Abstract

The hotel industry is one of the most demanding sectors when it comes to supply chain systems. This situation is a result of the nature of the business, which demands the need for fresh and quality produce, in order to attract and retain customers. For this reason, this paper will focus on the issues surrounding hotel supply chains, the uptake of lean or green supply chains in the industry, as well as the impact, such techniques have on the sustainability of the supply chains.

We decided to study and analyze lean and green techniques of three major hotels in the UAE, namely, the Rotana Beach Hotel, Jumeirah, at The Etihad Towers Hotel and the Intercontinental Hotel. The choice of hotels was influenced by customer ratings which are based on service quality as well as customer experience. These hotels formed the proper representation we sought to reflect in the study. We analyzed these hotels with respect to their uptake of lean and green techniques in their supply chains. This strategy was an attempt to understand the rate of incorporation of lean techniques in the hotels’ supply chains.

We used two main research methodologies in data collection for this report. We adopted a quantitative methodology, in the form of questionnaires and surveys submitted by the hotels’ staff and correlation or regression analysis, which sought to show a distinct relationship between independent and dependent variables.

From our study, we found out that lean and green techniques have a direct impact on the performance of hotel supply chains. However, this realization is yet to be adopted by hotels in the UAE and a lot of work needs to be done to encourage the uptake of these green techniques.

Introduction

The main consideration that goes into the success of a hotel in the industry is its supply chain. A majority of hotels grapple with the challenge of ensuring stable supply chains hence affecting their performance. A hotel must be able to balance the supply of fresh produce and the demands of their customers. Whenever one aspect is affected, either supply or demand, the hotel is bound to face numerous challenges which may affect its business decisions. Cost is another challenge that hotels experience in their supply chains. The competitive hotel industry is facing the challenge of having to provide the best service to its customers for the lowest possible cost. Hotel logistics are part of the costs that are accounted for in the price tag. The global financial crisis has further put a dent on hotel finances, with some hotels being forced to close down. These trying times have forced hotels to rethink their business strategy. One area that provides a cost-cutting focal point is the supply chain. In order to understand the impact that supply chains have on hotels, it is best to analyze the challenges that the hospitality industry faces as explained below:

- Labor shortage as a result of attracting and retaining talent, is a recurring challenge that affect most hotels.

- The hospitality industry is forced with the persistent need to keep their costs low and not compromise service quality for their customers.

- The competitiveness of the hospitality industry has forced hotels to re-strategize to keep their costs low, so as to transfer the cost savings to their customers. With the entry of more hotels in the industry, hotels are prompted to work twice as hard and find strategies to attract and retain their client base.

- The changing global trends have affected traditional means of doing business in the hospitality industry. Hotels have been faced with the challenge of finding ways to incorporate such changes in their business strategies in order to survive.

- The hospitality industry is widely affected by the national economies of their countries. Changing economic trends have a huge impact on the industry. This situation leaves the industry dependent on the state of the economy

- Globalization has made the world a small village. As a result, travel has become easier and more affordable, following advancements in technology. The hospitality industry is one of the most affected sectors when it comes to this trend. Therefore, hotels are forced to revise their policies to accommodate the pot of different cultures and values of the world traveler.

- Global climate change has resulted to changes in weather patterns. As a result, the food chain has been adversely affected by aspects such as erratic rainfall and persistent drought. The hospitality industry has been the most affected industry in this regard. Most hotels’ food supply chains have been adversely affected by shortage of produce as well as diminished food quality.

The above challenges have a direct impact on operations in the hospitality industry. As a result, hotels are seeking better strategies in order to cope with the changing business environment.

Purpose

The primary purpose of undertaking this study is to investigate alternative processes, such as lean and green techniques, that can be incorporated in hotel supply chains. This study will help provide means by which hotels can reduce their costs and achieve long-run profitability. In addition, the adoption of the proposed lean and green techniques can assist hotels achieve sustainable supply chains.

Literature review

The area of sustainable supply chain is one that has received attention in the recent past. Global changes such as climate, globalization and the global economy have directly affected operations in the hospitality industry. Being vulnerable to the above changes, the industry has paid special attention to lean practices and green techniques in the supply chain.

As mentioned previously, the supply chain is the connecting flow between the suppliers and the consumers. This system forms the backbone of almost all operations in hotels. As expected, the same system carries the majority of operation costs. The system is comprised of the production, procurement, transportation and storage stages.

