Executive Summary

The present work analyzes logistics management as an indispensible element of any economy and any enterprise applied to maximize profits, to optimize the resource expenditures and to minimize production, distribution and other operation costs. In fact, logistics, supply chain management and logistics management are terms that are closely interconnected and pertain to one and the same sphere – successful organization of the whole scope of operations that are undertaken in an enterprise to generate a project, to implement it, to produce goods and to make sure that they will be delivered to the place where they are needed by the customers. Thus, logistics and supply chain management have become a truly beneficial strategy to manage resources with the maximum saving thereof – time, physical and financial resources are spent on an incomparably low level as contrasted to the level that could be observed without supply chain management application.

The importance and usefulness of logistics in the world’s economic space is indisputable. So it is necessary to understand the concepts of logistics and supply chain as well as elements that they include to be able to compose an efficient logistical strategy that will be further on applied to manage the corporate resources successfully, avoiding excessive expenditures. For this reason such topics as the algorithm of creating a logistical strategy, perspectives of logistics management and the existing ways to improve its economic effect and the supply chain management policies are discussed in the present work.

The natural conclusion of the paper is that logistics and supply chain management are vital components of any economic or business process observed on the global scale; for this reason it is important to understand basic concepts of these activities to manage resources effectively, to move forward on the way of wise and balanced distribution of natural resources as well as designing an efficient model of resources distribution that would take into consideration all peculiarities of resources availability in all regions of the world and would allow to provide all customers with goods and services they need, at the reasonable price, in the necessary amount and within an acceptable period of time.

Introduction

Business is evolving nowadays, and there is hardly any enterprise that would not try to maximize profits and to optimize production, transportation and distribution systems to achieve better results and to ensure its growing competitive advantage as compared to other firms acting in the same market segment. It is a common rule nowadays that all companies are vigorously engaged in continuous improvement programs that allow them achieve better working conditions, reduce costs and time expenditure for the product to go through the whole supply chain.

Many entrepreneurs have reasonably noticed already that at times it is much more profitable and convenient not to produce all work needed within the supply chain requirements on their own but to generate alliances with firms that can help them in part with their work, thus optimizing time and money expenditures. This is why supply chain management and the strategy that can be pursued to build strategic alliances as well as the whole science of logistics have acquired exceptional importance recently, making specialists of every company take into consideration multiple opportunities offered by logistics for their particular enterprise.

The success and prospective profitability of logistics was foretold several decades ago when the tendency to form logistical alliances was noticed by some outstanding economists of that time. For example, the observation and prediction of Bowersox (1990) was the following:

“The benefits of these alliance are tangible enough and often big enough to attract quite a few players – many of them strangers to logistics service industry. A very fast-growing segment of the field is the fulfillment or full-support company that specializes in turnkey services…By the mid-1990s, such value-added logistics business is expected to surpass $20 billion in volume” (p. 318).

As it can be seen from the prediction made nearly two decades ago, logistics was a very perspective field of economics, which turned out to be true later on. Even according to the latest information about business indicators in logistics are more than promising, especially taking into consideration the economic recession through which the whole world is going through nowadays. Judging from the overall figures that were arrived at through comprehensive economic analysis show that logistics is still the most popular means of arranging business matters, and supply chain management remains one of the key elements of a successful enterprise to keep on conducting business affairs:

“new orders for manufactured goods in November were up 1.1 percent-or $3.9 billion-to $365.3 billion, according to the Department of Commerce, and shipments of manufactured durable goods in November were up for the third straight month at $0.4 billion or 0.2 percent to $166.9 billion” (Berman, 2010).

It is clear that logistics management is a highly complex structure that constantly needs control and improvement to correspond to the current needs of the business and the changing needs of customers. However, from the previous quotation it is evident that transportation is an indispensible element in logistics – without it the exchange of goods and services would be impossible:

“These days, it’s imperative that logistics professionals gain a comprehensive understanding of how transportation management affects all areas of a company—from business strategy to finance, sales to service—in order to develop a supply chain that drives value to the bottom line” (Transportation management’s role in the new supply chain, 2009).

