Introduction

Business firms, in a bid to garner as much of the available market share and maximize their revenue streams, often tend to accord relatively less importance to the operations management aspect. Yet, it is through operations management that firms plan how to deliver a quality product or service to the end consumer. This is to the peril of the firm in question, as lack of timely delivery of an acceptable grade of quality would invariably influence the top line of the business. Further, in keeping with the tenets of continuous improvement, organizations are required to augment the efficiency of each of the business processes that they have in place (Jeston & Nelis, 2006).

This report seeks to re-establish this notion by using an empirical case of a retailing organization, TK Maxx, and the operational processes followed therein, linking the core competencies of the operations processes within the firm directly to its overall competitive strategy. The report also tries to identify ways in which TK Maxx can improve these processes to augment effectiveness and better the quality by lowering the avenues for manual errors.

Company Background

TK Maxx is a chain of retail stores that operates in the United Kingdom and Ireland among other countries in Europe. Operated by the TJX Europe group of companies, the retail chain was first known as TJ Maxx (Pederson, 2003) and the name was only changed to distinguish it from the less known discount retail chain of shops, TJ Hughes. The first TK Maxx outlet in the United Kingdom became operational in the year 1994 in Bristol, following soon after with further outlets across the UK, including locations such as Cardiff, Southampton, Hull, Reading, and London. Marshall’s chain of stores in the U.S. complements TK Maxx among the TJX parent group company (TK Maxx, 2011(www.tkmaxx.com)).

With over 250 outlets across Europe, TK Maxx is the tenth-largest fashion retailer in the United Kingdom (Plunkett, 2006). TK Maxx has changed its operational logistics in favor of the large store format, which has also led to the genesis of the Maxx Maxx store outlets across the United Kingdom including outlets at the Birmingham Bull Ring, Manchester Market Street, and Dundee and Cork. While the retailer is mainly a fashion reseller, it also specializes in selling other merchandise such as accessories, homewares, toys, and luggage. The company’s business model focuses on “off-price” retailing and offers premium branded products for as low as 60% less compared to high street prices.

Methodology

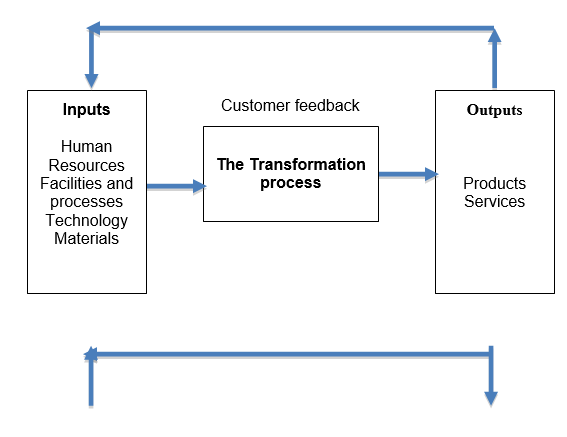

This report uses the input/output transformation model for operations management to analyze the existing processes of TK Maxx. Slack et al. (2007), states that all operations are processes that are employed to utilize a set of input resources, which are either transformed into something or used to transform something. Slack and Lewis (2001) use the same notion when defining operational and processes management.

The use of this model will provide the clarity of thought that is required when conducting an analysis of the existing process and the inadequacies observed therein, which in turn will point to the available options for improving the process and eliminating or mitigating the problems associated with it. A generic representation of the transformation model as adapted from Sanders and Reid (2005) is available in appendix 1 at the end of this report.

The next part of determining which of the available options represent the ideal recommended solution will be achieved through setting out upfront, the performance objectives expected from the retail chain to facilitate its overall strategy and reinforce its competitive strategy. This will also mandate a suitable prioritization of these objectives where there could be a potential conflict.

