Introduction

The world of business lives and develops according to its rules and regulations. As well, to succeed in this world a company needs to adapt and constantly update the basic business practices that determine its relations with the suppliers, partners, competitors, and customers in the market. In this respect, the concepts of supply chain management and logistics acquire additional importance. The ways in which a company structures its business practices and delivers goods to the customers is considered essential, especially in the modern globalized market with the fast pace of its development. Accordingly, this paper considers the fundamentals of supply chain management and logistics, touches upon the issues of value chain and supply chain partners’ relations, and exemplifies the major points with the examples of Toyota Motor Company supply chain management practices. As well, the paper provides assessment and recommendations as for the role of organizational culture in supply chain management and improvements to this area.

Supply Chain Management

Naturally, the basic concepts to be considered at the beginning of the paper are supply chain management and logistics. As for the former, there are numerous approaches to its functions and major components, but the universally accepted is the definition provided by EC-Council (2009), according to which “supply chain management (SCM) is the oversight of materials, information, and finances as they move in a process from supplier to manufacturer, to wholesaler, to retailer, to consumer” (EC-Council, 2009). The major function of the supply chain management is to reduce the amount of inventory that a company has to operate with provided that the effectiveness of the company’s work remains the same or increases. Here, the first reference to Toyota Motor Company can be made as reduction of inventory accompanied by the productivity growth is one of the leading ideas in this company’s philosophy (Liker, 2005). Therefore, supply chain management can be referred to as the basis for the business development of a business entity.

Logistics

The concept of logistics also plays an important role in understanding and proper structuring of the company’s supply chain management. Generally, logistics can be defined in three basic ways. According to the first one, logistics is referred to as “the science of the movement, supplying, and maintenance of military forces in the field” (Hullet, 2009). However, in relation to the business world, the other two definitions are of greater values as they see logistics as either “the management of materials flow through an organization, from raw materials through to finished goods” (Open Text, 2009) or “the detailed planning and organization of any large complex operation” (EC-Council, 2009). Therefore, logistics can be viewed as a comprehensive organizational approach to its business activities that starts with obtaining the raw materials for its production process and ends up by the delivery of the manufactured goods to the retailer or wholesale stores and directly to the customers.

SCM Software

In the modern world of technological progress and the proliferation of the digital solutions, the role of software in supply chain management, logistics, and relations between the business partners becomes prominent. The three notable software solutions for the supply chain management include the Supplier Nonconformance Management tool produced by INTELEX, the AdvancePro Inventory Management solution by AdvanceWare Technologies, and the Warehouse Management Software (WMS) by 3PL Central (Open Text, 2009). The Supplier Nonconformance Management tool enables the company that implements it to control its relations with business partners by proper and timely scheduling and assessing the activities of the suppliers and business partners. The AdvancePro Inventory Management solution is the powerful tool of managing the company’s inventory in the areas of logistics, warehousing, distribution, and retail trade. Finally, the Warehouse Management Software (WMS) is a third-party logistics tool that enables logistic providers to connect and effectively communicate with their customers and business partners.

SCM Software’s Use in Business Communication

It is natural that the supply chain management software on the whole and the three software solutions discussed above have the improvement of the company’s communication with its business partners as their major goal (Chapman, 2009). In more detail, the Supplier Nonconformance Management tool enables the company that adopts its use to establish better contact with its business partners through the online scheduling and confirmation system in which the history of the company – partners relations is recorded. Moreover, the Supplier Nonconformance Management provides the opportunity for business partners to communicate with the company and provide feedback on each other’s work (Open Text, 2009). The AdvancePro Inventory Management not only allows controlling the amount and state of inventory in its use by the company but also provides this information to the company’s partners so that the latter could see the openness of the company for cooperation and mutual accountability. Finally, the WMS creates the online system for the multi-sided communication that involves the company, its partners, logistics providers, and customers.

SC Partners’ System Integration

As it is clearly displayed by the major characteristics of the supply chain management and the software solutions designed for its purposes and discussed above, the integration of the supply chain management system and the software system among all the partners of a business company is of crucial importance. The point here, according to Seuring (2003), is that business activities that involve multiple sides having interested in their outcome can be successful only when the work of all the partners is coordinated and mutually agreed with the needs and current opportunities of other partners (p. 176). Thus, if a supplier fails to provide the necessary amount of raw materials to the manufacturer, the interests of other manufacturer’s partners including distributors, wholesalers, retailers, and customers are affected along with the manufacturer’s interests. Success of business activities involving numerous partners depends of the system integration of all these partners.

