Executive Summary

The purpose of this report is to evaluate the potential outline technologies that are available for energy storage in the domestic sector. To help our company to select the prospective product, it also pinpoints various advantages and disadvantages of the technologies to provide a rich framework for the development and supply of new energy storage devices in the United Kingdom. The report also explores how energy is consumed in the domestic sector by showing various percentages of electricity that are used for different applications. The scope of the project will cover the design, manufacturing, and distribution of embedded, flywheel, chemical, and pumped energy storage technologies.

The final decision is to deliver a cost-effective product for domestic energy storage. Furthermore, the report outlines the process that is involved in the evaluation of feasible opportunities that can drive the company towards success. Various stage-gate processes will guide the achievement of the project by guaranteeing the development and fabrication of quality products. It also covers the SWOT analysis for the product that will guide the determination of feasible markets. Since the report describes a new product, it explores aspects of research and development that will determine the competitiveness of the product. Finally, yet importantly, the steps and time of development are detailed using a table and a Gantt chart to provide a guideline towards the realization of the project’s objectives.

Competitive Product Development

Introduction

Commissioned by the board of our company, I present this project report to introduce a means to develop and supply an energy storage device. The report aims at reviewing various issues that affect the demand and supply of electricity and energy storage devices. The broad objective of the report is to analyze the different types of energy storage devices in the UK market to select a suitable one for our company. It provides insight into designing, manufacturing, and distributing energy-saving products that meet the demands of electricity consumers. Many consumers are concerned with reducing energy costs by adopting appliances that consume fewer units. Therefore, the report proposes a plan to manufacture appliances that can store energy for later use successfully with the minimal energy consumption during the process.

Background to Energy Storage Technology Systems

Numerous researches show that the UK’s domestic energy usage has been largely dependent on location, construction of buildings and their designs, specifications of heating systems, appliances, dwelling size, climate, and behavior of consumers. A change in the behavior of consumers has been noted to reduce the overall cost of consumption of energy by about 30-percent. The energy conservation adoption is primarily influenced by the income of the consumer. The domestic utilization of energy in the UK is focused on heating, cooling, heating water, providing power to appliances, entertainment, and cooking (Rodica et al. 2010). This situation offers our company a broad portfolio of products that can be manufactured. The report reveals that the increased availability of power at the household level has compelled companies to design, produce, and distribute the most efficient consumption electrical appliances that are more appealing to the consumers. The current trend that consumers tend to apply is the storage of electricity to ensure that they balance the supply and demand. The electricity used by consumers is usually converted into other forms for easy storage (Rodica et al. 2010). The following section explains the various domestic energy applications in the UK.

Energy Usage for Various Applications in the Domestic Environment of UK

The reason for developing energy-saving appliances is to reduce the cost of electricity amongst domestic consumers in the United Kingdom. Domestic energy consumption in Europe had increased by 2004. The UK Energy Research Centre (2007) confirmed that the energy was used for space heating, domestic hot water systems, lighting, cooking, and running appliances. These applications accounted for about 30.23-percent of the total energy consumption in the UK. London City recorded the highest amount of consumed power, approximately 37-percent.

The domestic consumption of electricity in the UK has been increasing for the last 4 decades with the source of electricity dominating the pack due to amplified usage of appliances. Various factors that have immensely contributed to increased domestic consumption include amplified use of domestic appliances and light fittings. According to a report that was released in 2004, space heating accounted for 60.51 percent, water heating 23.60 percent, appliances and lighting 13.15 percent, and cooking 2.74 percent (see table 1) (UK Energy Research Centre 2007). 47-percent of the energy that is used in the UK is derived from oil-based products, 32-percent from natural gas, and 18-percent from electricity. The rest only contributes about 3-percent of the energy sources. Both water and space heating contribute over 80% of the overall domestic energy consumption (see chart 1).

Table 1: Showing the percentage consumption of energy by end-users in the year 2004.

The above information justified that the UK domestic consumption of energy was mainly for space heating in 2004. It justified a significant increase in the cost of fuel (Abram 2006).

