Introduction

In a complex manufacturing environment, a large number of components, some critical, and other not so critical, go into the manufacture of a product. It is practically impossible for a single company to produce all these components within its own capability or production facilities. This is especially true in the case of high technology areas like manufacture of aircraft and satellite communication and launching. Sometimes, the whole process will need the capability and expertise of many companies. The central organization in this case will need competent suppliers. This paper deals with the selection process which a company should follow in identifying suppliers. The central organization in this instance will be the Boeing Satellite Systems, primarily engaged in launching and placing satellites in space and the supplier will be Hughes whose expertise lies in manufacture of satellites. This paper is a quality plan with regard to selection of suppliers.

Project Quality Plan Purpose

A lot of care and consideration have to be given in the process of a critical component supplier. This is especially true in high technology areas. Ideal examples would again be the manufacture of large aircrafts or launching of a satellite into space. In the case of the former, the fuselage and the wings will be manufactured by one company while the engines will be purchased from competent suppliers. Airbus Industries will typically buy engines for its aircraft from Pratt & Whitney or Rolls Royce. Boeing also follows the same strategy. In the case of the second example, in many instances, the satellite is made by one company and is supplied to another one which has its expertise in the area of launching them. Boeing can be cited as an instance here also.

Quality Management Method

The most obvious requirement with regarding to a competent supplier is the ability to meet product specifications. A detailed specification can be made available to potential suppliers and those that have the ability to meet them can be shortlisted. All potential suppliers interested in competing for the position will apply and the eligible companies can be short listed. This is because the following factors should also be evaluated before a final selection of the supplier. There is no doubt Hughes has the capacity to meet Boeing’s specifications. This can be corroborated by the fact that “Los Angeles-based Company, which has built nearly 40 percent of the world’s commercial satellites, now plans to concentrate on expanding DirecTV and restructuring its other wireless communications services.” (Hoversten). This achievement has proven that the company is a good supplier for Boeing in their quest to become the largest player in the industry. In fact the VSAT or the Very Small Aperture System was developed by Hughes which means that the company has good research facilities also.

The next aspect once the technical capability has been resolved is to assess the ability to stick to schedules. In accordance with good business and economic practices, no supplier should deliver products too much before schedule to after it. There is no explanation needed for suppliers to stick to schedules. But supplying before schedule will mean that inventory of the purchasing company will be locked up unnecessarily. In other words, techniques like the just-in-time system should be followed by suppliers also. The required products should reach Boeing on when they actually need it and not before. In the case of the satellite manufacturing industry, manufacturers are now unable to keep schedules and a backlog of orders exists in this area. Boeing has solved this problem to a large extent by acquiring the company and making it a subsidiary supply firm to the company.

Suppliers should not only be technically capable and be able to supply on time. They should also be able to stick to the agreed pricing. Due to the high tech nature of the products, there are possibilities that costs may escalate. In such a case of escalation of costs, prior intimation should be given to Boeing who will then review the situation and verify whether the facts are correct. If it is so, then the products can be purchased by paying the higher price.

The above mentioned steps are general strategies followed by companies when evaluating suppliers. A more scientific approach is given below.

