Abstract

Walmart has emerged as one of the largest retailers globally, with 11,700 stores, which signifies an exceptional example of supply chain management (SCM) and logistics. Although the store began operating in the United States, it successfully expanded and opened retail chains in Canada and Europe. The example of Walmart versus Target in Canada demonstrates the superiority of SCM practices of the former since Walmart’s revolutionary inventory management practice allows for timely restock and mitigation of additional costs. Moreover, Walmart uses information technology (IT), including Vendor Managed Inventory (VMI), Electronic Data Interchange (EDI) and Radio Frequency Identification (RFID) and others.

Introduction

For a retailer that sells a large variety of products including food, clothes, home decor, and others the cost and the availability of stock are essential, meaning that the proper management of SC and inventory determine the success of such business. The latter is essential because having a solid choice of retailers, and consumers are more inclined to choose the ones that manage to fill empty shelves with new stock on time, requiring superior planning and logistics that Walmart was able to achieve (MacKenzie, Meyer, &Noble, 2013).

This Walmart research aims to examine a global retailer Walmart and evaluate the SCM practices it applies to deliver products to its 11,700 stores. The objective is to determine how large companies, more specifically retailers, can use SCM principles in their work to ensure a continuous supply of products. Additionally, this paper will evaluate sustainability and supplier relationship management using the example of Walmart.

The specific questions that will be addressed are: How do retailers manage to track their stock and keep a substantial supply without over hoarding the inventory? How does Walmart manage to keep low prices for its products, and what is the role of the global supply chain in it? What specific tactics does Walmart use to manage the relationships with suppliers?

Walmart is one of the revolutionaries in the industry of retail because the company’s approach to managing its supply chain effectively allowed reducing the time necessary to deliver goods to its stores drastically. Additionally, the increased attention from consumers regarding the sustainability of manufacturing pressures companies such as Walmart to change their approach to SCM and introduce products that were manufactured sustainably (Yin et al., 2018; Sun & Ho, 2019).

Literature Review

The theory of transaction costs economics (TCE) explains the benefits that Walmart has from employing outsourcing. According to Wang (2019) and Kim (2017), TCE allows achieving a cost advantage through outsourcing, which the company can focus on its main tasks and boundaries. Moreover, according to research by Lee (2019) and Coccia (2017), companies that use innovation can significantly reduce their TC.

When the company chooses to outsource the non-core elements of its business, it can dedicate more attention to its internal processes and competitive advantage. Next, the resource-based view (RBV) is a concept that perceives the company’s assets as its main competitive advantage. According to Sminia (2017), RBV the business becomes the starting point of strategic planning. Hence, its assets, both tangible and intangible, allow achieving a competitive advantage. TCE and RBV are the two main concepts that will be used to examine Walmart.

Cross-border outsourcing is a practice of partnering with vendors from other states to outsource some of the businesses’ activities. Tomiura (2018) argues that this practice has many barriers, such as mere misunderstandings due to language differences and more complex issues of strategic planning. Walmart is among the companies that successfully use this practice. Mostly, the sourcing is from low-wage countries that can be outsourced to the unskilled workforce, which creates some issues with sustainability.

Most companies rely on a standard procedure of SCM. According to Xuejie et al. (2019), the following are the key elements of supply chain management – “plan, purchase, manufacture, distribution and return” (p. 235). A concept of integrated supply chain strategy allows for better control over producing, positively affecting the speed and flexibility of operations. This leads to the exclusion of the option to “manage each part of the supply chain as an independent function” (“Integrated supply chain,” n.d., para.1).

The main positive impact of this approach is the ability to overcome the issues of the short supply cycle, product variety, and uncertainty. Sustainability is a broad concept that refers to business practices that do not cause harm (Krmac, 2016). This can relate to the environment or the ethical practices of employment and other issues. Supplier relationship management (SRM) is a systemic approach to evaluating a supplier’s contribution and determining a strategy that can help improve their performance (Krmac, 2016). This is necessary to establish an effective and positive relationship with the vendor and determine what activities can improve the cooperation.

Findings

Firstly, some background information about Walmart will help understand how the management approaches supply chain planning as well as how the retailer evolved to become of of the biggest companies globally. It was established fifty years ago as a small discount store. Currently, Walmart operates and has “265 million customers and members visit approximately 11,500 stores under 56 banners in 27 countries and eCommerce websites” (“About us,” n.d., para. 1).

