Abstract

Practical improvement is essential in the dynamic business environment. Brilliantly, this idea defines the sustainability of an organization and its dissolvability inside of a predefined timeframe. In the contemporary society, the term sustainable business alludes to the capacity to support profitable operations in the short and long terms as part of the complete business capacity. In a business environment, sustainable business operation is influenced by powers in the business sector, choice science, corporate structure, and genuine financial related administration.

Along these lines, a business must put set up stringent measures and systems pointed at observing expansionary modules inside attainable levels. In particular, this paper reviews the quantitative examination of value and supportability perspectives as identified with Nestle Company, which has existed for more than five centuries as a leader in the provision of different food products and nutritional services within Switzerland and across the globe. The company has an effective operations management system due to its ability to integrate different aspects of quality management and improvement.

The holistic approach in managing operational dynamics at the company has resulted in the utilization of different sustainability variables such as cost management, speed, dependability, flexibility, and quality to guarantee continuous operations effectiveness. However, the system has not been efficient due to the dynamic nature of the business environment of the Nestle Company. Among the notable recommendations highlighted to ensure that the current operations management strategy is efficient include incorporation of flexible monitoring system (FMS), six-sigma in the supply chain, and radical modification of variables for measuring performance.

Introduction

Organizational culture is the primary determinant of an operational model that a company might apply in enhancing production and sustainable business operations. However, it is getting harder to interpret the hypothetical points of view into useful components that reinforce the association’s operations. The issues additionally reach out to many-sided quality when the whole workplace is taken into contemplations. As organizations are selecting to converge up, the key component of accentuation is how correspondence society is to be kept up by such associations. Primary difficulties confronting worldwide business players are the selection of legitimate correspondence and operations administration models that can be more adaptable to change operation of these associations (Escrig-Tena, Bou-Llusar, Beltran, & Roca-Puig, 2011).

Indeed, quality operations administration model is the foundation of a promising organization since it decides survival and efficiency as far as streamlining the operations and overhead expenses. Brilliantly, organizations must support their procedures with the point of cost minimization, instead of utilizing expensive materials or procedures to the detriment of the value of the company (Bowman, 2009). This technique is essential in checking choice science and dispersion of risk components and determining future swings in the operational dynamics of an organization. Reflectively, this paper will review the operations management strategies that have been applied by the Nestle Company to sustain its productivity and distribution in the dynamic markets.

Overview of Nestle Company

The fundamental mission of the Nestle Company is to create and assemble the highest quality and most affordable food products and nutritional services within Switzerland and across the globe (Nestle Group, 2015). This is likewise towards fulfilling the needs of clients in a constantly developing business sector inside of the business. The experts in the field of food services dependably endeavor and work hard to fulfill the needs of the market by always developing demand from the purchasers. Setting of objectives by the organization’s administration began path back in the19th century. The primary reason was towards the procurement of moderate, naturally agreeable, and dependable restorative food items that can satisfy customers. The thought was to offer assistance in recuperating to individuals who were experiencing different diseases.

Nestlé’s corporate structure

As a holding group, Nestle Incorporation comprises of 250 offices that work in more than 60 countries over the world. It is one of the biggest organizations on the planet in the food services business. The structure of the organization depends on the three fundamental fragments; same as their corporate basic association which is sorted out into establishments and other remedial structures (Nestle Group, 2015). The primary auxiliary fragment manages the customer as food services dependant.

The second auxiliary classification is the technological and logistics divisions. The center of this portion is basic in receiving all matters identified with innovative progressions and offering arrangements in the field research on production and sustainability. The last fragment of corporate structure manages the actual production plans to ensure that the variables such as cost, speed, dependability, and sustainability are balance and efficiently executed (Nestle Group, 2015). The division is assigned with the role of guaranteeing that all needs in terms of nutrition, quality, and affordability aspects are met.

Quality of Nestlé’s Decision Structure

The decision structure at the Nestle comprises correspondence and operations administration framework, which help in deciding effective execution and ideal asset use. Taking into account the philosophy of quality and affordability, it weighs on moral conduct and consumer loyalty inside acknowledged norms of good commitment on the edge, while the partners at base of corporate culture (Chase, Jacobs, & Aquino, 2007). This was executed with the perspective of long advantages. For instance, the continuum of expanding the estimation of value in the operation of the person lies in information, data, and learning.

