Abstract

Chevron is among the largest companies in the oil and gas industry and operates in several nations. The company’s operational management manifests itself in its Operational Excellence Management System (OEMs), which utilizes at its core the ideas gathered from both Lean and Agile theories (Chevron, 2021a). Such an approach allows Chevron to gain a competitive advantage by shaping its operations management around efficiency and continuous response to the changing environment.

As the prices of oil continue to fluctuate globally, Chevron responds to the elasticity by introducing new technologies into the operations; however, it still values the foundation of the Resource-Based Theory (RBT) in supply chain management. This review explores how Chevron can leverage OEMS and advanced technology to resolve environmental problems, ensure workers’ safety and reduce costs.

Introduction

Chevron is among the largest oil and gas companies globally, making it a highly compelling organization to conduct a case study (Chevron, 2021b). Oil and gas industries develop differently from the digital sectors that are at the center of much operations management analysis (Handscomb, Heyning and Woxholth, 2019). Nevertheless, they continue to integrate new theories and technological advancements into their processes (Nafisah, Suzianti and Ardi, 2019).

Chevron can be taken as one of the examples of companies that combine the traditional approaches (such as the resource-based view on oil and gas) and relatively new theories (such as Agile) (Chevron, 2021a; Hetz and Connor, 2018; Bromiley and Rau, 2016). The firm’s Operational Excellence Management System (OEMS) is the focus of exploration for this paper as this system is the basis of all management culture at Chevron (Chevron, 2021a).

Following a brief description of the company, this paper intends to conduct a comprehensive and in-depth analysis of the three aspects of Chevron’s critical operations. First, the operations management at the company will be reviewed through the lens of such approaches as Lean and Agile, suggesting the idea that Chevron combines the two seemingly different methods with technology. Second, the supply chain management of the firm will be discussed using the Resource-Based Theory as a foundation. Third, Chevron’s increasing efforts in using technology to improve its position as an oil and gas company will be appraised.

Operations and Project Management and Strategy

Many theoretical approaches to operations management have been developed through the years. Two of them – Lean and Agile – are often viewed in opposition to each other, as they prioritize different parts of the process to reach efficiency (Ghobakhloo and Azar, 2018). For instance, Lean focuses on physical efficiency that is tied to low costs (Holweg et al., 2018). In contrast, Agile processes are viewed as responsive, flexible and quick (Slack, Brandon-Jones and Johnston, 2016). Thus, it may be challenging to imagine how a company can introduce these theories to one process simultaneously.

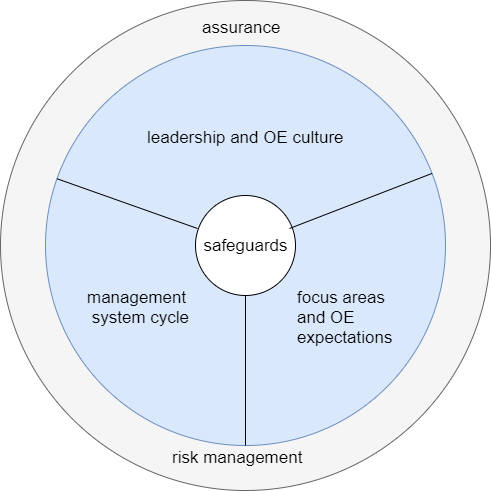

However, one can argue that Chevron’s Operational Excellence Management System (OEMS) combines the parts of these approaches in its mode when translating the theory of operations management into practice (Figure 1). On the one hand, the model demonstrates its Lean focus through such elements as risk management and focus areas (Ghobakhloo and Azar, 2018). On the other hand, one can see the management system cycle as one of the basic parts of the system. This cycle is used in all types of operations, demonstrating that Chevron aims to conduct its projects flexibly, adapting to the changing industry environment with each step and decision (Chevron, 2021a). Thus, on the basis of the theories’ core values and the company’s main system for all operations, one can see the integration of Lean methods in order to avoid risks and identify focus areas that could potentially lower the use of resources (Ghobakhloo and Azar, 2018).