The same case can be observed with the Pacific Rim venture needing the transportation of details and ready wheel dozers for the construction site in the Northern territory of Australia – the case initiated the present study that aims at finding the reasons for logistics’ necessity for an enterprise and the mechanisms through which it makes operation of certain companies much more efficient and economizing. The present paper will investigate the concepts of logistics, supply chain and supply chain management, and will pursue an objective of finding the efficient ways to optimize businesses, as in case with wheel dozers – the purpose is to find out why and how they should be ordered, transported and implemented to represent a good example of logistics management, and what elements successful logistics should include.

Logistics and Supply Chain Management

The Concept of Logistics

The term ‘logistics’ derives from a French military term that denotes “the art of transport, supply and quartering of troops” (Magee, Copacino and Rosenfield, 1985, p. 2). The meaning of the term for economics is practically the same, if applied to economic resources. The concept of logistics derives from the natural inequality of resource distribution, which brought about the necessity of exchange with the purpose of their maximally profitable application.

Logistics has been created following the major assumption that consumers are dispersed all over the world, and they are not led by such factors as availability of resources on their way of localization. Instead, it is the task of an industry or a firm to find the way to bridge supply and demand and to deliver goods to the place where they will be needed by the customers, and will be logically bought. Such a situation is normal for a free enterprise economy where firms pursue self-interests in profitability, thus being individually responsible for logistics services provision.

No matter how simple it may seem, but logistics is essential in the modern economy, both on a local and on the international level. According to the opinion of Singh, Kundu and Singh (1998), logistics is the basis for trade and allows specialization of any country and any region on something that they can produce, hence not needing to be self-efficient and being able to gain the maximum advantage from the resources available at their territory.

International trade has become a great way out for the majority of countries in the world that failed to produce all goods necessary for the successful existence of their population, or managed to do that but under the conditions of great material expenditures. With the emergence of international trade and logistics, it became possible for any economy to specialize on the sphere that is the most suitable and easily handled there, thus reducing expenditures and raising standards of living in any particular region (Singh et al., 1998, p. 49-50).

Thus, many logistics systems exist to suit the individual demands of any enterprise. To create a good logistical system, it is vital to take into account such factors as: physical form (choice of factory sites, functions, warehouses, modes of transportation), and operational policy and technique (Magee et al., 1985, p. 5). Generating an efficient logistics system using the offered pattern, it is needed to consider the following variables.

Physical variables:

- Number and location of plants

- Number and location of warehouses

- Modes of transportation

- Communications

- Information system means

Operational variables:

- Product availability

- Service reliability

- Product stocking locations

- Product design

- Nature of the product

As a conclusion on the subject of logistics concept, it is needed to assume that logistics is a wonderful alternative to self-efficient economies that are unable to economize on production and provision of services. Logistics is extensively studied nowadays to improve the production and distribution systems on the local and international scale, but there are still some aspects that need to be considered for the sake of creating a genuinely efficient, productive logistical system that will allow saving costs and making the local economy much more profitable, balanced and advantageous for all participants.

Supply Chain

A supply chain, despite its great importance in management, is a truly vague term that can be interpreted in different ways. On the one hand, a supply chain (according to the definition of Harrison and van Hoek (2005) “ranges from basic commodities… to selling the final product to the end-customer to recycling used product” (p. 6). As one can see from this point, it is hard to apply the term ‘supply chain’ to some certain situation in business without knowing the genuine conditions thereof. To support this point, it is necessary to have a look at one more definition of the supply chain: “a group of partners who collectively convert a basic commodity (upstream) into a finished product (downstream) that is valued by end-customers, and who manage returns at each stage” (Harrison and van Hoek, 2005, p. 7).

It is also necessary to have a look at the definition given by Wright (n.d.) summing up and simplifying the general essence of supply chain – “a supply chain starts from scratch – mines, fields or forests, and ends in the consumer’s hands”. And what should be remembered about any supply chain is that it represents a number of elements that add value to the product (Harrison and Hoek, 2005, p. 6).

A supply chain should be viewed as one whole, because it is the main function of a supply chain is to connect all operational processes into an integral unity and to guide its effectiveness. It combines finance, marketing and sales, IT etc., making the manufacturing process aligned and logical.

