Introduction

Total Quality Management (TQM) are the activities in the management function that influence the quality of policies, responsibilities, objectives and their implementation through quality control, quality planning and quality improvement. Most organizations are focusing on quality improvement process than on the product itself. In other terms quality management system is the process of quality improvement where skills are used to add value to the quality of the products and enhance their future. This is done for the purposes of retaining present customers, and welcoming new ones.

In almost all organization, the production process has been modified in order to ensure quality improvement. Total quality management involves managing processes for a desired benefit. It involves structuring and controlling all processes involved in an organization so that they give effective results. Large and complex processes are normally broken down into small and inter-related processes for easy management. In doing this, one has to take into consideration, the time and the budget allocated to the specific processes.

Total quality management consists of competitive moves and business approaches aimed at producing successful performance; it is a management’s “game plan” for running the business, strengthening a firm’s competitive position, satisfying the customers, the stakeholders, share holders and the staffs. It seeks to develop the way into which all those that are a party to the business get satisfied. It aims at going a step further and satisfying the customers beyond their expectations.

There is a lot of focus on the customer; the customer is the greatest asset that an organization can have. To get customers loyalty is the dream of every business and that’s what most businesses target. The compliance to TQM is one of the key factors required for the improvement of quality. Its implementation takes place in either the project level or the organization level (O’Connor 183).

Given the speed with which change occurs in the global business environment, standard, planning techniques and asset allocation methods have become woefully outdated. Achieving new levels of business sophistication is a never-ending process, requiring companies to rapidly reallocate assets to meet changing conditions. To effectively accomplish this reallocation the organizations need a system that provides continuous evaluation and improvement, ensuring effective use of both business (hard) and organizational (soft) assets.

Because of the ever changing market place, many organizations are transforming their business in order to compete favorably. Total quality management happens to be the widely applied technique in virtually all organizations. They have realized the benefits that come with this technique and it has been applied in all processes. In the implementation of TQM six concepts which are considered to be vital must be taken into consideration. These are customers (both internal and external), leadership and teamwork, continuous improvement, control of business processes, preventive action, and preventive management.

Most of the successive organizations have realized that a key factor in TQM is monitoring performance to ensure that all of the needs and requirements of customers are being met. They have come to the understanding that the term customers do not only refer to the people who buy products from them but also to the internal employees. Employees are one of the valuable assets that any organization can boast of and therefore they have to be handled with care at all times.

One of the organizations that have realized the benefits of TQM in its operations is Coca-Cola Company. This company ensures that all its personnel interact with its own supplies in its processes, this does not only refer to the people who sell products or services to the company, but all its internal suppliers. These internal suppliers are personnel involved in the production processes and they are people who provide input to the next level of production. Each customer has specific needs and demand appropriate requirements; it is upon suppliers to focus their efforts in order to build quality and ensure that they are able to meet all the requirements of customers. This includes making appropriate identification and improvement of the production process. Adoption of TQM in the company raises several questions (Gotzamani and Tsiotras, 1326). This include

- How is the satisfaction of external customers measured?

- How does the company compare itself wit its competitors?

- How does the company identity and meet the requirements of its internal customers?

- Does the work force understand and accept the concept of TQM?

Research objectives

This research paper will try to examine the implementation of Quality Management System from an institutional theory point of view. It aims to explain the process of institutionalization of the Total Quality Management (TQM) in the Coca-Cola Company and also to explore the extent this TQM has affected the organization’s work culture.

With these objectives in mind, several research questions have been identified that are pertinent to this research. They are:

- What form of management system exists in the organization?

- How does the quality management system become institutionalized in the organization? Has it been institutionalized ceremonially or instrumentally?

- How do the members of the organization respond to the quality based culture?

Overview of Coca-Cola Company

Coca Cola Company is the largest manufacturer and distributor of soft drinks and non alcoholic drinks in the world. Its headquarters is in Atlanta, Georgia where products are manufactured and sold to bottlers for packaging. Coca cola’s operations are distributed in more than 200 countries (the UK being one of the biggest markets for the product) and produce more than 3000 products. It specializes in soft drinks, energy drinks, water and fruit drinks. Consumers all over the world enjoy over 80 different flavors of soft drink manufactured by the coca cola Company.