In the wake of directing an intensive exploration of clients in the business sector, the management of the Nestle established that clients favored a solitary organization contract. In light of the requirements of clients, the management chose to concoct quality food services framework consolidation that could help in supporting a solitary contract point, as the premise of the operations administration model. Tended to in the organization’s magazine, it was distinguished to be the best system that would encourage the organization’s expansion and sustainability of the production processes (Fandel, Reese, Fistek, & Stutz, 2011).

Focus, Methodology, and Significance of the Research

Focus of the research

The center of this study is to audit the part of operations administration framework that has capacities coordinating handling divisions in the Nestlé Company, as a component of their quality administration framework. This framework tracks info and yield proportion by measuring the productivity of the workers and the management team by set targets (Harrison & St.John, 2010). When this proportion has a higher numerical quality, it implies that the organization works in a section of high productivity (Murphy, 2010).

However, when the proportion is low, the operation administration framework becomes the most important factor by following conceivable reasons for such a situation (Samson & Singh, 2008). Therefore, the rationale of the paper is to dissect the operations administration structure of the Nestle Incorporation, particularly on the nature of its quality framework, as the real determinant of production sustainability at the company. This perspective is vital in the comprehensive operation of a firm and identifying alluring business choices, which impacts gainfulness, proficiency, and survival amid rivalry and business sector swings.

Methodology

Through secondary research, the paper endeavors to make a proposition towards the vital appropriation of a model for sustainable quality operations. Use of the quality model is made through the utilization of the data concerning operational strategies of the organization as indicated in secondary literature. The paper investigates the roles of different stakeholders in the company towards the improvement of corporate correspondence and holistic production strategies. It additionally applies the quality model in the suggestion of the right course of action that may guarantee long terms predictability of the current operations management strategies. The outcome from the study consolidates three main considerations, that is, human resources, production, and logistics in creating hierarchical order of managing quality in operations management at the Nestle Incorporations.

Significance of the Study

The center of this study is to audit the part of operations administration framework that has capacities for coordinating the handling of divisions in the Nestle Company, as a component of quality in the operations management framework. This framework tracks information and measures for productivity in accordance with set targets. Therefore, the findings of the research will be used by the management of the Nestle Company to modify the operations management strategies in line with the recommendations that may guarantee efficiency in the current effective operation model of the company.

Findings and Discussion

Operation Management Model at Nestle Company

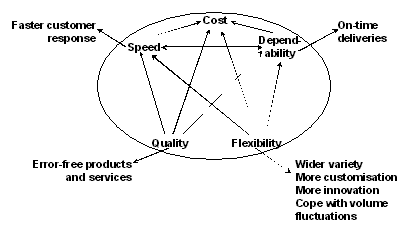

The operations management model applied at the Nestle Company is summarized in the diagram below.

From the above chart, the operations model in Nestlé’s operations management supervises the reaction rate and screens all production processes from product creation to distribution channel. The model helps with following expenses and effectiveness of work efficiency devices such as apparatus, human resource, and ideal utilization of these devices in most cost-effective way. Also, it tracks externality and internality variables that are subject to the speed of execution such as productivity within a specific period, reaction by client, and nature of item discharged into the production process at the Nestle Company. This factor applies to cost, productivity, dependability and quality in the entire operations process (Slack, Chambers, Johnston, & Betts, 2012). In particular, the Nestle Company has set up an effective operation administration display that balances the variables to create a flowing transition from production to distribution in the most effective manner. It is clear that the Nestle Company has a proficient production model, which is unique in tracking the production process as summarized in the chart below.

The above grid shows the reliability of one viewpoint to another in the production processes at the Nestle Company. The above capacities are joined at the central planning point which envelops costing, velocity, quality, adaptability, and reliability to make a smooth ceaseless operation model that works like PC starting with one section then onto the next. The Nestle Company is aligned with the human resource department, finance department, marketing department, operations department, and supply chain department. The operations administration arrangement of the Nestle Company incorporates the aspects of proactive planning, systematic development, strategic implementation, and consistency in disclosure (Slack et al., 2012). The procedure is supported by process maps, status reports, production activities, human resource use, and quality in the output over a definite duration of time.