This scale of operations requires an innovational approach to the SCM, moreover, Walmart claims to be a “leader in sustainability, corporate philanthropy and employment opportunity” (“About us,” n.d., para. 1). According to Lu (2018), Walmart has approximately $32 billion invested in inventory. This retailer sells a variety of products, including food, clothes, consumer goods, and others.

Walmart was able to simplify some of its processes, which allows for faster product delivery. The literature suggests that Walmart’s supply chain is state of the art, allowing the business to reduce the costs of obtaining and transporting the inventory significantly. Despite what one may anticipate, Walmart shares a lot of information with its partners and suppliers, employing collaborative effort into planning, forecasting, and delivering products to stores. Walmart’s SCM is remarkable because the retailer fulfils its promise to deliver goods to customers when they need it at a low price. The company uses the following systems to improve its inventory management – “Vendor Managed Inventory (VMI), Electronic Data Interchange (EDI) and Radio Frequency Identification (RFID)” (Tan et al., 2018, p. 169).

Additionally, Walmart works towards removing the unnecessary elements of its supply chain. The innovative supply chain that Walmart uses is distinctive because the company removed several chains to adjust the cost structure (Lu, 2018). This was the case since the establishment when Sam Walton would purchase some products in bulk and transfer them directly to the stores in 1962 (Hisrich & Ramadani, 2017).

The strategy of Sam Walton is understandably efficient when considering several stores with a local supply chain. However, Walmart is successful in applying it to its modern SCM, with a large number of stores and international suppliers. One method that Walmart is used is purchasing directly from suppliers, which allows avoiding costs associated with distribution (Lu, 2018). All of these SCM elements contribute to the TCE.

Next, Walmart developed its own strategy for ensuring that they always have a sufficient amount of stock in each store titled Vendor Managed Inventory (VMI). Under this system, the manufacturer or supplier is responsible for monitoring the stock in stores (Lu, 2018). This allows having an order fulfilment of up to 100%. The ability of Walmart to form strategic partnerships with suppliers is partial because the company can guarantee a large volume of orders and long-term cooperation, in return, requesting a lower price. This is part of Walmart’s supplier relationship management, which allows effectively collaborating with vendors and reducing the time for restocking inventory.

Walmart uses cross-docking to cut down the time of transporting the goods from the warehouses to stores. The concept refers to transportation using trucks or carts without having to use storage in between (“Cross-docking vs. warehousing,” n.d.). More specifically, the goods are transferred from one truck to another, which transports them to the store. This cooperation between the inbound and unbound trucks is remarkable because suppliers can deliver the products to distribution centres where they are immediately transferred on trucks to the stores. Apart from saving the time necessary to deliver the goods from the supplier to the store, Walmart is able to cut costs associated with transportation and storage.

Apart from merchandise and consumer goods, Walmart also sells food, which requires special attention in terms of sourcing. Tan et al. (2018) state that recent scandals with contamination, such as salmonella outbreak in the United States in 2017 and problems with contaminated eggs in Europe make it necessary for retailers to create supply chains that allow tracking the source of contamination.

To address this, Walmart partnered with IBM and several other organisations to employ blockchain technology in its food SCM. In general, traceability is important in the context of SCM and ISO defines it as “totality of data and operations that is capable of maintaining desired information about a product and its components through all or part of its production and utilisation chain” (cited in Tan et al., 2018, p. 168). This enhances several processes of SCR, including planning and tracking inventory.

Walmart uses innovation to manage and track the vendors of food. According to Tan et al. (2018), “food supply chain is a complex chain including financial flow, goods flow, and information flow, which involves all collaborative enterprises from raw material suppliers, manufacturers, logistics parties, wholesalers, retailers, and consumers” (p. 168). Other challenges for the retailer include the fact that in Walmart’s case, the supply is usually crossing borders and comes from hundreds of suppliers, both local and international. Food tracking systems must trace the raw materials, packaging, and any additives that go into the final product.

The use of Bid Data in SCM is another element that allows for better SCM analytics. According to Heller (2017), “it was estimated that Walmart was collecting roughly 2,5 petabytes of data every hour from customers’ transactions in 2012” (p. 5). Walmart, in particular, applies the practice to analyse inventory through SKU. With better supply and demand planning, it is possible to achieve the objective of always having goods in stores.

