Executive Summary

The sustainability and conditions for the formation of reliable supply chain management are examined on the example of the delivery of COVID-19 vaccines. Modern technologies utilised in this process are designed to improve the quality of tracking and interaction at the supplier-recipient level. Specific tools have been reviewed, and procurement models have been identified that are relevant to the topic in question. The containment and delivery of COVID-19 vaccines in the UK have been described, and distribution methods have been presented from safety and convenience perspectives.

Introduction

Supply chain management is the flow control of goods and services within an organisation, which involves the supply and demand of products in the market. Supply chains cover manufacturing, product development and sales. The supply manager coordinates logistics in the supply chain in every company, incorporating materials, delivery and logistics, manufacturing, return system and plan or strategic management. Purchase department in a company is fundamental to the health of the organisation. Purchasing provides materials to the manufacturer and helps to direct and minimise costs and stabilise prices.

Additionally, purchasing improves the supply strategy by analysing the market, improving the procurement department’s technology to make it more efficient and economical. Strategic tools and techniques in supply management ensure that the company is efficient in accounting and understanding its needs. Technology is commonly integrated as part of the methods used. For instance, machine learning protects the company’s data from a breach.

Procurement models and strategies are used together to improve the company’s supply management department and save costs. The most advanced procurement models include the Dominick formula, procurement funnel, Dominick matrix and Dominick sourcing see-saw. The purchasing team mainly uses these procurement models to analyse the best strategies to use when determining the contracts’ finances, supplier and effectiveness.

Transportation and storage of vaccines is a challenge during the pandemic. Hence, the manufacturers often use the cold chain to transport, store and track COVID-19 vaccines at extremely low temperatures. The cold supply chain’s main aim is to maintain the product’s quality in a controlled temperature range. Pfizer and Moderna are the trusted pharmaceutical companies to manufacture and provide COVID-19 vaccines worldwide. However, AstraZeneca produced and distributed a vaccine in Scotland.

Purchasing Within an Organisation

Purchasing is an essential part of the procurement process required to add value to every business. The supply of goods, production materials, and equipment is needed to run a successful company. Organisations need to procure raw materials to be used in the business at the right quantity, time and quality. The risk of losses when purchasing is not done right is immense. Consumer demand is met when the demand and supply of a product are sufficient, which requires adequate sourcing of materials (Bals et al., 2019). Businesses require a constant production of goods and services, and they should meet the company’s requirements to be relevant in the market.

In supply chain management, the purchasing team is responsible for outsourcing goods to be sold in the business. The strategic role of the purchasing unit within an organisation implies using market analysis, transport, procurement technology, as well as storage, supplier and producer negotiations to ensure that it meets the products’ supply and demand without loss in a time-efficient and economical way (Lysons and Farrington, 2016). Identifying reliable suppliers, delivery terms, order quantities, budget and payment management, storage capacities and reviewing bids and contracts are some of the specific roles of a purchasing department.

Role of Purchasing

Purchasing is divided into strategic and operational buying to cater to all the department’s needs. Strategic purchasing focuses and supports procurement roles while actively dealing with the administrative part of purchasing, which covers ordering, payments, returns, inventory and complaints. The transactional role is mainly handled by the operating team of the purchasing unit. Needs analysis is a critical aspect of the business. Each departmental cost is benchmarked, and the business performance determines the company’s purchasing power. Supplier analysis is also conducted to verify the cost and supplier quality (Lysons and Farrington, 2016). Needs and supplier analysis ensures that goods and services are of good quality and cost-effective.

Furthermore, contracts are drafted to identify a detailed strategy of the suppliers’ cost, reputation, production capacity, quality, reliability and delivery schedules ahead of signing a supplier contract. The financial health of the bidding business is closely examined to determine its credibility. Inventory control under the operational team identifies the quality of raw materials used to develop the final goods and items used to trade. Insufficient or excess materials relate to low quantities or quality of goods on sale, loosely translating to losses. Quality regulation must analyse an integral part of the procurement process as the interest rate continuously examines its performance, reliability and value. Integration of information systems is essential as the supplies can easily access the storage server to monitor the quantity remotely and transport more goods when stock runs low.