Competitive Advantage

Process analysis and design

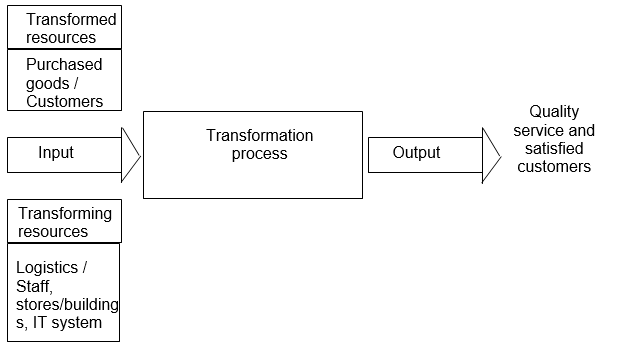

Appendix 2 shows the input-transformation-output model as applied to TK Maxx. The transformed resources are those that transform in some form (Pycraft, 2000). For TK Maxx, these include designer wears, accessories, and homewares that their customers purchase daily. A typical TK Maxx retail store holds a stock of close to fifty thousand items and receives approximately ten thousand new items weekly (TK Maxx, 2011).

Another transformed resource input component is the customer community itself. As they come to TK Maxx retail outlets with a need, overt or latent, they are transformed into satisfied customers whose needs are met by the goods they purchase. Transforming resources are those that act upon the transformed resources (Barnes, 2008). These include the procurement logistics, technology, i.e. the systems that are used by TK Maxx to carry out retailing activities, and the customer-facing and back-office staff who facilitate these individual processes. The transformation process involves converting goods and services into quality products that meet customer demands.

Through its procurement and retail philosophy that focuses on global sourcing of quality goods at discounted prices, TK Maxx can deliver a variety of quality products at low prices to its customers (TK Maxx, 2011).

Business strategy at TK Maxx

Strategic management involves two fundamental steps. The first is the formulation, whereby the company tries to understand where it will fit in tomorrow’s world and decides where it wants to be (Reading, 2003). The second is implementation by determining how the firm will deploy its resources within its business environment to satisfy its long-term goals (Reading, 2003). In the case of TK Maxx, the company has a long-term goal of expanding its market coverage in Europe to about 650-725 stores (TJX Company’s Inc, 2011). To achieve this, TK Maxx decided to extend its market coverage beyond the U.K and Ireland to other destinations such as Germany and Poland.

The company had plans of opening 48 new stores in the year 2010- 25 in Germany, 20 in the U.K. and Ireland, nd and three in Poland- to increase its market coverage of 263 stores by the end of 2009 (TJX Company’s Inc, 2011). Given the potential complexity of enlarged market coverage, TK Maxx is well aware of the need to re-evaluate its operational processes with regard to procurement and distribution channels to ensure efficiency and effectiveness in the process (Total Logistics).

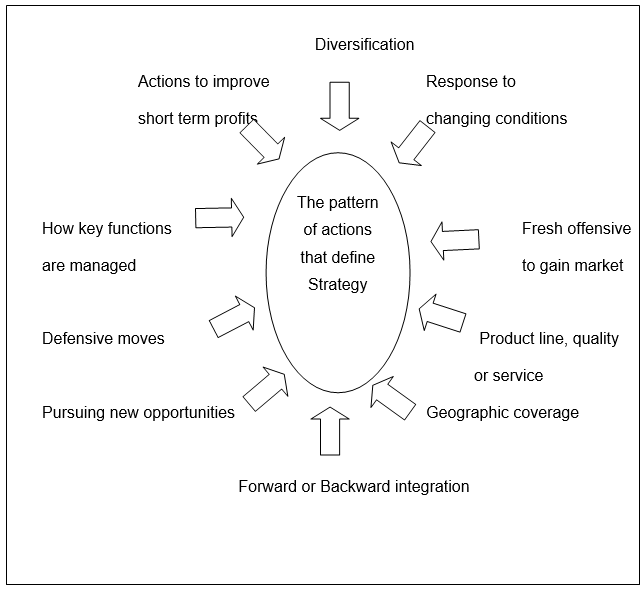

Appendix 4 illustrates the level of complexity involved in formulating and implementing the corporate strategy of an organization in the face of a dynamic business environment. The interplay of relative intensities of each element will vary according to the particular company under review. Further, the strategy in itself is not static but is an ever-evolving one as none of the elements remains constant in nature or extent of favorable or unfavorable disposition.