Competitive Advantage

The industry is a competitive field, with a low cost of the final product being the main focus of retailers. According to Raynaldo et al. (2018), “retailers have been facing a new height of competition ever since the birth of e-commerce disrupted the conventional, brick-and-mortar business model” (p. 1). Walmart’s innovation in the domain of SCM allows this business to improve the time of delivery to a store for its products; mainly this becomes evident when examining the competition between Walmart and Target in Canada.

From the TCE perspective, this suggests that Walmart can significantly reduce the costs of the goods because it spends less on transportation and storage. The latter company failed to establish an adequate supply chain in the country, leading to delays and empty shelves, which ultimately resulted in customers choosing to go to other stores (Cheng, 2015). From the perspective of RBV, Walmart has been a reliable retailer, both for consumers and suppliers.

Discussion and Analysis

Based on the findings, Walmart has been successful in managing its SC for its stores in the United States and internationally. According to Walmart, its supply chain consists of “more than 100,000 suppliers globally” (“Social,” n.d., para. 1). TCE is one of the major theories used to analyse outsourcing management, and from a TCE and RBV perspectives, Walmart achieves excellent results by outsourcing all of the unnecessary activities, including inventory monitoring to the suppliers. This is beneficial for the SCM because it provides greater autonomy for the latter and mitigates the waiting time between order placement and inventory restock. However, in terms of sustainability, Walmart has not been making major advancements.

Sustainability

Sustainability can be defined as performing certain business activities without causing harm to people or the environment and ensuring that following generations will be able to meet their needs with the existing resources by using them responsibly. Main concerns emerged for sustainability after several incidents in Bangladesh factories, where thousands of workers were killed, forcing retailers and other businesses to review their SCM and approaches to choosing vendors. The analysis of changes that occurred after by Land and Zakaria (2019) suggests that businesses decided to change their SCM models. It is unclear if Walmart will be able to achieve full sustainability of its SC since a majority of benefits from TCE are associated with the low cost of labour in the outsourced countries.

Regardless, Walmart introduced a regular report titled “Sustainability in Value Chains” where the retailer discusses the changes it makes to ensure a better SCM (“Sustainability in Value Chains,” n.d.). Additionally, Walmart claims that it uses a risk-based approach to managing the global SC and audits countries that have a greater risk potential. Therefore, currently, Walmart evaluates the risks associated with its suppliers and issues reports about advancements in sustainability the company achieves.

For Walmart, sustainability is achieved through audits of the regions where the retailer’s partners have their manufacturing facilities. According to the retailer, they strive to “create zero waste, operate with 100% renewable energy and sell products that sustain our resources and the environment” (“Sustainability,” n.d., para. 1). Sustainability has become an important issue for many industries in recent years. Mainly, this is connected to increasing consumer awareness regarding the sourcing of materials and labour, which mainly come from developing countries with poor work conditions and unfair wages.