Quality Plan Processes

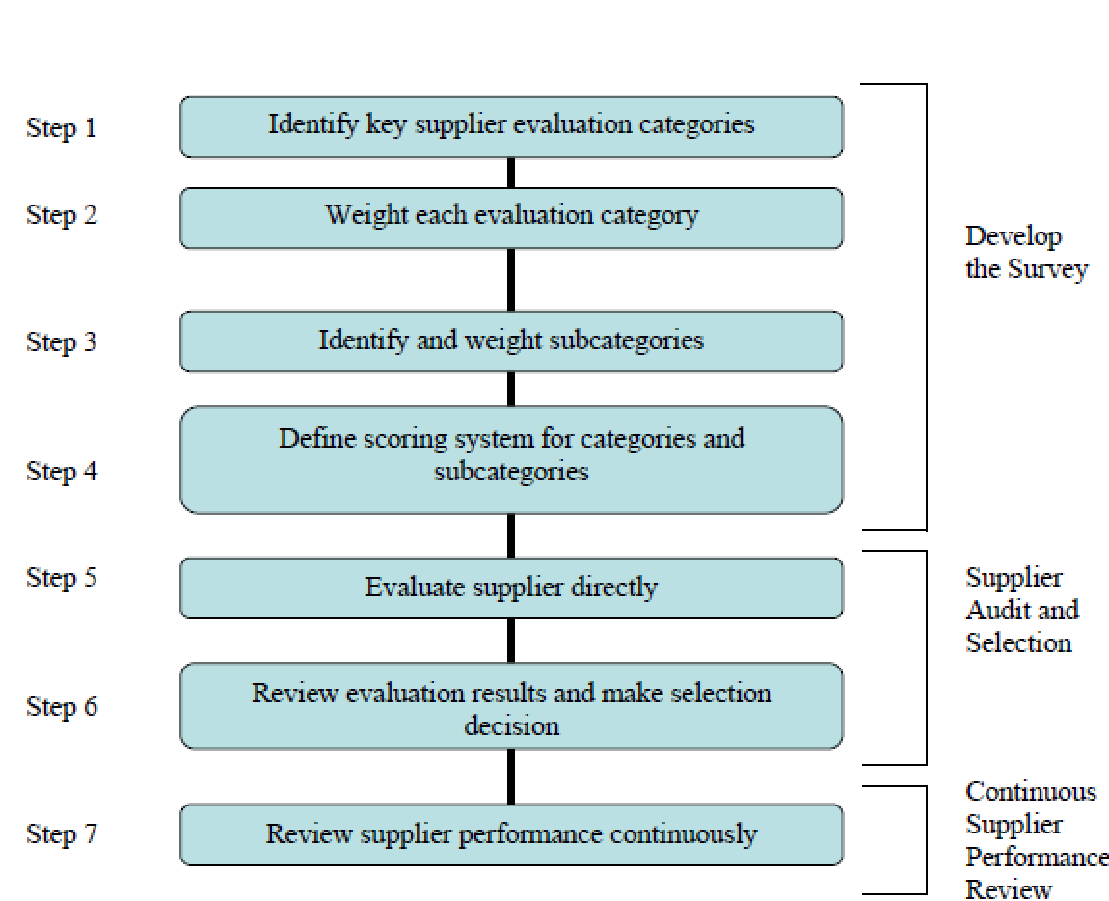

A scientifically structured selection procedure entails the following steps as shown in the figure below

Key supplier evaluation categories: Most companies use the quality, cost, and delivery capabilities as the key evaluation categories. (Bello). The above categories and the sub categories in case of critical component suppliers should be weighted according to the requirements of the buyer. In this case, quality is the most important component, followed by delivery and price. The sub-categories that Boeing should evaluate should include the following. The management capability of the supplier (apart from technical capability) should be evaluated. Proper management is also an important factor for quality and eventual continuity of an organization. Hence this should be evaluated strongly. Employees are an important factor that determines how a company performs and how they can supply the required products on time. A review of the personnel employed by the potential supplier will also be very useful criteria. All companies will have a cost structure that determines that ultimate cost of the product. An efficient cost structure can bring down unnecessary waste and also result in bringing down the cost of a product. An analysis of the same will be useful for selecting a supplier. The work culture, organizational vision and philosophy etc also can be considered when appraising suppliers. Other relevant factors include the ability of the supplier to maintain a long term relationship, the financial strength of the supplier, and whether the supplier can manage environmental regulations.

Weighing of the above categories: Each of the above categories should be weighed in relation to its importance or criticality to the buyer, in this case Boeing. Quality will be the one component that will be weighted the highest. Other factors like financial capability, quality of personnel, management capability etc will come next and have similar weightings.

Scoring: A scoring technique will have to be applied for providing weights. For example a five or ten point scale can be assigned to each category. The two ends of the scale can be excellent and very poor. The scores in between will gradually move from one end of the scale to the other and points assigned to each of them.

Direct evaluation: A purchaser must keep a minimum score or criteria which a supplier should have for it qualify for the supplier pool. Direct periodic evaluation is advisable to see whether each of them or the selected one does keep its score within acceptable standards.

Selection: Once the scoring has been done according to the weightings, the next step is to take the decision of selecting the supplier (or suppliers). Many companies may keep the option of having more than one supplier for economic and other issues (delivery schedules, cost etc)

Continuous review: This is an important component in supplier evaluation and selection. A supplier may be excellent at the time of selection. But internal and external factors may result in lower supplier quality in any of the above categories. Hence suppliers, especially in the case of critical products have to be evaluated on a regular basis for the full time that they remain as such.

Project Overview

Boeing Satellite Systems (BSS) is the largest manufacturer of commercial communications satellites in the world. One of the largest suppliers of satellites in the world is Hughes. Likewise BSS is also one of the largest suppliers of launch vehicles in the world. Both the supplying company and the launch company should work in close cooperation for a launch to be successful. A lot of technology sharing has to be done for this. Selection of a supplier depends on a number of factors given below.

