Gathering information on the business operations is crucial in business decision-making. It requires the stakeholders to use tools such as checklists, scores, experiments, and observations. This process is vital because it helps the company to track its progress, identify its service processes, and create instructions that are used in planning. Business owners often determine how difficult a situation can get or how severe a problem look and determine the strength and weaknesses that involve the basis for framing policies and measures (Yazdani et al., 2017). It is essential to gather information regularly and analyze how procedures and guidelines formulated by the company impact the organization’s performance.

Program evaluation is also crucial in determining the progress of operational activities and the effectiveness of a particular program and implementing corrective measures and modifications that help enhance the process and the evaluation needed. As such, it is necessary to outline steps that are effective and necessary for completing a particular task or project. For instance, the steps for preparing an espresso beverage include the following:

- The customer submits the order to the team.

- The team decides on the correct portafilter that they want to drink.

- Then the initial process of grinding coffee starts. It is important to note that ground coffee begins to go stall after almost 20 minutes, which calls for trying as much as possible to grind the coffee as the process goes.

- The next step is placing the portafilter on the holder on top of the grinder and haul its level for the coffee to get inside the portafilter.

- Following this by holding the portafilter up to the grounds chambers with the help of finger or chamber lid level off the coffee that is heaped within the chamber.

- It essential to understand that tamping is important thus, must be done correctly.

- It also crucial to flush and wash out various old grounds that may have remained in the group head, thus may add to a particularly sharp state to the prepared coffee.

- The last step in the preparation of the beverage is brewing of the coffee. It includes inserting the portafilter and choosing the suitable button to begin the process immediately.

- After the brewing the coffee, it is handed to the consumer.

After completing the above steps, it is crucial to identify the differences in the process and whether they cause significant damage to the expected final product. Once the differences are recognized, they have to be minimized. According to Caudill et al. (2018), a dissimilarity that exhibits features that have a stable pattern is known as a controlled variation, while that having an unstable trend is referred to as uncontrolled variation. It is crucial to precisely define duties so that each employee understands what they should do at any moment, thus reducing possible complications that can occur when there are no well-defined work schedules. Moreover, the workers should be trained on the concept of the two types of variations mentioned above, as this would help them determine any specific one based on the situation. In addition, they are likely to know if any particular process is stable, if it is working as expected, or if the task is unstable, which means that it is inconsistent with the expected working conditions.

Wild Dog Coffee Company

The consumption of coffee has been continually growing over the years and across different countries in the world, making it one of the most exchanged items in the global markets. The product was initially discovered in the sixth century when the first consumers begin to use it. However, since its discovery, the consumption of coffee has exponentially increased in every nation. The supply chain of the commodity comprises of several units, each of which must ensure that the quality of the product is high, beginning from the sustainable coffee growing and roasting process.

Supply Chain Design

There are two possible supply chain scenarios that Wild Dog Coffee Company can choose and use.

Since Supply Chain Management is crucial in business operations, the adopted process can differ from one commodity to another. For coffee, the supply chain comprise the following:

- Growing

- Harvesting

- Hulling

- Drying and packing

- Bulking

- Blending

- Roasting.

The above supply chain is further dominated by multiple intermediaries such as exporters, shippers, wholesalers, and retailers. Shipping plays a crucial role in the coffee supply chain and in increasing a global network, which terminates when the product reaches wholesalers and retailers, who may range from small eateries to big cafeterias and stores in different parts of the globe. Consequently, it is essential to note that the higher the number of brokers in a supply chain, the more detailed and robust the supply chain must be to keep the business running. A dependable and least-cost logistics rely heavily on progressive and meaningful interconnection between different parties involved in the process.

It is essential to understand that supply chain comprises of a sequence of processes that make products transform from their raw state to the final consumable form. The management of Wild Dog Coffee Company is more complex than it should be with respective to similar businesses. The complication in this management approach arises from inclusion of following secondary supply chain management analysis:

- Growers. These are those individuals who have to work on small pieces of land where they must pick the coffee cherries as well as green beans and dry or hull them, depending on their chosen technique.

