Executive Summary

This report provides a detailed overview of the operations management in the “Burger King” franchise. It highlights the key areas of the operations management in Burger King, provides the process chart for the hamburger production and examines the lean principles implemented in the production process.

In the second section, it examines the current capacity management involved in “Burger King”, measuring it against the industry standard and evaluating the main challenges the management teams are faced with. The findings are then used to discuss whether the companies should always attempt to match its capacity to its forecast and known demand patterns or there might be situations where this might not be needed.

Finally, the third section of the report summarizes the contents of the other two parts in greater detail and develops recommendations for the organization management development in “Burger King”.

Introduction

“Burger King” is one of the biggest and most recognizable fast-food companies around the world, with over 11,000 restaurants in 60 countries. As multi-national franchise, it has a complicated operation system that requires detailed strategic planning from the management team. Ensuring the consistent profitability, environmental responsibility and stable growth is a difficult task for a market as established as the fast food. This paper aims to provide a detailed overview of this system on every stage, taking all the existing operations and processes into consideration. As per the requirement of the question, the paper is divided into three main sections, more of which is previewed below.

The first part critically evaluates the existing operation functions within the organization and the role of the operations manager. It compares Burger King’s existing practices with the general practices of the industry and strengthens the analysis by accompanying it with the process chart. It then identifies and discusses (if applicable) the Lean processes within the organization, as well as the benefits and overall impact of those. The second part and aims to assess whether the statement “organizations should always attempt to match its capacity to its forecast and known demand patterns” is true for Burger King. It focuses on the assessment of the management practices and prioritization within the company. Finally, the third part of the report collates the findings about Burger King’s organizational processes and summarize the conclusions on the basis of the analysis as a whole.

To conduct the assignment 15 sources have been utilized, including academic articles, books, reports, and several websites. To guarantee the relevancy, all of the sources picked were published in 2016 or later. The selection process was conducted with the intention of balancing the potentially conflicting approaches and covering the topic from multiple perspectives, keeping in mind the industry standard. When needed, the academic articles were prioritized over the websites, yet the latter group contained some of the most interesting and relevant information about Burger King’s internal structure and was therefore included. All of the sources are referenced on a separate page in the end of the assignment in the Harvard style.

Part A1: Operations management

Current Operations

Below is the summary of the areas in which Burger King’s operations managers maintain and supervise the firm’s current operations. These are also common specifications for the operation management across large-scale firms with multiple outlets (Burger King, 2021). As Burger King is among the industry leaders, its performance in these operation areas is up to the standard, but naturally certain diseconomies of scale are a source of issues.

Design of Goods and Services. This area of focus is concerned with product differentiation from the competitors and ensuring the company maintains its selling point. Namely, Burger King’s flame grilled burgers are widely recognizable and relatively unique at the fast-food market. Continuous and consistent differentiation supports the firm’s intensive growth strategies and serves as a focal point for the marketing campaigns. The key issue related to this are is to do with the general uniformity of the fast-food market, where the customers often perceive substitute companies as interchangeable.

Quality Management. This strategic decision area involves satisfying the quality expectations of the customer base across the existing locations. To address this area, Burger King’s operations management widely utilize product tests and keep their recipes to the same standard. Issues in this area are largely due to the taste consistency difficulty problem, as local suppliers’ specifics might affect the taste of the product.

Process and Capacity Design. Burger King’s objective in this strategic decision area is to maximize capacity utilization and productivity, avoiding the loss of valuable financial and human resources. For example, the company continuously monitors demand and sales at its restaurants worldwide. Burger King adjusts its production facilities’ operations accordingly to ensure the demand is met on a consistent basis.

Location Strategy. The primary operations management concern regarding location is to strategically optimize market reach. Burger King’s strategy to address this decision area involves market penetration, with focus on urban centers and malls. As typical for the fast-food franchises, Burger King frequently places its outlets in food courts. This strategy facilitates the market reach but might lead to the intense competition.

Layout Design and Strategy. Burger King’s operations management strives for efficiency, which informs the layout design of the company locations. For example, the company’s kitchen design is as compact as possible to save space while enabling worker productivity. Thus, Burger King addresses this strategic decision area through efficient layouts and workflows. Such focus on efficiency in the layouts can lead to ethical and legal conflicts due to the individuality of needs of different workers.

