Introduction

PepsiCo Inc. is one of the leading food and beverage companies in the world. This American company was started in 1965 after the merger between Frito-Lay and Pepsi Cola and had its headquarters in Purchase. Through mergers and acquisitions, this company has been able to diversify its products to include snacks and beverages. The company has experienced massive growth and currently operates in the global market, with about 274,000 employees.

This company exemplifies a perfect demand-driven supply chain strategy, which is appropriate in the current market. The market where this firm operates is highly competitive. Other major players, such as Coca Cola offer stiff competition in the world market. In order to manage this competition, the management of PepsiCo has realized that it needs to employ superior strategies in its supply chain strategies. It is always under pressure to ensure that the products are delivered to the retailers in a consistent manner to avoid cases of stores running out of stock.

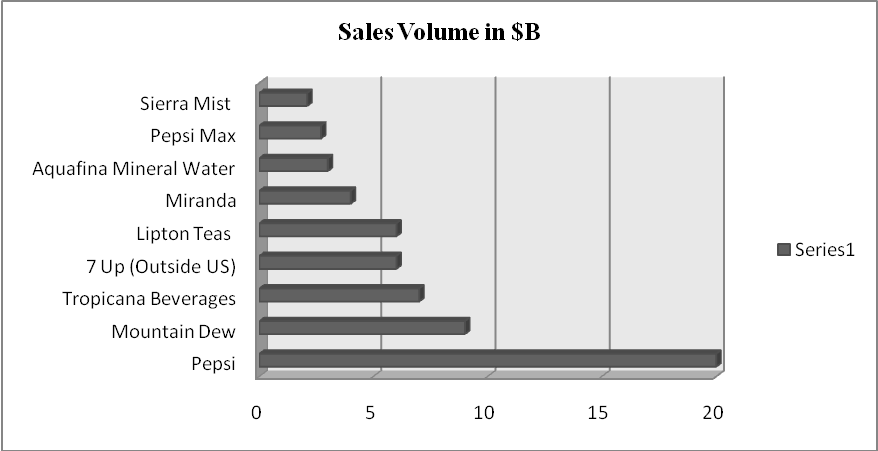

It also has the responsibility of acquiring the right raw materials for its beverage products, transporting them to the manufacturing plants, and ensuring that they are in the right condition before they can be used to manufacture various products. This research will focus on the supply chain strategies used by PepsiCo in its beverage segment. Some of PepsiCo’s products that we will focus on in this paper include Pepsi, 7 Up, Mountain Dew, Gatorade, Sierra Mist, and Mirinda. The figure below shows some of the top beverage brands from this company.

Supply Chain Management

According to Shah (45), companies in the current society have realized that in order to remain competitive in the current market, offering high-quality products is not enough. The need to ensure that the customers have access to the products when they need them at the right locations has forced PepsiCo to reformulate its strategies in the supply chain management in order to maintain efficiency and reliability. The company has come up with a supply chain management, which is customer-centric. The following are some of the areas of supply chain management that this firm has perfected over the years.

Purchasing

PepsiCo has realized that getting the right materials at the right time is critical in achieving success. According to Jespersen and Larsen (112), the management of a firm needs to ensure that it has a team of suppliers who can deliver the needed raw materials in time. PepsiCo has embraced a decentralized purchasing strategy to improve its efficiency (Ehrhardt and Edmond 41). It operates various production plants in different locations.

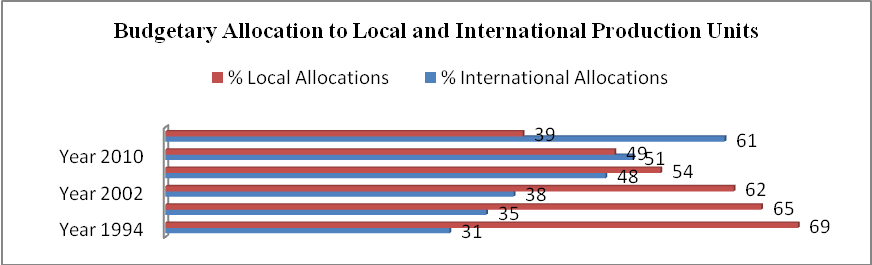

At each plant, the regional head is given the authority to make the purchasing decision based on the local environmental forces in that region. Decentralizing the purchasing of raw materials is an effective way of empowering branches in different locations. By allowing the plants in these two countries to operate semi-autonomously, the top management has made it possible for the managers in these regions to act based on the local forces. The graph below shows the budgetary allocations to the local and overseas production units at PepsiCo.