Supply of COVID-19 Vaccines

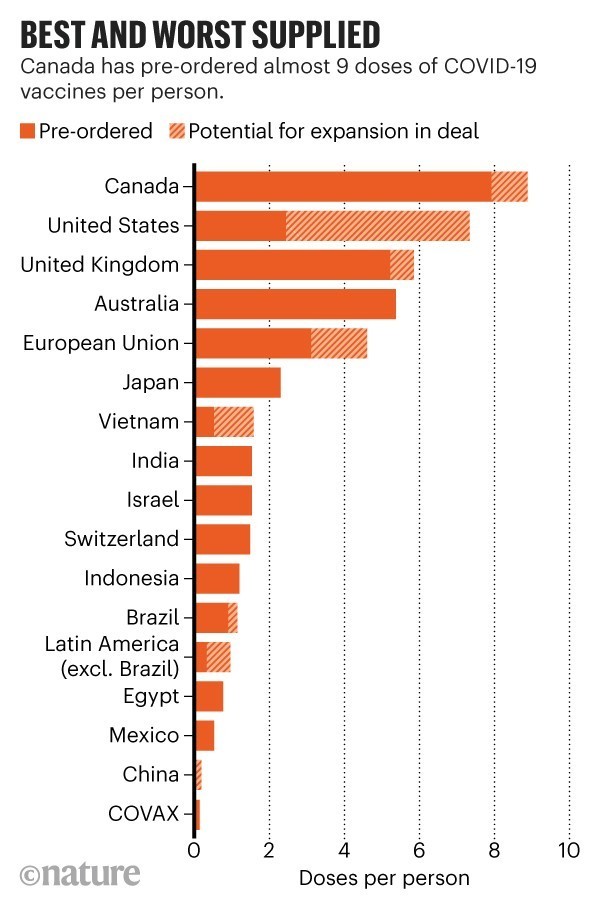

In the case of COVID-19 vaccines, the procurement unit critically analyses the reputation of Pfizer, Moderna and BioNTech, which are reputable companies in producing drugs and vaccines from the medical perspective. As the pandemic condition worsened in 2020, the COVID-19 vaccine demand increased when the immunisation supply was critically low (Le et al., 2020). The production of the vaccine and the need for quality control increased to minimise losses in Pfizer. The affordability and production cost of the vaccine is a concern as it is a new life-threatening virus. The dynamics of vaccine orders is reflected in Figure 1 (COVID-19 vaccine orders, 2021).

Transportation and storage remain a significant challenge not only in the United Kingdom (UK) but also globally. The vaccine needs to be preserved in cold storage at -70 and -80 degrees Celsius to conserve its quality and effectiveness. Several companies have to produce COVID-19 vaccines on a large scale during the pandemic. For instance, AstraZeneca has manufactured large amounts of vaccines that have been administered in several parts across the UK but are not authorised in the United States (US). The vaccine from AstraZeneca is stored at normal refrigerated conditions of 1 to 7 degrees Celsius without compromising its quality, providing a competitive edge in the supply management compared to Pfizer (Pfizer and BioNTech, 2020). Therefore, the new vaccine poses fewer logistical challenges compared to the previous vaccines.

Strategic Tools and Techniques for Supply Management

Supply management techniques are essential in underpinning the performance of sales in business. The right tools and supply management methods ensure that organisations remain competitive by attracting a broader target audience.

Proper tools and techniques help companies grow on a larger scale by saving costs, providing high-quality value-added goods and achieving flexibility and innovation. Supply management consists of four major parts, including demand management, supply management, sale, operations planning and product portfolio management (Ateş, van Raaij and Wynstra, 2018). Demand management controls the product’s reliability in the market by improving the revenue of the goods and enhancing the profitability of the products or the service provided. This systematic approach to strengthening revenue through proper planning, buying, and selling products creates a significant investment return change (ROI).

Supply management consists of production, capacity planning, inventory, supply and distribution – comprehensive and elaborate planning analyses of how the organisation implements its needs through resource allocation (Ateş, van Raaij and Wynstra, 2018). Sales and operations are an integral part of the business, emphasising new product introduction, production, sales, and marketing. The sales and process aim to execute the businesses’ plans through informed decision-making strategically and consumer needs delivery. Cost reduction, green purchasing, risk management, global sourcing, supplier management and quality management are supply management tools.