This includes brands such as fanta, sprite and the popular coca cola brand. Coca cola recorded the highest sales in 2009. Its products remain to be the most favored soft drinks by majority of people and this has resulted in an increase in the sales volume for the products. However, the company lags behind in the production and sale of Non-Alcoholic beverages where Unilever takes the lead. In 2004, Coca cola recorded total sales amounting to 13.7 billion liters of soft drinks in the UK market and sales worth over £9.2 billion in 2005 (Coca-Cola 2).

Coca cola has a strong and close relationship between its suppliers and distributors. It has expanded its markets in the social and cultural contexts and this has contributed to its success. Coca cola has been using high technology which has been rising over the years leading to success in all its activities. Most of its products are advertised over the internet making in easy for all people to access information (Giebelhaus 2).

Coca cola’s innovativeness is facilitated by the use of decentralized structures where managers are allowed to experiment new products. An effective procedure is followed in order to establish new and attractive ideas for the success of the organization. Some times it is not able to make the expected profit margins due to competition. However, it has an opportunity of merging with global retailers and to expand into other countries. However, Coca cola is often faced by the threat or intense rivalry, price competition, and government regulations.

Coca Cola aims to retain its position as the world’s largest soft drinks manufacturer. To attain this, it has improved its products with the needs of customers (Gotzamani and Tsiotras, 1330). It has a research department which advises the company on the kind of products it manufactures for better customer satisfaction. It also has a quality department with the responsibility of ensuring that its entire products are of high quality. It respects its consumers and nature by producing high-quality products which are eco-friendly.

Quality Management at Coca-Cola Company

Coca-cola was discovered in 1886 at the soda fountain of Jacob’s Pharmacy in Atlanta. In 1899, the company was introduced to the world when it started selling its products packaged in glass bottles. By 1916, multiple designs of bottle had been discovered which have evolved to the contour shape which are now universally recognized. Back then, the company only produced one brand of product but soon it diversified into many brands and by 1980, it was producing more than three brands, this includes the Diet Coke and caffeine free Coke. In early 1990s, Coca-cola expanded extensively in its processes, products, and packaging designs (The Coca-Cola 4).

From the inception of the company, the executive had realized that quality was the only significant facet that would place the company away from its competitors. The leaders emphasized on the management of quality in all its processes. Towards the end of the 1990s, the global market started experiencing structural changes which forced Coca-Cola Company to review its quality management system. There was need to maintain consistent quality as well as meet consumer tastes and preferences. To address these changes the Coca-Cola Quality System (TCCQS) was introduced in early 1995. This technique helped the company to redefine its environmental standards as well as its quality requirements (The Coca-Cola 5). This was a decentralized approach to managing quality which was achieved after operating for about one hundred and nine years.

In 1999, TCCQS was modified to include safety, quality planning, and quality review. It continued evolving to incorporate business goals and objectives, among other things required by the global market, such as safety standards. Today, TCCQS has continued to evolve. It has been branded as the Quality Management System for Coca-Cola. It helps the company to manage and steer its activities to make sure that quality is achieved in all its processes. TCCQS has helped Coca-Cola to in all of its processes. It is now able to produce high-quality products that have helped in to retain its competitive advantage. This has also helped it to come up with innovative ideas in production of new products.

Why does the system keep on evolving?

TCCQS has to develop constantly in order to integrate changes in quality management, comply with regulations, meet the circumstances in the global market, as well as take on the best practices to be used in production. For instance, off late food manufacturing companies have become aware of the importance of maintaining food safety. Because coca-cola has been quality conscious since its inception, TCCQS has to evolve in order to embody the most recent practices in the manufacturing sector. Coca-Cola Company focuses more on its customers by ensuring that all consumers are satisfied, therefore, TCCQS has to concentrate of customer satisfaction. The quality management system (TCCQS) must ensure that safety and environmental stewardship is maintained at Coca-Cola because it is a responsible company (The Coca-Cola 5)

The latest evolution of TCCQS

The latest evolution known as evolution 3 of TCCQS offered notable benefits to the company when it comes to management of quality. Some of these benefits include:

- A simplified structure

- Proper configuration with external standards

- Provision of unique training and auditing resources that meets Coca-Cola’s requirements

- Alignment of business objectives with metrics that can be used to keep an eye on performance

- Ensures that executive managers are involved in the quality management process at every unit

- Helps in planning and introduction of new products

- Defines the methods to be used in problem solving as well as for continuous improvement

The framework of TCCQS

The core of TCCQS evolution 3 is quality, and environmental and safety aspects. Its framework allows other business to ally with the processes of Coca-Cola. TCCQS pyramid is mainly composed of four layers promise, policy, assurance, and control. Each aspect of the pyramid has equal number of components. That is, every facet, for environment, excellence and protection has to incorporate the four layers named above.