The data shows that the percentage budgetary allocation to the international production facilities has increased to surpass that of local allocations.

Supplier relationships

Maintaining a positive supplier relationship is needed to achieve success in this competitive industry. PepsiCo is one of the companies that have been keen on maintaining a close relationship with their suppliers. In fact, it has developed a close relationship with these suppliers to the extent that most of them feel that they are partners other than mere suppliers (Ehrhardt and Edmond 35).

This close relationship has been maintained by extending its various benefits to these suppliers, including loans, when they prove that it is necessary. Another strategy used by PepsiCo is organizing sporting events and end-year parties for all its regular suppliers (Ehrhardt and Edmond 48). Such get-together forums create a close bond between these suppliers and the company. This strategy has helped it maintain a pool of loyal customers, eliminating some of the problems faced by other firms in this industry.

Strategic sourcing

Strategic sourcing is very important in enhancing purchasing strategies within an organization. The management of PepsiCo appreciates the importance of maintaining superior purchasing strategies in order to maintain the flow of raw materials into the firm. The raw materials needed for the production of these beverage products include fruits such as pineapple, apple, orange, mangoes, among others. Other raw materials include sugar, flavor, and preservatives. These raw materials are readily available in various markets where the firm operates. The management at the local levels has partnerships with farmers who supply these products directly to the firm.

At this firm, Erickson (39) says that there has been a deliberate effort by the management to improve its purchasing processes based on the local environmental forces. The company has created an information management system that allows the regional managers to share new knowledge in the supply chain so that they can know how to handle various issues in the market. However, each of them is given the liberty of modifying such knowledge to suit the local environmental forces within that particular region. These factors have enabled this firm to be very successful in the global market (Erickson, 54). PepsiCo is currently making positive strides as it seeks to capture the market in the emerging economies, especially in Africa and Asia.

Operations

According to Gattorna (113), efficiency in operations is one of the most important factors that can help a firm achieve success in today’s demanding market. The management of PepsiCo has been struggling with the challenge of managing competition both in the local and international markets. In order to remain competitive, the management knows that it has to maintain superior operational strategies that will help in reducing time and cost of operation in order to cut overhead costs. The following areas of operation are very important in enhancing production.

Collaborative planning, forecasting, and replenishment (CPFR) model used in the firm

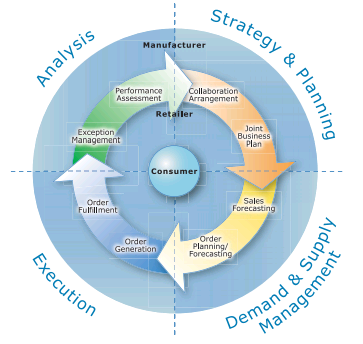

CPFR model has become popular in managing the needs of customers in the market (Gattorna 41). This model makes use of intelligence about various trading parties in the process of planning in order to meet the needs of consumers in the market. As Leeman (82) simply puts it, “The model provides a basic framework for the flow of information, goods, and services.” This model has several rings of players, with the customers being at the center. The following diagram shows how the model works.

This model has been very relevant to PepsiCo in improving its operations in the market. The focus of the firm is to ensure that its customers are satisfied. It is the responsibility of PepsiCo and all its distributing agents to ensure that customers are given the products that meet their needs at the right time. On the other hand, it is the responsibility of the firm, which is in the outer ring, to ensure that the retailers have the right products to deliver to the customers. The retailers are just links between the manufacturers and consumers. When using this model, the management needs to follow the steps given in the four quadrants systematically.

