Abstract

The following report deals with the expansion of the giant leader of the industry in specialty coffee, ‘Starbucks’. The focal point of the study where Starbucks can improve in the course of their operations management is the response that the company should give to the recent market research which is indicating that Starbucks is not keeping as per the expectations of its customers regarding the service rendered.

To solve the problem, Starbucks has come out with a plan to increase the workforce in the stores to speed up the service process however the plan of the company costs $40 million per year as an expense and the problem lies in the bottom line of the company which is unclear. The report would highlight the concept of ‘service’ as an integral part of operations management especially for ‘Starbucks’ which is emerging as a leader both in terms of size and customer base. With the help of certain operation tools, models, and techniques, Starbucks can resolve the issue of rendering satisfactory service and creating a link between “customer satisfaction” and a company’s sales and profitability.

Introduction

Operations management is a field of business where the production of goods and services is constantly monitored to ensure that business operations are run efficiently and effectively in other words operation management is the management of resources, the distribution of goods and services to customers, and the analysis of queue systems. On the whole, operation management tends to promote the merchandise sales of a company (Satoshi S, Ishida Soji)

When someone says “Let’s go out to have a cup of coffee”, the first word that captures the mind is ‘Starbucks’. Starbucks Corporation is the world-famous retailer of specialty coffee with a total of 13,168 retail outlets in varied areas of North America, Latin America, Europe, the Middle East, etc.

The company deals with numerous product lines like ice creams, tea, compact discs, etc. the vivacious entrepreneur Howard Schultz implanted the operations strategy which was created in his mind in 1990 when he purchased the 17-store Seattle chain and turned it into a grand and global success. The core factor to its success was ‘the service strategy, offering a variety of specialized products and services, such as Internet access, phone ahead ordering, and CD burning, all in a friendly interactive environment (Company Profile, 1997)

Yet, formulating policies that rely completely on customers’ good hearts or opening up more stores as an expansion policy so that customers are willing to pay more for coffee isn’t a justifiable and quantitative factor to support Starbucks (Thiele A, 2008). Shultz and the senior management at Starbucks now have to decide how to react to the opportunities that are being made available because of their rapid expansion. The crucial issue for Starbucks in the current scenario is deciding on an effective strategic growth plan to accomplish long term objectives

Operation Process in Starbucks

As far as operation management is concerned, Starbucks has its strengths and weaknesses. SBUX strong leadership command and consumer acceptance in the industry make the company heading forward towards positive growth prospects, it realizes more sales per unit in comparison to the competitor’s stores, the international business of the firm reveals steady profits but Starbucks is facing intense competition in the specialty coffee market which has negligible entry barriers, due to the company’s premium pricing and US market downfall, there has been a significant reduction in the demand for specialty coffee which has affected the company’s profits, disruption in the coffee beans supply and uncertain economic conditions with constant fluctuations in the foreign currency, Starbucks is seen in a fix, paying more for its supply than projected.

Starbucks has two non-retail domestic 50-50 joint ventures one with PepsiCo, Inc. who develops and distributes ready-to-drink coffee-based products, and the other with Dreyer’s Grand Ice Cream, Inc. to develop and distribute Starbucks premium coffee ice creams. Starbucks also utilizes mail orders and online services to market its coffee and coffee-related products. Starbucks is vertically integrated and controls its coffee sourcing, roasting, and distribution through its retail outlets.

Starbucks’ strategy for expanding its specialty operations is to reach customers where they are. Starbucks stores are located in prime and busy areas such as office buildings, downtown, and suburban retail centers, airport terminals, and kiosks, etc. Starbucks has installed Blue Martini’s order management system to its retailers and channel partners which helps the company to centrally manage and deliver contract-based products.

Operation Issue in Starbucks

Starbucks is combating the issue of exploring ways to control its core competencies against the numerous and varied alternatives available for future growth such as introducing its coffee in McDonald’s, looking for expansion possibilities in retail operations, and directing the brand penetration into other areas. Starbucks has an abundant cash supply as most of its stores are corporate. The only problem lies in the sustaining of its core competencies in the value chain and not grinding down its strengths in the process of expansion.