Lean practices

Lean practices first found their application in the automotive and manufacturing industries. These practices were applied in processes in order to increase customer satisfaction as well as profits. As a result, companies that adopted such practices were identified as focused on customer needs as well as having efficient business systems (Plenert, 2007)

From the outcomes described above, lean practices can have a positive impact on the entire supply chain process. Plenert (2007) indicates that lean processes can lead to operational effectiveness, thereby enhancing service delivery. According to Wincel (2004), lean practices have been adopted to improve product replenishment in stores. As a result, companies can track their store supplies and only order when they are almost replenished. This system enables companies to save on warehousing costs, at the same time reduce wastage. With time, lean practices have been adopted in other industries, including the hospitality industry. Hotels that have adopted these practices have reaped many benefits from their supply chain systems. This strategy has enabled hotels enhance efficiency in their business systems. As a result, these hotels have gained a competitive edge in the industry; while at the same time managed to keep their costs low.

Adoption of lean processes in operations has seen hotels record short product cycles, as well as ensured quality service. As a result, such hotels have coped with changing customer preferences for turnaround time, hence ensuring customer satisfaction in the competitive environment. According to Wincel (2004), following the adoption of lean practices in the Venetian Hotel’s supply chain, the hotel has properly utilized its warehouse space as well as reduced its product cycle time.

Green techniques

According to Chiras (2013), green techniques are applications that take environmental aspects into consideration. For instance, reduced wastage is an example of an environmental technique.

The need for incorporating green techniques in business processes stems from the fact that going green for businesses is not only beneficial, but also important. The environment is becoming part and parcel of business strategies. Businesses are realizing the impact that the environment has on strategies and processes. This situation mostly affects supply chains. The entire process from production to storage has a direct bearing on the environment. The hospitality industry is realizing that in order to ensure sustainability of the supply chain, there is need to adopt techniques and processes that are friendly to the environment. This strategy starts from policy makers to the implementation level. In this regard, most hotels have formulated and implemented policies that aim at promoting a clean environment.

The change is as a result of the realization that there is need to protect the source of production, such as growth of vegetables, to ensure the same can be done several years down the line. Furthermore, the need to embrace green technology has also been influenced by customer demand. The propagation for a healthy lifestyle has made hotels take a closer look at how their produce is being generated. In this regard, hotels must be able to guarantee the quality of their produce to their customers who are now informed of the production process, and opt for products that are produced ethically and are environmental friendly. In addition, hotels are also embracing green procurement. In this case, hotels are promoting better transport alternatives that help in reducing the carbon footprint, through the reduction of carbon emissions (Worthington, 2009).

Regulating authorities have not been left behind in the adoption of environmental policies. In this case, green certifications have been introduced, in an effort to drive the environmental agenda in all industries.

Hotel supply chains

One of the factors that are crucial to a hotel’s success is its supply chain. This process involves the co-ordination of activities and processes involved from the production stage, (the suppliers) to the consumption stage (the final consumer). Logistics management is part of the supply chain. Voortman (2004) defines logistics management as the co-ordination of plans and communication surrounding goods and services from production to the storage stage.

The primary objective of supply chains is to ensure customer satisfaction at the very last stage of the process. As a result, all processes, activities and communications are developed with the customer as the reference point. This strategy ensures that every stage in the supply chain adds value to the customer, and if does not, it is disregarded.

A majority of hotels still embrace traditional practices in supply chain management. These practices involve the direct communication between the suppliers and the hotels. In addition, the need for a variety of products in the hotel requires the services of different suppliers in their respective areas. As a result, hotels are tasked with keeping track of every supplier, as well as the inventory. The result is a disorganized and slow process, which leads to high turnover time on the customer’s side, hence resulting to customer dissatisfaction.

However, modern technology has stepped in to save the risky process. Information and communication technology has provided better means of communicating with suppliers, at the same time tracking inventory. In this case, different software has been introduced to ensure seamless communication and co-ordination between the supplier and the hotels. As a result, the production and transportation processes are tracked and managed to ensure timely delivery. In addition, hotels are also able to reduce wastage of products, which occurs as a result of double-ordering. Utilization of resources such as space is also made possible by a computerized supply chain. This situation is as a result of proper inventory management. Hotels are able to track their inventory levels and only order when new products are needed. This process has reduced warehouse costs and encouraged proper management of the supply chain.

