Introduction

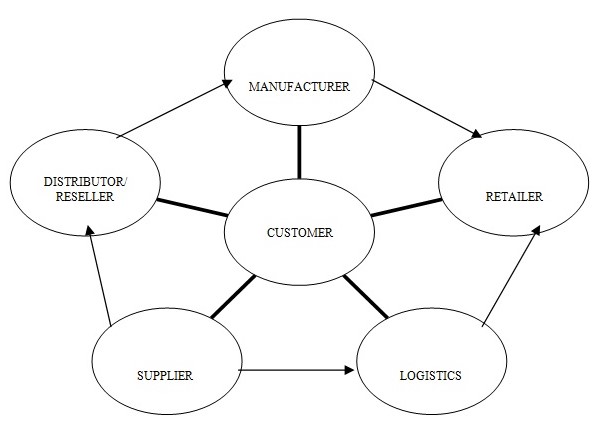

An architectural diagram of Supply Chain to illustrate the depth and breadth of technology used in managing Supply Chain Management Process:

“Supply chain management (SCM) is the combination of art and science that go into improving the way your company finds the raw components it needs to make a product or service and deliver it to customers.” (Wailgum, What Is Supply Chain Management, para.1).

Main Text

Supply chain management means managing a network of businesses that are connected to each other and are engaged in producing and distributing the goods to the ultimate consumers. In order to make supply chain management process more effective, the companies use modern technologies to update themselves and also to meet the customer demands. There is no appropriate software that meets the requirements of supply chain management of a company, because supply chain management process differs according to the functions of the organization. The internet and web are very effective communicators. It allows reviewing the performance in the past. Supply chain management is like playing cards. The company doesn’t want to show others how the supply chain management process is working in the organization. The success and failure of the company’s product largely depend upon the quality of supply chain management. The SCM process and the use of technology in each process can be explained with the help of an architectural diagram:

By using appropriate technology, supply chain management process can be improved. On the part of manufacturers, they use machines and equipments to convert raw materials into finished goods. These goods are transported to the retailers by using various means of transportation. A part of the produced goods is kept in the store to meet future demand for the product. Then the required quantities of the products are transported to the suppliers. Suppliers are responsible for selling those goods to the resellers. These sellers, by using various promotion strategies, deliver the product to the ultimate consumers.

Communication objectives with upstream and downstream members of the supply chain

Some of the communication objectives of the company with upstream and downstream members of the supply chain are as follows:

- The current performance can be monitored

- Past performance can be reviewed.

- Future production level can be predicted

- Helps in sharing the information on the demand of the consumers.

- Helps in increasing the speed of processing the transactions

Operational objectives with upstream and downstream members of the supply chain

Some of the operational objectives of the company with upstream and downstream members of the supply chain are as follows:

- To reduce uncertainty

- To minimize the delays in distributing the goods

- To manage proper inventory levels in the chain

- To provide maximum and efficient customer service

- To increase the partner co-ordination

- To improve the quality of demand forecasting

The sell-side process in a value chain

Sell-side is a part of the business through which the dealings of order take place. That means sell-side collects orders from buy-side and completes the work. Usually, retail brokers, institutional brokers and traders, and research departments are considered as sell-side. “It ought therefore to be adding significant value to investors’ understanding of quoted companies. And, since sell-side analysts disseminate their research widely, it should also improve the all-around quality of market information.” (Stevenson, para.1).

The sell-side for the value chain is always in connection with the customers. Their main duties are order management, channel management and customer relationship management. Order management include, production of catalogue of the product, collecting orders and fulfilling the order completely. Channel management include working with distributors, retailers, other partners. Customer relationship management comprise marketing, sales, customer service, field support.

The buy-side process in a value chain

The collaboration of buy-side process to sell-side is important in supply chain. Buy-side is used in financial securities trading. The buy-side consists of the buyers of the services. In the buy-side, the relationship between client and vendor is good. Here, the service providers get high level of profits. Buy-side analysts usually work for the firms managing money. The buy-side includes the suppliers. Here, the buyer buys something from seller. The selecting of the suppliers and measuring of their performance is done at buy-side. The supply chain is used to connect the buy-side to the sell-side. “Collaboration is a platform to share expertise, knowledge and assets to bring out synergies of more than one organization.” (Collaborate and Conquer, para.3).

In the collaboration process, buy-side and sell-side processes are tied together. Before the collaboration, it was only a one-way flow of information. Buy-side process helps in acquiring companies and also improving shareholder value. By the collaboration of buy-side processes and sell-side, the value of fulfilment, reporting and savings can be increased. It also helps the two processes to have one centralised system. In the past, the investment of buy-side was more than that of sell-side. But now the measurements are almost equal.