Starbuck’s specialty operations are its core competencies which the company tries to encash by establishing healthy relationships with the third parties that share a common vision, values, and goals like the company sets for itself. Starbucks can reach customers where they work, shop, and travel due to its coordinated and implanted operations management generally Starbucks does not outsource operational control of its retail stores but under conditions when the other companies can match with Starbucks requirements, the company agrees to license its operations (David R F, retrieved on 15th Oct, 2008).

However, The major issue in the operations management observed is that Even though Starbucks has many strengths especially innovativeness in business such as recognizing the profitable opportunities in beverage retailing, coupling of coffee with books, etc but the opportunity is present only for the smaller sized cities and suburbs to experience an Italian-style coffee shop which in turn squeezes up the profit margins of the company. Another area of concern is the gas station & restaurant industry. Above all, the growing customer dissatisfaction with the services rendered by the company is one of the major issues to be sorted out. The weak operations management in Starbuck’s is one of the reasons for the company ill-advised policed, in its all-out drive to optimize profits.

Directions for Improvement

Use of Models and Techniques

The company main motive is to maintain a balance between the expansion policies and the sustaining the core competencies, to move ahead with the objective , Starbucks must use the Capacity Planning Model in judging its overall capacity through which it can fix up the target limits of business extension (Banerjee B, 1999). Various tools can be used for capacity planning such as Present Value analysis which can help in analyzing the time value of capital investments and the corresponding fund flows.

Breakeven analysis can be a tool in comparison of projected costs and revenues. Aggregate Planning model can be implemented to judge the short term existing capacity of the company while linear programming and computer simulation along with decision tree analysis can be used for long term capacity problem of facility expansion which is dire need of Starbucks in the current situation (Dixon S P, Silver A E, 1981).

Starbucks aims to move ahead for setting up of new plant locations in the coming years, for this a careful study on the high tariffs and limited markets need to be undertaken because factors have the markets economically infeasible for future expansion. Starbucks can also include the process layout models for further assistance such as the Graphic and Systematic analysis or the Load Distance Model which is used to produce diversified products in variable work flows ((Russell S R, Taylor W B (III), 2006).).

Operations management in Starbucks must be well defined with clear cut targets and aims to be accomplished from the short term as well as the long term perspectives. The company to maintain its past success must give priority to reducing the time and cost related to supply of materials and rendering services to the client.

Starbucks could also consider the selection of suitable master schedule units and the resulting consequences for the framing of the invoices of the bills of material; appropriate choices of relevant procedures for authentic booking using the information from budgets and forecasts, past and the present confirmed orders, and the master schedule, all such techniques help in combating the counter effects of forecast errors related to the demand posed by the customers (Wemmerlöv U, 1884).

Rapid Prototyping can be implied which is a preliminary design model used for quick testing and further modification is required. Such models can be physical or electronic, rough facsimiles or full scale working models ((Russell S R, Taylor W B (III), 2006).. Starbucks to render efficient services requires a Concurrent design which can aid in the improvement of the quality of past designs of supply. Starbucks needs to plan every action of its employees. The company needs to create a service package that is a perfect blend of physical products offered, sensual benefits and psychological benefits as well.

Starbucks correct expansion techniques and time to market can be accelerated by using efficient design teams and CAD/CAM systems (Adam E E (Jr), Ebert J R, 2003). The quality of service rendered can be improved through service process design reviews, environment design, and metrics on design quality, quality function deployment for fruitful and better output.

Starbucks customers are unhappy due to unsatisfactory services, to overcome the issue; Starbucks can utilize the elements of waiting line analysis. Waiting line is analyzed through a set of some mathematical formulas which generate from the study called ‘queuing theory’. A major reason for discontent and displeasure is the waiting line which may form because customers do not arrive at the same time or a constant pace, they arrive randomly and need different time limits for processing of demand.