These activities and processes are experienced by the customer at the end of the supply chain. This outcome is as a result of improved quality of service, as the customer gets the products he/she wants, when he/she needs. In addition, the cost savings experienced in the process as explained above are transferred to the final customer. As a result, customers are able to pay less for more.

In order to understand the impact that lean and green techniques have on supply chains, it is best to illustrate the different stages of supply chains diagrammatically as indicated below:

- Production- The goods or services are produced by the supplier

- Transport- the goods or services are transferred from the point of origin to the supplier’s storage

- Procurement- The goods or services are sourced from the supplier

- Distribution and storage- the goods or services, once they are procured, are stored in warehouses

- Customer- the final stage involves the customer accessing the goods or services produced by the supplier.

Meanings and implications

Supply chain management

There are a variety of different meanings of the above term. The most popular and relevant are as explained below:

The co-ordination and management of supply chain activities, such as production, sourcing, procurement, transport and co-ordination of processes using information technology (Taylor, 2003)

The oversight and co-ordination of flow of goods or services from the producer to the consumer (Ayers, 2006).

The management of materials, information and processes as goods or services flow from the supplier to the consumer (Leeman, 2010)

Sustainable supply chain management

From the above definitions, Taylor (2003) defines sustainable supply chain management as a concept that takes into consideration environmental and waste reduction perspectives in supply chains. This concept identifies sound choices in the entire process in an attempt to achieve long-term profitability as a result of reduced costs. The hospitality industry would gain tremendously from the adoption of this strategy as it will reduce operation costs in the supply chain.

Just In Time

According to Cheng and Lai (2009), Just in Time (JIT) is a production process that aims at reducing the turnaround time in the flow of products or services from the suppliers to the customers.

Kaizen

Kaizen refers to the practice of continuous improvement in processes (Cheng and Lai, 2009). As a result, the previous process is improved upon to create a better process. This strategy leads to improved efficiency and effectiveness of processes.

Quality improvement

Cheng and Lai (2009) define quality improvement as the analysis of existing processes and implementation of strategies to improve the processes.

Green procurement

This process involves the consideration of the environment in the purchasing of products and services. As a result, such processes cause minimal, if any, adverse environmental impacts during procurement.

Lean and green techniques

Worthington (2009) defines the above techniques as those that incorporate environmentally sound principles in their processes. The incorporation leads to less usage and wastage of materials. The application of these techniques leads to cost savings by businesses in the long run hence improving profit margins.

The application of these techniques in the hospitality industry is bound to achieve similar results of cost saving as well as reduced operation costs.

From the above concepts, one can deduce the important perspectives in the hospitality as identified below:

- Cost reduction

- Quality retention

- Efficient and effective supply chain management

- Green and lean technologies in supply chains

Hotel supply chains have a focused aim of incorporating the above perspectives in their processes. This strategy is bound to reduce operation, costs hence extending the same quality of service to customers at a lower cost.

Brief history of the hotels

Jumeirah Beach Hotel

The hotel began operations in Dubai, the United Arab Emirates. The hotel opened its doors for business in the year 1997. The unique wave design complements the iconic Burj Al Arab that is at the backdrop. Following the construction of the hotel, it was identified as the 9th tallest building in Dubai (Riewoldt, 2006).The hotel’s ideal location attracts visitors in droves, as a result of its close proximity to the airport. In addition, the world-class facilities, such as the Wild Wadi Park, where guests have an exclusive entrance to the park, enables the hotel to retain its customers.

Facts and figures

The hotel prides itself in having 598 rooms and suites, as well as 20 villas located at the beachfront. In addition, the hotel also as 20 restaurants and bars in its approximately 364,000 Square Feet area (Riewoldt, 2006).

Jumeirah Beach Hotel’s connection to green principles

The choice of the hotel to be part of the study, stemmed from the fact that the hotel has been recognized as being environmental conscious. In the recent past, the hotel was accredited the Green Globe Certification (GGC) as a result of its environmental-friendly practices. Therefore, the choice of the hotel was intended to shed light on the specifics of its green practices.

The Intercontinental Hotel

The intercontinental Hotel is a chain of hotels that operates under the Intercontinental Hotels Group. The global hotel chain started its operations in 1946. The introduction of the 5 star hotel in the UAE was a result of the realization of the burgeoning hospitality industry in the region. In addition, the start of operations in the region was also prompted by the fact that the expansion into the UAE region was part of its global strategy of facilitating global travel.