Embedded Energy Storage Technology

Electricity is hard to store. However, embedded energy storage technology can be used to convert electricity into other forms for future use. One of the ways through which electric energy can be stored is by converting it to thermal energy (Nordell & Hellström 2000). The off-peak energy can be used for warming purposes in water heaters. This technology reduces electricity consumption costs, especially during peak times. The embedded energy storage technology allows the usage of electric storage heaters, heat pumps, and domestic hot water among others (Hasnain 1998; Lefteri 2006). This system can be used in homes to heat water during the cold weather. Heat pumps that utilize this technique can be used to heat water or warm rooms when modified or installed within the walls of the rooms.

Electrical Storage Heater and Heat Pumps

Electrical storage heaters are home appliances that can store thermal energy at night to keep the cost of electricity minimal. The appliance can also release heat energy during the day when needed by the consumer, especially in cold weather. The heat energy is stored in bricks or ceramics that are located within the appliance. Water in a storage tank can also be used to store heat (Sharma et al. 2009). In our prospective company, we will use pumps to deliver heat at lower temperatures and then release it at high temperatures in the water tanks (Benyus 1997). These pumps will be designed to release heat three times for every unit of electricity consumed. They can be used to save electric energy in homes (Medrano et al. 2010).

Reasons for choosing Embedded Energy Storage Technology

The benefits of embedded energy storage technology include reduction of expenses on electrical purchases at the retail level (Wood & Newborough 2003). Besides, the usage of ice-point machines and other gadgets is currently on the rise due to the development of embedded energy storage technology. Another advantage is the increased use of renewable energy sources such as windmills and solar panels due to the need to possess private energy-saving technology at the domestic level (Kelley & Littman 2001). Therefore, embedded storage energy technology ensures the efficiency and utilization of such techniques. Another advantage is that the systems are secure since they are installed in homes; they cannot be hacked. Lastly, there is increased reliability of power due to more storage grids and other gadgets. This grid helps in reducing fluctuations (Brownell 2010).

Challenges of Embedded Energy Storage Technology

One of the drawbacks of embedded energy is the consumption of extra power during the development and fabrication of electrical storage heaters and heat pumps. The initial cost of installation and maintenance fees can be relatively high, especially where large-scale usage is required (Kelley & Littman 2001). For instance, the electrical storage heater and heat pumps are considerably expensive to both install and maintain since they entail sophisticated technology. Numerous studies have revealed that most consumers cannot meet the initial costs of installation. The design also depends on the type of building where it will be installed. As a result, most consumers cannot meet the cost of ordering customized designs to meet their requirements. Our prospective company will be geared towards the development of technologies that will reduce material costs by ensuring high-level production efficiency. The following section discusses the various methods that are currently used for energy storage.

Inter-seasonal Thermal Storage

Most companies are currently manufacturing seasonal thermal energy storage (STES) devices to meet the demands of consumers in the UK. For instance, air conditioning technology is used for cooling purposes. Thermal storage is also used in some refrigerators for the preservation of drinks and food. Such technology ensures that more energy is stored in less space. Rodica et al. (2010) report that the method is cheaper since it conserves fuel that can otherwise be used in cells or flywheels to tap wind energy. This technology ensures that ice is made during the night hours when electricity costs have reduced. The ice is then used for cooling the air during the day or hot periods (Rodica et al. 2010).

Energy Storage Technology in Chemical Fuels

The energy that is obtained from Gasoline, diesel, natural gas, petroleum, ethanol, and biodiesel can be stored in the form of fuel. Mechanical engines are used to convert the above forms of fuel into electrical energy through heat engines to be used in homes. However, evidence indicates that energy storage technology is disadvantageous due to the production of hydrocarbons that lead to the emission of greenhouse gases that cause global warming and pollution (Rodica et al. 2010). Furthermore, the use of chemical fuels is expensive.

Pumped-Storage Hydroelectricity

This kind of storage entails the accumulation of water in reservoirs when electricity demand is low. When its demand increases, the water is used to turn turbines that generate more electricity to meet both commercial and domestic needs. Such plants then provide electrical energy on daily, weekly, or seasons depending on the capacity (Rodica et al. 2010). However, grid integration challenges and the accompanying initial cost of infrastructure development led to the rejection of pumped-storage hydropower.