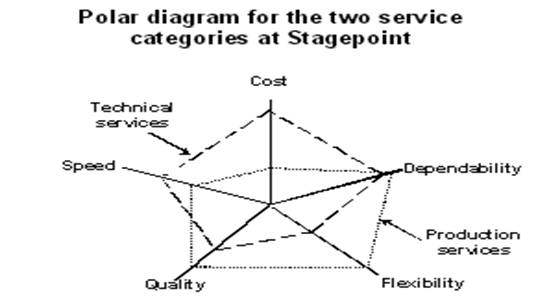

Quality Variables in the Nestlé’s Operations Management

Essentially, the operations administration frameworks at the Nestle Company incorporate part of cost, constancy, pace, quality, and adaptability. These variables determine the strength or weakness in the operations module at the company. These aspects are attainable through quality conveyance, continuous expansion, and innovativeness through the company’s research and development division (Escrig-Tena et al., 2011). Specifically, these variables are part of the systems and apparatuses, which are vital in the specialty of operations administration at the company. For instance, specialized procedure of comprehension in the operations at the company includes operations administration, its application, and assessment criteria (Harrison & St.John, 2010).

Corporate Operations Strategy at the Nestle Company

Service and product design

The organization has assorted food products and keeps on growing new product lines that satisfy the demand of customers. Case in point, the baby food product line was established in the year 2013 to tap the infant market segment across the globe. The products are exhibited in quality holders (Nestle Group, 2015). The diverse production ability has positioned the company as a global leader in different food products across the globe.

Quality Management

Exploring the operations administration arrangement of the Nestle Company is vital to considerably arranging and realizing quality management, which works by reducing expenditure through planning and managing the production budget. The Nestle organization has an ideal quality management strategy to balance the cost against output as part of its primary generator of competitive advantage. So as to accomplish this, the current cost management frameworks are intermittently moved up to present numerous working channels, for example, quality affirmation in operation administration that is good at tracking progress in the short term and long term (Bowman, 2009).

Process and Capacity Design

The abilities displayed by the Nestle Company frame yet another part of its general process management as far as procedure and limit are concerned. The organization runs a dynamic corporation that is divided into different food, beverages, and nutritional additives. These structures frame a portion of generation lines for distinctive process management. The decision approach at the Nestle is marked by a consultative structure characterized by endorsements originating from the top managerial staff comprising of capable and experienced managers. The organization depends vigorously on operations administration in choice-making (Chase et al., 2007). For instance, the proposed expansion in the Indian market in the year 2014 was supported by comprehensive market research.

Location

The Nestle Company divisions are situated in strategic regions over Switzerland and different parts of the world. Since the business targets different clients, the company is known for its extensive production facilities that produce different product lines. This translates into expanded production volume across the globe (Harrison & St. John, 2010).

Layout Design

The Nestle divisions are connected with dynamic and efficient organization environment through the state of art production facilities and employee recreational centers. This strategy has empowered the Nestle Company to emerge as a vivacious domain for employees, who are motivated by the ideal work environment. As indicated in the company website, Nestle has a healthy work environment that encourages employee innovativeness and creativity (Slack et al., 2012).

Human Resource and Job Design

The business has an element and a profoundly gifted workforce. Through setting of performance mark for each employee, the expert employees have always endeavored to put effort to fulfill the needs of continually dynamic customers. The topological approach in human resource management at the Nestle Company comprises of correspondence and operations administration framework which helps in employee efficiency execution and motivation strategies.

The continuum of expanding the value of human resources in production has enabled the company to be one of the leading organizations across the globe with highly skilled personnel (Escrig-Tena et al., 2011). The company offers exceptionally focused pay rates to its representatives to guarantee quality in administration conveyance to clients. Through its 360-degree employee management model, the Nestle Company is in a position to deal with the level of worker fulfillment, execution, and proficiency through its dynamic human resource department (Samson & Singh, 2008; Slack et al., 2012).

Supply Chain Management

Effectiveness in the inventory network is extremely basic in the circles of value affirmation as a component of an organization’s operations administration procedure. The Nestle Company has an automated supply chain framework, which guarantees a smooth stream in the production model from inputs procurement to conveyance of the end products in the market (Fandel et al., 2011). The framework has an adaptable module that adjusts the control channels, structure, and extension to guarantee manageability.

With a specific end goal to accomplish a reasonable level of productivity, the parts of cost, steadfastness, quality, and adaptability are consolidated through value addition, delivery, and constant creativity in managing the global supply chain (Murphy, 2010). The company’s supply chain management has been integrated to fit in different markets and regions across the globe through the inclusion of aspects such as outsourcing and insourcing, depending on the dynamics of each region of operation.

Inventory Management

The business model of the Nestle Company is managed as a corporation with different interests in the food products. The business is managed as divisions, which work as partitioned branches that are managed from a central point. This has improved the company’s rating in the global business market in balancing competing interests in different divisions. The company has a simple logistic plan in getting credit from banks due to its large capital structure (Chase et al., 2007). The aspect of financial well-being is associated with the level of vulnerability and the extent of insurance set up for obligations in the business. Because of the balanced and stable financial management framework, the Nestle Company has remained extremely aggressive and feasible in terms of its business sector extension procedures.