Job Design and Human Resources. Sufficient and effective human resources are the objective in this strategic decision area of operations management. Burger King implements the training programs for new employees to ensure their smooth introduction to the work process (Elobeid, Savvaidis and Ganji, 2019). Nevertheless, the operations managers have to consider that by its nature most of their employees are dealing with monotone, low-skilled job with comparatively low payrates. Thus, a high turnover in employment is a standard management challenge for a fast-food restaurant.

Supply Chain Management. Burger King has a global supply chain and therefore its production process is affected by a variety of local supply laws and regulations. In this strategic decision area, the objective is to ensure the sufficient amount of the materials supplied and its required level of quality. Burger King’s operations management strategy involves consolidating all supply chain activities under Restaurant Services, Inc. (RSI). Burger King’s materials and ingredients are supplied through RSI.

Industry Standards

The industry standards, already mentioned above, remain generally consistent and uniform across the fast-food market. As parts of an oligopoly, companies like Burger King, McDonalds, Taco Bell and so on provide similar ranges of easily obtainable cheap foods. Their operations and marketing campaigns primarily target low to middle class people who don’t have time or other resources to cook at home. The olipogopic structure of the market leads to the firms being reluctant to raise their prices or engage in price competition altogether. If one of the industry players was to lower the price, due to the similarity of available options the other firms would be forced to do the same. Similarly, price increases of the individual company would not result in the increase in revenue since the customers can always switch to the available closer substitutes.

With this factor in mind, it is no surprise that the companies engage in other forms of competition. To maintain the existing competitive advantage, if there is any, and to keep the loyal customer base, all of the large industry players ensure that the operations they maintain are up to the standard across the industry. Consecutively, Burger King is not lacking in this department, and, on the contrary, demonstrates impressive results. Burger King’s operation management is consistently up to the industry standard in all of the areas mentioned above.

Role of Operations Manager

The key role of operations manager is to oversee the activities that are part of the production of goods and services. They control the production process from the product design until its launch in an outlet. Therefore, it is essential for an operations manager to be familiar with the inputs and outputs of an organization in all areas dedicated to its regular activities. The responsibilities of an operations manager include but are not limited to human resources management, cost management and assets management (Burger King, 2021). Those are the core of the management team who ensure the firm stays on track with its resources and processes, generates profits and provides consistent value to its customers. The upcoming sections of the report are dedicated to the assessment and discussion of the more specific areas of Burger King’s operation management: process management, lean management, and capacity management.

Part A2: Process Management

Process Management in the organisation

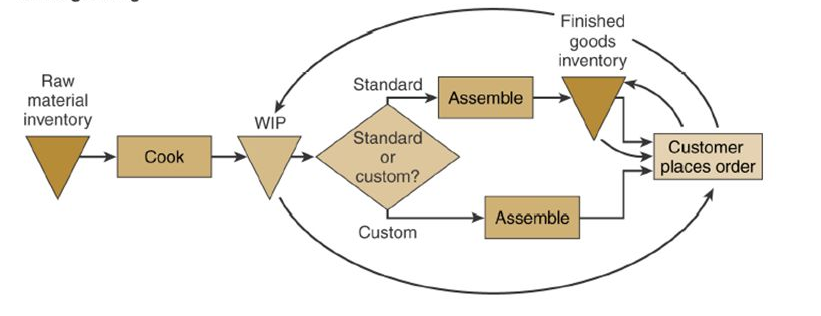

The process chart above is based on the information provided in Fundamentals of Operations Management textbook by Paul Hopkin. It demonstrates the process of the hamburgers’ production from the stage of raw materials to the stage of being bought by customers. It can be seen on the diagram, that the components of the future burger are first cooked, and then assembled with the potential customization being taken into account.

Process Analysis and improvement

The analysis of the production process can only be conducted when compared to the government production firms of the close substitutes, such as McDonalds or Wendy’s. In particular, the process chart of Wendy’s demonstrates the customization being implemented earlier, before the hamburger is fully cooked. That means, the Burger King’s competitor cooks the elements of the final product after learning whether a customer wants any modifications from the standard model. Hypothetically, this could be a potential improvement for Burger King as well. Since the company, as discussed in greater detail below, is committed to the production waste reduction, it would make sense for Burger King to only process the raw materials after learning whether there is a need for them or not (Thiemann and Roman-Alcalá, 2019). As counterargument, one might insist that customization is a comparatively rare scenario in mass fast-food production, whereas the quantity of raw materials involved in cooking is already estimated based on the average demand.