Facts and figures

The 5 star hotel has 390 guest rooms, 54 suites, 25 meeting rooms and 9 restaurants in its luxurious resort.

Choice of Intercontinental Hotel

The main reason as to why we decided to include the hotel in our case study is as a result of the green practices the Hotel has introduced in its operations. In this regard, the Hotel has implemented a system that seeks to assess the level of waste and energy produced within the Hotel. The system is the Intercontinental Hotel Group Green Engage System. This system assists the Hotel to keep track of its environmental performance. In this case, the Hotel can assess the utilization of resources and reduce waste, as the system proposes recommendations aimed at ensuring efficiency in the current systems.

Rotana Beach Hotel

The Rotana Beach Hotel was started in the year 1992 following an agreement between two partners. The foundation of the partnership was the need to combine the Arabian culture and luxurious living. As a result, the Rotana Hotels sought to provide high quality service to their guests, with an Arabian touch.

Facts and figures

The hotel has a presence in 85 countries in the Middle East and Africa. The Rotana Beach Hotel in Abu Dhabi is a 5-star hotel and has two main wings, namely the Tower wing and the Beach wing. The former is 20 floors high and has a capacity of 128 rooms. The latter has 286 rooms and suites in its 7 floors.

Data Analysis

In order to understand the uptake of green techniques and lean practices in the UAE, we identified 3 hotels that formed part of our focus group. The study sought to determine the level of conformity to green and lean practices in the hotels’ supply chain systems.

Quantitative means of data collection were adopted in this study. This procedure involved the distribution of questionnaires to the staff of the identified hotels. The questionnaires were categorized into four main sections. The first section required the respondents to include general information such as name, title and work duration among other aspects. The second section comprised of green techniques that included a total of 6 sub-sections (waste disposal, green procurement, green technology, health and safety, green certifications and green products). The third section comprised of lean practices. This section was further categorized into 6 sub-sections, namely, quality improvement, inventory control, product maintenance, Kaizen, JIT (Just in Time) and standardization.

The identified hotels were the Jumeirah Hotel, Rotana Beach Hotel and Intercontinental Hotel.

The response rate for the three hotels averaged 5 staff members. Rotana Beach Hotel recorded the highest response rate at 60% while Jumeirah Hotel and the Intercontinental Hotel each recorded 20%.