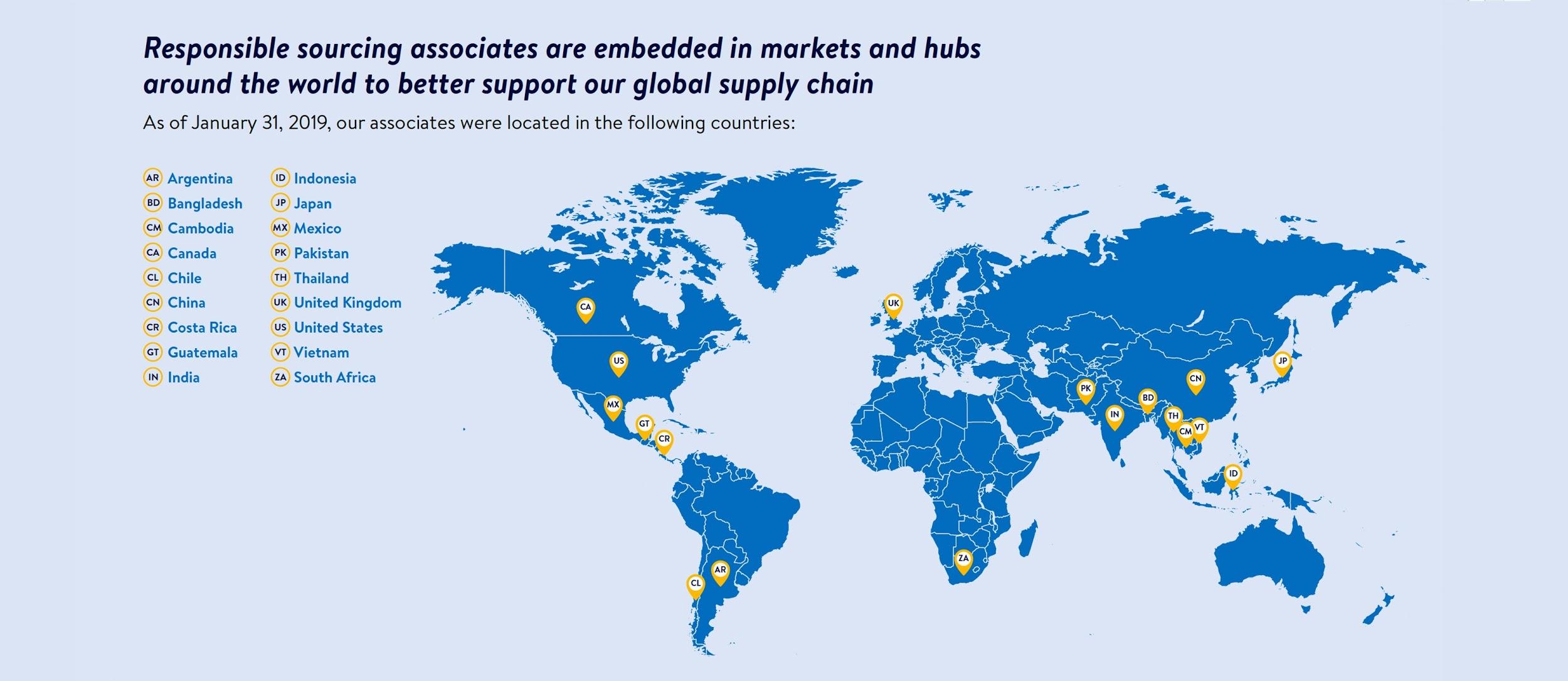

As consumers become more conscious of what they buy, Walmart, similarly to many other retailers, pursues the idea of working towards establishing a sustainable supply chain. To ensure that the suppliers adhere to the sustainability standards, Walmart established the “Responsible Sourcing initiative in 1992 (“Social,” n.d.). Picture 1 shows the location of Walmart’s suppliers. Picture 1 demonstrates the SC of Walmart and the main countries where its partners reside, with a large number of developing states. Therefore, while Walmart strives to employ sustainable practices, the obvious difficulties are associated with the cost structure of goods and the ability to maintain low prices while partnering with sustainable manufacturers.

Supplier Relationship Management

Walmart has a unique system for managing its in-store stock. As the literature review suggests, the company works in close cooperation with its suppliers, forming strong partnerships and shifting away from the centralised inventory purchases. SRM allows for better cooperation between the retailer and its partners. Walmart incorporates its suppliers closely into the process of inventory management. IT plays an important role in Walmart’s SCM.

Apart from the IT solutions discussed above, Walmart uses Retail Link, which is one of the systems that collect real-time data about sales from all cash registers and transfers it to the suppliers. This technology provides two leverages for Walmart – the ability for advanced analytics to predict demand better and fast restock from suppliers. Next, frequency identification tags (RFID) is used to track inventory and transportation (Lu, 2018). Heller (2017) states that RFID allows tracking products in real-time, with more efficiency than provided by the traditional bar codes providing more efficiency.

Walmart is one of the first retailers to use the RFID system, which also allowed it to leverage technological innovation as a competitive advantage. Researchers from Arkansas University suggest that through these innovations, Walmart was able to reduce the percentage of out-of-stock items by 16% (Roberti, 2005). These systems are necessary to monitor the inventory and notify the vendor that the items are out of stock in certain stores. Therefore, the practice of supplier management that Walmart employs allows the company to outsource the function of inventory restocking.

Conclusion

In summary, there two main tasks that Walmart needs to accomplish with its SCM are – ensuring that the inventory is always in stock in stores and reducing the costs to provide the lowest prices for consumers. Based on this research, the company successfully achieves both objectives, with approaches such as cross-docking, and technologies of blockchain, RFDID, and EDI satellite data collection enabling for better efficiency.