The promise

The most important reason of the existence of Coca-Cola Company is to do good to and rejuvenate all its stakeholders. Irrespective of the function of the business, each aspect of TCCQS must support the company’s promise (The Coca-Cola 7).

Policy

This layer contains the policy statement for the company. This comprises of the security and environmental policies as well as the quality statement which is placed on the excellence part of the pyramid.

Assurance

Management systems are contained in this layer. These systems are designed to make sure that control activities are reliable and efficient in order to ensure that the company meets its performance requirements. The management system contains the standards of the quality management system which must be in line with the requirements of ISO Standard 9001:2000. This certification was erected in order to meet the requirements of Global Food Safety Initiative (GFSI) and be up to date with worldwide requirements regarding food security. On top of that, the management system features other standards that are specific to Coca-Cola, for instance crisis resolution.

Control

For more that one hundred years, controls have been part of the daily operations at Coca-Cola company. However, the modern world has changed and today’s necessities are dissimilar to the past requirements. The TCCQS pyramid provides a comprehensible dissimilarity between the control actions and the assurance actions. Examples of control activities at Coca-Cola include cleaning methods, excellent environmental practices and high-quality manufacturing practices (Anon. “Coca-Cola Products” 3).

ISO certification

TQM allows a business to realize the purpose and objectives laid down in its policy and plan. It gives constancy and contentment in terms of techniques, resources, apparatus, etc, and interrelates with all actions of the business, starting with the recognition of customer requirements and concluding with their contentment, at every operation interface. In the light of the improving the performance and competitiveness of the Coca-Cola Company, the Quality Management System (mainly the ISO 9001:2000) was adopted. The ISO standards are a generic standard that has its origin from the engineering field. As generic standards, some of the terms used in the standard could be misconstrued as being vague, ambiguous and imprecise. Confusion also arises as there is a lack of definition of these terms in the standards (Kerzner 45)

Quality Management Excellency (QME) courses ensure Strategic & Operational outsourcing through trainings that cover areas related to Risk management, tax, professional, management services, intellectual, people development and accounting. Coca-Cola opted to adopt ISO 9001:2000 as its excellence model because it is the most effective model to help the company achieve its quality standards. This model has seen Coca-Cola’s products being ranked as among the products with high quality allover the world. According to Lari (170), the purpose of the ISO certification is to boost quality in organizations, enhance communications, and decrease the cost of operation. Brecka (20) also observed, that the information management system required for ISO certification is based on decision making, problem shooting and prior understanding of management

This has been done in order to promote quality performance due to the increased competition on the available resources in the company. To facilitate understanding and compliance of the quality standard requirements Coca-Cola established a training and consultancy firm. It provides a wide range of consultancy, support service and training. Support services are available to the field of business, strategic management and quality management

The process of seeking for certification of ISO 9001:2000 was hectic and required compliance to certain standards. Most of the organizations that have already received ISO certification had to do a lot of changes in order to satisfy the ISO standards. One of the problems that were encountered by the company was staff resistance to the ISO requirements (Serpell 320). Most of them were ignorant about the requirements and the management had to train the staffs on these requirements. Some were quick learners while others were not ready to learn and vigorous training had to be embarked on by the management. Some of the employees ‘minds have adopted the daily operations and it becomes difficult to introduce something new to them. Some feel that what they know is enough that there is no need for any improvement either on the product or service delivery

ISO certification ensures that the customer demand is met effectively. It helps to regulate the number of companies that can produce a certain product or service. It is a way of protecting the end users from exploitation. It ensures that they get quality products or service and are not charged highly for the same. The compliance of quality management ensures the company does not lag behind in international trade. It ensures that, its products and services compete favorably with other company’s. It is through quality management that the production of goods and services becomes effective and wastages are minimized.