Importance of investigating and collecting information on prospective SC partners and the consequences of skipping such an important step in forming a relationship with SC partners

The selection of supply chain partners is very important for the success of every organization. To run a business in an effective way, proper investigation and right collection of information on prospective SC partners are very important. “Working closely with other participants in the chain can build goodwill, streamline operations and shave expenses, all valuable in ramping up your business. Ideally, a good partnership will take demand and supply planning to a new level of efficiency and profitability.” (Zieger, para.1).

The important thing in SC partnerships of a business is that partners are to be consistent in nature and costly SC partners should be evaded. “The wrong partnership may burn up profits, waste valuable staff time and even damage long-term business prospects.” (Zieger, para.2).

If we skip the important steps like investigation and collection of information on SC partners, the result would be “Bullwhip Effect”. That means rising demand inconsistency through the supply chain commonly which poorly affects the business. Therefore, in order to fulfil the demand of the customer more effectively and efficiently Collaborative Planning, Forecasting and Replenishment are very important.

An evaluation tool that includes the most critical aspects that need to be examined in SC partners

The supply chain partners can be selected by using the questionnaire method. Some of the questions that must be included in such questionnaire are as follows:

- Name of the person

- Age

- Sex

- Education

- Field of experience

- What is his role as a supply chain partner

- What made him to take up this role

- Financial capability of the partner

- Previous role

- Current market knowledge

- Knowledge about the company

- Whether the partner will create a trustworthy relationship

The role of culture in SCM and the top five changes made to the culture of organization to improve the way in which supply chain activities are done

Culture plays an important role in supply chain management. Culture management helps in the transformation of an organization and also improves its performance. The obstacles in culture restrict any changes from taking place in the organization. It also hinders organizational transformation. There may be obstacles within the culture of an organization. The improvement of supply chain is a good method to make short term and long term profits. A lot of money is spent on supply chain activities. So, improvements should help to reduce the huge costs. To improve the supply chain activities, changes can be made in the culture. The change in culture will improve the organizational performance. Leaner supply chains will help in faster growth of the organization. The target of improvement should be both competitive and tactical. The commitment of management, universal approval and suitable rewards are some methods to improve performance. A change in values and behaviour can be done by changing the people. Changing the team will lead to a cultural change. There should be a clear vision for the people. Changes can be made by the development of strategy. The capacity of the organization for change has to be considered. There should be a motivation for change. Also, communication should be effective. People of the organization should work regardless of their position. Only then, the supply chain activities can improve.

Evaluation of culture in supporting SC

“Culture plays an increasingly important role in supply chain management, as many manufacturing firms have linkages to suppliers and customers from various countries. Previous research in supply chain management has often addressed culture as a control variable.” (Kristal, Pagell and Sheu, 1251).

Conclusion

Culture plays an important role when considering the outsourcing of manufactured products and back office services. “First, employees that used to go down the hall now have to coop with time differences, remote collaboration and all the usual issues related with moving activities to different locations. On top of that, the latest recession has reduced travel, resulting in more work to be done over the telephone. And then there are the culture clashes.” (Culture and the Supply Chain, para.2).

In order to improve the performance of an organization, change the basic values, beliefs and standard among the stakeholders is important. But, there exist cultural barriers which block these changes. Corporate culture is important when planning a supply chain management system. Culture can explain and predict the process of supply chain decision-making internationally.

Work Cited

Collaborate and Conquer. The Decision Makers’ Direct: New insights, New Tools, New Solutions. 2004. Web.

Culture and the Supply Chain. HP: Community Home. 2009. Web.

Kristal, M Murat., Pagell, Mark., and Sheu, Chwen. Is There Cultural Bias In Supply Chain Management Theories? An Empirical Assessment: Abstract. 2009. Web.

Stevenson, Jamie. Three Simple Steps to Improve Sell-Side Broker Research. Responsible Investor. 2009. Web.

Wailgum, Thomas. Supply Chain Management Definition and Solutions: What Is Supply Chain Management?. CIO. 2009. Web.

Zieger, Anne. Don’t Choose the Wrong Supply Chain Partner: Shared Goals, Structure Critical to Success. BNet: The Go-to Place for Management. 2003. Web.

Zieger, Anne. Don’t Choose the Wrong Supply Chain Partner: Shared Goals, Structure Critical to Success (Update: Supply Chain Management). Encyclopedia.com. 2003. Web.