Because Walmart shares information with its suppliers and employees the VMI system, the latter is responsible for restocking. This research examined the practices that Walmart uses in terms of managing its supply chain, determined how the company resolves issues, and what are the key features of its management practice that allow it to have a competitive advantage over others.

The literature was examined to define the main challenges of SCM for Walmart and examine the new approach that the company uses, which are TCE, RBV, sustainability, and supplier relationship management. Next, the findings were synthesised and discussed to determine how Walmart was able to change the SCM successfully. Finally, a critical evaluation of the results and some recommendations for further improvement will be presented in the section below. Walmart’s example suggests that proper management of SC can lead to improved efficiency of business processes, allowing the company to sell products and ensure an adequate and continuous supply for thousands of stores globally. The scale of Walmarts SCM is remarkable, with the main focus on the logistics of operations.

Recommendations

While Walmart appears to apply its SCM strategies successfully, some changes can be made to improve the operations further. One recommendation is to apply blockchain technology more broadly, not only for tracking food chains. Currently, Walmart launched test projects for blockchain, which mainly focused on one product in one country, more specifically, one food item. However, as shown by the research, blockchain can help improve retail practices significantly by allowing for tracking all stages of manufacturing.

Additionally, more attention to sustainability and working towards practices that create more value can be helpful for marketing Walmart to consumers. Walmart, like many others operating in the industry, faced the problem of sustainability due to consumer concerns regarding work conditions and wages of the people in developing countries, where many businesses usually outsource their manufacturing. Currently, the company produces its “Sustainability in Value Chains” report to inform consumers about the practices it uses, however, it is possible to reevaluate its approach to choosing suppliers in developing countries to ensure that Walmart’s ethics are not compromised.

References

About us. (n.d.). Web.

Cheng, A. (2015). What Wal-Mart got right in Canada, and what Target botched. Web.

Coccia, M. (2017). Sources of technological innovation: Radical and incremental innovation problem-driven to support competitive advantage of firms. Technology Analysis & Strategic Management, 29(9), 1048-1061. Web.

Cross-docking vs. warehousing. (n.d.). Web.

Heller, F. K. (2017). Technological innovation applied to Walmart and Tesco’s supply chain. [Unpublished Master’s thesis]. NOVA – School of Business and Economics.

Hisrich R.D., & Ramadani V. (2017). Effective entrepreneurial management. Springer.

Integrated supply chain. (n.d.). Web.

Kim, H. J. (2017). The complementary effects of transaction cost economics and resource-based view: A technological alliance perspective. International Journal of Business Excellence 13(3), 1-10. Web.

Land, A. & Zakaria, R. (2019). Rana Plaza Collapse, its aftermath, and future implications for sustainability. Web.

Lee, Y. H. (2019). Vertical integration and technological innovation: A transaction cost approach. Routledge.

Lu, C. (2018). Walmart’s successful supply chain management. Web.

Krmac, E. (2016). Sustainable supply chain management. BOD.

MacKenzie, I., Meyer, C. &Noble, S. (2013). How retailers can keep up with consumers. Web.

Roberti, M. (2005). EPC reduces out-of-stocks at Wal-Mart. Web.

Sminia, H. (2017). The strategic manager (2nd ed.). Routledge.

Social. (n.d.). Web.

Sung, H., & Ho, S. (2019). Supply chain finance and impacts of consumers’ sustainability awareness. The North American Journal of Economics And Finance, 1-10. Web.

Sustainability. (n.d.). Web.

Sustainability in Value Chains. (n.d.). Web.

Tan B., Yan J., Chen S., Liu X. (2018). The impact of blockchain on food supply chain: The case of Walmart. In: M. Qiu (Ed.), Smart blockchain (pp. 160-168). Springer.

Tomiura E. (2018). Cross-border outsourcing and boundaries of Japanese firms. Springer.

Wang, Z. (2019). The principle of trading economics. Springer

Xuejie, C., Chang, Q., & GuangHao, Z. (Eds.). (2019). Research on innovation supply chain management in fast fashion industry——A comparative analysis of ZARA and H&M. Proceedings of The 2019 3Rd International Conference on Education, Culture and Social Development. Atlantis Press.

Yin, J., Qian, L., & Singhapakdi, A. (2016). Sharing Sustainability: How Values and Ethics Matter in Consumers’ Adoption of Public Bicycle-Sharing Scheme. Journal Of Business Ethics, 149(2), 313-332. Web.