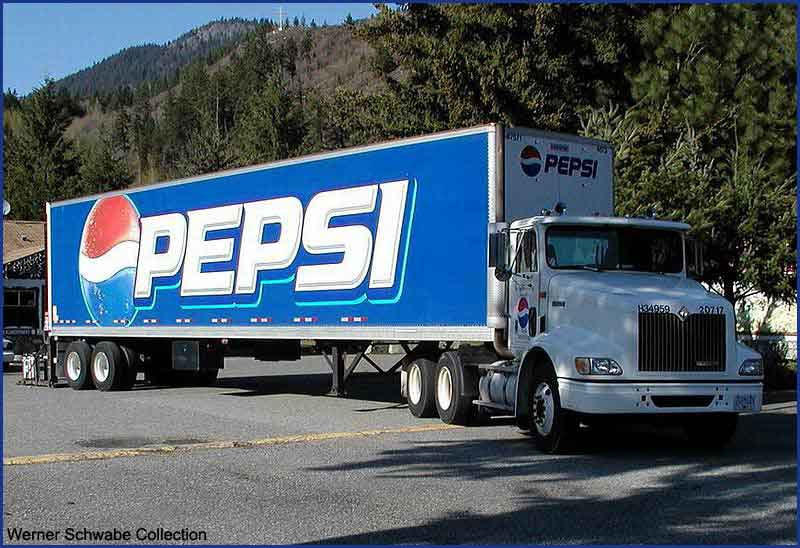

PepsiCo has used this model in order to plan for its operations in the market. It is in the outer layer of the model, and this means that it has to meet the needs of the retailers so that the retailers can ensure that the customers are satisfied. According to Erickson (29), PepsiCo uses retailers other than specialty shops to sell its products to the customers. It has large trucks, such as the one shown below, that helps it deliver products to the retailers at their stores. The retailers will break the bulk and sell the beverages in single units needed by the consumers. The graph below shows the sales volume of different types of beverages that this firm supplies to the global market in 2010.

The Pepsi drink is the most available PepsiCo’s beverage in the market, and it remains their most profitable product.

Resource planning systems

PepsiCo is a global company, and having an effective resource planning system is critical in achieving success in the market. The financial department is always under pressure to finance various projects, some of which may be beyond the capacity of the organization. At PepsiCo, resource planning is done at two tiers. The first tier of resource planning is done at the headquarters, where the chief financial officer and his team draw the overall budget for the firm on a yearly basis.

The second tier of resource planning is done at the regional level, where the regional manager is expected to draw a budget for the operational activities within the region. The resource planning system has been integrated to allow the top managers at the headquarters to understand the financial priorities given by the regional heads. Although these regional heads have the power to make the operational plans within their regions, sometimes they may need the approval of the top management before implementing the strategic plans.

The superiority of the model used by this firm lies in the fact that the regional managers are allowed to make strategic plans, and the top management at the headquarters only needs to make the approval. PepsiCo initially tried to use a one-tier resource planning system that was controlled at the headquarters. However, this proved futile and the company was forced out of some of the global markets, especially in the developing countries in Africa. Upon a careful analysis, the management realized that using a strategy that is successful in the United States in other markets is unrealistic. For this reason, when planning the resources to be used in these regions, the management realized that it is important to base the strategy on the local environmental factors that are unique to each region.

Inventory management

At PepsiCo, inventory management is always given priority because of the nature of the industry within which the firm operates. Food and beverage industry is one of the most sensitive industries in every world market. People take the products in this industry, and any small mistake may force a firm out of the market. Food poisoning is one of the issues of concern to the managers of the regional units of this firm.

If it is proven that, any of its products had ingredients that are not permitted within a given region, the firm may not only risk having its certificate of operation cancelled, but also it may face litigation. Customers are also very sensitive about the quality of beverages they take. Because of the numerous alternative products in the market, any complaint about the value of the products they receive from one company may make them switch to a different company in mass. Given the sensitivity of this industry, the management of PepsiCo has been very keen on managing its inventory.

Once the raw materials are inspected to be of the right quality, they are always stored under the right conditions and with proper supervision to avoid any possibility of contamination. Before being used to make the products, the raw materials are once again inspected to ensure that they are of the right value. Once the products have been manufactured, they are always packed in bottles and cans to enhance their safety. This strategy has enabled this firm to operate in the global market without facing any major complaints from the customers about their products being contaminated.

Inventory management in the beverage industry comes with numerous challenges, top of which is the fear of possible poisoning or contamination. PepsiCo has installed superior infrastructures at its production plants to deal with this issue. It has some of the modern storage facilities for its raw materials to help in expanding their lifespan. The new systems also help in detecting any contamination and presence of wrong ingredients in the raw materials. This automated system has eliminated some of the mistakes experienced in the past such as failure to detect contamination at the right time. When contamination is detected in the final product, the loss to the company will be huge. It explains why it is important to use these automated systems that stops the entire operation system once an irregularity is detected.

Process management approach

Process management is another aspect of operation that specifically deals with the activities of transforming the raw materials into the finished products needed by the consumers in the market. Shah (67) defines process management as “The ensemble of activities of planning and monitoring the performance of a process.” As mentioned in the section above, production of beverages is a very sensitive process because the products will be consumed. Pepsi drinks are always consumed directly without being taken through any further processing by the customer. This means if any products have any defect; the customer will ultimately be affected. This has forced the management to install the sophisticated automatic machines such as the one shown in the diagram below.