Strategic tools and techniques in supply management aid in achieving and implement the four components. The most commonly used tool is the Enterprise Resource Planning (ERP), which integrates the entire company’s supply into one system for easy tracking and accounting (Jonsson and Tolstoy, 2014). The ERP uses sales, stakeholders, finance and operations and then updates it to the system to better manage supplies. Historical statistics on the network determine the supply and demand in the market while also learning new needs that may affect the future collection of goods. For example, statistical estimation of order can be drafted based on the history of real-time connection.

Supply Management Tools

With the latest advances in technology, artificial intelligence (AI) and machine learning (ML), tools have in the supply and management become more accurate in the business aspect. AI and ML are trained to analyse the market based on future concerns, for instance, in tornados or the COVID-19 pandemic. The AI is built and installed in the networks to sense any consumer demand based on the current global event and then produce detailed strategies on the planning process to prepare the predicted changes (Walker et al., 2012). Pricing, product suggestions and supply quantity are aspects influenced by the AI and ML, which work to positively manage the market intelligence, affecting the business industry and saving cost.

Blockchain is another technique used to draw product demand by ensuring that businesses work together in the supply chain management sector. The acquired data is used to analyse and process supply within an organisation. Blockchain is also used to interpret contracts, sustainable and ethical supply chains, enhancing the security of inventory and confidential information; enhanced protection minimises data breach in the company, which may influence corruptible data.

Efficiency in an organisation can positively or negatively impact the company’s state; blockchain boosts its efficiency. Products for sale often include serial numbers, place of origin and destination, and manufacturer name to keep track of goods in the market; various software monitors them. However, blockchain creates a comprehensive system that tracks all products. Consumer survey gathers essential information from the consumers to determine the impact of the products.

The demand for COVID-19 vaccines remains high as organisations developing the immunisations struggle to meet the needs. Storage, packaging, transport, shipping and distribution across counties are critical in meeting the vaccine’s demands. There is limited source scaling since the vaccine’s packaging remains a significant challenge of COVID-19 production; vaccines require to be stored properly to maintain the quality; however, glass storage and stoppers require time to be produced in enough quantities the immunisation. In this case, the supply techniques and tools applied in the distribution and production of COVID-19 vaccine need to be critically monitored to promote a global balance between supply and demand of the vaccine without challenging the vaccine’s condition and effectiveness.

Purchasing and Supply Sourcing Strategies

Purchasing and supply sourcing categories include reactive, tactical, and strategic sourcing, which explicitly targets the raw material acquired from various sources. This part of the strategy is crucial. Reactive sourcing responds to the requests of the business by encouraging purchasing power. The tactical sector teams up with the sales and marketing to understand the technological aspects of bidding and provide support to all other departments.

The tactical team is also involved in obtaining the requirements by reviewing all contracts to determine the low value and high risk. On the other hand, strategic sourcing is a necessary part of the management when controlling and selecting bidding suppliers who meet the business’s predetermined needs. These three categories of supply sourcing are accompanied by various purchasing and supply sourcing within the organisation.

The positioning part of the sourcing is required to be a strategic source of the positioning tool. The sourcing requirements allowed the tools and techniques to be mismanagement within the business. The suitable governance structure was created as a form of authority and governmental management in the business sector (Glock and Hochrein, 2011). Spend analysis and market analysis are the other two issues involved in purchasing and sourcing strategies. Spending analysis aims at the historical usage of goods and services, supplier positioning, transactional costs, supplier historical analysis and products’ crucial nature.

On the other hand, the market analysis aims to assess market capability, power dependency in the supply chains, individual marketplaces, potential size and growth of the market and nature (Gangurde and Chavan, 2016). The type of sourcing strategy analyses the global, regionals and local views of the market; these analytical tools are highly dependable on the five forces (political, economic, social, and technological) and SWOT analysis of the company.