Decisions about waiting lines can hold in the management of waiting lines, customer arrivals and service time (Russell S R, Taylor W B (III), 2006). The mathematical formulas used in the waiting line analysis do not provide any best or optimal solution for Starbucks but can generate operating characteristics which can help the company to improve the performance by proper operations management. From the long run perspective, Starbucks has to focus on the quality aspects, the contemporary approach to quality management will lead to lower cost due to automatic innovations in processes and work designs.

The concept of ‘Zero Defects’ which in waiting line analysis means ‘no waiting’ raises the quality standards through quicker service , increased business and enhanced profitability. Since waiting is an integral part of Starbucks product delivery stores, it is an important area of analysis for achieving improved quality service. (Buffa S E, Sarin K R, 1994)

Sustainable supply chain management has to consider as a key factor in the smooth running of the business, Starbucks has good relations with the suppliers but the increasing demand with the increasing number of stores has to be balanced (Seuring S, Müller M,2007).

In the early January, 2008 Starbucks had announced a complete restructuring of the organization and a change in the strategy especially to acknowledge the downturn in the US market, as this is the stage where Starbucks can completely modify and reframe its operation management’s strategies by making use of the product and process innovation model. Contemporary management initiated approach to improve quality such as Deming’s Statistical Thinking (Adam E E (Jr), Ebert J R, 2003) who emphasizes on the use of control charts to assist in the evaluation of variations and help the management to work on the system to curb the causes of inefficiency and low quality.

Juran’s Management Processes through quality can be an extended help to Starbucks as the respective tool focuses on the rationality, analysis and management processes in solving service related problems. According to the approach continual improvement, hands on management and training must be incorporated to institutionalize improvement to combat fierce competition for delivering quality products and services (Adam E E (Jr), Ebert J R, 2003).

Initiating quality circles to identify problems collect and analyze data, recommending appropriate solutions and carrying out management approved changes can help Starbucks to a great extent. To achieve the above goals, it is of utmost importance that operations manager must provide direction and establish control. (Buffa S E, Sarin K R, 1994)

Quality motivation and behavioral modification techniques are some of the methods which can be used by the operations manager to encourage the company employees for better services rendered to the customer (Mahadevan B, 2007). Consumers access to the internet has made the competition more stringent, Starbucks premium pricing under situation can pose problems for which various operational tools should be applied to explore means of reducing costs and retain the customer base which can be wiped off by the competitors (Rabinovich E,2007).

Functionality or design, enjoyment, process, reliability and responsiveness are five key service perspectives which should be an integral part of any corporate plan or strategy of Starbucks. Such dimensions help in creating a positive impact on the outcome variables like perceived value of the customer and above all the customer satisfaction which has to be reconsidered by the Starbucks to mend the loopholes in the operations management and to eliminate the category of unhappy clientage (Russell S R, Taylor W B (III), 2006).

Apart from the above mentioned tools, quality control tools can also be applied such as ‘Histograms’, which is a simple method of graphically representing the frequency distribution of multiple attributes of interest, ‘Check Sheets’, ‘Pareto Diagram’ which helps in prioritizing and directing the improvement efforts, ‘Cause and Effect (fish bone) diagram can aid in tracing the problems to the root cause, CEDAC, Poka Yoke can help in identifying specific improvement opportunities. Affinity diagram, Relationship diagram, Matrix data analysis, PDPC etc are the management tools which can be applied in operational planning for building quality into the Starbucks products / services (Mahadevan B, 2007).

Recommendations

Starbucks has been rapidly advancing towards growth and expansion but it should not focus too heavily on opening several stores and increasing output but its main focal point should be to maintain its core competencies that is quality and brand image. Starbucks should aim at creating a consistent atmosphere that facilitates quality coffee products.