This machine is instrumental not only in improving the quality and safety of the products, but also in reducing the cost of labor. What this machine can handle within a day may require several employees whose cost may be very high for the company. The machine does the processing and bottling of the products at a very high speed, and produces standardized products. Using tools such as the total quality management enhances the quality of the supply chain.

Logistics and Distribution

When the company has successfully completed the production process, the next important stage is the logistics and distribution of the products. Any food product has a short lifespan despite some of the preservatives that may be used. Once the PepsiCo’s products are ready, this firm must use the shortest time possible to ensure that they are delivered to the market. The global logistics and distribution strategies used by this firm are unique. PepsiCo has the responsibility of ensuring that its beverage products are delivered to the retailers in the regions where it operates.

This may seem to be an expensive process, but is one of the reasons why this firm has been very successful in the world market. Most retailers do not have problems of stocking their products because they are assured that the products will be delivered to them other than having to incur the transportation cost. The following are some of the areas of logistics and distribution strategies used by this firm that has enhanced its superiority.

Domestic and international logistics

Managing domestic and international logistics may be a challenge, especially for a firm with wide a market coverage such as PepsiCo. However, this firm has been able to manage its local and international logistics very effectively. The United States remains the major market for PepsiCo’s products. It has special tracks that it uses to deliver its products to its domestic customers. The track below shows a typical truck used to distribute the products of this firm.

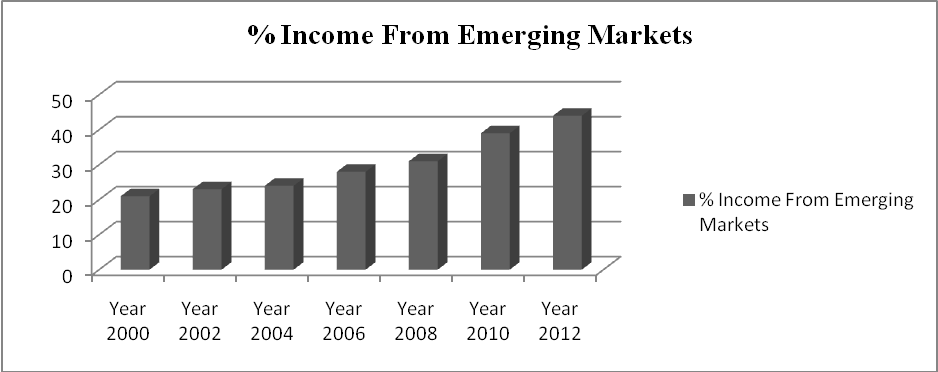

In the international market, this firm uses various types of trucks to ensure that their products reach the retailers within the right time. The chart below shows the growth of income of PepsiCo from the international market, which shows that the logistical demand, is on the rise.

According to Bachmeier 78), PepsiCo has an elaborate transport and logistics unit that has won several awards in the United States for its effeciency. In the United States and Europe, this firm has enough trucks that it uses to transport its products. It also has warehouses that are strategically located along the highways to help in the storage of its perishable products before they are delivered to the market. The same trend is now being used in the developing economies.

Customer relationship management

Managing customer relationship is one of the most important activities for the marketing unit. PepsiCo has a heavy market presence through regular advertisements in the global market. The following is the brand logo that this firm has been using to identify itself to the customers.

The firm has managed its brand in the domestic market, and has rolled out ambitious programs to penetrate the global market. Its interactive social networking strategy is specifically meant to enhance its relationship with the international market.

Global location management

As stated before, PepsiCo operates in the global market, and this means that it requires effective global location management strategies. Unlike its archrival Coca Cola Company that outsources most of the activities in the production and distribution processes, PepsiCo has established its own plants in the global market. The production process takes place at these plants, which in most of the cases also house the administrative offices. This gives the firm the total control of its production process. The firm is also directly responsible for the distribution of the products to the market. This eliminates the intermediaries whose actions may increase the prices of the products. Although this location management strategy is expensive, it gives the firm the full control of its own market operations.

Service response logistics

The consumers have become very demanding, and firms are forced to deliver products that meet their demands. Service response logistics is a relatively new concept that seeks to ensure that a firm delivers the products needed by the customers at the time of need. It involves basing the logistic strategies on the responses received from the customers. Erickson (19) says that PepsiCo has embraced this new strategy of using the social media platform that enables it to capture the response of its customers about its products and the delivery approach.