Customer service strategies

Customer service is generally considered one of the strongest areas in Burger King’s operational performance. As mentioned before, the fast-food companies typically do not engage in the price-based competition. Similarly, as menu items of Burger King and its closest competitors (McDonalds, Wendy’s, etc.) are practically interchangeable, the company relocates its competitive resources to the promotion and the customer service. The company provides intensive up-to-date training to its employees prioritizing their resilience, friendliness and effectiveness in potentially emotionally compromising situations.

Inventory Management

Burger King’s inventory management is, as usual for the fast-food firm, dedicated to the efficiency maximization with the intent to minimize the associated costs at the same time. It involves the management of raw materials, production equipment, as well as warehousing and processing of some of the products. For the businesses that deal with product output, the capacity of the production operations is practically stored in inventory. Hence the inventory management is closely tied to the product itself, and it is essential to have this area under control to avoid the disruptions in service (Cachon, Daniels and Lobel, 2017; Caldentey and Wein, 2003; Gijsbrechts et al., 2018; So, 200; Song, Van Houtum and Van Mieghem, 2020). Burger King’s complex supply chains and manufacturing processes make the inventory management a challenging task for the company. As the fast-food industry does not need the products to be exclusively fresh (as in not frozen), the firm does not need to engage in Just-In-Time inventory management approach. However, the Material Requirements Planning approach suits Burger King well (Tejesh and Neeraja, 2018; Song, van Houtum and Van Mieghem, 2020; Van Mieghem and Rudi, 2002). It utilizes the business development software to estimate the qualities of raw materials needed for the production output and then design the orders from suppliers accordingly.

Scheduling Operations

Burger King’s approach to this area is based on the industry trends of high turnover of lower-skilled workers and prolongated opening hours of the fast-food restaurants. When taken out of the outlets exclusively, scheduling introduces the time management component to the production process in general. It is essential for co-ordination between the suppliers, the production areas, the delivery and the retail. The main objective of the scheduling is to reduce the overall production time, avoid clashes and ensure the value is delivered to the customers on a consistent basis.

Part A3: Lean Management

Lean management in the organisation

Typically, lean operations constitute a significant amount of the strategy formation for a business organization with the franchise model. It focuses on the resource-conscious manufacturing that minimizes the waste involved in the organization’s functioning on multiple levels. Under the Lean approach, key areas of the organizational processes and resources, ranging from the manufacturing of the products offered to the human resources turnover. Modern companies implement the lean approach of continuous development and waste reduction to gain competitive advantage in the increasingly competitive atmosphere. The model aims to improve the company’s efficiency by incorporating five principles into its daily and strategic operations, all of which are related to consumer needs. The five Lean principles are: identifying the value, mapping the value stream, creating the flow, establishing pull and securing continuous improvement (Li, Field and Davis, 2017; Mohhamad, 2017). All of the following can be analyzed and identified, to a various degree, in Burger King’s operations.

When defining value, operations managers pay the most attention to what the customers are willing to pay for. This principle is generally secured by anything associated with the market research. Surveys, questionnaires, interviews, and all types of statistical analysis can be implemented to understand what creates and maintains value for the customer in the company’s product. Burger King implements this principle via these means, consistently keeping an eye on any potential changes in the customers’ taste. Afterwards the managers modify the product assortment of the company accordingly to ensure the customers are consistently satisfied.

The second Lean principle is identifying and mapping the value stream, using the customers’ value as a point of reference. The order of performance of the principles is important, since it allows the business to focus on the activities that deliver the aspects its customers value the most. Activities that do not add value to the end result are therefore considered waste and analyzed further to decide whether the management team should get rid of those entirely. The waste is then separated into two groups: non-value-adding but necessary and non-value-adding and unnecessary. By reducing and eliminating unnecessary processes or steps, the company can ensure that customers are getting exactly what they want while at the same time reducing the net production costs. In Burger King’s case this lean principle can be seen in unpopular food items being relocated to seasonal status or removed from the menu entirely.

The third lean principle concerns the flaw of value and ensures the stream’s consistency and ensures that the value creation steps occur in the tight sequence increasing the speed of the value delivery for the customer. This principle aims to eliminate the possible interruptions and disruptions in the value delivery schedule and utilizes optimization to achieve this goal. One of the potential options involves breaking down the production steps into more manageable bits that are easier to understand. Other available options involve the internal transformation of the organization: establishment of the cross-functional departments, investment in the communication system development and increase in training for the employees to make them more adaptable and willing to learn on the fly.