Insufficient mapping supply chains are some of the issues involved in the development of purchasing and supply sourcing strategies. Long-term data on the strategic sourcing analyses identify loss and gross margins within the organisations and strategic systems to resolve the challenges. Additionally, mapping the area to understand the required products and supply demands within the site and the community’s behaviour pattern. Risk assessment of the company establishes the potential causes of harm from a third party into the company to influence the supply of goods and services in a particular organisation (Hesping and Schiele, 2015).

The risk mitigation strategy in the supply management ensures that the company is protected from such risks through prevention, preparedness, response and recovery of the risk assessment. However, the cybersecurity state in the supply chain management is enhanced, preventing any digital malfunction which may enable threats from hackers, such as ransomware of the COVID-19 vaccine.

Procurement Strategy

Procurement is defined as purchasing products or services in a process that involves buying goods from an external source. The procurement process occurs in seven steps; identification of goods and services required, supplier options, negotiation of the contract with suppliers, payment, delivery and audit, and invoice record keeping (Bowman and Ambrosini, 2007). A proper procurement strategy is cost-effective and provides a clear outline of the efficient approach to making procurement decisions according to its needs. Procurement principles guide businesses on effective strategy when dealing with purchasing; the fundamental principles of procurement are transparency, value for money, accountability, integrity, economy, openness, fairness and competition (He, Huang and Yuan, 2016).

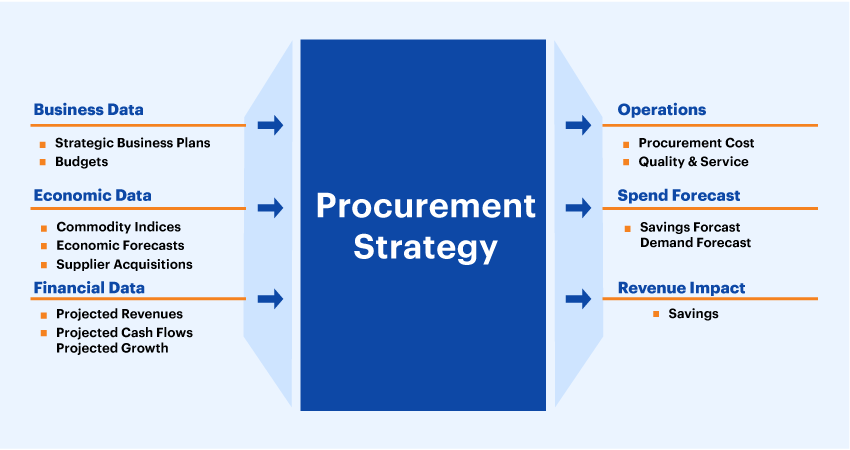

Transparency in purchasing means that information on the policy and contract is similar to all suppliers, contractors and service providers in the organisational industry. In Figure 2, the principles of a procurement strategy are displayed (Procurement strategy, 2020).

Decision making and actions are transparent during the purchasing of goods. Value for money conducts in the cost, quality and sustainability of the goods’ supply. Accountability ensures that the supply management department discharges honesty, responsibility and compliance according to its goals. Integrity in the procurement team is essential for the ethics carried out and in line with its ambition based on the reliability of the information passed on to the management. The efficiency determines the economy, value for money and standardised price of goods, which are reasonable and represent good value for money. The economy covers office abuse, fraud and other financial challenges associated with low transparency and integrity.

Purchasing Process Models

The purchasing process model is the strategic planning on the objectives, guidelines and communication to guide the procurement team in determining the most effective strategies to balance demand and supply. The Dominick Formula is an advanced model that compares suppliers’ prices and categorises them to the highest to lowest bids. The procurement funnel was structured to help organisations become cost-efficient by analysing various factors affecting the actual cost savings (Goggins, 2018). Dominick Matrix, a procurement model, is built to guide the purchasing team to choose the most effective strategy for working with a supplier.

The Dominick matrix model is dependent on materiality and sophistication level, which is then categorised into supplier management, rationale, collaboration and development. Dominick’s sourcing see-saw elaborates the need for assessing the balance of power between the buyer and the supplier.

Other older models used in procurement include linear process, strategic process, cynical and Hybrid Linear-Cyclical, emphasising the purchase decision-making process, sourcing, supplier management and supplier exit. The Kraljic procurement approach is the most commonly used approach across companies globally.