The report explaining the benefits of the new OEMS notes that Lean practices are vital in conserving resources without sacrificing costs. Moreover, risk management is a large part of this philosophy, and it is vital to the oil and gas industries (Ghobakhloo and Azar, 2018). The sites for oil development can malfunction, which might lead to oil leaks, explosions, fire and other incidents, the risk of which place the employees working at these sites in constant danger (Chevron, 2021c). Also, there is a long-term health risk imposed on workers near the drilling sites, caused by hydrogen sulphide intoxication or poisoning (Sun, Zhou and Gan, 2018).

Therefore, as a global company, Chevron cannot afford to be negligent in its operations’ safety. It launched an operational excellence (OE) program in 2004 to nurture an OE culture centred around safety performance, environmental protection and employee health (Chevron, 2021a; Oil & Gas Iq Editor, 2020). Here, the aims of the Lean approach are considered by Chevron to reduce risk.

At the same time, the use of cycles and their continuous checks and changes can be viewed as an element of an Agile system (Ghobakhloo and Azar, 2018; Handscomb et al., 2019). This part is particularly interesting, according to Handscomb et al. (2019), who find that heavy industries are slowly adopting more flexible approaches to their operations management. The authors note that agility is a natural element of companies that rely on assets (Handscomb et al., 2019).

Advanced analytics and investment into time-cutting processes lead to the improvement of processes which results in cost-savings and more efficient and responsive systems (Birkinshaw, 2018). As a business that heavily relies on its resources, Chevron as already benefitted from adding some Agile elements to its automated processes (Chevron accelerates its move 2019; Handscomb et al., 2019).

However, it is apparent that Chevron’s path from Lean to Agile is still underway, and the core of the company’s goals are still based on efficiency through cost reductions, while time and flexibility are not prioritised (Ghobakhloo and Azar, 2018). The discussion of technology that the company has implemented in the last few years is explored later in the paper, but one may note that Agile methods now play a significant role in the processes (Chevron, 2021a; Chevron accelerates its move 2019).

Operations management is an essential aspect of the company, where key processes are set through various stages (Slack et al., 2016). Operations management enables companies to create the highest efficiency levels to maximise profits. Proper and effective operations management is necessary for a company like Chevron to remain competitive globally (Slack et al., 2016). The strategy that is flexible enough to respond to the changes in prices and demands with equal ability is favourable in the market (Slack et al., 2016).

Thus, it is recommended for Chevron to move further towards Agile philosophy in its operations management. The company can improve its existing communication channels with customers and the target audience and maintain sustainable and safe supply chains (Slack et al., 2016). The global oil and gas industry is continually looking for new organizational and technological solutions that managers can use to increase operational efficiency and reduce costs (Slack, Brandon-Jones and Johnston, 2016). The Agile approach should not be restricted to digital industries, as it can benefit the heavy industry by influencing its communication and information dissemination (Ghobakhloo and Azar, 2018).

Supply Chain Management, Capacity and Quality

To fully understand the underlying framework of Chevron’s operations and project management approaches, it is essential to introduce the Resource-Based Theory (RBT). RBT was initially developed for strategic management but later applied to operations management and supply chain management (Hitt, Carnes and Xu, 2016a; Vitorino Filho and Moori, 2020). RBT mainly focuses on ensuring sustained competitive advantage when companies deliberate accentuation or emphasis on rare, valuable and hard-to-imitate resources (Hitt, Xu and Carnes, 2016b).

For long-term success, improved performance and a higher and global competitive advantage, RBT helps create an organizational environment that motivates employees to increase their productivity (Hitt et al., 2016b). In the context of the supply chain, RBT helps companies to use resources (including human resources and knowledge) to add value to products (Vitorino Filho and Moori, 2020).

The basic supply chain of an oil and gas company can be seen in Figure 2. As it is shown in the graphic, an effective relationship between the suppliers, producers and distributors is vital for the process. Supply chain management mainly focuses on integrating manufacturers, suppliers and retailers to provide customers access to the right quality products at convenient locations (Green et al., 2012).