The fourth lean principle is the establishment of the pull, which is directly tied to the inventory management, already discussed earlier in this assignment. The goal of this principle is to reduce the amount of work in progress (i.e. the products on the in-between production stages) while simultaneously maximizing the output available to the client. It favours the Just-In-Time inventory management system, as it largely requires the fresh raw materials to be available for when the processing has to begin. Consecutively, it is the only lean principle Burger King has not yet aimed to implement in its production. The fast-food highly processed food production is arguably poorly suited for Just-In-Time delivery of raw materials. Nevertheless, Burger King is concerned with the optimization of its processes and the reduction of the amount of the WIPs.

The fifth (and the final) lean principle is tied to the pursue of perfection and is, perhaps, the easiest to explain. It requires of a lean company to engage in the continuous improvement process and constant optimization. The selling points customers perceive as valuable change with time, and so do the areas where an organization might have unnecessary and avoidable amounts of waste. Burger King’s managers are committed to consistent market analysis and screening to ensure the company remains ahead of the existing trends and the potential problems.

Although the implementation of the lean principles into the international franchise is a complicated task that requires consistent effort, now it is more relevant for the business landscape than ever. The waste reduction is evidently tied to the sustainability politics and the commitment to the reduction of the CO2 emissions. To not engage in said sustainability politics would mean to put oneself into a disadvantaged position when compared with competition (Amaro et al., 2019; Koide, Kobayashi and Kikuda, 2018; Vu et al., 2017). The closed nature of the fast-food market influences Burger King’s commitment to remain on the same level as its potential substitutes: in the area of the lean management just as much, as in the others.

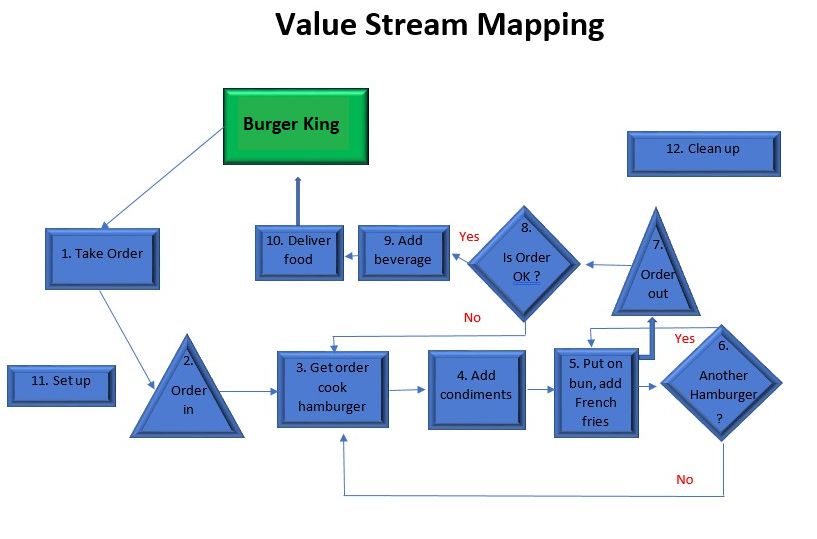

Value Stream Map in the organisation

Part B: Capacity Planning

Capacity management in an organization is dedicated to ensuring the business is always producing the maximum possible output. The term “capacity” in a business context refers to how much an organization can produce or sell within a given period of time (De Vries, Roy and De Koster, 2018). The capacity management also requires maintaining the existing equipment and inventory in the sufficient condition or amount to meet the existing demand and match the planned output. The difficulty of a task is further intensified by the fact that demand for food products is often seasonal and changes due to the external factors. Even within the industry as consistent and uniform as fast-food restaurants, the fluctuation exists: namely, the demand increases during the periods of major sports events. Although such factors do not affect the production capacity of Burger King per se, those should be accounted for during the capacity planning to minimize the waste.

Burger King’s capacity is naturally very large, since all the company’s operations exist on a mass production scale and target large international market. Due to the amount of outlets alone, the amount of product the firm is able to produce is significant and consistent (Weng, Gotcher and Kuo, 2016; Wang, Ferguson and Souza, 2013). The factors that directly affect Burger King’s production capacity are the availability of raw materials and the state of the inventory involved. This area of management is essential to the overall success of the organizational planning and management, since it determines organization’s ability to meet the demand. For example, to prevent a Burger King restaurant running out of meat in the middle of the major baseball game day, capacity planning is needed. Furthermore, the information on the expected capacity is one of the key factors to determine the amount of initial investment needed for the opening of a new Burger King outlet.