SC Architecture Diagram

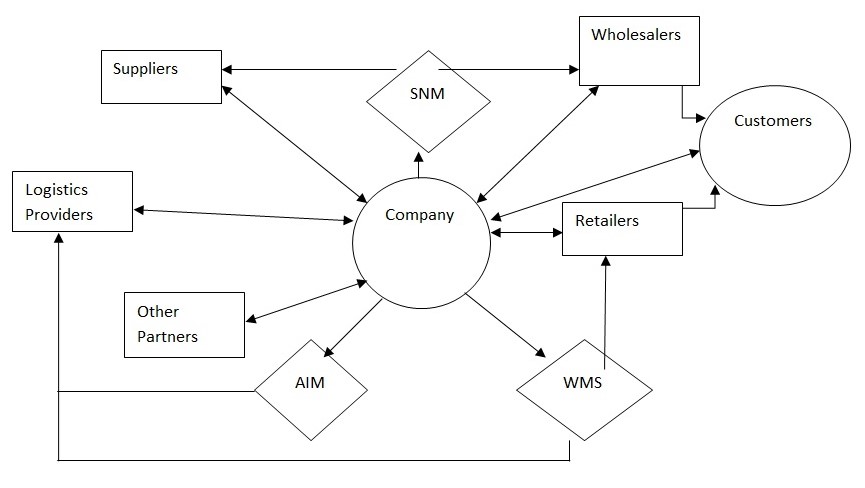

To illustrate the use of the above discussed software systems and technology in the basic supply chain management processes, the following supply chain architecture diagram can be used (Figure 1):

- SNM stands for Supplier Nonconformance Management software

- AIM stands for AdvancePro Inventory Management software

- WMS stands for Warehouse Management Software

Thus, the above SC architecture diagram reflects the major ways in which a business company can use its technology and the prior discussed supply chain management software solutions to carry out its activities and build relations with its suppliers, logistics providers, and other business partners. As well, the diagram reflects that the company’s suppliers can affect its wholesale and retail distributors through their interaction with the company.

Communication Objectives: Upstream and Downstream SC Members

Thus, the above diagram and the scholarly research on supply chain management by CPFR (2009), Seuring (2003), Liker (2005), and White (1999; 2001) allow speaking about the upstream and downstream direction of the supply chain development, as well as upstream and downstream business partners, i. e. suppliers and customers respectively. Among the five elements that constitute the supply chain management strategy, vision and mission, objectives, internal and external audits, and writing the strategy, the latter, i. e. writing the strategy is crucial as it is comprised of the major communicational objectives that the company has in dealing with its upstream and downstream business partners. To illustrate the idea, the example of Toyota Motor Company can be used:

Toyota’s Communicational Objectives with Upstream SC Partners

- Establish contacts and ensure friendly and fair cooperation;

- Ensure proper fulfillment of partners functions and guarantee of Toyota’s loyalty;

- Guarantee timely supplies (Likers, 2005).

Toyota’s Communicational Objectives with Downstream SC Partners

- Achieve customer loyalty;

- Widen customer base through displaying customer-friendly practices;

- Gain competitive advantage through attracting more customers.

Operational Objectives: Upstream and Downstream SC Members

It goes without saying, the companies have not only communicational but also operational goals while dealing with their business partners on the whole, and upstream and downstream supply chain in particular. White (1999; 2001), CPFR (2009), Seuring (2003), and Zieger (2006) argue that every business entity aims at its own goals during its business activities, and the success of their cooperation in supply chain process depends on the agreement of their goals at the time when they become involved into a single supply chain. In this respect, considerable role is attributed to the nine-step process model developed by CPFR (2009) as this model regulates all relations between business and supply chain partners and includes the guidelines concerning the establishment of supply chain partnership, developing the joint business plan, and working on any potentially arising disputes. Toyota’s operational objectives in relation with its upstream and downstream partners are based on this model and can exemplify the point better.

Toyota’s Operational Objectives with Upstream and Downstream SC Partners

- Reduce the inventory concerns involved in supply chain management;

- Increase return on the company’s equity;

- Increase rates of employees’ and customers’ satisfaction.

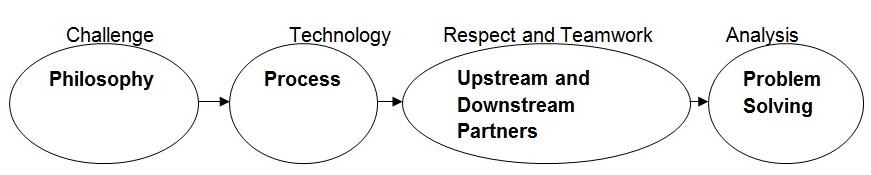

Sell-Side Process and Value Chain Map

The analysis of the sell- and buy-sides of the value chain management process can also be facilitated by the examples of Toyota Motor Company. On the whole, Chapman (2009) and White (1999; 2001) argue that supply chain management is greatly supported by the value chain and the proper fulfillment by companies of their duties in sell- and buy-side processes. These processes, in their turn, can be analyzed through the value chain map. Toyota’s value chain map can be characterized by four major levels and the basic vision values of the company used to operate those four levels (Liker, 2005):

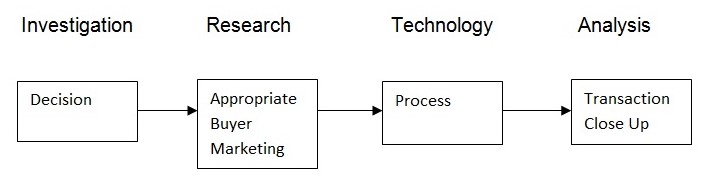

Based on the above Toyota value chain, the company’s process map for the sell-side process can be developed as follows:

Buy-Side Process and Value Chain Map

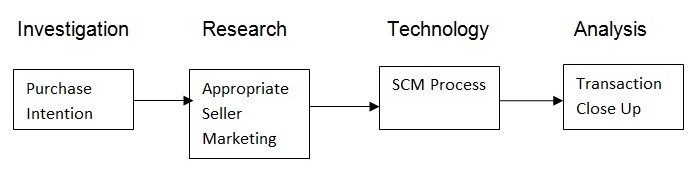

Thus, it is obvious that the sell-side process in Toyota Motor Company, as well as in any other company under the conditions of the proper supply chain management and value chain development, focuses on the need of the seller to make a decision about the need to sell goods or services, the marketing research work aimed at finding the most fitting buyers, technology use for the purpose of the proper product development and achieving the company’s communicational and operational goals with its partners, and the financial analysis for the transaction close up. The content of the buy-side process map for Toyota Motor Company can contain quite similar points with the only exception that the company’s activities as depicted in this map are designed for the purposes of finding the most fitting sellers and settling all purchase details with them:

Information Collection for Prospective SC Partners

One of the most important points informing the supply chain partnerships is the process of selecting the potential partners and getting detailed information about their background and current positions and any possible legal disputes or business-related controversy (Zieger, 2003). According to Zieger (2003), the mistake that companies often commit informing supply chain partnerships is placing too much hope on their partners without specific and detailed analysis of data accessible about the partnership history and feedback on their partners from their former or current associates. As a result of this information ignoring, the company might find itself in the situation when its partners either withdraw their duties to the partnership agreement or refuse to provide the equal funding share for concluding a specific transaction (Zieger, 2003). Thus, if a company fails to collect information on its partners prior to forming official relations with them, this company might fail in its short-term and even long-term goals when its partners do not cope with their duties in the supply chain management partnership.

SC Partners Evaluation Tool

For the purposes of collecting the most relevant data about the potential supply chain partners, a company should have a specifically designed tool, whose effectiveness should be proved in practice. One of the most effective and easy use tools for information collection might be the partner matrix that assesses the background of the firm, its history, current market position, competition conditions, reputation in the industry, specific data on the company’s participation in other partnerships, and guarantees of the company’s responsibility as a partnership member.

Figure 5. Data collection matrix

Culture in SCM: Top Five Culture Changes

The role of organizational, or corporate, culture in the development of the successful supply chain management is also considerable. As Seuring (2003) argues, there is a great dependency of the company’s success upon the ways in which its organizational culture and the human resources policies are developed. Proper organizational culture provides for the employees’ understanding of the joint values and goals of the organization and facilitates its success in the industry (Seuring, 2003, p. 386). Similarly, organizational culture can become an external phenomenon and affect the relations between the supply chain partners in the same way as it does with the organization/s employees. To exemplify the point, Toyota’s organizational culture is rather strong but minor improvements can still be made. The top five changes are:

- Put more emphasis on customer needs

- Increase employee involvement into decision making

- Introduce employee satisfaction measuring techniques

- Increase the value of employee over the value of the company’s benefit

- Practice environment-friendly activities

SC-Supportive Organizational Culture Evaluation

Although the above changes would potentially strengthen the organizational culture of Toyota Motor Company and make it more supportive of the supply chain management, the current state of the company’s organizational culture also allows speaking of the support to the supply chain. The assessment of this supportiveness can be carried out on the basis of the already mentioned supply chain management strategy and its basic elements, i. e. vision and mission, objectives, internal and external audits, and writing the strategy. The conformity of Toyota’s organizational vision and mission, objectives and business goals to the ideas of the supply chain management proves that the organizational culture of this Japanese auto-maker is actually supportive to supply chain management goals.

Conclusions

Thus, the conclusion from the above discussed data is that supply chain management is one of the most important aspects of the modern business. Naturally, in supply chain it is crucial that all the partners forming this chain should act in accord and support their other partners in the chain. Therefore, forming a supply chain involves, apart from other activities, the focused search and information analysis in relation to the potential partner. As well, supply chain management involves the conformity of supply chain ideas with the organizational culture of the company.

Works Cited

Chapman, Martin. “Supply Chain Management Architecture.” WS (2002) Web.

CPFR. “The Nine Step Process Model.” CPFR.org (2009). Web.

EC-Council. “Supply Chain Management.” Eccouncil.org (2009). Web.

Hullet, Ronald. “Sell-Side and Buy-Side Processes.” Hullet and Company (2009). Web.

Liker, Jeffrey. “The Toyota Way.” OESA (2005). Web.

Open Text. “Industry Value Chains.” The Content Experts (2009). Web.

Seuring, Stefan. Strategy and organization in supply chains. Springer, 2003. Print.

White, Andrew. “Return on Relationship versus ROI: Relationship Life Cycles and Collaboration.” Logility, Inc. (2001). Web.

White, Andrew. “The Value Equation: Value Chain Management, Collaboration and the Internet.” Logility, Inc. (1999). Web.

Zieger, Anne. “Don’t choose the wrong supply chain partner: shared goals, structure critical to success. (Update: supply chain management).” Encyclopedia (2003). Web.