Benefits of Total Quality Management

T.Q.M has a lot of advantage to Coca-Cola Company. There is satisfaction among the management, the stake holders and the customer. They are deliberate actions that the company takes to ensure that all its ways are been looked into and made in such a way that the outcome are favorable to the end customer (Coca-Cola 2). Customer is the most important asset the company has and his welfare satisfaction should be at the fore front of any company’s agendas. When the customer is satisfied, then he gives back to the company in many ways. Remember that a satisfied customer tells another and unsatisfied one tells two others. If the business attains customer royalty, it becomes a self advertising enterprise.

Many people talk about risk management but rarely do they do anything in connection to it. The major problem is that many people do not know whose responsibility it is to manage risk. TQM provides a solution to this since it defines the method of handling risk. This involves identification of risks, evaluation, and how to deal with identified risk within the manufacturing process. It also gives an idea of who is accountable for carrying out the diverse roles implicated in manufacturing process. It sets out the number and types of risks that an organization can be able to bear. It also recommends that, the probability and the impact of a risk should be considered to determine whether this varies over time and whether it has an impact on the quality of products and services.

The purpose of TQM is to ensure that, the products resulting from the company’s processes are of good standard, that is, they meet the quality criteria. More often than not, this is done in a quality reassess meeting in which inaccuracies in products are recognized. It is worth noting that the quality review meeting is not under any obligation to resolve the errors identified in products, its work is to bring the interested people together and to help the project team in addressing the identified issues.

Over many years, TQM application systems in the Cola-Cola Company have been in an increasing trend. So far, TQM has brought about positive changes in the company. However, the company is still facing problems in the implementation of TQM. From this research, four main advantages have been identified for Coca-Cola. These are:

- Organization image and reputation enhancement

- Performance and customers’ satisfaction improvement

- Documentation procedures and instructions establishment and

- Constant quality service

TQM application has enhanced the image and reputation of the company. It is a versatile and flexible management tool that an organization can use to improve their goals, efficiency and profitability. The application of TQM has also influenced the company to improve its performance and increase customers’ satisfaction. Moreover, Coca-Cola is able to establish clear documented procedures and instruction that includes the documented statements of policy quality and objective quality. Besides that, the implementation of TQM serves as a guideline to ensure quality services are able to meet the required standard.

A triumphant manufacturing process, that is, one that delivers quality results within the set budget and on time depends on the eminence of people who are concerned in its execution. This includes project board and the project team which does most of the work. Today, projects engross different groups of people including but not limited to the clients, contractors, and the users. The most important objective behind the use of TQM is to make sure that there is a universal language amongst the concerned parties (Ahire 95). Customers and suppliers are brought together by contracts, whereas the employees and the management are brought together by the responsibilities expected of them by the customers and or the users of the project. By using TQM managers have been able to manage the manufacturing process more easily and this ensures that the products that are delivered from the process are of the right quality

Steps to be followed for continuous improvement

Through TQM, the company has been able to develop customer royalty. IT has been able to surpass other companies to become the world largest distributor of soft drinks. What has made the company go this far? The answer is in total quality management. For a company to continuously improve its processes and attain the set goals as well as surpass the expectations of the customer, it has to follow some steps;

Develop a vision and mission

Developing a strategic vision and mission involves thinking strategically about the following three questions

- What are the customer’s needs?

- How much is the company offering? Can we do better?

- Where are we now?

- Where do we want to go?

- How will we get there?

A vision is a view of an organizations future and business course: it is a guiding concept for what the organization is trying to do and become. All must be looked into so as to ensure that there is no one area that benefits at the expense of the customer.

Setting objectives that are aimed at meeting the gap that the company had not been filling in the past

The aim of setting the objective is to ensure that the company has embarked on the fulfillment of the need of the customer. The aim this is to improve the feeling that the customer will get when he has transacted with the business. The objectives are aimed at improving all the area of the organization and the measurement is the satisfaction that the customer will get. A satisfied customer will be a loyal customer and the business stands to benefit.