Scheduling

Utilization of all the essential capabilities has empowered the Nestle Company to manage its position as a global leader in the aggressive business sector. Thus, the company is a central cause of a business that has kept on grasping quality operations administration in terms of steady organizational communication culture, proficiency, and ideal asset use in delivering food products to customers across the globe (Harrison & St. John, 2010).

Maintenance

The maintenance approach adopted by the Nestle Company is comprehensive of the exploratory perspectives, for example, specialized procedure of comprehension of the operations and legitimate utilization of measurable devices. These devices are basic in checking and dealing with the logistics behind the business capacities. These variables are legitimately adjusted as demonstrated in the productivity of the business across Switzerland and beyond. The procedure works on the fringe of the delicate aptitudes including the vision of authoritative standards, characterizing estimation of the business, deciding prerequisites, clearing up the vision, building groups, moderating assignments, determining issues, and giving guidance in the business logistics as part of the general management strategy (Escrig-Tena et al., 2011).

Elements Suggesting Effective Operations Management at the Nestlé

Efficiency of the Soft Skills

The key a portion of accomplishment riddle for operations administration procedure at the Nestle Company works on the proficiency of the delicate abilities including ageless vision of hierarchical standards, characterizing estimation of the business, deciding necessities, clearing up the vision, building groups, alleviating assignment, determining issues, and giving guidance. The quality operations technique framework of the company has joined these standards in the operations (Samson & Singh, 2008). The accomplishment of an operations administration framework is reliant on delicate aptitudes which are a vital part of framework administration at the Nestle Company.

Efficiency in the Value Maintenance

As a matter of fact, relating data on achievement is subject to operations procedures for quality support. During the time spent adjusting the demonstration, the quality operations administration framework at the Nestle Company is fit for applying the exploratory abilities in a creative way through educated and consummately encircled utilization of delicate aptitudes to address specialized parts of production matrix (Slack et al., 2012). The quality operations administration framework at the Nestle Company fulfills the production sustainability time plan without breaking down the primary production projections.

Balance Between the Short-Term and Long-Term Goals

The corporate methodology proposed by the administration of the Nestle Company is to guarantee long term production capacities. For execution of the methodology, the administration has been proactive in equalizing both the transient and long term goals as part of the decision matrix. This fete is achieved by making arrangements for assets in innovation, preceded with the development of new products through continuous research, and directing different experts to distinguish market demands by different segments of customers. It is evident that appropriate coordinating of delicate aptitudes, for example, group building, authoritative viability, initiative, choice-making, critical thinking, imagination, adaptability, and group building are well integrated in the management aspect of the company’s operations matrix (Samson & Singh, 2008; Slack et al., 2012).

Challenges in the Current Operations Management Model

Notwithstanding having this proficient operations administration framework, the Nestle organization has not completely settled a competent strategy for observing production efficiency at a macro level. At present, the company largely depends on macro production tracking tools that cannot pinpoint inefficiencies within each unit of production design. As a result, the company has struggled with consequences on poor decision making, dynamics in the production, and imbalances between different factors of production (Samson & Singh, 2008).

Recommendations and Conclusion

From the findings of the quantitative examination, there is a need to reorganize some of the operational strategies of the Nestle Company in order to ensure that the current quality model is sustainable in the long term. Since the operations administration framework determines the accomplishment of the business strategy, the Nestle Company should create a small scale inspection unit for interior decision making as opposed to depending significantly on full-scale market environment.

By relying on the full-scale market model, the supervisors driving production execution procedures may record challenges due to lack of understanding on how to incorporate small scale decisions and large scale choices made by the organization’s top managerial staff (Fandel et al., 2011). Subsequently, the achievement of the Nestlé’s operations administration framework is specifically subject to delicate aptitudes. For example, the strategy for balancing the creativity and correspondence as part of the administration standards in quality management should be credible (Escrig-Tena et al., 2011). In addition, the part of restricting work and variables of creation will assume the most essential part of the operations administration system.

This is a direct result of the part of social importance regarding dialect, inclination, and utilization that may be in the objective of the Nestlé business. Choices made ought to be subject to access assets such as venture portfolio, workforce size, experience, and proficiency for a particular task requiring particular capabilities (Bowman, 2009; Harrison & St.John, 2010). These outcomes would give a top to bottom estimation of circulation of success for future expected returns. The specific recommendations for adjusting the current operations management at the Nestle Company are discussed below.