General Results

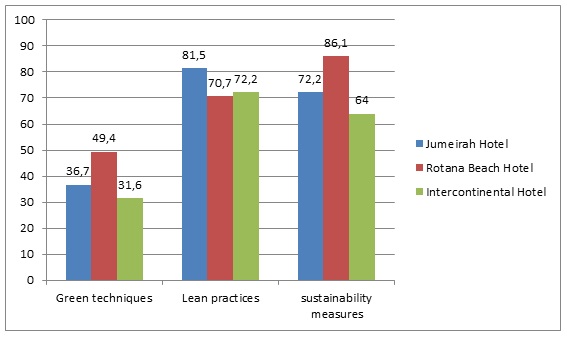

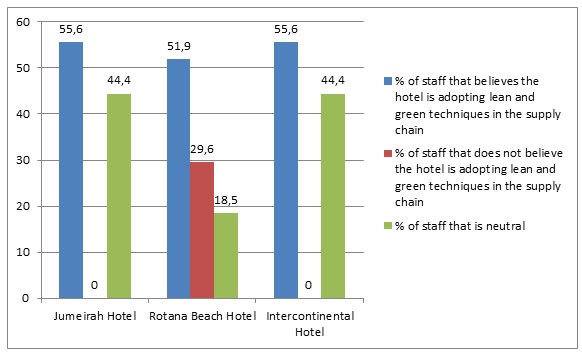

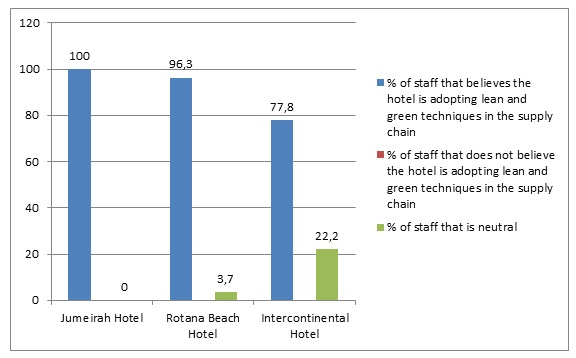

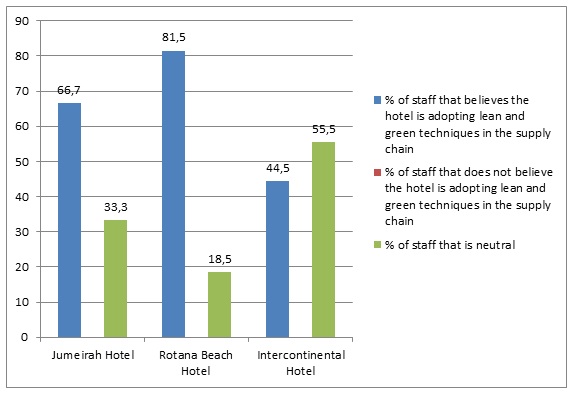

% of staff that believes the hotel is adopting lean and green techniques in the supply chain.

From the information presented above, the Intercontinental Hotel trails in green techniques, at 31.6%. These techniques are aimed at promoting the conservation of the environment, for example, the adoption of green procurement in the supply chain. On the other hand, the Rotana Beach Hotel leads the pack by registering a 49.4% rate in the overall green techniques category. All in all, the Rotana Beach Hotel recorded impressive numbers in all the three categories, green techniques, lean practices and sustainability measures.

Green Techniques

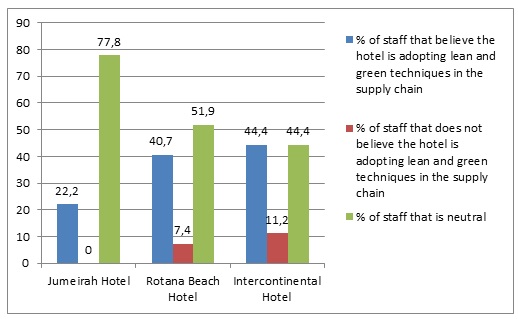

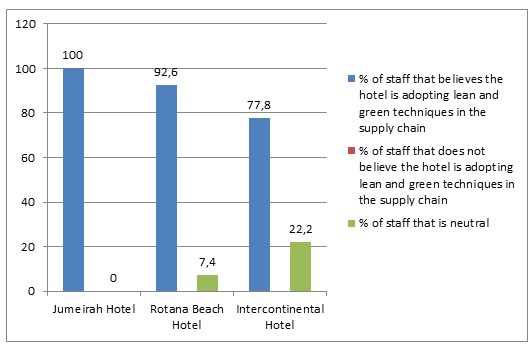

Waste disposal

The information represented in the graph above presents an above average performance in waste disposal of the respective hotels. Although the majority of the respondents have a neutral stand on this issue, the low rate of lack of adoption of waste disposal (7.4% in Rotana Beach Hotel) and 11.2% in the Intercontinental Hotel, indicates confidence in the waste disposal systems of the concerned hotels.

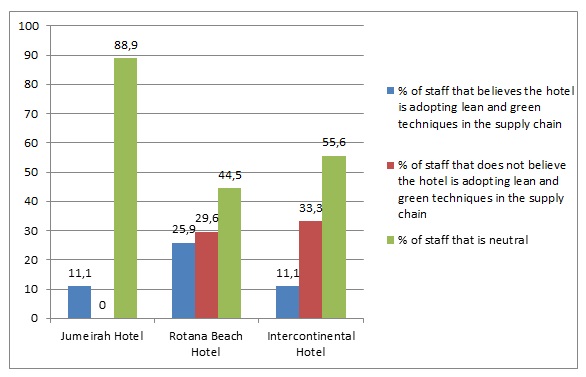

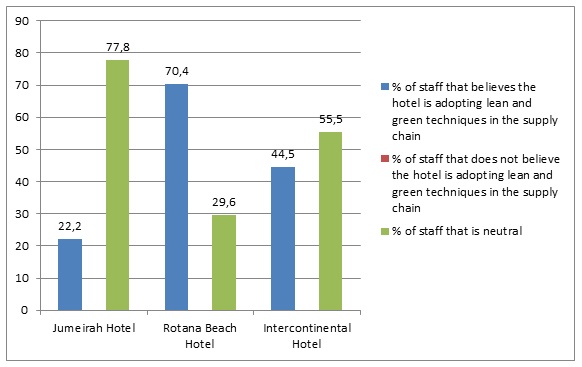

Green procurement

In green procurement techniques, the majority of the staff in all hotels has taken a neutral stand. In this case, they indicated that the hotels have indeed tried to adopt green procurement, although, there is still room for improvement. The Jumeirah Hotel recorded the most impressive numbers in this category, with 88.9% of the staff as neutral and 11.1% of the staff being confident in the hotel’s adoption of green procurement techniques.