Crafting strategies and implementing them

This is all about drafting the way and the objectives that the company has set. The need to have well set strategies assists the business to attain the targets. In this stage, the issue of the resources that is required to meet the objectives is also considered. If the company needs more employees or latest technology, this is the time to set it. In Coca Cola Company one of the strategies that it has used to attain the objective of customer satisfaction is continuous improvement.

Total quality management assumes a continuous change, therefore managers must constantly evaluate performance, monitor the situation and decide how well things are going and make necessary adjustments. The management should review the strategies that they had implemented and the feedback that they have gotten from the customers. In case of any area that is not well addressed, it should be handled. In TQM the views of employees as well as the feedback from the customers are of great importance (Sirim 2). There are suggestion boxes that the views of the customers can be gotten from. At Coca Cola company there is a research department that has the aim of undertaking the policy of Genchi Genbutsu (go and see). The section is supposed to survey the market and come up with various recommendations that are aimed at improving the services.

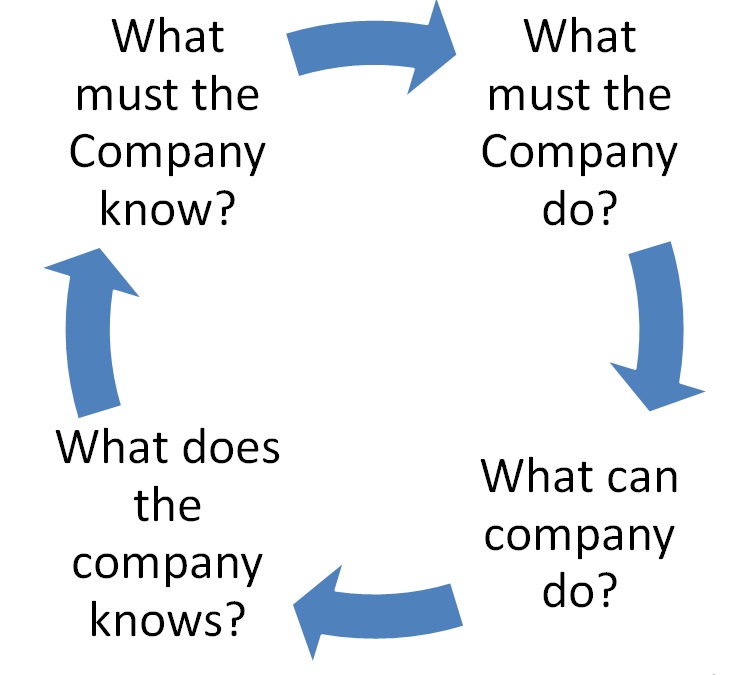

GAP analysis

A gap analysis is a tool used by managers to decide which tactics and strategies to use in order to increase production. It is a tool used to link a business vision with its strategies and goals. It helps in identifying a discrepancy in the performance which helps in selecting appropriate strategies to fill the discrepancy. It was necessary to conduct a gap analysis on the implementation and use of TQM in the company. This was done by asking two simple questions, where is the company now? Where does it want to be five years from now? The following diagram shows the process of identifying the gap within the company.

After looking at what the company has done and what it ought to do, certain problems were identified. These are grouped as follows;

Organizational culture

The employees have a set of belief that they are static to change. In developing a total quality management in the organization, change must appear. The people are sometimes opposing this change and hinder the process.

The management

There are some recommendations that are given by the sector employees but the management fails to implement them, this hinders how far the company responds to the demands of the customer.

Funds

Developing T.Q.M. system requires funds that the company may not be having. These funds may be for adoption of technology or development of Systems

Lack of information

The available information and feedback from the customers may not reach the company. If a customer encounters a problem with any of the products, they opt to keep quiet and thus the issue may never reach the company.

The above have consistently been a barrier because of two elements

- The nature of human beings that is opposed to change. Both the management and the workforce are not prepared to take in new changes at all the time. The concept of inertia applies.

- Lack of information and feedback

The customers are not giving feedback to the company about the areas they would like improved, but opt to solve by themselves.