In the case of TK Maxx, the company employs a combination of diversification in its products range, expanded geographic coverage, opportunistic sourcing, satellite monitoring and management of key functions, fast response to demand changes, and a no-frills and off-price retailing model to run its business. All these strategies fit well in the company strategy model as illustrated in appendix 4.

At TK Maxx, the entire business focuses on bringing to the middle-class consumer, quality products from renowned brands at a fraction of the price that they would otherwise be available in the high street. In TK Maxx stores, goods from reputed brand houses such as Yves St Laurent, Chanel, Hugo Boss, and House of Dior are available at close to 60% lesser than high street prices (TK Maxx,2011).

TK Maxx’s procurement strategy focuses on opportunistic shopping that allows the company to source premium branded products at highly discounted prices. This ability to procure premium branded goods from resellers across the globe at bargain prices and pass on the benefit to the common person is the core business strategy of TK Maxx.

This is further reinforced by the ability of the retailing chain to ensure timely availability of the products that are in vogue to its customers when they need them by focusing more on its logistics and warehousing functions and less on the frills that other players offer by way of in-store displays and point-of-sale promotions. TK Maxx’s procurement logistics focus less on planning restrictions and deadlines and allows its buyers to procure products on both close to the season and need approach. Besides, TK Maxx’s business model emphasizes the daily delivery of volumes of different brands and labels to its chain stores, a strategy that ensures fresh stock every day.

Application of Porter’s ICA framework

One of the most generic and universally applicable theories on business strategy is the Porter Industry Competitive Advantage (ICA) framework, which identifies three main strategies that a company can adopt to build a competitive advantage over its peers within the industry (McCraw & Cruikshank, 1999). These are cost leadership, differentiation, and focus. TK Maxx uses a cost leadership strategy to achieve a competitive advantage over other competitors in the UK’s competitive market space.

This can be justified by the fact that TK Maxx adopts an “off-price” retail strategy that has allowed the company, over decades, to offer premium branded and vogue products to its customers for 60% less compared to high street prices offered by competitors in the market. TK Maxx is widely recognized among shoppers as the destination of low-priced premium branded clothes and accessories. Since its launch in 1994, TK Maxx has tremendously grown to its current market coverage of 253 stores in the UK and Ireland, of which 237 stores are located in the U. K (TK Maxx press center).

According to Plunkett (2006), TK Maxx is the tenth-largest fashion retailer in the United Kingdom. All these are evidence enough to prove that TK Maxx’s cost leadership strategy has worked well towards its success as an off-price retailer in the United Kingdom. Firms that employ the differentiation strategy attempt to make their service offerings perceptibly different from other competitors. This is done in such a way that they are perceived to be better than other offerings along with certain attributes that are critical to the target segment, hence enticing consumers to choose the firm’s specific services over other competitors even at the cost of a premium being paid for these services over others (Williams, 2004).

Finally, instead of reaching out to the mass market, the firms that adopt the focus strategy try and align all attributes of their services offerings to the preferences and likings of a selected set of target customers, to maximize the percentage of this segment that patronize them by using their services.