Surely, with the emergence and evolution of logistics, the meaning of a supply chain may be extended far beyond the borders of a single company. Thus, a company specializing in one sphere may be operationally connected with other enterprises that utilize the end product of that particular company as an element that is needed for production of their end products. The essence of supply chains is based on the assumption that any production is a process that includes many stages that are indispensable for the creation of the end product stipulated by this or that company.

For this reason it is necessary to manage all these stages in such a way so that they were logically connected and brought about less expenditures and maximum profit. So, what does a supply chain involve to make the production process easier and cheaper? Commonly, there are three elements of outer influence that can be produced on a supply chain to make it more efficient:

- Planning (pertaining to the product)

- Controlling (keeping to the previously designed plan)

- Integrating (connecting the supply chain partners, including the consumer) (Harrison and van Hoek, 2005, p. 7).

The way it is done and the way it looks like may be seen in the next section dedicated solely to supply chain management and its implications.

Supply Chain Management

Supply chain management is a comparatively new sphere of management that evolved in 1982 when the term ‘supply chain management’ was created by Keith Oliver – he did this to operate a more structured vision of the enterprise in which he worked, Booz Allen Hamilton (Russell, 2007, p. 58). Further on the term found its recognition and expansion to designate the opportunities of coordination of activities and the efficiency in information sharing within the manufacturing process.

Supply chain management became popular later in 1990s – the results of supply chain management implementation in major enterprises brought about multifaceted, vigorous attention to the subject and initiated research in the field. As indicated by Cooper and Ellram (1993), supply chain and supply chain management notions are highly popular nowadays without losing interest due to their efficiency and effectiveness in the challenging environment of the modern world; this is why active research in that sphere is a reasonable choice. As a result of this scientific research and considerations connected with the field it became possible to formulate a comprehensive definition of supply chain management. According to the opinion of Russell (2007), it comprises: “utopian performance in commerce: all activities up and down a supply chain orchestrated and coordinated (as though a single entity) to synchronize supply and demand at all levels, the sharing of information and technologies to increase innovation and to shorten product development cycles, reduction in order cycle time, replacing stocks with flows, effectively and efficiently responding to customer demands, reduced costs, and increased customer satisfaction” (p. 58).