List of problems identified at the company concerning the adoption and implementation of TQM include

Lack of understanding in the TQM

- Lack of understanding on the process requirement

- Lack of awareness in the benefits of TQM

- Lack of available Quality System documentation such as procedures, records construction period, work instruction and record

- Lack of documentation period, work instruction and record

- Lack of planning to implement TQM

- Lack of continuous professional development

- Lack of TQM exposure among workers

- High cost of implementing TQM

- Time consuming

Even though Coca-Cola has been using quality management system for a long period of time, some of the employees are not aware of the existence of such systems. They have been left in the hands of top managers who have do not exposed them to workers who are actually involved in the manufacturing process. Therefore, most of the employees do not understand how these systems work and do not have an understanding of the system requirements. They are just given orders which they follow blindly without even aware of what they are doing. TQM is a process that requires continuous improving in the face of the ever changing global market. It requires high costs of implementation which limits the company on its continuous improvement.

Moreover, TQM is a time consuming process and this hinders the company on its implementation. The process of manufacturing involve a lot of administrative work, everyone has to be informed about the progress, meetings have to be arranged, plans have to be updated, and files have to be kept properly, among other activities. If some of the gaps identified in the implementation and use of TQM are addressed, the company can boast of high quality and efficiency in all its production.

Recommendations

One of the ways that the company can do to improve their quality system is to develop a feedback system. With this the company will know the weak points that need improvement. The people on the ground should be the ones who are in the forefront in giving the feedback from the customer and making recommendations to the management. The management should plan its operations and set some funds aside for future needs. Customer awareness of their right is another way that the company should embark on. This will help in attaining customer royalty and a two way system of communication.

Feedback assists in assessing the progress of the business in terms of goal attainment and what has to be done. It provides a basis on which other goals can be set. Feedback is most beneficial to the organization as well as the individuals. It adds individual motivation in goal setting which in turn influences the performance of the organization. The numerous inputs become another way of determining leadership effectiveness. The information gained from the feedback can be used to help leaders refine their attitudes and behaviors (Likert 80). For best results, it is really important that, feedbacks reflect on those behaviors and attitudes that the organization values most. Care should also be taken to ensure that the dimensions measured reflect important features of leadership execution.

The work of a manager is to organize and control processes within an organization. To do this, he selects human resources who are competent enough to work on these processes and it is his responsibility to supervise their work to ensure that it done timely and according to laid down standards. Opportunity for career growth and development is a good strategy for managing employee’s career development. Employees should be provided with opportunities to participate in educational seminars and programs. Employees acquire new skills which they use on their jobs for their benefit as well as that of the organization.

The following recommendations should be made to increase the usefulness and effectiveness of the TQM in the company. These include:

- Increase in effort by management

- Internal Quality Audit training for staff of all levels

- Increase the frequency of conducting Internal Quality Audit (Goh and Chng 20)

Achievement of global goals can only be possible if the concept of continuous improvement is adopted in all aspects of performance. New targets should always be set after the attainment of old ones and the company should always aim at for the highest level of product, and service efficiency. In this way, the company will be able to retain its competitive advantage. Adoption of continuous improvement and other concepts related to TQM involves a change in the management system. Total quality is not just a program of change. It requires a change in most of the organizations techniques and processes. All targets on the ongoing process must be steady and sustainable (Anand, Ward, and Tatikonda 313). This requires the company to adjust the measures of performance and management styles. Questions raised in the implementation of strategies for continuous improvement include:

Which review processes should the organization use?

- How will the organization maintain momentum to ensure further improvements?

- How will it convince its internal employees that the business survival depends on the achievement of a steady and continuous improvement process?

The quality of products in any organization is determined by the manufacturing process that is used to produce them. An effective and efficient manufacturing process results in efficient products or services. Therefore, efforts should be focused on controlling the manufacturing process, rather than concentrating on the products or services.

Conclusion

Total Quality Management is technique used to ensure that organizations produce products of high quality which are also friendly to the environment. For a long period of time, many organizations have been focusing on the quantity of the products produced but not the quality. However, because of the ever changing global market place, many practices have come up and are being adopted by many organizations. Moreover, customers have been quality conscious and they are now demanding for high-quality products. Technology advancement has brought about this changes and it seems it going to bring even more changes as time goes by.

One of the discoveries made through technology is quality management systems. Many organizations have realized the importance of producing quality products and have established quality management systems in their operations. This is a system that ensures that all the processes involved in the production of products are appropriate. It also makes sure that all customers (both internal and external) are contented by the products and services produced by an organization and that all their needs are fulfilled.