Flywheel Energy Storage

This type of energy storage accelerates a rotor at a very high speed. Electrical power is maintained in the form of rotational energy. However, the report reveals that the functionality of the system depends on a constant electricity supply (Cooper 2001). This system is considered due to its long life features. Nonetheless, various reasons such as expensiveness and consumption of many units of electricity to rotate rotors rendered the flywheel energy storage inapplicable based on the scope of the project (Rodica et al. 2010).

The above analysis reveals that the best way that a consumer can adopt to save energy is the application of embedded energy storage systems since they are more secure and affordable as compared to STES which requires the use of fuel from natural gas (Kelley & Littman 2001). The above analysis reveals that embedded energy storage systems are more competitive than other technologies since they conform to the scope and objectives of the project.

Structure of Competitive Product Development Plan

The development of the embedded energy storage appliances will require proper planning and knowledge about the prevailing consumer behavior in the UK market (Thompson 2007; Trott 2008). The product plan under development is for a new energy-saving pump that works with low electric power to generate heat at higher temperatures. The heat energy will be used to warm water for domestic purposes. The following stage-gate processes will be implemented to ensure the successful development of the prospective product.

Stage-Gate Plan for Developing the Project Plan

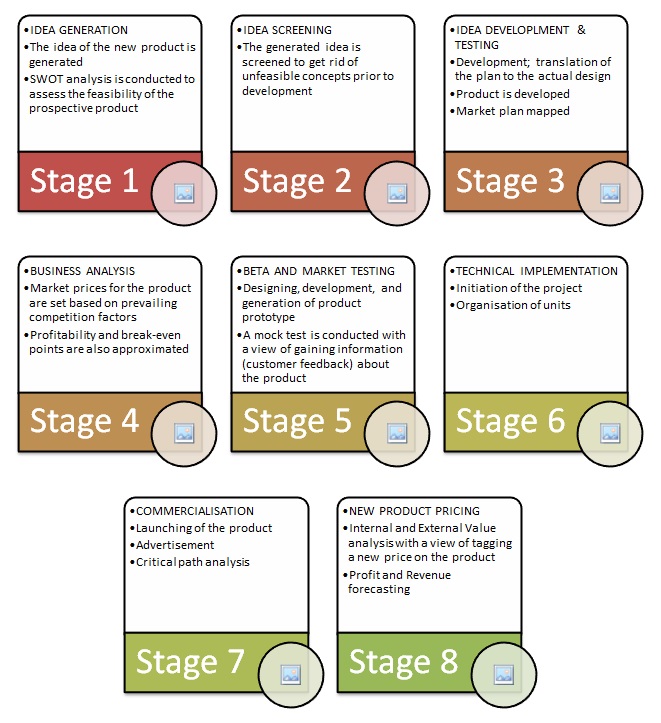

Various tasks that will be involved in the development of the new product include conception, development, production, and launch in the market. A stage-gate system will be implemented in the product development process in the company as follows (see Figure 1 below):

The gates contain deliverables that must be combined with the particular criterion to ensure the generation of quality outputs (Ulrich 2003; Runeson 2005). The CEO, departmental heads, and the product development manager will take charge of gate 1 to ensure the proper transition of the idea to the next level. The CEO and the development manager will lead the prospective company to access the feasibility of the product in stage 2. The CEO, product development and marketing managers will monitor the rest of the gates 3, 4, and 5 to ensure that the plan is implemented and market plans are established. They will also ensure testing and validation of the product at stage 4 before it is launched for commercial purposes.

Generation of the Idea (Stage 1)

A meeting will be organized whereby employees from the product development, marketing, and engineering departments. The marketing manager will ensure the development of effective interactions with the customers. An online survey will be conducted to investigate the perceptions of the consumers regarding the new product. Information concerning the strengths and weaknesses of the existing products will be obtained from the feedback of consumers to determine the appropriateness of introducing fresh merchandise in the market. Various issues that will be considered under this section include market research to identify current trends, competitors’ information on their success, and failures.

