Introduction

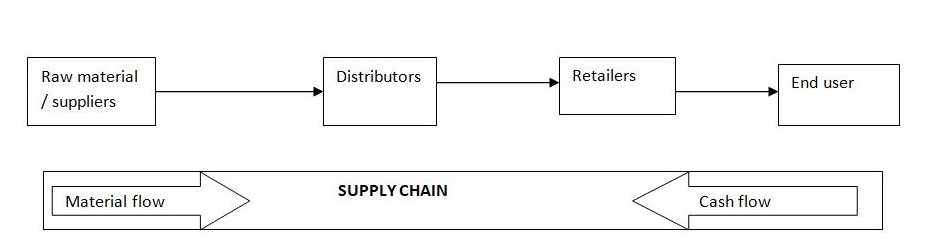

The process in which good moves to become a usable product to the final consumers is referred to as a supply chain. This chain is dynamic in nature because it involves a constant flow of products, information, and funds in the different processes (Chopra, 2007, p. 4). The chain of events is what is known as supply chain management (Saunders, 1997, p. 4). the chain flow can be represented as follows:

- The first step is obtaining the order from the customer with the specifications they require, quantities required, and due dates for delivery.

- Production is then commenced, here the raw materials have to be obtained and combined in a manner that will yield the expected output.

- After production the product can then be stored and distributed.

- The supply to the customer’s site is then done.

Customer satisfaction should be put in mind in the entire Tesco’s chain flow and thus high-quality products should be guaranteed (Cohen and Joseph, 2005, p.108). Supply chain management in Tesco has some benefits; they are outlined by Chopra as follows (2007, p. 18):

- Inputs into consideration the consumer needs and thus consumer satisfaction is the basis for production efficiency.

- It reduces inventories.

- It lowers the cost of operations since there is a systematic flow of activities.

- It also ensures that the products are available to the consumers through the distribution mechanism in place.

Abstract

Tesco plc was founded in 1919 in the United Kingdom; its scope was to trade in the grocery and the general merchandising retail sector. With its innovative and expansive strategies, it has spread to the international markets and has 4,811 locations around the globe. Tesco UK is one of the organizations in the world which uses the best practices in supply chain management and the use of radio frequency identification technologies (RFID). The organization has used numerous operational, managerial, and technological innovations to streamline its supply chain e.g. incorporating point of sale data, cross-dock distribution centers, replenishment to trigger demand, etc.

Christopher indicated that the forces driving supply chain management in Tesco include; First, is that there is the new communications technology available now that allows its managers to actively manage a supply chain. Second, customers are demanding lower prices and better products and services. To meet their customers’ demands, Tesco needs to optimize the entire supply chain. Supply chain management allows all the Tesco in a supply chain to look beyond their own objectives to the objective of maximizing the final customer’s satisfaction. The payoff for supply chain members that can do this is increased profits for their stakeholders (2005, p 13).

Supply chain in Tesco UK

Tesco’s supply chain is composed of integrated management of input, information technology, and communication and the financial flow from the initial stages of raw material extraction to the end-user in the chain i.e. (Moncza, 2009 p. 19);

The supply chain starts at the purchase of raw materials from suppliers, at Tesco, their raw materials are usually finished goods since they act as an outlet for most of the consumer commodities therefore their suppliers are the manufacturers who manufacture those goods. At this point the purchases and the stock levels are maintained at all times and with some adjustments in cases of a perceived increase in demand, this has enabled the outlets to use the control of an automated warehouse control system, this system in the centralized distribution mechanism help the organization maintain a favorable stock level and also the analysis of the different stock demands. This system helps in the determination of the quality levels and this maintains and helps the organization’s objective of provision of high-quality commodities. The ordering systems are also centralized and thus the benefits of large-scale operations are achieved by the company. These systems of stock management make it the most efficient organization in the retail outlet market and the most preferred in their all-in-one-store outlets (Lambert, 2004, p 27).

The second event is the distribution of the goods to the organization’s outlets all over the world, a centralized distribution system is in place i.e. they use one truck to distribute the same commodity in all the intended outlets in the UK thus increasing the efficiency, reducing the distribution costs and the speed of distribution. The transport is evaluated in terms of distance, weight, type of product, and the urgency of the supply. This process is not only cost-centered but also resource centered i.e. the availability of the resources in its sense influences the supply chain.

Thirdly the display and the handling of the commodities in the outlets are maintained in the highest level in all the four types of outlets in the organization namely:

- Tesco extra; they are large stores which stock all the Tesco’s products.

- Tesco superstores; they stock large varieties of groceries and non-food items; they are basically larger than the extra.

- Tesco metro.

- Tesco express; they are mainly found in the neighborhoods and stock mostly the foods and other high margin products.

- One stop.

- Tesco home plus.

These outlets are located in populated areas and in locations that are suitable to the consumers; they use collaborative extended networks to communicate. The product and business life cycles are managed to ensure the outlets remain the most preferred shopping malls in the UK.

And finally, the consumption of the commodities by the end-users in their respective outlets, at this stage, Tesco uses electronic data interchange in the radio frequency identification technologies (RFID) to sell their products in a fast and efficient way to deliver the service to the consumers. This is one of the process improvements processes the organization has been using in the recent past to ensure the commodities value is created for the consumers to increase and creation of loyalty. The stores are usually self-service with an easy and flexible layout for the inflow and outflow of consumers, commodities are arranged in terms of use e.g. electronics, groceries, etc. in specific locations in the stores.

The outlet has online selling mechanisms, this has contributed to its sales in the recent past, online sales are systems has reduced the consumer inflows in the chains since consumers order for the commodities online and a delivery is made.