- Processors. Involve lone farmers who possess the necessary equipment that enhance coffee processing, or unions such as co-operative that combine resources and use them to buy the needed equipment and avail such machines to its members.

- Government Agencies. Government may come in and control coffee production, processing, and trade in different ways, such as by imposing taxes, levies, or offering grants, or by enacting laws and regulations relating to coffee business as well as creating a wider market for producers.

- Exporters. These are individuals or organizations who buy coffee products either in raw of finished forms and sell them to dealers. Exporters have the knowledge of the local locations as well as producers, making it easy for them to guarantee quality of their shipment abroad.

- Dealers or brokers. These are firms or individuals who supply coffee beans to companies that roast the products in the best quality needed and produce them at the right time, and acceptable price to the potential buyers.

- Roasters. Rosters can add value to the processed coffee by marketing, branding, and packaging the roasted products.

- Retailers. These are the vendors of coffee products and comprise of small shopkeepers, supermarkets, restaurants, and catering organizations.

Inventory Management

Demand rate, D = 1400 pounds = 1400/25 = 56 packages per month

Cost per package = 9*25 = $ 225

Monthly holding cost per package, H = 225*10%/12 = 1.875

Considering an ordering cost (S) of $ 19.95 per order, EOQ = SQRT(2DS/H) = SQRT(2*56*19.95/1.875) = 34.5 packages

The value of EOQ lot size = 34.5*225 = $ 7763, which is greater than $ 250. Therefore, shipping is free on this lot size.

Since there is no fixed associated, hence, there is no need to order this lot size. Minimum possible lot size should be ordered to minimize the holding cost. However, a minimum order of $ 250 needs to be ordered to qualify for free shipping.

Minimum order size = 250/225 = 1.11 packages. Packages need to be in whole number. Thus, a minimum of 2 packages need to be ordered each time.

Forecasting Model

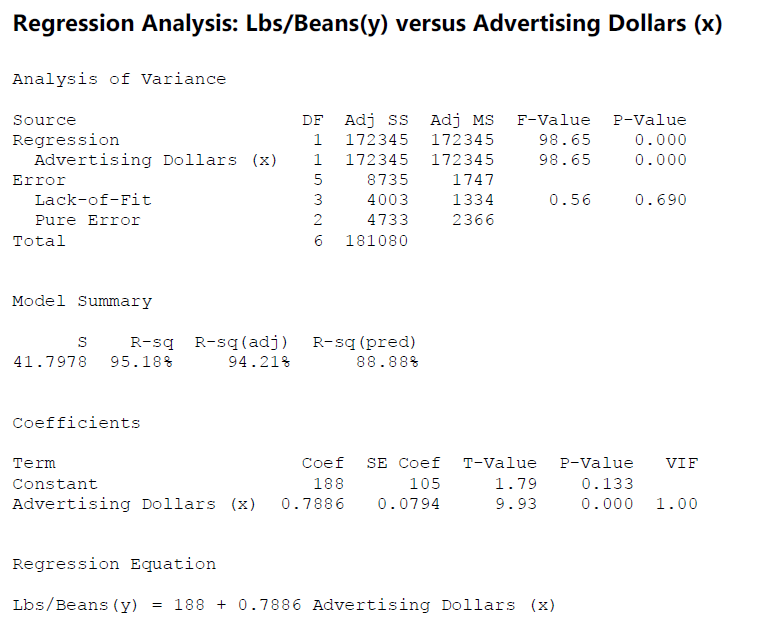

From the data in table 1 below and using Simple linear regression model to show the forecast, Minitab was utilized to conduct the analysis as follows:

- Go to Stat

- Regression

Fit Regression Model, then put Y column data as Response and X Column data as Predictors, then click OK, the output from the analysis appears as shown in figure 1 below.