SWOT Analysis of the Product

Strengths

At the outset, the product will be sold directly to the consumers. Secondly, the cost of the product will be kept below the competitors’ pricing. Besides, the product will have high responsiveness to consumer demands (Davila, Epstein, & Shelton 2012).

Weaknesses

Various weaknesses that were realized include a high workload that can lead to overworking. There is also high stock in the inventory and the likelihood of adopting updated research methods to market the product (Gassmann & Von 1999). Also, the existence of competing energy products in the market is likely to present customers with alternative devices. This situation will probably result in slower sales volumes than expected. The time of market entry is also another challenge that can lead to unbecoming decisions on product delivery. This set of circumstances can bring about unexpected losses to the company before it seizes an adequate market for the product (Gassmann & Von 1999).

Opportunities

The opportunities in place for the prospective product include the availability of one-stop shopping consumers. The customers’ knowledge about the product is also on the increase due to the need to possess energy-saving appliances. Abundant internet was also another opportunity that was identified. Online platforms will be used to market the product with a view of developing a broad customer base. Also, a feasible development of strong relationships amongst the organization, customers, and retailers is likely to strengthen the brand of the product (Brownell 2010).

Threats

However, the market has similar products that can limit sales volume. This situation requires the prospective company to design unique products that will attract customers in terms of both price and quality. Too much loyalty of customers to competitors and high demand for similar products is also a threat. Besides, a recent survey also indicated that rival companies have plans to launch new embedded energy storage devices. As a result, our company will have to use the most recent product development technology and expert personnel to ensure delivery of outstanding embedded energy products (Brownell 2010).

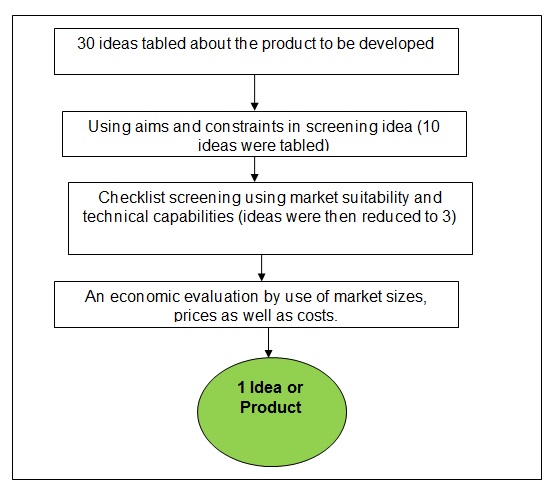

Idea Screening (Stage 2)

Factors to be considered when doing screening

The aims and barriers to the project will guide the screening stage. The constraints that will be considered include financial capability and national business regulations. Factors such as the market size, compatibility with the range of product line and market image, channels, and the existence of similar embedded energy products should be taken into account during the screening process. There is also a need to evaluate the existing distribution systems, promotional techniques, and market resources for water and heat pumps (Brown 2014). Other factors that will be analyzed include the cost of production, legal requirements, and availability of skills. Production time, accessibility to raw materials and equipment that will be needed to manufacture the product will also be assessed (Lewis et al. 2001). There is also a need to determine the risks that can lead to possible failures. The relationship between the available financial resources and feasible production costs will be determined based on the invested capital with a view of initiating a successful project (Lewis et al. 2001).

Idea Development & Testing (Stage 3)

This stage (see figure 1) is primarily concerned with the development of marketing and engineering frameworks. The company will choose a panel of decision-makers who will provide the organization with information about the purchasing processes. They will also seek the feasibility of the targeted market for the product. In this stage, the idea developers will determine the processes of production and their accompanying costs.

Besides, there is significant documentation of intellectual property and patent details for the new product. The organization will patent its innovativeness, designs, names, logo, and images among other items that will be meant for commerce with the UK regulations to protect intellectual property. This situation will prevent copyright infringement.