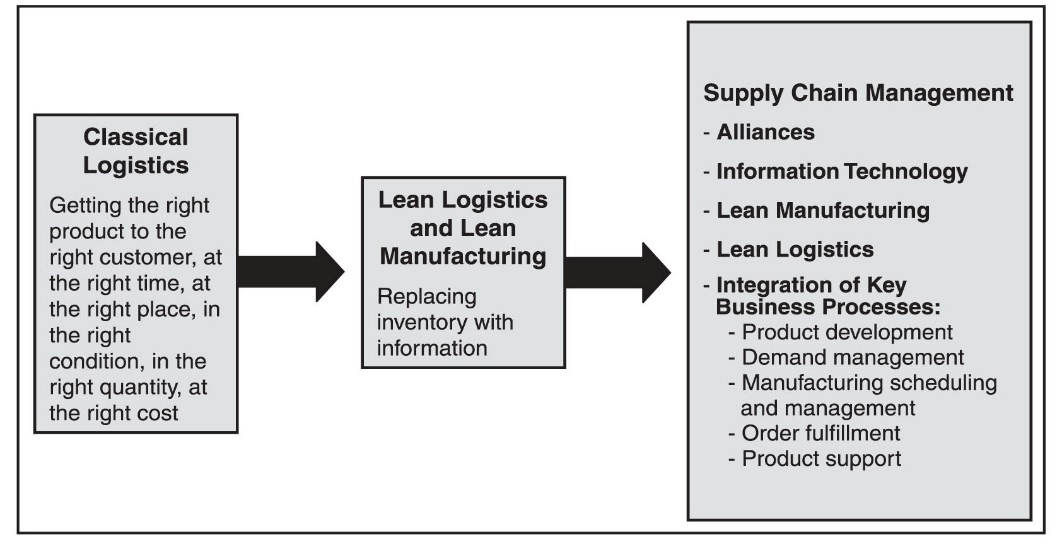

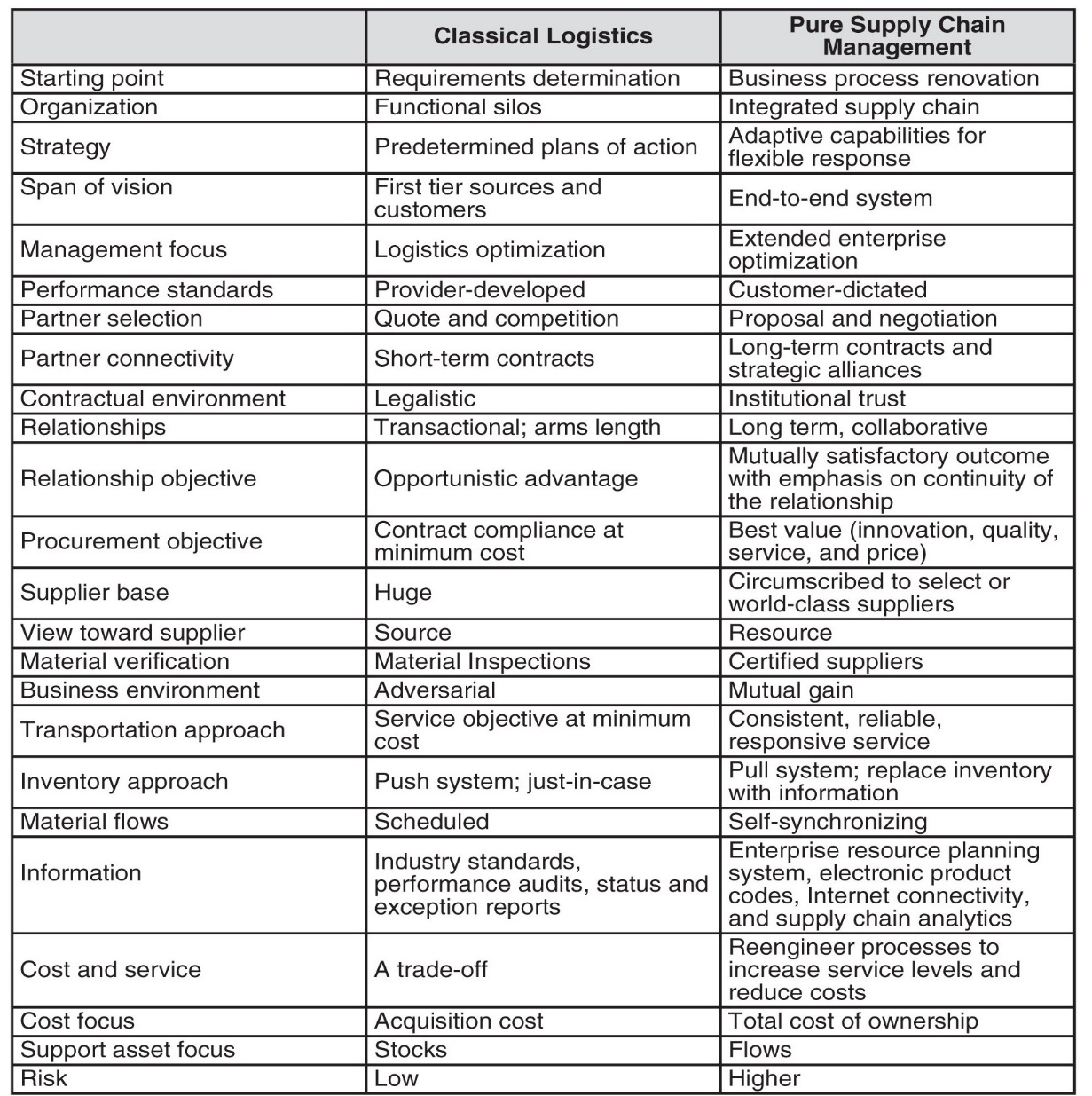

Russell (2007) in general dedicates much attention to the interdependence that is commonly seen between supply chain management and logistics. However, despite the widely spread opinion that these two notions are very similar, and supply chain management is derived from logistics, representing merely an operational tool thereof, Russell (2007) still assumes that they are substantially different and find varied application. To represent the comparative scheme of differences and similarities that supply chain management has as compared to logistics, it is necessary to have a look at two figures offered by Russell (2007) in his article dedicated to this topic. The first figure examines the logical, evolutionary connection between logistics and supply chain management, showing the principal differences testifying the distinguished essence and functions of both notions.