From the above result, the regression equation is shown, indicating how dollars, Lbs/ Beans can be calculated. As P value for Advertising dollars is Zero, which is less than 0.05 or alpha level, so it is concluded that Data for Advertising Dollars is statistically significant. Next, a look at the R Square Value reveals 95.18%, which sounds good, and variability of all the response data, here Lbs/Beans data are almost around the mean. After that, the amount of beans needed by the company in pounds is calculated, in particular, to give an estimate of a daily average. In this case, linear forecasting is used to get Lbs/Bean data for up to 12 Months. Using others forecasting techniques result in different outcomes. The data used are found in table 1 below.

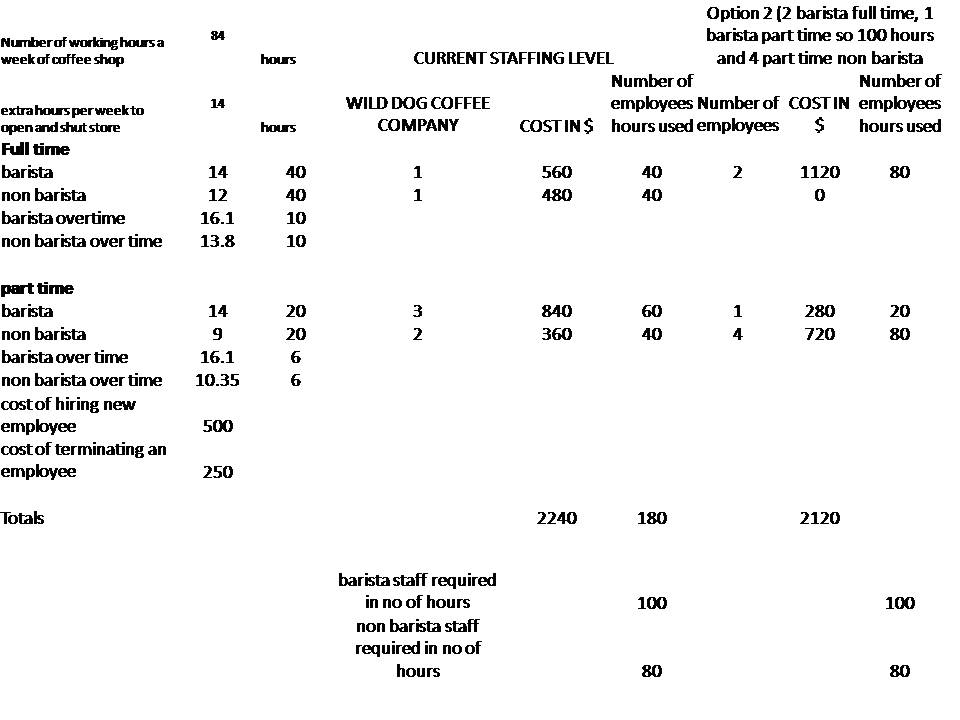

Employee Scheduling

The existing option has the following advantages:

- Full-time barista and one full-time non-barista staff are present and the same level standard of service are ensured throughout the weak.

- The cost is on the higher side as two full-time employees are hired.

- The negative is in case the full-time barista/ non-barista staff is absent his job will be done by a part-time help and the standard of service levels might fall.

The second option has the following benefits:

- Two full-time barista and 1 part-time barista will further enhance the standard of service. All the non-barista staff can be part-time and can come for 4 hours shift only every day.

- The part-time non-barista will be fresh and not show signs of fatigue, in case of absence can be replaced immediately with a part-time standby.

- The consistency in service levels will be maintained.

- The cost of manpower is also less.

- The negative is in case absence of part-time staff the new part times in non-barista will have no guidance and standard of service might fall.