Operations Strategy

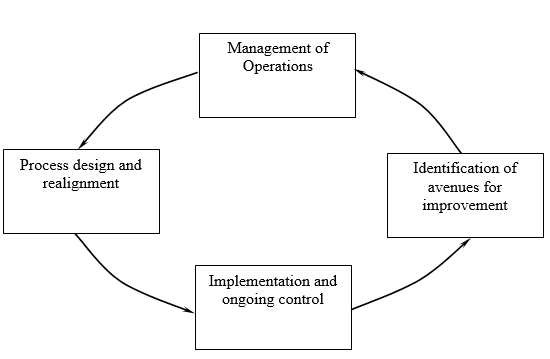

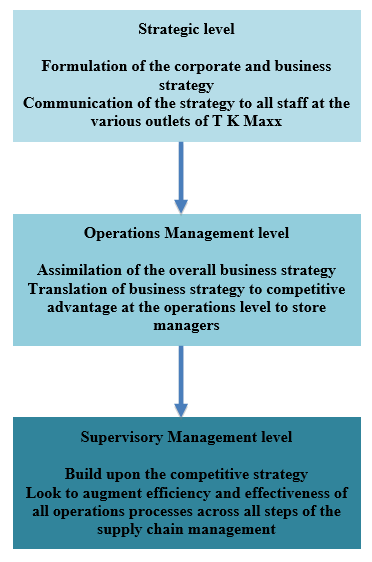

The transformation cycle illustrated in appendix 3 outlines the various considerations at play at the three different levels of the retailing chain. As an organization, TK Maxx tries to align its operational processes to further enhance its overall competitive advantage and reassert its strategic positioning as a firm that procures goods at cheap prices from big-brand companies and passes on the cost advantage to its customers.

The continual expansion of TK Maxx’s market coverage justifies the need to align its operational processes to handle the complexities of a broader supply chain. A case study report prepared by Total Logistics shows that TK Maxx is well aware of the complexity that its enlarged market coverage is likely to bring in its distribution channel. TK Maxx’s awareness of the need to align its operational process management is summarized in Alan Porte’s, TK Maxx senior vice president of distribution services, briefings to Total Logistics. He said, “…the consumer price point is critically important to our success and we needed to explore precisely how we could optimize the supply chain to enhance our competitiveness and efficiency edge” (Total Logistics).

Having given this analysis, the next section of this report conducts a detailed critical assessment of various facets of operations and process management at TK Maxx and makes recommendations to further improve these processes and contribute to the attainment of organizational objectives.

Assessment of performance against core competencies

Supply network design

Theory on supply chain management suggests that the performance of a network of suppliers employed by a firm should be as effective as the active management of the chain by the firm. Appendix 5 represents Vinas’ analytical model on channel performance criteria.

The main areas that TK Maxx focuses on, within the marketing mix, as part of its operations are its pricing and distribution strategy. The products themselves are the top echelon brands that sell for themselves at TK Maxx outlets so long as they are available promptly (distribution) and are perceived as offering value (price). The timely availability of goods is organized by TK Maxx right from the procurement phase of its supply chain with its buyers being given maximum autonomy to make purchasing decisions on behalf of the firm so that bureaucracy does not delay the availability of goods when there is pent up demand in the market (TK Maxx, 2011).

This is especially relevant in the fashion industry, which is dominated by fads and trends. Further, by spending less on store displays, advertising and promotion, the firm also ensures that maximum cost advantage is passed on to the end consumer, further offering value to the retail shopper visiting their premises (TK Maxx, 2011 (TK Maxx, 2011).

Supply chain and inventory management

A plethora of tools for business strategy is now available to managers at all echelons within the corporate world to aid the organizational decision-making process, aligning it with its core objectives. A number of these tools focus on the operational aspects of business, rather than the strategic level, while at the same time orienting the performance of the ground level processes in tune with strategic objectives of the organization.

TK Maxx takes several operational measures such as in-time procurement and distribution of stock to render reliability and stability of the supply chain, which represents another critical component of the Vinas model as depicted in appendix 5. Being a reseller of goods, TK Maxx operational management exercises maximum adequate control over supplies and takes corrective action when the first signs of slackening or slippage on the part of the suppliers are apparent. The firm undertakes satellite monitoring of its operations that can link the head office, the procurement and distribution channels, and stores instantaneously hence the ability to detect faults faster (Total Logistics).

This section describes several steps taken by TK Maxx and the underlying academic concepts that these steps can be mapped back to from the perspective of overall supply chain management (SCM).

Just-In-Time procuring and onward supply to outlets

This is an approach to operations management used by TK Maxx on an ongoing basis. This approach was first considered revolutionary but has increased in popularity over the past two decades. Using this approach to manage their flow of goods and their supply chain as a whole, goods and accessories are supplied at the TK Maxx central warehouse and from thereon to its respective outlets across the United Kingdom exactly when they are required as inputs at any stage of the assembly line. TK Maxx’s business model focuses on short procurement lead times, i.e. goods are made available at retail stores the same week they are sourced.