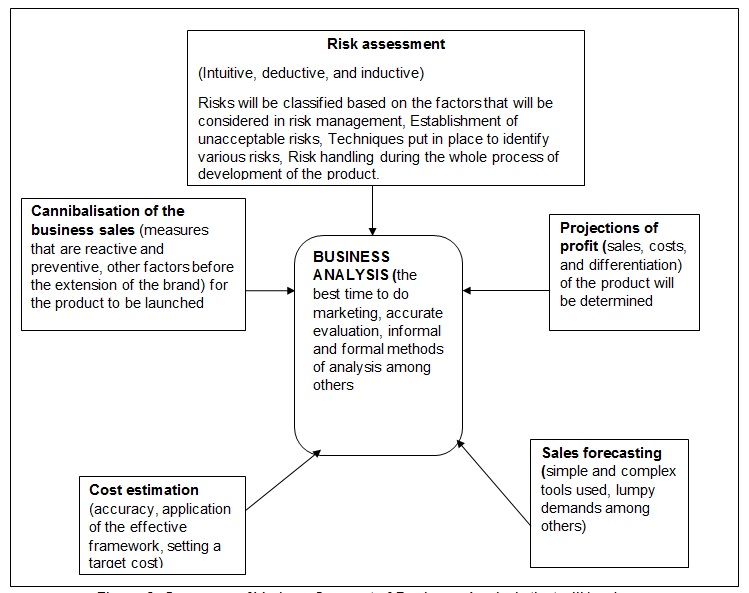

Business Analysis (Stage 4)

Various assessments that will be conducted by the inter-departmental management include business market prospects such as competitiveness and economic features among others.

Competitive Analysis of the Company

The plan entails the following information concerning the company’s position in a competing market (see table 2).

The economic features of the company that will enable the product to perform well in the UK market

Table 2: A summary of the economic features of the company is presented in the following table.

Competitive Position of the Company

The company’s success factors will be planned as follows to determine its position in the competitive UK market. In terms of technological advancement, the company has a highly-skilled workforce that has to invent new products. The personnel is conversant with research techniques on the technical capacity of the equipment. The placement of employees will be based on the tasks that will be assigned to them (McDonough & Braungart 2010). The production expertise will ensure that efficiency, low-cost production, and quality are ensured in the course of the business operations. Experts in the distribution department will ensure that the company has a stable network of wholesale dealers and distributors using the internet. Sufficient outlet retail entities will be established. These activities will be governed by cost reduction and quick delivery (McDonough & Braungart 2010).

A plan to strengthen the marketing system of the company will be ensured through the inclusion of competitive staff with a view of offering quick service delivery using high-level merchandising skills. Quality advertisement and issuance of warranties to customers will be given priority in the company (McDonough & Braungart 2010). However, management of the above strategies will demand a proper channel of communication that will link the units of the organization.

Market Testing (Building the Business Case; Stage 5)

Product description

Product description will comprise information about the product, its uses, and target market segments. It will also relate the new products with existing ones to keep the customers aware of the prevailing competition gap (Thackara 2006). The description will be broad-based to cover issues regarding technology, the market, and the business idea in detail. The details will be narrowed down to the idea concept, then to the product concept, and design specifications (Thackara 2006). After collection of the relevant information, an inter-departmental heads meeting will be conducted by the top management to pave way for the next stage.

Concept Development and Testing

The product development department in collaboration with the engineering and marketing managers will perform a procedural refinement of a business idea to make it acceptable in the market setup. This state of affairs will ensure that the product under development increases its chances to perform well in the market. Concept development provides clarity of communication uses, packaging, advertising, and approaches to sales. It also specifies information on products, distribution, and pricing strategies. Testing a concept improves the prediction of the success of the new idea before introducing it to the market. It encourages the reactions and ideas of consumers (Fuad-Luke 2002).

In the context of the business case presented in this paper, more information will be gathered about the product (heat pump) by various departmental heads from the engineering and product development units.

Objectives of the concept development that will be considered are listed below.

- To determine how the concept can be turned into a product.

- To obtain an initial product for evaluation.

- To understand the factors affecting product attributes.

- To screen all items and their formulations to make the product.

- To assess packaging and storage needs.