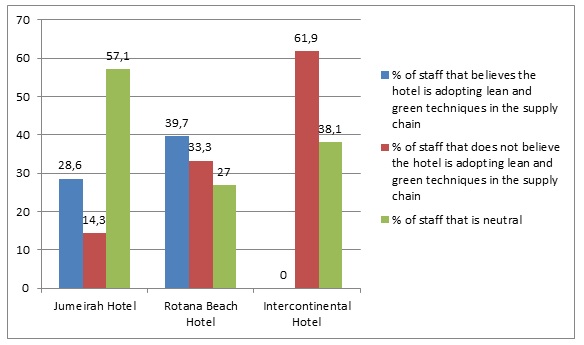

Green technology

Statistics from the Intercontinental Hotel staff indicated that the hotel is not adopting green technology in their system. The majority of the staff (61.9%), indicated that the hotel is not doing enough in the adoption of green techniques in the supply chain. On the other hand, the Rotana Beach Hotel received positive reviews in this aspect. 39.7% (the highest figure in this category) of the staff believe that the hotel is adopting green techniques in the supply chain.

Health and safety

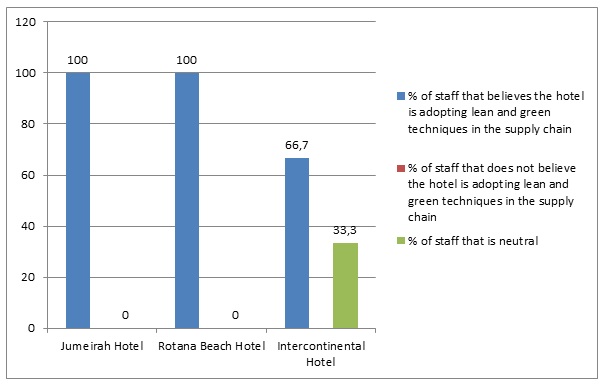

The health and safety category received the best reviews from all the three hotels that participated in the study. The Jumeirah Hotel and the Rotana Beach Hotel recorded an impressive 100% rate that indicated that the staff of the respective hotels believe that the hotel is adopting adequate health and safety techniques in the supply chain.

Green certifications

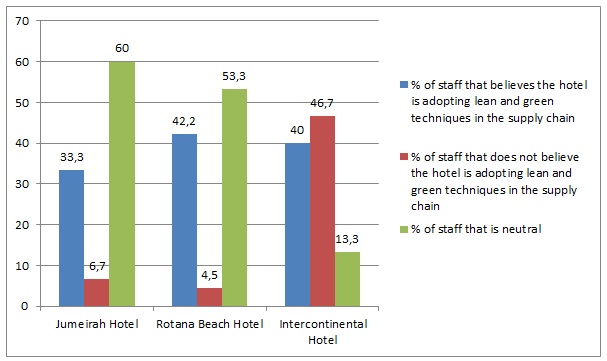

The Intercontinental Hotel received the worst reviews in the Green Certification category, with 46.7% of the staff indicating that the hotel is not adopting adequate green techniques in green certification. On the other hand, the Rotana Beach Hotel was the winner in this category, with 42.2% of staff showing their approval in the hotel’s Green Certifications.

Green products

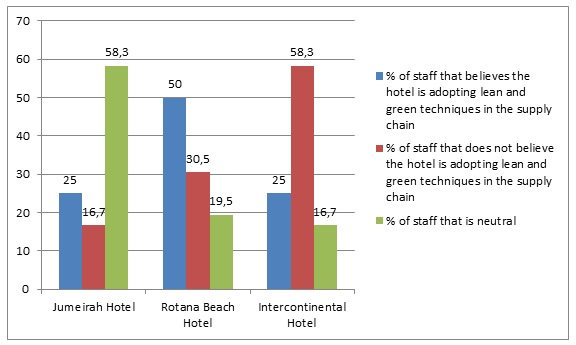

As in the previous category above, the Intercontinental Hotel scored poorly in the green products category. 58.3% of staff indicated that the hotel is not doing enough in the area of green products in the supply chain. On the other hand, the Rotana Beach Hotel received the best reviews, with 50% of the staff respondents indicating that the hotel has adopted green products in their supply chain.