The company’s fast processing and onward distribution of new stock policy allow for ultra-short procurement time leads. This has the effect of eliminating both the extremities of cost and risk arising from the high inventory pile-ups and associated costs on the one hand, and the opportunity loss and lack of adequate supplies of goods in demand on account of these supplies not being available on the other hand.

The last of these points are most relevant to the fashion industry in which TK Maxx operates. If a customer comes to one of their outlets looking for a particular branded apparel and does not find it in stock, he is certain to find it in another store, possibly paying a premium for the product instead of waiting for its arrival, lest it goes out of vogue. Same week delivery of new stock ensures that new fashion brands arrive in time and customers are sure of finding what they want or placing an order and waiting for a short time for the delivery of the product.

On the other hand, this approach also allows for a much more coordinated way in which T K Maxx can go about its capacity planning at its warehouse and various store locations and the management of its resources by way of storage and logistics personnel. Here, the performance is measured in terms of the waiting times undergone by goods for prospective buyers coming in to buy them at the stores and orders coming through for goods to be dispatched from the central warehouse to the store outlets, and the other way round, i.e. the waiting time a customer undergoes for a particular brand of goods.

A Partnering approach

Buyers within the procurement department at TK Maxx are given maximum latitude over the decisions concerning buying fresh consignments of goods from any of the hundreds of suppliers that TK Maxx has across the globe. The company’s procurement process is free of planning restrictions and deadlines hence allowing its buyers to take advantage of fantastic deals whenever they come across them (Total Logistics).

This explains why TK Maxx buyers sometimes source for downturn goods so long as the deal is fantastic. This approach to procurement at TK Maxx is responsible for the company’s major successes as a retailing firm. Besides, the procurement process at TK Maxx allows for a direct relationship between the company’s procurement team and suppliers. Buyers enjoy a strong and mutually trusting relationship with their suppliers because of the far-reaching roles and responsibilities of the procurement personnel.

The company’s procurement strategy as illustrated in its corporate social responsibility demands that buyers interact directly with suppliers so that they can inform them of any changes in procurement requirements upfront (TK Maxx, 2011). These changes could mainly be because of changes observed at retail outlets in fashion trends and fed back to the procurement department.

Recommendations for improvement

One of the main areas where T.K Maxx is relatively under-equipped is that of quality assurance of the products that it sells to the end consumer. The firm’s in-store arrangement is in such a way that there is no proper organization and goods are piled up hence quality is compromised. The strategic inclination of the retailing firm is to offer value to customers on premium brands of fashion products and accessories by pricing them reasonably and making them affordable. Given that the quality of the product is an inseparable part of what represents value to the customer, it is important to emphasize the quality of the product that leaves TK Maxx’s stores and the service offered within its shop premises.

This section makes some specific recommendations that TK Maxx can put in place within its operations to ensure that the quality of every product sold at its outlets is defect-free as is every aspect of the customer service offered by the staff at the establishment.

Total Quality Management

What some of the concepts and views above encapsulate is the QA approach and set of tools that are represented by Total Quality Management (TQM). Johri (2005) defines TQM as a cooperative form of doing business that emphasizes teamwork between labor and management and uses their talent capabilities to improve quality and productivity continuously. The emphasis here is on making quality everybody’s responsibility and ensuring that every activity and business process is undertaken with the underlying knowledge that defects were not admissible to any degree. Hence, this marks a shift in focus from defect correction to defect prevention on an ongoing basis until the point in time when the organization as a whole manages to achieve a state of zero-defect tolerance.

TK Maxx’s business model demands efficiency from its suppliers and distribution outlets. From Total Logistics’ case study report on TK Maxx, there is some evidence of quality assurance measures especially in the procurement network to check on the quality of products sourced (Total Logistic), but there is still a need for a comprehensive quality assurance approach that also includes quality assurance inside retail stores. The off-price retail strategy should not compromise the quality of products consumers shop at retail stores.