Logistics Management – the New Paradigm

The Logistics Management Concept and Perspectives

As it comes from the previous sections, logistics management is closely connected with the supply chain management; to be more precise, it is possible to say that logistics is a part of the supply chain process that unites all links and makes them function properly. To conduct logistics management means to make sure that “transportation, distribution, warehousing, purchasing and order management organizations must execute together” (The New Logistics Management Paradigm: The Impact of Today’s Trends, 2001, p. 1). This is an extremely complex process that requires attention to multiple aspects, so there is nothing surprising in the fact that additional alignment of all processes as well as sustaining an adequate level of supply chain efficiency depends on how well the logistics management process of a certain company complies with the changing environment.

There is no doubt in the fact that logistics is an essential component of any manufacturing process, and it has many perspectives for the future, which is preconditioned by a set of factors:

- The transformation to B2B economy (the change observed in the Internet usage for commerce leading to more efficient transactions eliminating unnecessary intermediaries and leaving only sufficient actors of the supply chain)

- Reverse logistics (an innovative trend in logistics that is applied to managing the goods that are returned to different partners in the supply chain due to some reasons; the portion of returned goods equals nearly one fifth of the total number of items sold, which surely speaks for the necessity of introduction of reverse logistics in the supply chain management process at every firm)

- Real-time logistics event management (taking into consideration the growing demand for timely, accurate and speedy deliveries, this type of logistics management is gaining popularity)

- Technology solutions provide visibility (visibility is one of the major requirements for logistics management nowadays – it is a recognized indicator of supply chain efficiency, cost reduction and customer satisfaction) (The New Logistics Management Paradigm: The Impact of Today’s Trends, 2001, p. 1).

Ways to Improve Logistics Management

For the reason of such a quick pace with which logistics and logistics management evolves it is necessary to ensure proper training and instruction that can be offered to specialists wanting to connect their lives and careers with logistics. Thus, for example, if one consults the training program offered by the International Society of Logistics, it will be clear that among all competences that are required from a logistics specialist to act efficiently in the modern supply chain management process one should seriously consider the following:

- Mathematics

- Reliability

- Human factors

- Management and leadership

- Quality – six sigma and lean

- Engineering economy and life cycle cost analysis (Logistics Management Professionalization Guide, n.d., p. 5-6)

This is surely not the limit for competences that a professional in logistics should have nowadays – the evolution of marketing environment takes place every second, so it is vital to keep pace with the progress in order to keep the enterprise and its production processes on a sustainable, profitable and efficient level.

Another alternative way to sustain the worldwide competition that poses strict rules and standards for every company to remain competitive and profitable is to ensure customization of products – it is an innovative trend in the sphere of logistics and supply chain management that helps solve a number of challenges that still bear a significant threat even under the conditions of a well-designed supply chain and strong logistics management in a company. The problem is the following:

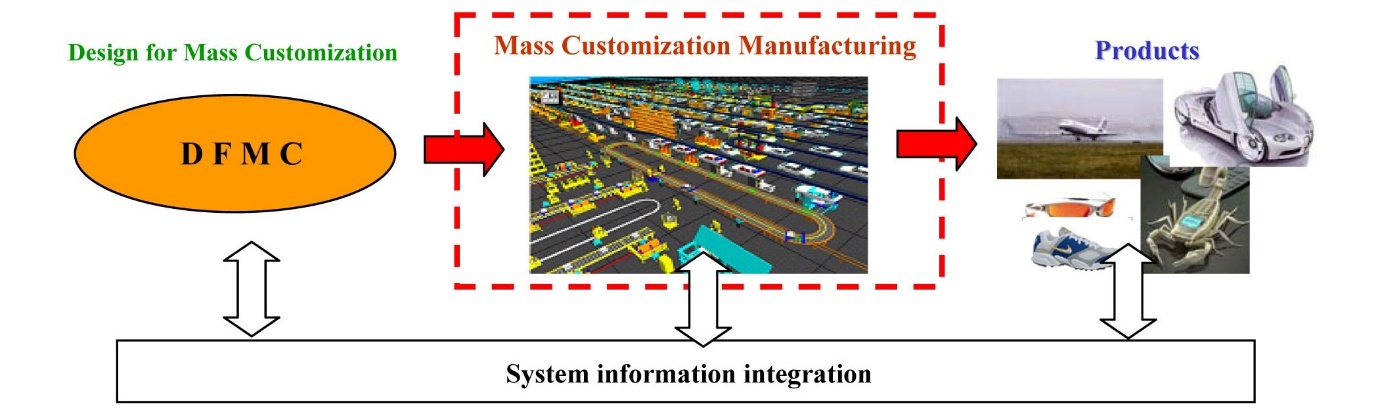

“Today’s competitive industry environment is characterized by unpredictable and changing world-wide markets. Mass production can no longer capture market shares and gain higher profits by producing large volumes of standard products. Companies are forced to search for sustainable strategies for surviving and thriving within the global competition” (Qiao, Lu and McLean, n.d., p. 1).

The authors of the article underline the fact that profitability and customization of products are directly interlinked nowadays, thus bringing an additional set of options to any company to increase profits and to design the supply chain of their production process in such a way that it would be able to satisfy the need of the maximum of its clients. The way the authors see the solution visualized may be seen on Figure 3.

Thus, it becomes possible to suppose that logistics is a key element for success of any company due to the only vital role that it plays – optimization of the production process and minimization of losses and expenditures, which has always been such a desired goal of all entrepreneurs. It is highly possible to design a well-functioning supply chain and arrange logistics management under the condition of having the qualified staff and specialists in logistics who will be able to achieve the goal of reducing costs and ensuring high customer satisfaction through high performance indicators and efficiency of operations.

Conclusion

Judging from the present analysis of logistics management and related spheres such as supply chain and supply chain management, it is possible to state that these notions are still having much influence on the profitability of any company and sustainability of its production processes. Through a significant historical period of time it has been scientifically proven that logistics is a wonderful alternative to self-sufficiency of any economy, providing the adequate, rational utilization of resources, which helps reduce costs, increase customer satisfaction and achieve much more profound success than in case when a company would use only its own facilities.

The reason of such high popularity of logistics within every company and the recognition of its indispensible presence within the supply chain management structure of any enterprise is that it manages resources in a wise, balanced way, finding out which elements should be produced on their own and which ones would be much cheaper to be bought from an outer supplier. Generating such a balanced and well-thought logistics management system in a company will always assist any entrepreneur keep his or her production processes on a profitable, comparatively sustainable level, being able to react promptly to the changing environment, evolving customer needs and other variables that determine the success of any business undertaking.

References

Berman, J 2010, ‘Logistics and business news: Despite improving data, a new year brings the same economic outlook’, Logistics Management. Web.

Bowersox, DJ 1990, ‘The Strategic Benefits of Logistics Alliances’, In SA Montgomery (ed), Strategy: seeking and securing competitive advantage, 5th edn, Harvard Business Press.

Cooper, MC & Ellram, LM 1993, ‘Characteristics of Supply Chain Management and the Implications for Purchasing and Logistics Strategy’, The International Journal of Logistics Management, vol. 4, no. 2, pp. 13-24.

Harrison, A & van Hoek, RI 2005, Logistics management and strategy, 2nd edn, Pearson Education.

‘Logistics Management Professionalization Guide’ n.d., SOLE – The International Society of Logistics. Web.

Magee, JF, Copacino, WC, & Rosenfield, DB 1985, Modern logistics management: integrating marketing, manufacturing, and physical distribution, John Wiley and Sons.

Qiao, G, Lu, RF & McLean, C n.d., ‘Process Control and Logistics Management for Mass Customization Manufacturing’, Manufacturing Systems Integration Division National Institute of Standards and Technology, Gaithersburg, U.S.A.

Russell, SH 2007, ‘Supply Chain Management: More than Integrated Logistics’, Air Force Journal of Logistics, Vol. XXXI, no. 2, pp. 56-63.

Singh, SK, Kundu, SC & Singh, S 1998, Logistics Management, Mittal Publications.

‘The New Logistics Management Paradigm: The Impact of Today’s Trends’ 2001. Web.

‘Transportation management’s role in the new supply chain’ 2009, Logistics Management. Web.

Wright, G n.d., ‘All You Need To Know About Supply Chain Jobs’.