When engaging in the capacity planning, Burger King’s management team should remember that the firm provides not only goods, but services. As a restaurant chain, Burger King additionally requires the capacity planning to estimate the size and the internal layout of its current and future locations. All of these tasks lead to the necessity of forecasting, to a degree, the number of customers expected at any given period on any given location. In this area, however, Burger King is aided by its long organizational history, since every new outlet might rely on the research conducted in the already existing ones. Based on the internally collected data, Burger King managers might estimate the average number of customers at the locations for any given city or area. Other factors incorporated in the potential analysis include the additional variables such as number of cars passing by or the situation with the nearby positioned competitors.

The scale of Burger King’s operations and its status as one of the leading fast-food chains in the world indicate that the company has achieved efficiency in its capacity planning. The forecasted demand is considered every time another outlet is opened within the franchise. Where possible, the production capacity is later revised to match the latest technological advancements in the output Burger King is able to generate. As the marker dependent on the combination of factors and the relationships between said factors, capacity management can sometimes overlap with many other types of management, namely inventory or HR (Najdawi, Chung and Salaheldin, 2008; Schrunder, Galletly and Bhicheno, 1994). This multidimensionality only intensifies the importance the capacity management has for the overall performance of the organization.

Whether organizations should always attempt to match its capacity to its forecast and known demand patterns or not is a topic largely unique for any separate company. For Burger King, the answer to this question appears to be positive since the consistency between capacity and forecast facilitates the production waste reduction and further increases the efficiency. However, with the speed at which service industry evolves in current times and the recent impact of COVID-19 pandemic, it is reasonable to expect inconsistencies in capacity estimates. All of these factors might have a toll on the capacity markers, such as the number of customers, waiting times between orders and the correlational relationships with the outside factors (holidays, location specifics, and so on). Therefore although striving for the perfect match between forecast and eventual capacity is within lean principles and profit maximization, it is not a fully realistic outcome. Yet certain consistency between these markers is essential for the prosperity of an organization, since capacity-related investment decisions cannot be reversed without major costs associated with the process.

Part C: Conclusion and Recommendations

Burger King’s organizational performance turned out to be a largely successful, fully functioning and self-sufficient system that generates big product and service outputs across its existing branches. Its nature of a fast-food restaurant makes the firm an effective illustration for many of the existing models and concept in the organizational management studies. The managers of the company monitor and oversee its supply chain, production processes, internal and external communication, customer demand and logistics at all levels. It provides them with a complex multi-layered vision of the organization and the position it occupies in the business landscape as a whole. Consecutively, such management is only maintainable when the proper delegation is applied.

The main recommendation for Burger King’s organization management would be to establish separate departments for the management of daily operations, capacity, lean principles, and other areas within the process if required. Such departments would be able to communicate trough the well-developed internal channels and exchange the expertise when necessary. This communication can be facilitated trough the key transformative power across management fields in the business world of the last decade: digital technology.

Newer operating models rely increasingly on digital networks connecting people and organizations to enable their independence. Yet the foundations of lean principles and capacity management demonstrate that traditional organizational theories maintain its’ relevance due to the universality of the principles in question. When, for Burger King, food delivery apps and online orders become the source of profit, the necessary hardware and software become integrated in the supply chain. Embracing such technology further is a key recommendation for the evolution of the organization management for the company since it has the increased potential to add value to its customer service. To utilize the obvious trend for the greater commercial success in its operations, however, Burger King would have to go further than a simple design of the app.

Arguably, such technological implementation is now a requirement more so than the source of the potential competitive advantage, as the companies have to adopt it to “stay in the game”. However, Burger King could progress the trend further and become a pioneer of the industry by introducing digital order customization features to a greater degree. There is a possibility that it would require the company to switch to the alternative inventory management technique and adopt Just-In-Time. In the end of the day, sources of competitive advantage or disadvantage in the fast-food industry are tied to the taste of the products available. Thus, by equipping the customers with greater control over said taste, Burger King would be able to take the lead.

Other potential recommendations involve following trough with the commitment to lean principles and waste reduction. The model is an evident way forward when it comes to minimizing the empty costs and increasing efficiency in the production, while simultaneously upholding the code of ethics and sustainability (Harun, Prybutok and Prybutok, 2018). Although establishing the pull would require significant and large-scale transformations from the company, it is likely to increase its revenue and perhaps even market share in the long run. By emphasizing its strong selling points and taking the risk in the digital sphere Burger King might establish itself as the king of the international fast-food industry.