Concept Testing

The product development department will share the idea with the top management and other units. This strategy will boost the verification of the idea. Issues of warranty, the convenience of use, information about the product, and customer feedback among others will be considered in detail (Wheelwright 2010). Customers who have developed their loyalty in the premise will be allowed to reveal their perceptions of the idea and testing. A clear understanding of the concept by the consumer is paramount to the successful presentation of the business opportunity. Other activities that will be accomplished include a screening of the items and formulations and assessing the processes required during the production of the initial product. Understanding of the product attributes, and assessing packaging and storage techniques will also be taken into account (Wheelwright 2010). The testing techniques that will be implemented include concept reaction and adoption checks. This situation will ensure the identification of the benefits of the product that the customers value most. These features will be regarded as ‘needs to have’ for customers (Wheelwright 2010)

Technical Implementation (Stage 6)

The relevant designs and manufacturing methods will be considered. The product prototype will then be modified through various stages and designs. Finally, a finished product that will suit the consumer needs will be realized (Kim & Wilemon 2007). The product will then be tested in the presence of the management, selected employees, and consumers before proper packaging.

A smaller percentage of consumers will be invited to use the product as a test before its actual launching to the market. Methods that will be implemented in the testing of the product are explained below.

Running the Product in the Plant Location

A plant’s trial module is accomplished before the launch of a new product. It also conducted when there is a need to conduct consumer testing. The management will borrow techniques for the development of the product (heat pump). The plant location is within the UK market segment. The engineering and product development manager in the organization will conduct the activities.

Steps in Running the Product in the Plant

The objectives will be identified first since they are used to guide the product development department in the trial operations. During the inter-departmental meetings, a trial plan will be determined by classifying the items and equipment that will be used in the project. There is also a need to elaborate on how the work will be coordinated among the departments to realize the workability of the product (Bruiyan & Nadia 2011). The plant trial will also be scheduled during the meeting. Employees will be required to attend the testing and trial of the product. The evaluation process of the product will entail the connection of the pump to an electric energy source. Next, it will be switched on to pump heat into a water tank. The heat produced is supposed to be used to warm some water in a tank. The factors to be considered during the product trial include short runs, over control, and product disposition, which includes scrap, rework and selling of the product (Smith & Reinertsen 1991). The engineering and product development managers in the organization will conduct the activities.

Employee Testing

Employee testing will be conducted during and after running the product. The project manager will ensure that procedures for the production operations are followed appropriately (Koen et al. 2001).

Consumer Guidance Testing

Consumer guidance testing determines how to improve new products before market research. This process will be undertaken for the heat pump. It will aid further development and identification of the areas needed for improvement. Our target consumers will be the UK population. The project will cover a vast category of consumers with differences in behaviors. The product qualities will be graded using the leaker’s scale (Sawhney, Verona, & Prandelli 2005). The product development manager who will collaborate with the marketing manager will conduct the activities.

Commercialization and Launching (Stage 7)

After testing the product, the final decision on how the product should be launched in the market will be made by the management. The marketing experts in consultation with the top management and product development manager will also determine the pricing processes. The sales and marketing teams will be briefed on how the product should be launched by the marketing manager within two months before the official launching day (Kenneth 2013). The management will ensure that a detailed procedure is used to guarantee a greater impact on the market. The product will be launched at the right time and place to ensure maximum capture of the consumers (Krishna & Ulrich 2001). The manager will organize roadshows for one month for a teaser campaign before launching to advertise the product within the UK market. Posters and flyers that include the information about the product such as ‘coming soon’ pages, ‘how to use it’, and the day of launching will also be distributed to the public by employees and during the roadshows.

Other aspects that will be considered before the execution of the product include assessment of similar products in the market, modeling process, market segmentation and development, existing opportunities, regulatory limitations, competition gap, and acceptability or rejection of the product (Van Trijp & Steenkamp 2005). The marketing manager in collaboration with the product development manager will conduct these within four months.