Franchising is not a very suitable option for Starbucks as it would lead to dilution of control, hence it showed keep stores corporate and ensure a high employee and customer relations through consistent management, store operation, and location environments. Starbucks need to implement a concentration growth strategy whereby its core competency of producing high quality coffee products stays intact.

The Company could be cautious about the market changes and should respond as quickly to the market especially in the current scenario where downfall of American economy has greatly affected the Starbucks profitability margins. Constant innovation to compete with its rivals McDonalds and Denny’s should be a min component of its strategic and operational management. Apart from the above Starbucks also needs to concentrate on the small sized income economies for increased market share.

Conclusion

On the whole Starbucks has displayed a strong, well established company profile in all aspects of varied fields of management. As an industry leader the company can build a positive brand image. The company exhibits strong and consistent relations with its suppliers. The company just needs to strengthen its operations management, not to deviate from its core performance areas, in a rush of attaining more output and increased store locations.

Graphs

Operations Issues Faced by Starbucks

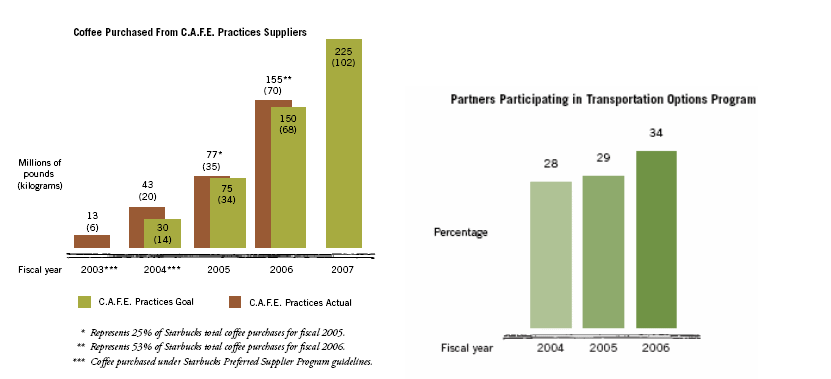

Starbucks Approach to Sustainable Trade

References

Adam E E (Jr), Ebert J R, 2003, Production and Operations Management: Concepts, Models and Behaviour, 5th Ed, Pearson Education (Singapore) Pte Ltd, New Delhi.

Buffa S E, Sarin K R, 1994, Modern Production/ Operations Management, 8th Ed, Replika Press Pvt Ltd, New Delhi.

Banerjee B, 1999, Operations Management and Control, 1st Ed, A.H Wheeler & Co. Ltd, New Delhi.

Company Profile, Starbucks Corporation (A), 1997. Web.

David R F, Case Map for Operational Management. Web.

Dixon S P, Silver A E, 1981, a heuristic solution procedure for the multi-item, single-level, limited capacity, lot-sizing problem, Journal of Operations Management, Vol 2, Issue 1, p 23-39.

Kembell B, Hawks M, Kembell S, Perry L, Olsen L, 2002, Catching the Starbucks Fever.

Mahadevan B, 2007, Operations Management: Theory and Practice, 2rd Ed, Dorling Kindersley (India) Pvt. Ltd, New Delhi.

Russell S R, Taylor W B (III), 2006, Operations Management: Quality and Competitiveness in a Global Environment, 5tf Ed, Wiley India (p) Ltd, New Delhi.

Rabinovich E, Linking e-service quality and markups: The role of imperfect information in the supply chain, Journal of Operations Management, Volume 25, Issue 1. 2007, Pages 14-41.

Satoshi S, Ishida Soji, 2003, Business procedure and business operation/management apparatus. Web.

Seuring S, Müller M, 2007, Core issues in sustainable supply chain management – a Delphi study. Web.

Thiele A, 2008, Operations Research at Starbucks. Web.

Wemmerlöv U, 1984, Assemble-to-order manufacturing: Implications for materials management, Journal of Operations Management, Vol 4, Issue 4, p. 347-368. Web.