Lean practices

JIT

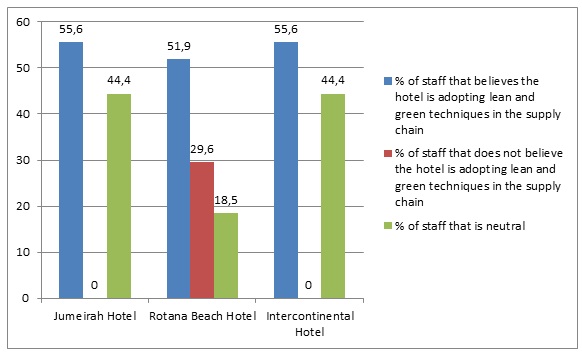

The Just in Time (JIT) category has been adopted widely by the three hotels.55.6% of Jumeirah’s and Intercontinental Hotel’s staff respondents agreed that the hotels have adopted the JIT strategy in their supply chains.

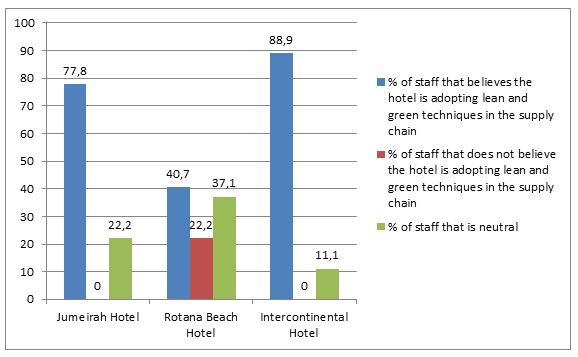

Kaizen

The Intercontinental Hotel received the highest ratings in the Kaizen category, with 88.9% of the respondents indicating that the hotel has adopted the Kaizen system in the supply chain. As a result, the hotel continually improves its processes in the supply chain system. Rotana Beach Hotel on the other hand, received only a 40.7% rating of the same.

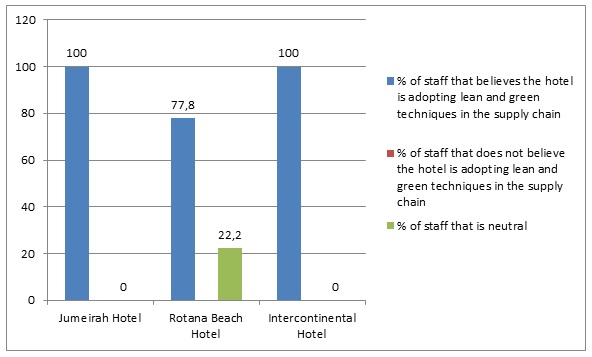

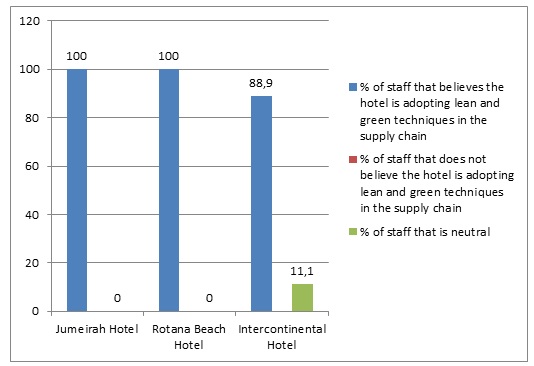

Quality improvement

The three hotels used in the study scored highly in the quality improvement aspect of their supply chains. Both the Jumeirah Hotel and the Intercontinental Hotel received impressive reviews, at 100% for each hotel. This trend indicates that the three hotels have committed to ensure quality supply chains.