New Product Pricing

Business analysis will be conducted further to determine the profitability of the idea to the organization or losses that will be incurred with a view of establishing a new price for the product (see figure 1). Other factors that should be considered during the analysis include environmental factors and regulations that govern the business environment. This practice will ensure adherence to corporate social responsibility (Wong & Tong 2012; Sethi 1979). Various costs that will be analyzed include expected costs of development, R&D marketing, and technical situations. Production, equipment replacement, and distribution expenses costs that will affect the economies of scale will be evaluated. There will be a need to assess promotional, distribution, and management costs among others to determine the financial ability of the prospective venture. Other issues that will be considered during the analysis are competition, customer feedback, sales volumes, profitability, and break-even points (Fleisher & Bensoussan 2007). All the departmental heads chaired by the marketing manager will conduct these activities.

Sales forecasting

Aspects that will be agreed upon by the management of various departments concerning sales forecasting include feasible market share and demand estimations among others. The activity will be conducted under the supervision of the marketing department. Profit feasibility will be realized through the evaluation of various success factors, revenue generation, and operational costs among others. The marketing manager will play a crucial role in the realization of this objective.

Risks Assessment

Various risks that exist in the business environment will be identified as internal, external, high, low, and/or future risks. The marketing manager will accomplish risk assessment to ensure the protection of the product against uncertainty.

Estimation of Costs

Various stages will be involved in cost analysis. The first phase will entail designing. This phase will ensure that quality is factored into the development of the new product (Bose 2008). Secondly, the planning stage will provide a summary of the objectives to be implemented in the process, scheduling, and communication channels among others. The third stage will constitute cost identification through description, estimation, quantification, and costing methods. Cost allocation, estimation, and analysis will be accomplished at this stage (Bose 2008).

The following table shows the steps and time of development and contact persons who will be involved in the project.

Table 2: showing steps and time of development and the contact persons.

The following Gantt chart provides a summary of the events of product development and the duration of the prospective project.

Conclusion

The report has highlighted various techniques that are involved in the development of a plan for ensuring a competitive product in the market concerning the Leamington Spa Company. It further elaborated the trends of consumer demand concerning energy consumption and conservation in the UK. It is realized that most consumers are conscious of the need to conserve energy using appliances that store or use minimum power to ensure reduced expenses. Therefore, companies in the UK that deal with home appliances must adhere to constantly shifting consumer demands.

References

Abrams, H 2006, World changing: a user’s guide for the 21st century, Harry N. Abrams, New York, NY.

Barton, J & Infield, D 2004, ‘Energy storage and its use with intermittent renewable energy’, Energy Conversion, IEEE Transactions, vol. 19 no. 2, pp. 441-8.

Benyus, J 1997, Biomimicry, William Morrow, New York, NY.

Bose, R 2008, ‘Competitive intelligence process and tools for intelligence analysis’, Industrial Management & Data Systems, vol. 108, no. 4, pp. 510-28.

Brown, H, Suryanarayanan, S & Heydt, G 2010, ‘Some Characteristics of Emerging Distribution Systems Considering the Smart Grid Initiative’, The electricity Journal, vol. 23 no. 5, pp. 64-75.

Brown, T 2014, Change by design, HarperCollins, New York, NY.

Brownell, B 2010, Transmaterial 3: a catalog of materials that redefine our physical environment, Princeton Architectural Press, New York, NY.

Bruiyan, N 2011, ‘A framework for successful new product development’, Journal of Industrial Engineering and Management, vol. 4 no. 4, pp. 747-70.

Cooper, R 2001, Winning at new products: Accelerating the process from idea to launch, Basic Books, New York, NY.

Davila, T, Epstein, M & Shelton, R 2012, Making innovation work: How to manage it, measure it, and profit from it, FT Press, Upper Saddle River, NJ.

DECC, 2013, Energy consumption in the UK (ECUK): domestic data, Web.

Donnellon, A 1993, ‘Cross-functional teams in product development: Accommodating the structure to the process’, Journal of Product Innovation Management, vol. 10 no. 5,pp. 377-92.

Druckman, A & Jackson, T 2008, ‘Household energy consumption in the UK: A highly geographically and socio-economically disaggregated model’, Energy policy, vol. 36 no. 8, pp. 3177-92.

Farhangi, H 2010, ‘The path of the smart grid’, Power and Energy Magazine IEEE, vol. 8 no. 1, pp. 18-28.