Sustainability

Sustainability is an issue that many business entities have been struggling to achieve. According to Leeman (49), sustainability has three pillars, which include the environment, society, and customers. PepsiCo has shown its commitment to the environment through various programs that are meant to conserve forests and reduce green gas emissions. Its annual reports also indicate that it has been working closely with the members of the society to enhance the living standards of people by sponsoring sports and education of children from poor families. The firm has been keen on maintaining the quality of services to its customer, which has earned it a pool of loyal customers.

According to Bachmeier (39), PepsiCo is currently running an initiative in Belgium, France, Iberia, Germany, and Holland to support sustainable agriculture among the fruit famers. The initiative, which is part of PepsiCo’s sustainable programs, is meant to support these farmers to ensure that the raw materials used in producing the beverages are protected. In order to support the farmers, PepsiCo, in collaboration with Cambridge University, has been creating awareness among its farmers to help them understand the benefits of renewable energy in their farming practices (to Bachmeier 56).

This program aims at lowering the cost of production for the farmers. This will help them sell their produce to PepsiCo at fair prices but still make good profits. Water is the most important raw material that Pepsi uses to produce beverages. In some countries, this firm has experienced shortage of clean water that it can use in its production process. In India, this firm has been facing the problem of clean water shortage (Bachmeier 41). In 2009, PepsiCo introduce Positive Water Balance Initiative in India to help it address the issue of clean water scarcity in this country.

This sustainability program helped PepsiCo replenish more water than the amount it used in its production process. This was done through water conservation programs and protection of water catchment forests in India (Kanani 1). In 2010, the company introduced water-recycling policies at all its plants, including those in India. This helped in reducing water consumption by over 30%. Currently, the firm is closely working with farmers to embrace drip irrigation system because of the minimal amount of water that is used (Kanani 1).

Strengths and Weaknesses of the Firm

The main strength of this firm lies in its financial capacity and many years of experience in this industry. It understands the market dynamics, which gives it an edge over other market competitors. However, the slow pace in implementing the emerging technologies, especially in marketing, is one of its main weaknesses (Erickson 19).

Conclusion

The management of PepsiCo has made an effort to ensure that its supply chain management for its beverages is very effective in order to maintain high quality products in the market. This management has been keen on acquiring quality raw materials, transports them to the firm, transforms the materials to final products, and delivering the products to the clients in the market. In its supply chain, the firm has always emphasized on maintaining quality at all the stages using various quality management tools such as Total Quality Management. It is clear that PepsiCo is one of the best examples of firms that have used the modern methods of supply chain management to enhance their operations in the market. Although the market is very competitive, this firm has been able to remain very competitive because of its ability to access quality raw materials, use efficient production processes, and deliver quality products to the customers in time.

Works Cited

Bachmeier, Kristina. Analysis of Marketing Strategies Used by Pepsico Based on Ansoff’s Theory. München: GRIN Verlag GmbH, 2009. Internet resource.

Biswas, Arijit, and Anindya Sen. Coke vs Pepsi: Local and Global Strategies. Economic and Political Weekly 34.26 (2007): 1701-1708. Print.

Ehrhardt, Moses and Brigham Edmond. Corporate Finance: A Focused Approached. New York: Cengage Publishing, 2014. Print.

Erickson, Gary. Advertising Competition in a Dynamic Oligopoly with Multiple Brands. Operations Research, 57.5 (2009): 1106-1113. Print.

Gattorna, John. Gower Handbook of Supply Chain Management. Aldershot: Gower, 2008. Print.

Jespersen, Birgit, and Tage Larsen. Supply Chain Management: In Theory and Practice. New York: Cengage, 2005. Print.

Kanani, Rahim 2013. Why PepsiCo is a Global Leader in Water Stewardship and Sustainable Agriculture.Web.

Leeman, Joris. Supply Chain Management: Fast, Flexible Supply Chains in Manufacturing and Retailing. London: McMillan, 2010. Print.

PepsiCo: Production Budgets 2014. Web. Shah, Janat. Supply Chain Management: Text and Cases. Upper Saddle River: Pearson Education, 2009. Print.

Smith, Andrew. Drinking History: Fifteen Turning Points in the Making of American Beverages. New York: Columbia University Press, 2013. Print.

Yahoo Finance: Historical Prices 2014. Web.