The Kraljic model maximises supply consistency and significantly reduces the purchase cost in an organisation; this approach uses supply management by using market analysis, strategic positioning, purchase classification and action planning. Using purchasing power as a company strategy and constant risk assessment and evaluation is a sure way to meet the consumers’ demand and have a continuous supply flow. Purchasing strategies boost the sales and profit of the company, increasing demand in the market. Balance of demand and supply, exploitation of reasonable prices and long-term supplier contracts, and diversification of products in the markets are significant in the Kraljic model.

Vaccination Program in the UK

Most COVID-19 vaccines are stored and transported at shallow temperatures of negative 70 and 80 degrees Celsius, which is entirely a frozen state. Vaccines are stored at much warmer temperatures of +2 to 8 degrees Celsius, similar to the type of vaccine disseminated in Scotland. Dry ice is the most preferred form of transportation and storage as it is regarded to maintain the required temperature of the vaccine.

The vaccine’s supply chain system is different from the transportation of other goods. Distribution, storage, temperature, tracing, monitoring, tracking and reporting are followed clearly, and gaps in supply management are identified, and solutions are developed. Cold transportation and storage capacity were designed to enable the movement of COVID-19 vaccine from manufacturers to the hospitals and the Scottish local authorities to systematically disseminate the vaccine to Scotland’s residents.

The effective deployment strategies used in the UK include access to cold storage facilities in the country and drafting a lease agreement of the available storage facilities (DeRoo, Pudalov and Fu, 2020). They are establishing a tracking and monitoring system of the vaccination to access the transportation data easily and monitor the movement’s temperatures. Equipping staff with adequate information concerning the vaccine allows them to carry out various tasks while following the standard operating procedure. Constant power supply within the storage facilities prevents the loss of vaccine during a power shortage.

Using automatic power backup systems in cold facilities minimises the chances of failure. In the UK, the AstraZeneca vaccine, which follows the necessary vaccine storage and transportation guidelines, is widely accepted in Scotland. Although the vaccine still prevents individuals from getting COVID-19, the same policies ensure that the vaccine’s quality does not tamper.

Transportation and Storage of COVID-19 Vaccines

The development of cold transportation and storage capacity was based on the safety medical standards of handling vaccines. Cold chains are a dynamic aspect of the market as a result of the new life-threatening virus. The cold chain is majorly temperature-controlled supply management of goods from manufacturing to distribution, which focuses on sustaining desired temperatures (Lin, Zhao and Lev, 2020). The pandemic has highlighted the gap in cold chains; the current storage facilities are not feasible for COVID-19 vaccination. There has never been a need for supply chains to transport any fragile goods sensitive to temperature. The vaccine is currently transported using dry ice, which would be at the required temperature during transport. Perhaps not for its entire storage time, cold supply chains can be made part of cargo airplanes to supply and transport the vaccine efficiently.

Public Sector Preparation for Emergence of Future Life-Threatening Virus

Amidst the COVID-19 pandemic, the public sectors can only learn from the strategies put in place and prevent mistakes from reoccurring in future pandemics. Surveillance and containment play a critical role in the management of life-threatening viruses. However, the main strategies that require to be refined are the epidemiological factors associated with the risk and spread of infections. Redesigning new prevention and crisis management frameworks with the current data formed can help create new strategies to manage future pandemics.

The public sector can use techniques to minimise the pandemic’s impact by developing research centres that make rapid vaccines and the advanced technology that builds pandemic strain vaccine. Containment measures, such as quarantine, lockdown, and social distancing, have proven to effectively curb the virus’s spread (DeRoo, Pudalov and Fu, 2020).

Access to a vaccine does not equate to yet another pandemic, based on the strategies currently in use during the COVID-19 pandemic, the public health sectors should prepare by strategising on effective vaccine distribution, efficient and easy modes of home test kits, and strict containment protocols. However, future life-threatening viruses will identify vulnerabilities and inadequacy of preparation in the public sectors. Investments in production and research can help produce vaccines in a smaller timeframe. Pfizer and Moderna companies can pull resources together and share designs with other pharmaceutical companies willing to make more jabs and increase supply globally. The public sector can carry out research programs that analyse different scenarios in case of a life-threatening virus using the current COVID-19 data and analyse ways to improve and prevent the spread of germs and viruses.