Adopting the Flexible Monitoring System (FMS)

Business productivity reflects the ideal usage of distributed variables in the creation of products at the most cost-effective module. From the above refection, it is clear that the Nestle organization should integrate the Flexible Monitoring System (FMS) to balance the quality variables that determine the magnitude of production sustainability in the short run and long run (Slack et al., 2012). In spite of lower rates of return beneath the projection, the general impact of adopting the FMS is that the company will have advantages that will exceed its restrictions.

For example, when the FMS is completely embraced as proposed, the company will be in a position to manage expenses from production and logistics management (Escrig-Tena et al., 2011; Bowman, 2009). Despite the fact that the value of the Nestle venture is lower than often anticipated, the FMS will make it reasonable since it manages the element of costs in managing operations by ensuring that optimal productivity is achieved at the least possible cost (Williams, 2007). In addition, the part of productivity as a consequence of FMS will push the generation logistics management towards manageability over a long period of time.

Fundamentally, the prompt adjustment of the proposed FMS will contribute towards supportability in the part of cost, reliability, velocity, quality, and adaptability of the current operations management module (Slack et al., 2012). In particular, the increased productivity at the least cost will give room for the development of different products without expanding the physical production utilities. More space means more products being created inside of the same production lines. Because of expanded yield, the Nestle business will grow as the organization becomes more attractive for the investors (Escrig-Tena et al., 2011).

Through enhanced flow in the production schedule, the Nestle organization is set to quickly and considerably pick up from the unwavering quality perspective when contrasted with its rivals. Since customers will have the capacity to get their requests inside of a shorter time, the organization stands to gain from consumer loyalty and referrals (Bowman, 2009; Chase et al., 2007). Since the length of time of conveyance will diminish by around 33% of its present rate when the FMS is integrated, the organization is equipped to profit from economies of scale because of expanded ability to create and disseminate inside of a brief timeframe will guarantee increased productivity for different product lines currently being produced by the Nestle Company (Slack et al., 2012).

Within the dynamic Switzerland manufacturing industry, the quality framework is guaranteed by the integration of the FMS system since the production structures are well placed. Subsequently, when the framework is arranged effectively, the whole chain organizing these fragments would bring about ideal operations at the Nestle. In spite of the fact that operations administration frameworks experience steady transformation as a consequence of short term, midterm, and long term goal setting, no organization can work productively without quality framework (Slack et al., 2012).

Accordingly, quality will evaluate ideal production sustainability and competitiveness to ensure that the Nestle Company is not only profitable but also efficient in managing the entire operations management matrix (Murphy, 2010). Furthermore, the efficiency requirement as integrated in the FMS operations administration tracks implementers of business procedure with a specific end goal to exhaustively confirm reason for supporting current, anticipated, and real results for each complete production cycle, through a quality awareness framework (Fandel et al., 2011; Harrison & St.John, 2010).

Adopting the Six-Sigma

The Nestle Company should consider adopting the six-sigma approach in quality control and certification in the logistics division. Six-Sigma is an ordeal of operations administration that is utilized to create business operations that guarantee productivity through ideal and convenient production cycles (Williams, 2007). Six-Sigma is embraced to accomplish huge impacts of creation effectiveness through occasional audit of the generation logistics network across the major departments in an organization (Fandel et al., 2011). Really, Six-Sigma is an arrangement of business occasions that conveys positive yields and creates a business point of dependability in the production chain. Six-Sigma guarantees that production functions are vital and enhanced through the proactive administration of the components of production such as labor, time, and ideal efficiency timeline (Slack et al., 2012).

Six-Sigma is intended to diminish wastage in the productivity resources that can create an unstable production cycle and inadequate output from each resource input. Quality control is generally used to advance the nature of business production. Six-Sigma typically incorporate workers to give optimal productivity through self-appraisal and proactive way to deal with efficiency in job performance. Six-sigma is done to plan, synchronize, and deal with the diverse exercises of organization through productivity module (Chase et al., 2007). By actualizing the six-sigma approach at the Nestle Company, the organization can focus the future dangers and obstacles in the execution of any production activity and take appropriate measures for addressing the unforeseeable dangers such as machine breakdown or swings in the market (Slack et al., 2012).

