Introduction

Operations management is a major determinant of success in any given business venture, regardless of the industry within which the company is operating. Several concepts are used to explain the phenomenon of operations management. In the current study, the author of this paper conducts a comparative analysis of the supply chain and the quality management aspects of operations management in Samsung Electronics and Caterpillar Inc.

Samsung Electronics and Caterpillar Inc.: Background of the Companies

Samsung Electronics

Samsung Electronics is one of the leading global electronics companies. The company is a flagship unit of the Samsung Group of Companies (Yang et al. 89). The entity has invested heavily in the semiconductor and electronics sector. Samsung Electronics focuses its operations on these two sectors of the industry.

The investment and operations management at Samsung Electronics has put the company ahead of the competition in the global industry. For instance, in 2004, Samsung Electronics Company was among the only two global manufacturing companies to hit the $10bn profit mark (Yang et al. 89).

The Samsung Group of Companies owns 516 sub-companies. Out of these, Samsung Electronics operates 195 fully-fledged subsidiaries (Han, Liem and Yoomi par. 3). Samsung Electronics is mainly popular for the manufacture and distribution of mobile phones and television sets. Also, Samsung Electronics and the subsidiaries manufacture and distribute a wide range of other products.

Caterpillar Inc.

Caterpillar Inc. is a significant player in the global construction industry. It deals with the production of mining and construction equipment in the world. Also, the company manufactures and distributes natural gas and diesel engines, as well as industrial gas turbines (Gillett, Ross and Bevington 27). Caterpillar Inc. also engages in the provision of related services, such as logistics, financial, and remanufacturing operations.

The industry within which the company is operating is very capital intensive. For instance, in 2006, Caterpillar Inc. had a capital expenditure of $1.6bn. The expenditure was spread across the company’s plants, equipment, and property (Gillett et al. 27).

An Analysis of Quality Management and Supply Chain Management

Operations management refers to the organizational processes and functions responsible for the production and delivery of valuable and quality goods and services to customers (MBA 5503 2). Operations management entails a wide range of processes in an organization. Essentially, for the conversion of inputs into goods and services to take place, operations require effective and efficient management.

Supply chain management (SCM) is one of the various examples of operations management. Supply chain management refers to the extensive “network of manufacturing and service operations that supply one another” (MBA 5503 4). The functions involved in supply chain management cover the entire production process. The functions entail the management of activities involved in the processing of raw materials and the delivery of the goods and services to the consumers. Today, many companies acknowledge the importance of supply chain management as a strategic means of improving the entire spectrum of business operations in a company (Yang et al. 89).

Quality management is the responsibility of the entire organization. It is only the customer who can determine the quality of goods or services offered by an organization. However, the organization has the responsibility of “meeting or even exceeding customer requirements, now and in the future” (MBA 5503 4).

A Comparative Analysis of Supply Chain Management in Caterpillar Inc. and Samsung Electronics

Samsung Electronics maintains a large and complicated global supply chain for the various products it manufactures and distributes. Supply chain solutions, as well as process innovations, plays a major role in supporting and improving the operations of the organization. According to Yang et al. (89), Samsung Electronics was recently voted as one of the top 25 global companies with regards to its supply chain management.

There are several supply chain systems used by Samsung Electronics. They include, among others, the Advanced Planning and Scheduling (APS) system (Yang et al. 90). The system has brought considerable success to the organization lately. Samsung Electronics supply chain comprises of numerous subsidiaries. As of 2012, Samsung Electronics was operating 195 subsidiaries (Han et al. par. 4). Most of the company’s products are manufactured in different locations across the world. China is the location where most of the products are manufactured.

The agency theory has been used to analyze how Samsung Electronics deals with suppliers. The theory is significant to Samsung Electronics since it centers on the principal as the manufacturer and agent as the supplier (Ndubisi et al. 335). Samsung Electronics relies mainly on suppliers, who form a major part of its operations. The supplier requires essential capabilities and performance to meet the short-term or long-term supply needs of the company.