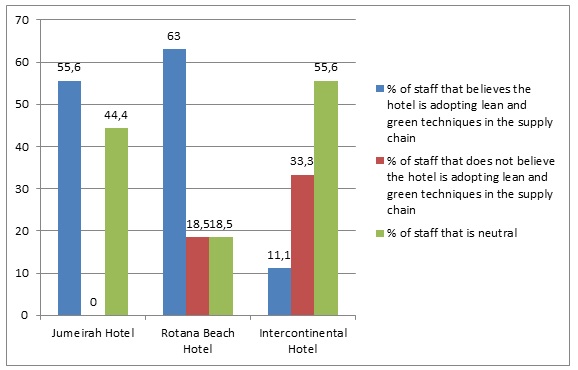

Inventory control

The Rotana Beach Hotel has the highest rating in inventory control of their supply chain system (63%). On the other hand, the Intercontinental Hotel has the lowest rating, at 33.3%. This trend indicates that the Rotana Beach Hotel and the Jumeirah Hotel have efficient inventory control procedures that lead to a reduction of waste.

Productive maintenance

The data indicated above shows that the three hotels have adopted maintenance plans that have contributed to productive supply chains. In addition, the impressive figures indicate that the hotels undertake scheduled maintenance plans that assist in troubleshooting any problem areas in the supply chain process.

Standardization

The above results indicates that the hotels have incorporated different standardized certifications such as the Standard Operating Procedures (SOP) and also ensured standardization of their services.

Sustainable measures

Economic performance

As a dependent variable, the economic performance is influenced by the lean and green practices adopted by the hotels. As the above data indicates, the majority of the staff is neutral on the impact that lean and green techniques have on economic performance benchmarks such as market share and operation expenses.

Environmental performance

In this category, a majority of the staff believes that the environmental performance has been influenced by the incorporation of lean and green techniques in the supply chain. As a result, environmental friendly policies that curb wastage and reduce carbon footprint are encouraged.

Social performance

The majority of respondents from the three hotels indicated that the adoption of lean and green technologies in the supply chain, contributed to improved social interactions between the hotel and the community, as well as the suppliers.

Operational performance

The average response rate of the respondents from the three hotels indicates that the adoption of lean and green techniques in supply chain promote the system’s sustainability in terms of its efficiency, effectiveness and its quality.

Conclusion

The business environment has changed drastically over the past years. In particular, the changes in weather patterns as well as lifestyle activities have directly affected the environment. As a result, the environment has reacted adversely, as characterized by erratic rainfall patterns, extended drought periods, among other effects. Therefore, there is need to evaluate processes that adversely affect the environment.

Problem statement

The hospitality industry in the UAE has been growing by leaps and bounds. Improved economic status in the region has propelled the industry to global heights. This situation has seen visitors from around the world come to the UAE in droves, hence boosting the industry.

However, the aspect of operation costs remains a thorn in the flesh of most hotels in the region. Increased expenses that come from the hotels’ logistics and supply chains have reduced profit margins or have resulted to cost transfers to customers in an attempt to maintain service quality.

Way forward

The introduction of lean and green techniques in supply chains has been identified as a suitable solution to overcome the situation. In this case, the adoption of lean and green techniques, as discussed throughout the paper, is a crucial means of dealing with the persistent ecological issue.

The analysis of the results from the case study has revealed an upward trend in the incorporation of green systems in supply chains. As a result of the dependent nature that hotels have on supply chains, the search for efficient systems is gaining ground.

References

Ayers, J. (2006). Handbook of supply chain management. New York: CRC Press.

Cheng, T. E. & Lai, K. (2009). Just-in-time logistics. Farnham, England: Gower.

Chiras, D.D. (2013). Environmental science. Burlington, MA: Jones and Bartlett Learning.

Leeman, J. (2010). Supply chain management: Fast, flexible supply chains in manufacturing and retailing. Dusseldorf: Institute for Business Process Management.

Plenert, G. J. (2007). Reinventing lean: Introducing lean management into the supply chain. Amsterdam: Elsevier/Butterworth.

Riewoldt, O. (2006). New hotel design. London: Laurence King.

Taylor, D. A. (2003). Supply chains: A manager’s guide. Harlow: Pearson Professional Education.

Voortman, C. (2004). Global logistics management. Cape Town: Juta Academic.

Wincel, J. P. (2004). Lean supply chain management: A handbook for strategic procurement. New York: Productivity Press.

Worthington, T. (2009). Green technology strategies. Belconnen, A.C.T: Tomw Communication.