According to the company itself, “in addition to efficiency and operational excellence, Chevron’s approach to managing our supply chain focuses on two elements that are critical to maintaining our commitment to being a good partner: creating prosperity through local and inclusive economic opportunity and encouraging our partners to meet high standards of safety, social and environmental performance” (Chevron, 2021c, p. 1).

In the modern world, high quality is not limited to the product – it is also vital to pay attention to the social aspect and to associate resource use with responsible practices (Vitorino Filho and Moori, 2020). The oil and gas company industries require companies to put a great deal of environmental awareness (Wan Ahmad et al., 2016; Wan Ahmad, De Brito and Tavasszy, 2016). Therefore, it is essential for such companies to help the local community and small businesses by assisting them through various partnerships (Chevron, 2021c).

For instance, Chevron helps minority-owned and women-owned enterprises promote diversity (Chevron, 2021c). Ostensibly, the firm’s corporate social responsibility engagement plays a crucial role in making it receptive and acceptable by the surrounding and local community. Arguably, RBT is a theory that, in the supply chain management context, pushes for such social responsibility, as it promotes high-quality collaboration that does not only conserve resources for costs but also for a better image (Vitorino Filho and Moori, 2020).

One can take a closer look at each step in the supply chain. It begins with drilling sites located worldwide – specialists consider this activity the most vital link in the supply line (Green et al., 2012). The drilling process itself is a dangerous endeavor, which also harms the surrounding environment. However, large containers still need to store drilled oil, which is also at the drilling site (Chevron, 2021b). Drilling sites are of critical importance to Chevron’s business because they are the main locations for acquiring rare resources (Chevron, 2021b).

Oil supply, oil refining and oil product distribution are also crucial aspects – they ensure that the resource stays valuable and non-substitutable (Lima, Relvas and Barbosa-Póvoa, 2016). Chevron’s RBT approach in its supply chain management focuses on distinguishing itself from other competitors by integrating OE and obtaining a high competitiveness level (Chevron, 2021b). For example, by engaging with minority-owned and women-owned enterprises and promoting diversity, the company increases the product’s value in the ethical sense and ensures that its product is non-substitutable (Green et al., 2012).

Thus, it is apparent that the procedural steps that Chevron takes play a central role in ensuring sustainability and well as the unique place of the company’s products on the market. However, as mentioned earlier in the analysis, Chevron lacks agility and responsiveness to the changing environment due to the poor integration of technological tools and Agile systems necessary to monitor all processes in real-time. (Junior and Filho, 2012). These options can help the company improve its choices in the supply chain further, potentially opening new opportunities for using human and knowledge resources.

Technology, People and Ethics

As mentioned in the analysis of Chevron’s operations management, the company has been taking steps to introduce new computerized systems and changing its approach from Lean to Agile. In particular, the firm has implemented the Scaled Agile Framework (SAFe) into the project management and development process (Chevron accelerates its move in 2019). Chevron has made a significant leap in cloud migration, basing its choice on Agile methods (Chevron accelerates its move in 2019).

However, the global nature of the company has made it difficult for the teams to use this approach for some time – until they partnered with Microsoft to build their own cloud infrastructure on Azure DevOps (Chevron accelerates its move 2019). This decision has moved Chevron in a new direction, further increasing the potential to move toward Agile processes in project management (Chevron accelerates its move in 2019).

The progression of Chevron to an agile oil and gas company raises the question of what other ways to implement technology for operations management exist currently. Chevron is not stopping its evolution at this cloud integration, and it is likely to seek new ways to further better flexibility and efficiency (Chevron accelerates its move 2019; Chevron, 2021a). Thus, one can look at which other technologies are consistent with the Agile approach, allowing such companies as Chevron to save time and resources without losing the quality or the satisfaction of their customers. Additionally, one may discuss how the future of technology affects the companies’ social and ethical issues related to oil and gas extraction.