References

Amaro, P., Alves, A.C., Sousa, R.M.: Lean thinking: a transversal and global management philosophy to achieve sustainability benefits. Lean Eng. Glob. Dev. 1–31 (2019). Web.

Burger King Corporation (2021). Burger King Corporate Responsibility.

Boute R.N, Disney S.M, Van Mieghem J.A (2019) Dual sourcing and smoothing under non-stationary demand time series: Re-shoring with speed factories. Working paper, KU Leuven, Leuven, Belgium

Cachon G.P, Daniels K.M, Lobel R (2017) The role of surge pricing on a service platform with self-scheduling capacity. Manufacturing Service Oper. Management 19(3):368–384.

Caldentey R, Wein LM (2003) Analysis of a decentralized production inventory system. Manufacturing Service Oper. Management 5(1):1–17.

Gijsbrechts J, Boute RN, Van Mieghem JA, Zhang D (2018) Can deep reinforcement learning improve inventory management? Performance and implementation of dual sourcing-mode problems. Working paper, KU Leuven, Leuven, Belgium.

De Vries, J.: Worth the wait? How restaurant waiting time influences customer behavior and revenue. J. Oper. Manag. (2018). Web.

Elobeid, T., Savvaidis, I. and Ganji, V. (2019), “Impact of food safety training on the knowledge, practice, and attitudes of food handlers working in fast-food restaurants”, British Food Journal, Vol. 121 No. 4, pp. 937-949. Web.

Harun, A., Prybutok, G. and Prybutok, V. (2018), “Do the millennials in the USA care about the fast food industry’s involvement in corporate social responsibility?”, Young Consumers, Vol. 19 No. 4, pp. 358-381. Web.

Koide, T., Kobayashi, T., Kikuda, M.: A multi-agent simulation study for congestion minigation in a university campus restaurant. Trans. Eng. Technol. (2019).

Li, G., Field, J.M., Davis, M.M.: Designing lean processes with improved service quality: an application in financial services. Qual. Manag. J. 24(1), 6–19 (2017). Web.

Mohammad, A. (2017), Approaching the adoption of lean thinking principles in food operations in hotels in Egypt. Tourism Rev. Int. 21(4), 365–378

Najdawi, M. K., Chung, Q. B., & Salaheldin, S. I. (2008). Expert systems for strategic planning in operations management: a framework for executive decisions. International Journal of Management and Decision Making, 9(3), 310-327.

Schrunder, C. P., Galletly, J. E., & Bicheno, J. R. (1994). A fuzzy, knowledge‐based decision support tool for production operations management. Expert Systems, 11(1), 3-11.

Rotter, T., Plishka, C., Lawal, A., Harrison, L., Sari, N., Goodridge, D., Flynn, R., Chan, J., Fiander, M., Poksinska, B., Willoughby, K. and Kinsman, L., 2018. What Is Lean Management in Health Care? Development of an Operational Definition for a Cochrane Systematic Review. Evaluation & the Health Professions, 42(3), pp.366-390.

So K.C (2000) Price and time competition for service delivery. Manufacturing Service Oper. Management 2(4):392–409.

Song, J., van Houtum, G. and Van Mieghem, J., 2020. Capacity and Inventory Management: Review, Trends, and Projections. Manufacturing & Service Operations Management, 22(1), pp.36-46.

Tejesh, B. and Neeraja, S., 2018. Warehouse inventory management system using IoT and open source framework. Alexandria Engineering Journal, 57(4), pp.3817-3823.

Thiemann, L., Roman-Alcalá, A. (2019) Fast Food Sovereignty: Contradiction in Terms or Logical Next Step?. J Agric Environ Ethics 32, 813–834. Web.

Van Mieghem JA, Rudi N (2002) Newsvendor networks: Inventory management and capacity investment with discretionary activities. Manufacturing Service Oper. Management 4(4):313–335.

Vu, H.M., Chan, H.K., Lim, M.K. and Chiu, A.S.F. (2017), “Measuring business sustainability in food service operations: a case study in the fast food industry”, Benchmarking: An International Journal, Vol. 24 No. 4, pp. 1037-1051.

Wang W, Ferguson M, Hu S, Souza GC (2013) Dynamic capacity investment with two competing technologies. Manufacturing Service Oper. Management 15(4):616–629.

Weng, S., Gotcher, D. and Kuo, C., 2016. Lining up for quick service—The business impact of express lines on fast-food restaurant operations. Journal of Foodservice Business Research, 20(1), pp.65-81.