Modification of the Variables in Performance Management

Keeping in mind the end goal to accomplish quality operations administration, the current performance management matrix should be occasionally moved up to track the various working operations models such as proportion examination in operation administration, which is perfect in proactive management of the entire performance matrix in the short term and long term production activities. These variables are achievable through quality assurance, production expansion, and inventiveness as part of the performance management (Williams, 2007).

The modification of performance management variables as a strategy is fundamental in the specialty of operations administration at the Nestle Company (Murphy, 2010). Notwithstanding, having proficient operations administration framework will enable the Nestle Company to completely track the component of checking advancement at miniaturized scale beside the large scale production cycle across different divisions within Switzerland and beyond (Fandel et al., 2011).

The second technique for reviewing the performance management variables at the Nestle Company should be adjusted to correspond to quality assurance strategies across the departments such as logistics, human resource, production, research and development, and supply chain. In order to guarantee success in the performance management, the quality administrators at the Nestle Company should adjust both the performance trackers and complete production cycles across different divisions as independent entities (Chase et al., 2007).

This proposal will ensure that the company is in a position to locate areas with efficiencies or inefficiencies. As a result, the quality management strategies that guarantee long term commitments are satisfied in the production cycle in each division (Williams, 2007). This is conceivable in light of the fact that this model of operations administration framework takes into consideration operations process aggressiveness as it manages the superfluous overhead expenses from waste and underutilization of production inputs (Fandel et al., 2011).

In accordance with the primary goal of estimating the completeness of the operation management matrix, it is of quintessence to reverberate upon the standards of relative execution of distinctive contending operation variables as a major aspect of the framework of the operation at the Nestle Company. For consistency, the parameters and variables utilized should be adjusted to guarantee that quality model is accomplished inside contending production matrices since the Nestle Company has series of divisions with different production cycles (Williams, 2007).

Keeping in mind that the end goal is to address the hidden issues in stochastic instability estimation, the parameters should rotate on the fringe of pertinent data which is steady with the genuine and expected results from the quality model (Slack et al., 2012). When the proposal is implemented, the Nestle Company will not only be in a position to create an ideal performance management network but also track the progress of other production support functions such as labor, supply chain, and capital structure (Fandel et al., 2012).

Conclusion

The Nestle Company has a generally stable operations administration framework. The company has quality and proficiency certification framework that specifically affects the operations station, as the procedure is comprehensive of key and reasonable decision science. The certification framework is portrayed by the need to create an ideal performance management matrix. Thus, the operations management arrangement approach has encouraged the ideal execution of different production constraints as effective variables of tracking general efficiency and sustainability of the production cycle, which is particular to the objectives and of the organization in the dynamic manufacturing industry in Switzerland and beyond.

However, the Nestle Company is currently experiencing challenges in the quality management matrix due to dynamics in the market and poor focusing strategies. For instance, the company largely depends on macro production tracking tools that cannot pinpoint inefficiencies within each unit of production design. Therefore, it is very difficult to monitor efficiencies in different production divisions since the current system generalize on operations management in all divisions. In order to effectively address this challenge, the Nestle Company must make alterations in the effectiveness column through embracing the Flexible Monitoring System, Six-Sigma, and execution variable to guarantee maintainability in its business operations. These strategies will ensure that the Nestlé Company can track efficiencies and inefficiencies in each division as an independent unit and design quality model that is unique to each division.

References

Bowman, S. (2009). Corporate restructuring: Reconfiguring the firm. Strategic Management Journal, 1(4), 5–14.

Chase, R., Jacobs, R., & Aquino, N. (2007). Operations management: For competitive advantage with global cases. New York, NY: Mcgraw-Hill Publ. Comp.

Escrig-Tena, A., Bou-Llusar, C., Beltran, M., & Roca-Puig, V. (2011). Modelling the implications of quality management elements on strategic flexibility. Advances in Decision Sciences, 1(1), 1-27.

Fandel, G., Reese, J., Fistek, A., & Stutz, S. (2011). Operations management. New York, NY: Springer.

Harrison, J., & St.John, C. (2010). Foundations in strategic management. Ohio, Oh: South Western Cengage Learning.

Murphy J. (2010). Organization theory and design. Hampshire, Ha: Cengage Learning EMEA.

Nestle Group. (2015). Operations management. Web.

Samson, D., & Singh, P. (2008). Operations management: An integrated approach. London, UK: Cambridge University Press.

Slack, N., Chambers, S., Johnston, R., & Betts, A. (2012). Operations and process management: Principles and practice for strategic impact. London, UK: Prentice Hall.

Williams, C. (2007). Re-thinking the future of work: Directions and visions. New York, NY: Palgrave.