are usually established on a piecemeal basis, which is generally less effective. What is required is a long-range approach. For the automotive industry, the selection of distribution centers or storage facilities is a decision to locate inventory at various points. The warehousing facilities will be located in the eastern and western parts of Lyon. Where plants are concentrated for mass production while raw materials and finished product markets are geographically isolated, then warehousing becomes extremely important. As car plans in Lyon are decentralized and located near material sources and markets, then warehousing needs are relatively less important. The related issue is the impact of market development; markets expand, volume increases and plant changes are possible (Kotler and Armstrong 2008, see appendix 1,2,3).

In the Lyon area, the costs of transferring parts and raw materials will be influenced by the location of all plants, warehousing facilities, and markets, and combinations of transfer approaches. Considerations of such financial data will pull plant location toward markets or sources of raw material, even if higher financial spending of operation is required. Marketing issues will have an impact on location. If product demand is developed successfully there is a differential benefit and therefore a price premium achieved, then goods can enter geographically diverse markets and meet lower-cost competition (Kotler and Armstrong 2008).

Airfreight will not be used by the procurement management because it is irrelevant in short distances. This, the raw materials and plastics will be shipped by rail (from the North and the South)m by tracks (from the eastern and westerns parts of Lyon). In terms of the Regional Hub, the procurement management department will take into account that warehouses are added to procurement management systems to serve markets better and to affect economies in freight rates by consolidating shipments. Procurement management must decide whether to ship direct to consumers, to a public warehouse, or a company warehouse (Simchi-Levi et al 2005). The choice will depend on the nature of the brand and service, whether current and potential volume will justify warehousing costs and management programs, policies, and resources. The procurement management department must also take into account whether warehouses, as components of logistics systems, are not merely storage depots but also are points of sorting and assorting — thus permitting the accumulation and dispersion of products to meet the requirements of market segments. As such, the company moves products, links suppliers with markets, and permits consolidation for mass movement and the breaking of bulk for specialized orders. Specifically, the company managers facilitate movement by receiving, unloading, transferring, selecting, checking, and shipping activities. the managers perform the storage function both temporarily and more permanently; temporarily for the replenishment of inventories, and more permanently for seasonal production, conditioning, erratic demand, and speculation (Hanlan, 2004).

Demand characteristics are directly related to procurement management systems. Where demand is extensively variable, then distribution facilities are concentrated in fewer locales. Where demand is continuous and quite consistent, as is the case for some car products, distribution facilities can be decentralized. A highly variable demand makes it difficult to develop effective procurement management systems and control costs, while a stable demand permits it. In between these extremes, where demand patterns can be discerned through analysis, as with seasonal products, reasonable procurement management may be approximated. the proposed structure of procurement management will help the company to share information and develop new products saving financial resources and time usually spends on delivery and transportation (Kotler and Armstrong 2008).

Adequate procurement management has a great impact on customer service and satisfaction. It can influence the percentage of buyers who get their orders in a given number of days and the limitation of backorders for a certain product. Procurement management determines such components as product availability, delivery service, and order-cycle time (Daniels and Daniels 2005). The standard of buyers’ services offered is determined by the consideration of both buyers and direct competitors. The services and products offered by other companies develop a general standard. Yet, procurement management should think of the particular impact of product variations on customer response and profitability as a direction in considering alternative procurement management strategies (Hanson 1999). Usually, no one person is responsible for these activities, several organizations and suppliers may be involved, costs are not controlled efficiently, and procurement management is not successful. It is a matter of balancing a wide variety of financial costs against end products. Car manufactures, because of the very nature of their operations and the impact of procurement management on success, pay special attention to location analysis, and some sophisticated approaches and models. The process of locating procurement management processes in auto industry illustrates the application of logistics analysis in reaching the best management decisions.

Conclusion

The case of automotive industry demonstrates that procurement management systems are geared to the optimization of the system as a whole rather than of any part of it. To achieve this requires analysis of the total procurement management pattern, for changes leading to cost reductions or improved services in one part of the system often result in increased costs in other parts. The Lyon area shows that procurement management activities are divided among the sales, traffic, purchasing, and production departments of a company. For effective control and direction, these logistics activities are grouped into a single department under the direction of the marketing manager. Only recently has management begun to pay attention on the organization of procurement management. In many companies, procurement management has been made the specific responsibility of a major executive. The chief procurement management executive may have the title of distribution manager or vice president in charge of distribution. Specific changes will be related to the significance of procurement management within the firm, particularly its impact on costs and market cultivation. Although procurement management as a concept stresses the necessity of coordinating transportation, storage space, management, location, and inventories, responsibility for these factors is often divided. Procurement managers should attempt to reduce transportation costs, inventory managers to reduce inventory costs, production managers to reduce production costs, and marketing managers to increase buyers’ satisfaction.

Bibliography

Bacal, R. 1996, Performance Management. McGraw-Hill; 1 edition.

Baudin, M. 2005, Lean Logistics: The Nuts And Bolts Of Delivering Materials And Goods. Productivity Press.

Christopher, M. 2005, Logistics & Supply Chain Management: creating value-adding networks. FT Press; 3 edition.

Cohen, Ch., Roussel, J. 2004, Strategic Supply Chain Management. McGraw-Hill; 1 edition.

Daniels, A. C., Daniels, J. E. 2005, Performance Management: Changing Behavior that Drives Organizational Effectiveness. Performance Management Publications.

Hanson, W. 1999, Principles of Internet Marketing. South-Western College Pub; 1 edition.

Hanlan, M. 2004, High Performance Teams: How to Make Them Work. Praeger Publishers.

Jamison, M. 2003, The Virtual Assistant’s Guide to Marketing. Word Association.

Kotler, Ph., Armstrong. G. 2008, Principles of Marketing, 12ed, Pearson Prentice-Hall.

Leenders, M.R., Fearon, H. E., Flynn, A.E., Johnson, P. F. 2005, Purchasing and Supply Management (13th Edition). McGraw-Hill, New York, NY.

Monczka, R. M., Trent , R.J., Handfield, R. B. 2005, Sourcing and Supply Chain Management (3rd Edition). South-Western/Thomson Learning, Mason, OH.

Murphy, P. R. Wood, D. 2005, Contemporary Logistics. Prentice Hall; 9 edition.

Naylor J. 2002, Introduction to Operations Management, 2nd Edition Pearson Education.

Stroh, M. 2006, A Practical Guide to Transportation and Logistics. Logistics Network Inc.

Simchi-Levi, D., Kaminsky, Ph., Simchi-Levi, E. 2008, Designing and Managing the Supply Chain. McGraw-Hill/Irwin; Bk&CD-Rom edition.

Appendix

DC – the main plant in Lyon

FSL – warehouses