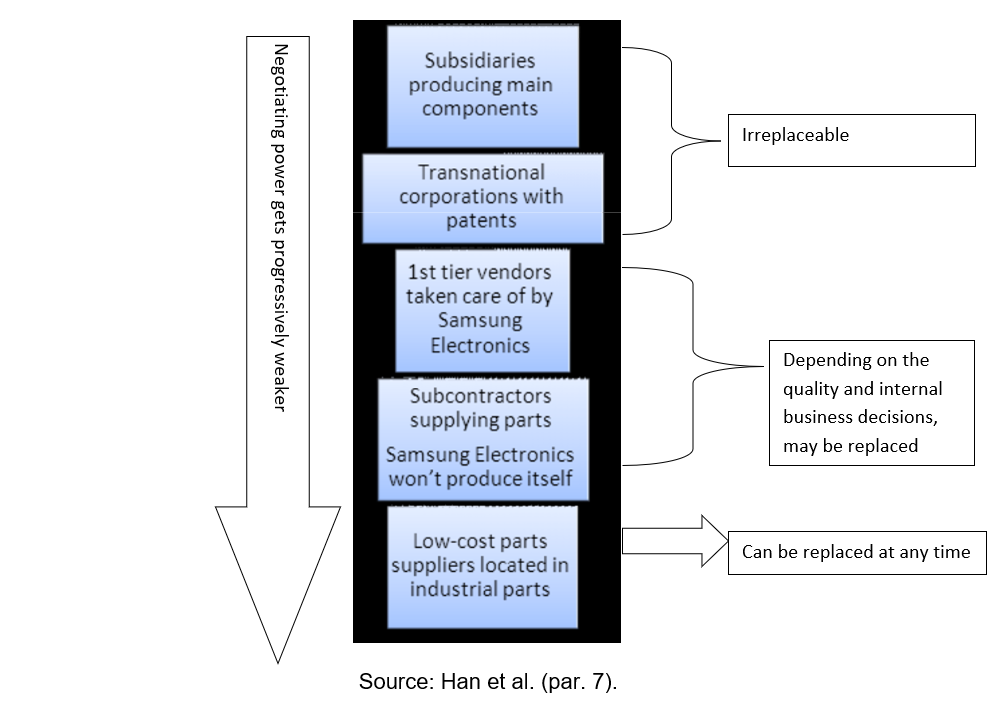

Most of the subsidiaries produce components that are then utilized by other Samsung Electronics units (Han et al. par. 6). The company’s component production and supply element have a unique structure. It comprises five layers. The first layer entails Samsung Group subsidiaries. The second tier involves components of suppliers from different parts of the world.

The third layer in the Samsung Electronics supply chain is made up of suppliers of outsourced parts. The agents are involved in the supply of parts that the company can produce itself (Han et al. par. 6). Production capacity and cost factors, however, necessitate outsourcing. The fourth layer consists of domestic sub-contractors of the company. The sub-contractors supply the components that Samsung Electronics cannot produce. An example of such a supplier is Interflex Company. The company is responsible for the supply of printed circuit boards.

The fifth and final layer in the company’s supply structure is perhaps one of the most important components. It is made up of small and medium-sized suppliers. The suppliers deal with components commonly found in industrial parks (Han et al. par. 6). The companies usually produce low-cost parts. In a bid to exacerbate price competition, Samsung Electronics switches between them. The fifth layer also forms the largest supplier of Samsung Electronics.

Samsung Electronics subsidiaries usually distribute the company’s products. Also, most of the products are distributed through the umbrella organization, Samsung Group. The management of the Samsung Electronics supply chain through the layers presented above focuses on the strength of innovations and reduced costs to enhance operations and profitability (Yang et al. 89). The figure below shows the various layers in the company’s supply chain:

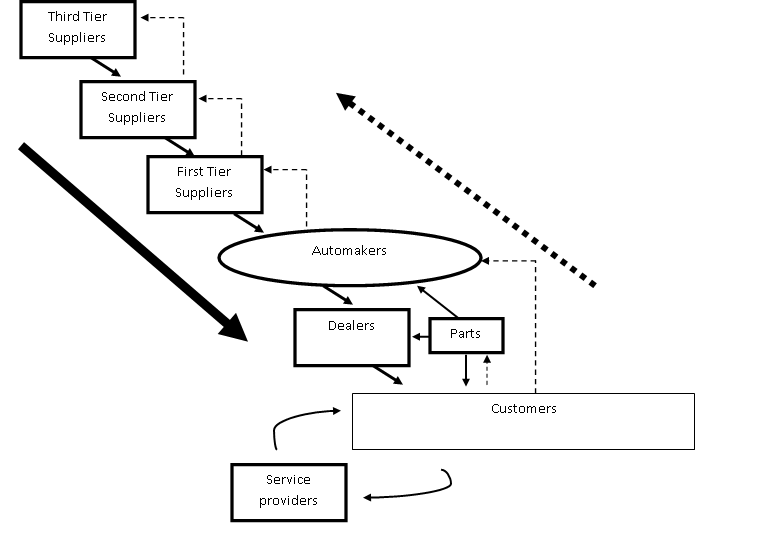

On the other hand, Caterpillar Inc., despite being a global organization like Samsung Electronics, adopts a different supply chain management. The nature of production operations in Caterpillar Inc. is very capital intensive. Therefore, the company’s supply chain focuses on the creation of a network enhancing profit maximization, flexibility, and market share increase (Rao, Wolf, and Tayur par. 2).

Unlike Samsung Electronics, Caterpillar Inc. does not deliver products to end-users. The company utilizes a global network of dealer distributors. It is the dealership that links the company to the customers (Gillett et al. 27). For instance, as of 2008, there were over 180 Caterpillar dealerships across the world.

Currently, the company employs a supply chain model referred to as the P2000 (Rao et al. par. 3). The supply chain model is necessitated by the international shipping nature of Caterpillar Inc. products. The logistics capabilities of the model effectively address this nature. The products of the company are considerably heavy. As such, their supply consumes a lot of time and leads to increased shipping costs.