Conclusion

In conclusion, supply chain management regulates goods and services by transporting and storing materials and tracking inventories. Supply chain management is an integral part of every business. Planning, controlling, and monitoring the company activities and the flow of goods are achieved while making a profit and increasing the products’ demand. The balance between supply and demand requires strategic tools and techniques incorporated into the business to ensure maximum yield, reduce loss and predict the market’s future by critically analysing the data provided. Technology has helped improve how the supply chain operates, providing a comprehensive report on the way forward. Machine learning, artificial intelligence and blockchain are the most commonly used tools in supply management; these tools analyse the market and provide a supply strategy that minimises loss. Blockchain enhances the security from any threats, such as data breaches.

In the light of the COVID-19 vaccination transportation and storage, setting up technological cold chains across the globe would be an ideal first step before distribution. The public sector would monitor the cold chain remotely to determine the effectiveness of the temperature control. Transportation of the vaccine remains a challenge; vaccine producers can use airplanes to drop vaccines worldwide by creating cold chain storage inside the planes and preserving the vaccine’s integrity throughout the transportation time.

COVID-19 vaccines can be stored in freezers or vaccine carriers when there is movement between storage facilities and distribution points and a modern refrigerator device to monitor the temperature. Distribution of the vaccine is allocated to the public categorically according to the most vulnerable, starting with health workers, the elderly and individuals with underlying conditions moving further to the community’s least susceptible people.

Reference List

Ateş, M. A., van Raaij, E. M. and Wynstra, F. (2018). ‘The impact of purchasing strategy-structure (mis) fit on purchasing cost and innovation performance’, Journal of Purchasing and Supply Management, 24(1), pp. 68-82. Web.

Bals, L. et al. (2019). ‘Purchasing and supply management (PSM) competencies: current and future requirements’, Journal of Purchasing and Supply Management, 25(5), 1-15. Web.

Bowman, C. and Ambrosini, V. (2007). ‘Firm value creation and levels of strategy’, Management Decision, 45(3), pp. 360-371. Web.

COVID-19 vaccine orders (2021). Web.

DeRoo, S. S., Pudalov, N. J. and Fu, L. Y. (2020). ‘Planning for a COVID-19 vaccination program’, JAMA, 323(24), pp.2458-2459. Web.

Gangurde, S. R., and Chavan, A. A. (2016). ‘Benchmarking of purchasing practices using Kraljic approach: benchmarking’, An International Journal. Web.

Glock, C. H. and Hochrein, S. (2011). ‘Purchasing organization and design: a literature review’, Business Research, 4(2), pp.149-191. Web.

Goggins, G. (2018). ‘Developing a sustainable food strategy for large organizations: the importance of context in shaping procurement and consumption practices’, Business Strategy and the Environment, 27(7), pp. 838-848. Web.

He, B., Huang, H. and Yuan, K. (2016). ‘Managing supply disruption through procurement strategy and price competition’, International Journal of Production Research, 54(7), pp.1980-1999. Web.

Hesping, F. H. and Schiele, H. (2015). ‘Purchasing strategy development: a multi-level review’, Journal of Purchasing and Supply Management, 21(2), pp. 138-150. Web.

Jonsson, A. and Tolstoy, D. (2014). ‘A thematic analysis of research on global sourcing and international purchasing in retail firms’, International Journal of Retail & Distribution Management. Web.

Lin, Q., Zhao, Q. and Lev, B. (2020). ‘Cold chain transportation decision in the vaccine supply chain’, European Journal of Operational Research, 283(1), pp.182-195. Web.

Le, T. T., et al. (2020). ‘The COVID-19 vaccine development landscape’, Nature Reviews Drug Discovery, 19(5), pp.305-306. Web.

Lysons, K. and Farrington, B. (2016) Procurement and supply chain management. London, UK: Pearson.

Pfizer and BioNTech to supply the European Union with 100 million additional doses of COMIRNATY. (2020). Web.

Procurement strategy. (2020). Web.

Walker, H., et al. (2012). ‘Sustainable procurement: past, present, and future’, Journal of Purchasing and Supply Management, 18(4), pp. 201-206. Web.