A motivation for companies in all industries to introduce new technology is optimization (Koroteev and Tekic, 2021). In the oil and gas sector, especially in the upstream segment, innovations can lower the risk of mistakes and accidents and increase the success of each operation (Hetz and Connor, 2018). For instance, Koroteev and Tekic (2021) suggest that Artificial Intelligence (AI) is changing the upstream. They predict that AI tools will support a large part of all decision-making, extending the importance of oil in energy production and other spheres of manufacturing (Koroteev and Tekic, 2021). A positive prognosis is that oil will stay relevant, thus helping such companies as Chevron to continue thriving.

Nevertheless, the concern for environmental protection remains vital to the industry, as the role of solar and wind energy is changing in light of the shifting perspective on oil development (Koroteev and Tekic, 2021). As with any oil and gas company, Chevron is under environmentalists’ watchful eye (Chevron, 2021b). The root cause of environmental degradation is that oil production involves drilling sites, which pollute air and soil and lead to workers’ poisoning because of hydrogen sulfide intoxication (Chevron, 2021b). Integrating technology into the industry can create a foundation for solving this problem, adding to the company’s rising ability to quickly adjust to the market’s changing preferences.

Technology has a significant impact on business operations by allowing the company to conduct ethical business practices and minimize its human resources risks. Despite all the progress with technological innovation, the process of a marginal stock of producing wells remains a crucial concern (Mohammadpoor and Torabi, 2018). Today, the supply of producing wells with an oil flow rate is less than acceptable standards. Under the existing situation, the number of operating wells operations can be unprofitable and dangerous for workers (Mohammadpoor and Torabi, 2018). From an economic perspective, the firm should halt such operations and consider utilizing appropriate technological advances to cut down the cost.

Still, since these wells participate in the reservoir development system, their shutdown can disrupt effective reservoir development and, ultimately, lead to a decrease in oil recovery. These insights provide companies with unique opportunities to utilize the alternative best option as an urgent task to reduce supply chain costs and avoid unnecessary logistics expenses. For example, Big Data can offer a wide range of opportunities for gaining a sustainable competitive advantage for Chevron (Matthias et al., 2017). In other words, the company gains significant benefits, as shown in Figure 6 (Quantzig, 2019).

Based on the potential of both AI and Big Data in improving the company’s processes, several recommendations can be given. First, Chevron should invest in the development of AI tools for effective drilling and risk prevention. This decision is likely to prolong the popularity of the oil and gas industry as a supplier of fuel (Koroteev and Tekic, 2021). Second, the company can utilize Big Data to address the rising concerns around the environmental impact. Both solutions are expected to improve the efficiency of all processes, conserving resources and lowering the impact of drilling on the planet (Koroteev and Tekic, 2021).

Conclusion

From the discussion, it is apparent that Chevron’s primary approach towards its operations management and strategy is OEMS, which bases itself on a combination of Lean and Agile approaches. While the company is on the path toward flexibility, it still can improve its operations by prioritizing Agile approaches. In addition, supply chain management could also benefit from introducing Agile to its system. Currently, the company has taken some steps to position its products as rare and non-replicable, which is in line with the RBT.

The supply chain is also heavily reliant on technology, and the most critical aspects of the chain locate at the drilling site. Therefore, aiding the local community and ensuring proper automation is crucial for the company. In the case of people and technology, Chevron views the advancement of the latter as the only plausible solution for staff safety, which is also a significant part of its ethical concerns.

Reference List

Birkinshaw, J. (2018) ‘What to expect from agile’, MIT Sloan Management Review, 59(2), pp. 39-42.

Blommestein Analytics. (2018) Oil supply chain. Web.

Bromiley, P. and Rau, D. (2016) ‘Operations management and the resource-based view: another view’, Journal of Operations Management, 41, pp. 95-106.

Chevron accelerates its move to the cloud and sharpens its competitive edge with SAFe® built on Azure DevOps (2019). Web.

Chevron (2021a) Operational excellence management system. Web.