Benchmarking

In the context of retail customer-facing operations such as TK Maxx, one of the most effective ways of conducting a benchmarking exercise for the products that arrive from suppliers is through according a high level of importance to the quality of products. Benchmarking is the continuous process of measuring products, services, and practices against the toughest competitors or those companies known as industry leaders (Viswanadham, 2000).

TK Maxx can achieve this by setting achievable quality targets for its suppliers as well as ensuring a certain degree of quality on its products at outlet stores. TK Maxx should also employ an outside-in perspective that allows it to compare its products and services with those of competitors in the market. The company can make use of available market survey reports from credible sources such as Verdict Research to evaluate its performance against that of the competitors in the market.

Even though TK Maxx carries out periodic audits of service levels at its retail stores in a bid to ensure efficiency, there is a need for an elaborate audit that also focuses on the quality of products. This information including customer feedback should be made available to service staff to complete a cyclic loop of continuous improvement as illustrated in appendix 3.

Summary

As has been explained in the earlier part of this report, TK Maxx is a renowned off-price retailer that makes premium brands accessible to middle-class shoppers. TK Maxx achieves this through a combination of a comprehensive supply chain network, a robust procurement team that operates with complete autonomy, and the incorporation of contemporary concepts throughout all steps in its supply chain management such as JIT and lean operations.

All these operations and processes in effect contribute to the underlying business strategy of the TK Maxx, which emphasizes cost leadership and offers value to the end consumer. However, one of the areas where TK Maxx needs to step up its measures from an operations and process management perspective is in the quality of products that it sells at its outlets and the ancillary services that it provides through its in-store personnel to its shoppers.

More focus should also be on product branding given the fact that the firm’s brand stores, like Maxx footwear departments, are among the best market performers in the United Kingdom. Not only will this have the effect of increasing the footfalls into TK Maxx stores, but it will also go a long way in retaining existing shoppers, both of which are in keeping with the cost leadership strategy of the firm.

Appendix 1 – Generic Transformation Model Diagram

Appendix 2- Input/ Output Transformation Model as Applied in T.K Maxx

Appendix 3 – The Transformation cycle

Appendix 4- Understanding Company Strategy: What to look for

Appendix 5- Vinas’ analytical model on channel performance criteria

Appendix 6 – Operations Management within the functional hierarchy

References

Barnes, D., 2008. Operations management: an international perspective. London: Cengage Learning EMEA.

Jeston, J. and Nelis, J., 2006. Business process management: practical guidelines to successful implementations. Oxford, U.K: Butterworth-Heinemann.

Johri, P. K., 2005. Encyclopedia of Tourism in 21st Century. New Delhi: Anmol Publications.

Marketing Planet. Distribution channels performance and brand image influence. Marketing Planet. Web.

McCraw, T. K. and Cruikshank, J. L., 1999. The Intellectual Venture Capitalist. Boston: Harvard Business School Press.

Pederson, J. P., 2003. International directory of company histories. Michigan, U.S: St. James Press.

Plunkett, J. W., 2006. ‘Plunkett’s apparel and textiles industry almanac 2006.’ Houston, U.S.: Plunkett Research Limited.

Pycraft, M., 2000. Operations management. Johannesburg: Pearson.

Reading, C., 2003. Strategic Business Planning. London: Kogan Page.

Sanders N. R. and Reid R. D., 2005. Operations Management. New Jersey: Wiley Publishing Company.

Slack, N. and Lewis, M. 2001. Operations Strategy. New Jersey: Pearson Education.

Slack, N., Chambers, S. and Johnston, R., 2007. Operations Management, 5th edition. New Jersey: FT/ Prentice Hall.

TJX Companies Inc., 2011. Our Business: TK Maxx. TJX Companies Incorporation. Web.

TK Maxx Press Centre. About TK Maxx: Useful Information. Web.

Total Logistics. ‘Total Logistics takes it to the max- for TK Maxx.’ Web.

Viswanadham, N., 2000. ‘Analysis of manufacturing enterprises: an approach to leveraging value delivery processes for competitive advantage’. New York: Springer Publications.

Williams, C., 2004. Management with Infotrac. Mason, Ohio: Thomson Southwestern.

TK Maxx, 2011. TK Maxx. London. Web.