The bulk of Caterpillar Inc. products undergo development at the main plant. They are then distributed to dealers, who deliver them to the consumers. The structure of the supply chain assumes a collection of nodes. It incorporates the sources, the dealers, and the trans-shipment points. Edges in the supply chain model constitute connections between the nodes (Rao et al. par. 9).

Both Samsung Electronics and Caterpillar Inc. utilize technology to exploit the strength of suppliers. Technology also enhances the development of new products. Samsung Electronics, however, focuses on forming alliances with suppliers to effectively and efficiently manage purchasing and supply functions.

Caterpillar Inc.’s supply chain model, on the other hand, focuses on the dealer. The greatest concern of the company is the flexibility of the supply chain (Gillett et al. 27). The heavy equipment developed by the company is shipped to the dealers, who then offer them to customers on behalf of the company. The flexibility of the supply chain is a key operational objective in Caterpillar Inc. The figure below is an illustration of the various layers in the supply chain of this company:

A Comparative Analysis of Quality Management in Caterpillar Inc. and Samsung Electronics

Both Samsung Electronics and Caterpillar Inc. exhibit a similar approach to quality management. At Samsung Electronics, activities involving product design and development, and basic research constitute primary functions of the organization (“Global Value Chain Analysis on Samsung” par. 13).

Both Samsung Electronics and Caterpillar Inc. employ the concept of “Six Sigma” in their operations. The concept refers to a “total quality management technique pioneered by Bill Smith and applied in Motorola processes during the 1980s (Fink et al. 27). The approach is data-driven. It aims at the elimination of defects in a given process. It is applied in manufacturing to transactional processes, as well as in the delivery of goods and services.

In addition to the Six Sigma technique, Samsung Electronics employs another concept referred to as “new management”. The concept was adopted by the company as early as 1993 (Yang et al. 89). It is a business innovation approach that focuses on quality. It maintains the quality of operational processes in the company. Initially, the approach targeted product quality assurance. With time, it diversified to incorporate the quality of entire business processes (Yang et al. 89). The new management approach adopted by Samsung Electronics assumes the same rationale as Six Sigma. Six Sigma and the new management approach are some of the factors behind the success of Samsung Electronics.

In Caterpillar Inc., the Six Sigma technique was adopted to realize long-term strategic goals. Some of these strategic goals include global quality leadership in the production of earthmoving equipment (Gillett et al. 28). Other strategic goals in this company include market leadership, product availability, and high levels of safety standards (Gillett et al. 28). The technique is beneficial to Caterpillar Inc. not only through quality management but also through the development and maintenance of a quality culture.

In managing quality, Caterpillar Inc. utilizes a disciplined approach. It focuses on information gathering, data analysis, and the making of decisions based on facts. The methodology enhances the efficiency and effectiveness of processes. Quality management approaches adopted by Samsung Electronics differ from those used by Caterpillar Inc. For example, the former relies on a network of component producers or suppliers. On the contrary, Caterpillar Inc. produces the components used in the manufacture of the machinery. Suppliers at Samsung Electronics apply the Six Sigma technique in their production processes (Gillett et al. 28).

The differences between Samsung Electronics and Caterpillar Inc. with regards to quality management are process-oriented. Both companies use the Six Sigma technique in quality management. As such, the differences are found in their production techniques.

Conclusion

The importance of a relevant and efficient supply chain and quality management frameworks in every organization cannot be ignored. Samsung Electronics and Caterpillar Inc. are global leaders in their respective industries. An analysis of their supply chain and quality management frameworks reveals that the two concepts have played a key role in the success of these companies. Even though the two companies operate in different industries, they appear to use a common quality management technique, Six Sigma.

One can conclude that the planning and implementation of operations management strategies determine the success of an organization. Without an elaborate, effective, and efficient supply chain and quality management frameworks, the excellence of both companies is not guaranteed.

Works Cited

Gillett, John, Ross Fink, and Nick Bevington. “How Caterpillar uses 6 SIGMA to Execute Strategy.” Strategic Finance 91.10 (2010): 25-28. Print.

Global Value Chain Analysis on Samsung Electronics. 2012. Web.

Han, Jiwon, Wol-san Liem and Lee Yoomi. 2013. In the Belly of the Beast: Samsung Electronics’ Supply Chain and Workforce in South Korea. Web.

MBA 5503. 2013. “Production and Operations Management Week 1 Lecture: Introduction to Operations Management and Supply Chain Management”, The McGraw-Hill Companies, Inc. Lecture Notes.

Ndubisi, Nelson, Muhamad Jantan, Hing Loo and Ayub Mat. “Supplier Selection and Management Strategies and Manufacturing Flexibility.” The Journal of Enterprise Information Management 18.3 (2005): 330-349. Print.

Park, Sung. 2003. SIX SIGMA and its Role in Quality Management. Web.

Rao, Uday, Alan Wolf and Sridar Tayur. 1998. Development of a Rapid-Response Supply Chain at Caterpillar. Web.

Yang, Hong, Choi Byung, Hyung Parrk, Jin Suh and Chae Bongsug. “Supply Chain Management Six Sigma: A Management Innovation Methodology at the Samsung Group.” Supply Chain Management: An International Journal 12.2 (2007): 89-95. Print.