Chevron (2021b) Supply chain management. Web.

Chevron (2021c) Promoting responsible supply chain management. Web.

Ghobakhloo, M. and Azar, A. (2018). ‘Information technology resources, the organizational capability of lean-agile manufacturing and business performance’, Information Resources Management Journal (IRMJ), 31(2), pp. 47-74.

Green, K.W., Zelbst, P.J., Meacham, J. and Bhadauria, V.S. (2012) ‘Green supply chain management practices: impact on performance’, Supply Chain Management: An International Journal, 17(3), pp. 290-305.

Handscomb, C., Heyning, C. and Woxholth, J. (2019) ‘Giants can dance agile organizations in asset-heavy industries’. McKinsey & Company. Web.

Hetz, S. and Connor, M. (2018) ‘Operations research at Chevron’. ORMS Today. Web.

Hitt, M. A., Carnes, C. M. and Xu, K. (2016a). ‘A current view of resource-based theory in operations management: a response to Bromiley and Rau’, Journal of Operations Management, 41(10), pp. 107-109.

Hitt, M. A., Xu, K. and Carnes, C. M. (2016b). ‘Resource-based theory in operations management research, Journal of Operations Management, 41, pp. 77-94.

Holweg, M., Davies, J., De Meyer, A., Lawson, B. and Schmenner, R. W. (2018). Process theory: the principles of operations management. Oxford: Oxford University Press.

Junior, M. L. and Filho, M. G. (2012). ‘Production planning and control for remanufacturing: literature review and analysis’, Production Planning & Control, 23(6), pp. 419-435.

Koroteev, D. and Tekic, Z. (2021). ‘Artificial intelligence in oil and gas upstream: trends, challenges and scenarios for the future, Energy and AI, 3, p. 100041.

Lima, C., Relvas, S. and Barbosa-Póvoa, A.P.F. (2016). ‘Downstream oil supply chain management: a critical review and future directions’, Computers & Chemical Engineering, 92, pp. 78-92.

Matthias, O., Fouweather, I., Gregory, I. and Vernon, A. (2017). ‘Making sense of big data–can it transform operations management?’, International Journal of Operations & Production Management, 37(1), pp. 37-55.

Mohammadpoor, M. and Torabi, F. (2018). ‘Big Data analytics in oil and gas industry: an emerging trend’, Petroleum, 6(4), pp. 321-328.

Nafisah, S.R., Suzianti, A. and Ardi, R. (2019). ‘Risk analysis of agile framework in project management exploration drilling in oil and gas sector’, IOP Conference Series: Materials Science and Engineering, 505 (012010), pp. 1-8.

Oil & Gas Iq Editor (2020) How Chevron Canada is driving operational excellence to the frontline: an interview with Troy Geertsen, Vice President, Health, Environment & Safety at Chevron. Web.

Quantzig (2019). Benefits of big data in the oil and gas industry. Web.

Slack, N., Brandon-Jones, A. and Johnston, R. (2016). Operations management. 8th edn. London: Pearson.

Sun, Z.-Y., Zhou, J.-L. and Gan, L.-F. (2018) ‘Safety assessment in oil drilling work system based on empirical study and analytic network process, Safety Science, 105, 86-97.

U.S. Energy Information Administration (2017). Gasoline supply chain overview. Web.

Vitorino Filho, V.A. and Moori, R.G. (2020). ‘RBV in a context of supply chain management’, Gestão & Produção, 27(4), pp. 1-20.

Wan Ahmad, W.N.K., De Brito, M.P. and Tavasszy, L.A. (2016). ‘Sustainable supply chain management in the oil and gas industry: a review of corporate sustainability reporting practices’, Benchmarking: An International Journal, 23(6), 1423-1444.

Wan Ahmad, W.N.K., Rezaei, J., Tavasszy, L.A. and De Brito, M.P. (2016). ‘Commitment to and preparedness for sustainable supply chain management in the oil and gas industry’, Journal of Environmental Management, 180, 202-213.

Appendix

Table 1.