Value in Tesco’s supply chain

The management of Tesco’s supply chain has seen frequent improvements in the areas like point of sale scanning, centralized ordering, distribution, automated warehousing controls, and electronic data exchange (Christopher, 2005, p. 13). The main and the important process for Tesco are to create value in its supply chain, Lambert indicated that they aim at increasing the value for the following stakeholders (2004, pp. 18-26);

- Financial value of its products and operations; this aims at reducing the costs and the increase of the financial performance of the organization. The cost-cutting measures in the supply chain enable the organization to give discounts, promotions, and maybe social responsibility initiatives.

- Customer value; Product engineering and transformation basically to conform to consumer needs emerged necessitating the producers to carry out surveys and sampling the markets for consumer rating and expectation analysis as competitive advantage mechanism aimed at increasing dominance in the market. Tesco aims at increasing the consumer value in the following ways:

- Increasing and maintaining a high quality of the products and services.

- Increasing the affordability and availability of consumer goods and services.

- Increase in the service delivery e.g. the inclusion of warrants, after-sales services, etc.

- Social value; Tesco has initiated several projects aimed at protecting the environment e.g. the adoption of green policies in its outlets, paying tax obligations, poverty reduction, and the jobs creation in the employment opportunities it provides, etc.

Importance of Supply Chain in Tesco UK

The supply chain has contributed greatly to the success of the outlet chain; it has the following benefits:

- It has enabled Tesco to efficiently maintain and identify the consumer needs and requirements and thus increasing their value.

The growth of communication and information technology such as the Internet selling, online ordering, and payments has enabled greater supply chain collaboration activities between supply chain trading partners in a marketing model, it is characterized by the following ideology:

- By failure to do something the competitors will certainly do it to beat you in the market thus you should take every opportunity that comes your way.

- The increase in the Availability of supply chain management technologies and products on the market has enabled firms to acquire a large variety of products e.g. in the warehouse control systems, distribution systems, point of sales, and use of electronic data interchange in the radio frequency identification technologies in the outlets.

Difficulty faced by Tesco UK in its supply chain and the ways of improving these areas

The largest barrier to successfully managing a supply chain is perhaps the human physiological characteristic elements as noticed by New and Roy (2006, p. 91). Failure to correctly manage the issues of trust and communication will abort any attempt to manage the supply chain. When there is a lack of trust and communication, the supply chain’s members will soon succumb to greed or suspicion that other members of the supply chain are profiting at their expense. Tesco has tried to improve and eliminate this ill by increasing its workforce training programs and introducing the organisation’s code of ethics and standards which apply to all levels of the management tree.

Another challenge is communication; the communication among the stakeholders in the chain is not very efficient especially between the workforce and the consumers. When the communication is not adequate, the supply chain will not improve its response enough to increase profits for its members. Without an increase in profits, the efforts to manage the supply chain will be reduced, because there will be no reward for actively managing it. The outlet firm should increase the consumer handling standards and also increase the training of its workforce in interpersonal skills to reduce this ill in the outlets (Bowersox, David and Bixby 2002, p. 93).

Supply chain management requires an unprecedented level of cooperation between the members of the supply chain which is sometimes low in the supply chain, the link between the suppliers and the organisation, the internal cooperation in the outlet chain, and the link between the outlets and the end-users. Those are the most affected areas; the organisations efficiency may be affected by external factors e.g. supplier’s efficiency and timing thus the firm must streamline all the processes in the supply chain. It requires an open sharing of information so that all members know they are receiving their full share of the profits. Since many of the firms in a supply chain do not have a history of cooperation, achieving the trust necessary for supply chain management is a time-intensive task.

Finally, the area of internet marketing and selling needs at times requires the services of courier firms to deliver the commodities to the end-users, their efficiency and reliability are usually not guaranteed and their handling of the consumers might be a disadvantage to the firm and thus the best thing to do in the future is to create or select an efficient and reliable firm with will uphold the interests of the outlet chain at all times (Christopher, 2005, p. 180).

Conclusion

There is no cookbook for managing the supply chain. However, some basic principles can be used for it. And, a set of best management practices is evolving as managers gain experience managing their supply chains. Tesco UK is one of the organizations in the world which uses the best practices in supply chain management and the use of radio frequency identification technologies (RFID). The organization has used numerous operational, managerial, and technological innovations to streamline its supply chain. The success of the outlet chain has been brought about by its supply chain management innovations and changes.

References

- Bowersox, D., Cross, D., & Bixby, C., 2002. Supply Chain Logistics Management. 3rd edition. USA: Mc Graw Hill.

- Chopra, S., & Mendi, P., 2007. Supply Chain Management: Strategy Planning and Operation. 3rd edition. Upper Saddle River, New Jersey: Pearson Education Press.

- Christopher, M., 2005. Logistics and supply chain management: creating value-adding networks. 3rd edition. Prentice Hall Education.

- Cohen, S., & Roussel, J., 2005. Strategic Supply Chain Management: The Five Disciplines for Top Performance. Mc Grawhill.

- Lambert, D., 2004. Essential Supply Chain management Processes. Supply Chain Management Review, 18-26.

- Lambert, D., 2004. Supply Chain Management: Processes, partnerships and performances. USA: Supply Chain Management Institute.

- Moncza, R., Hanfield, R., Giunipero, L., & Patterson, J., 2009. Purchasing and Supply chain management. 4th edition. USA: South-Western Cengage Learning.

- New, S., & Westbrook, R., 2006. Understanding Supply Chains; Concepts, Critiques and Futures. New York: Oxford University Press.

- Saunders, M., 1997. Strategic purchasing and supply chain management. 2nd edition. Great Britain: Prentice Hall.