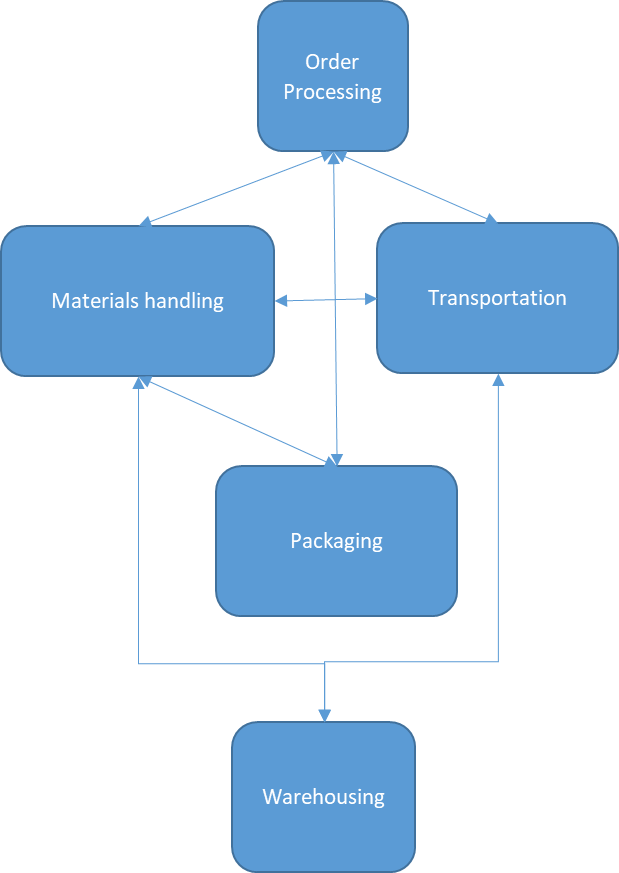

Flow Chart

Logistics refers to the management of how goods flow from one point to another with the main goal of reaching the consumer. It encompasses every aspect of merchandise traced from the manufacturer to different intermediaries and finally to the customer. The supply chain intersects as shown in figure 1 below.

Roles of Logistics in Supply Chain

The leading roles of logistics include helping the business create and improve the value and reduce costs associated with delivering products to the consumer and improving the efficiency in operations between supply chain intermediaries. Logistics also helps to deliver the products to the right location within a stipulated time. It possible for the company to experience bottlenecks in production, distribution, and order fulfilments. This can result from inadequate equipment as well as in production scenarios where capacity is insufficient. Moreover, gridlocks can arise from inefficient processes that have been maxed throughout the supply chain. Finally, congestion can result from poor productivity due to incapacity in labor-related activities.

Overcoming Bottleneck in the above Supply Chains

The following approaches can be used to reduce jams in the supply chain scenarios above:

- Overproduction.

- Increasing the process capacity

- Examining the production schedule

- Increasing the period the operation works.

Supply chains and logistics create value for the Coffee Company business as

- Get final goods and use ready. Value-added services, which comprise price definition, tagging, and display building can help in streamlining the process of finding the products on store racks.

- Improve inventory management

- Reduce suppliers used by the company.

- Track and react immediately to the dynamic business needs.

- Closely monitor and manage shipping costs.

- Control labor-related costs.

A logistics process represents the approach taken to provide products to the final consumer. It is recommended that the supply chain scenario 1 is less sophisticated and easier to operate than any scenario 2. Thus, the company should use the suggested supply chain management approach for it to continue operating efficiently and make profits that can sustain the organization. It is also important to understand how to manage each of the intermediaries and players within this supply chain to help the company effective in delivering its products to the intended consumers. This should include tracking every aspect of the supply chain, and adjusting it to fit the needs of the company.

References

Caudill, M. A., Strupp, B. J., Muscalu, L., Nevins, J. E., & Canfield, R. L. (2018). Maternal choline supplementation during the third trimester of pregnancy improves infant information processing speed: A randomized, double‐blind, controlled feeding study. The FASEB Journal, 32(4), 2172-2180.

Stopka, O., Černá, L., & Zitrický, V. (2016). Methodology for measuring the customer satisfaction with the logistics services. NAŠE MORE: Znanstveno-Stručni Časopis Za More I Pomorstvo, 63(3 Special Issue), 189-194.

Yazdani, M., Zarate, P., Coulibaly, A., & Zavadskas, E. K. (2017). A group decision making support system in logistics and supply chain management. Expert Systems with Applications, 88, 376-392.