Quality Standards

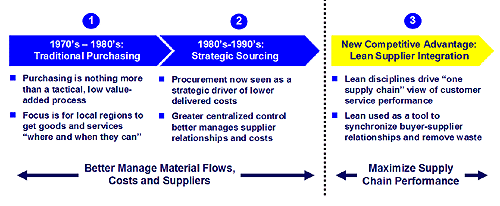

The modern approach (as compared to earlier approaches) in supply chain management will provide buyers the information about the need, whether to manufacture a product or outsource it from a supplier.

(Hawkey). The concept of lean management is actively pursued by many organizations today by using techniques like just-in-time. The concept can be extended to outside the company as well by applying it in supplier selection and management also. ISO standards with regard to selection and evaluation can be used even though it is not mandatory.

Quality Tools

Apart from a well laid out process, there is certain software that can be used as selection tools. Such software can be made to order or are available as readymade ones.

Quality Manager’s Responsibilities

Responsibilities include developing and maintaining the selection process and being in charge of the supplier selection team. He has to maintain proper documentation of suppliers and see to it that it is updated as and when needed.

Project Quality Assurance

Following the above mentioned supplier selection process will help in keeping the quality of the supplier at the time of selection. Continuous monitoring across all parameters will ensure that their quality is maintained in future as well.

Quality Assurance Procedures

Inspection of manufacturing facilities and quality management system followed by the supplier at regular intervals will be adequate procedures.

Project Monitoring Processes

The monitoring process is a part of the procedures mentioned above in the section titled continuous monitoring.

Project Quality Control

Inspection of supplier products and periodic sampling of products should be a process involved in the purchase system.

Project Deliverables

Delivery of products as per agreement and according to quality, cost, and schedule are the deliverables expected of a supplier.

Project Quality Control Procedures

Continuous monitoring, sampling and testing of products, and having an audit system are the procedures to be followed.

Project Deliverables Test & Acceptance Process

As mentioned earlier, the sampling and testing of products at regular intervals should be followed. Products from every batch should be sampled and tested for quality.

Project Deliverables Acceptance Criteria

The purchaser should have minimum standard criteria for this purpose. Whenever products are tested, it should exceed or match these criteria.

Project Audits & Quality Reviews

A separate audit department or section should be maintained. They should conduct periodic onsite review of the supplier. The audit or review should cover all parameters mentioned in the above processes. Moreover other aspects like, review of plant, machinery and buildings should also be included. Hygiene factors and environmental concerns/factors should also be audited. Processes, risk and hazard factors, product recalls etc must also come under review. A formal audit report should be sent to the supplier selection manager and to the board if the products are of a critical nature.

Quality Team Roles & Responsibilities

The supplier selection procedure involves team work that is to be handled by the manager in charge. They also should have regular contact with the purchase and stores department. Close association with the audit department is also necessary. These are the fundamental roles to be performed as a team and as individuals. Each member has to be assigned clear instructions as to the tasks to be performed.

Quality Plan Audit Log

An audit log is to be prepared as a part of the audit procedure and report. A sample audit log (report) is given as appendix.

Quality Plan Approvals

This report has to be presented to the management of Boeing for approval. This will be done with the consultation of the concerned departments like purchase, store, production, and audit.

Conclusion

The above mentioned criteria or category should be followed by Boeing when evaluating a supplier. This must be applied in the case of Hughes also. Given the profile of the company and its international stature and reputation, the company will qualify as a preferred supplier to Boeing. This could be the reason why Boeing took over Hughes in the first place. The vision of the company has been to become the world’s largest player in the field of satellite supplying and launching and the company has a very able supplier in Hughes.

Appendix

(Supplier Audit Report, 2).

Works Cited

Bello, Marlene J Suarez. A Case Study Approach to the Supplier Selection Process. University of Puerto, Rico. 2003. Web.

Bello, Marlene J Suarez. A Case Study Approach to the Supplier Selection Process: Initial Supplier Evaluation and Selection Audit Development. University of Puerto, Rico. Web.

Hawkey, Robert. Discovery the Lean Supply Chain: Transformation Suppliers into Powerful Lean Differentiations. Superfactory: Resources for Lean Manufacturing and Lean Enterprise Excellence. 2007. Web.

Hoversten, Paul. Boeinh Buys Hughes’ Satellite Sector. Space.com. 2000. Web.

Supplier Audit Report. Web.