Coca Cola Company is one of the companies that have been using quality management systems for a long period of time. Since its inception in the late 19th century, its management has been aware of the need to produce quality product and this has contributed to its success. However, back then, it did not have a well defined quality system and it was difficult to maintain its quality standards. With the introducing of Total Quality Management, Coca-Cola Company has been able to keep pace with the changes in the market places by producing products which are not only of high quality but are environmental friendly. It has come to the realization that, a satisfied customer will always come back and will come along with friends thus facilitating growth. Focus is aimed at the requirements of the external customers by guaranteeing that all their needs are met. However, this does not mean that it has neglected its internal customers as they too are given proper consideration.

Some of the benefits that Coca-Cola has gained because of the adoption of TQM are a good reputation, strong brand name, high number of customer, and global recognition. Because of the production of high quality products, Coca-Cola has remained to be the largest manufacturers and distributor of soft drinks all over the world. Its brand is recognized in every part of the world and this has resulted in an increase in its sales volume. There is no single company that has been able to imitate its flavors although many companies have been trying to compete with it. TQM especially the adoption of ISO 9001:2000 as its excellence model has contributed to this success. This model ensures that the company complies with all rules and requirements at the same time meet the highest standards of quality.

Nevertheless, the company faced some problems in the implementation of TQM. Some of these problems are lack of awareness in benefits of QMS, lack of TQM exposure among workers, and lack of understanding of TQM. Another problem is inadequate monitoring of TQM and training. In order to ensure the success of implementation of ISO 9001:2000 QTM standard in the Coca-Cola Company, the management should endeavor towards being focused and systematic.

The recommendations to solve this problem are extracts of respondent’s opinions and established organization suggestions. The recommendations are to increase management effort, to train all organization management levels, to ensure proper documentation system is in-place, to increase the level of TQM understanding, to promote and monitor levels of management participation in training and monitoring programs and to provide guidance for ISO 9001:2001.

Works Cited

Ahire, Sanjay. L. Management Science- Total Quality Management interfaces: An integrative framework 27.6 (1997): 91-105. Print.

Anand, Gopesh;Ward, peter and Tatikonda, Mohan V. Role of explicit and tacit knowledge in six sigma projects: An empirical examination of differential project success. Journal of Operations Management 28.4 (2010): 303-315, 2010. Print.

Anon. Coca-Cola Products: New Coca-Cola Products, Brands of Beverages & More, 2008. Web.

Brecka, Joseph. Study finds that gains with ISO 9000 registration increase over time. Quality Progress.27.5 (1994):18-20. Print.

Coca-Cola. Product quality, 2011. Web.

Giebelhaus, August. “Coca-Cola Company”. The New Georgia Encyclopedia. Georgia Humanities Council, 2008. Web.

Goh, Kurosawa C. and Chng, Tin Seok. Internal Quality Qudit as a measure of effective implementation of ISO 9000 Quality Management System. Singapore: Singapore Institute of Management, 2000.

Gotzamani, Kennedy and Tsiotras, George. An empirical study of the ISO 9000 standards contribution towards total quality management. International Journal of Operations & Production Management 21.10 (2001):1326-1342. Print.

Kerzner, Harod. Project Management/ A system Approach to Planning, Scheduling and Controlling. New York: John Wiley and Sons, Inc, 2001. Print.

Lari, Antony. An Integrated Information System for Quality Management. Business Process Management 8.2 (2002):169-182. Print.

Likert, Rensis. “Motivational Approach to management development”. Harvard Business Review 37. 4 (2009): 75-82. Print.

O’Connor, Patrick. Total Quality Management. Quality & Reliability Engineering International 5.2: (2010): 183. Print.

Serpell, Alfredo. Integrating Quality Systems in Construction Projects: The Chilean Case. International Journal of Project Management 17.5 (1999): 317-322. Print.

Sirim, Berhad. Standard and Quality News. Quality Management Beyond ISO 9000, 12.5 (2005). 23. Print.

The Coca-Cola Company. Evolution 3 the Coca-cola Quality system, 2009. Keeping our promise, Quality pdf. 1.1. (2009). 1-16. Print.