Fleisher, C & Bensoussan, B 2007, Business and competitive analysis: effective application of new and classic methods, FT Press, Upper Saddle River, NJ.

Fuad-Luke, A 2002, The Eco-Design Handbook, Thames & Hudson, London.

Gassmann, O & Von Zedtwitz, M 1999, ‘New concepts and trends in international R&D organisation’, Research Policy, vol. 28 no. 2, pp. 231-50.

Godin, S 2011, Meatball Sundae, Hachette, Paris, France.

Hasnain, S 1998, ‘Review on sustainable thermal energy storage technologies, part I: heat storage materials and techniques’, Energy Conversion and Management, vol. 39 no. 11, 1127-38.

Kelley, T & Littman, J 2001,The art of innovation: Success through innovation the IDEO way, Crown Business, Broadway, New York, NY.

Kenneth, B 2013, The PDMA handbook of new product development, John Wiley & Sons, Hoboken, New Jersey, NJ.

Khurana, H, Hadley, M, Lu, N & Frincke, D 2010, ‘Smart-grid security issues’, IEEE Security & Privacy, vol. 1 no. 1, pp. 81-5.

Kim, J & Wilemon, D 2007, ‘Sources & assessment of complexity in NPD projects’, R&D Management, vol. 33 no. 1, pp. 16-30.

Koen, P, Ajamian, G, Burkart, R, Clamen, A, Davidson, J, D’Amore, R, Elkins, C, Herald, K, Incorvia, M, Johnson, A, Karol, R, Seibert, R, Slavejkov, A & Wagner, K 2001, ‘Providing Clarity and a Common Language to the Fuzzy Front End’, Research-Technology Management, vol. 44 no. 2, pp. 46-55.

Krishna, V, U’lrich, K, 2001, ‘Product Development decision: A review of the literature’, Management Science, vol. 47 no. 1, pp. 1-21.

Lefteri, C 2006, Materials for Inspirational Design, RotoVision, Hove, United Kingdom.

Lewis, H, Gertsakis, J, Grant, T, Morelli, N & Sweatman, A 2001, Design environment: a global guide to designing greener goods, Greenleaf, Sheffield, UK.

McDonough, W & Braungart, M 2010, Cradle to cradle: Remaking the way we make things, MacMillan, London.

Medrano, M, Gil, A, Martorell, I, Potau, X & Cabeza, L 2010, ‘State of the art on high-temperature thermal energy storage for power generation. Part 2-Case studies’, Renewable and Sustainable Energy Reviews, vol. 14 no. 1, pp. 56-72.

Metke, A & Ekl, R 2010,‘Security technology for smart grid networks’, Smart Grid, IEEE Transactions on, vol. 1 no. 1, pp. 99-107.

Nordell, B & Hellström, G 2000, ‘High temperature solar heated seasonal storage system for low temperature heating of buildings’, Solar Energy, vol. 69 no. 6, 511-23.

Office of National Statistics. 2009. Digest of UK Energy Statistics, Department of Energy and Climate Change, London.

Renewable Energy Association. 2006, A Proposed Energy Hierarchy, REA, London.

Rodica Loisel, Arnaud Mercier, Christoph Gatzen, Nick Elms, Hrvoje Petric, 2010. Valuation framework for large scale electricity storage in a case with wind curtailment, Energy Policy, vol. 38 no. 1, 7323-37.

Runeson, P. 2005, ‘Combining agile methods with stage-gate project management’, IEEE software, vol. 3 no. 1, pp. 43-9.

Sawhney, M, Verona, G & Prandelli, E. 2005, ‘Collaborating to create: The Internet as a platform for customer engagement in product innovation’, Journal of interactive marketing, vol. 19 no. 4, pp. 4-17.

Sethi, S. 1979, ‘A conceptual framework for environmental analysis of social issues and evaluation of business response patterns’, Academy of Management Review, vol. 4 no. 1, pp. 63-74.

Sharma, A, Tyagi, V, Chen, C & Buddhi, D. 2009,‘Review on thermal energy storage with phase change materials and applications’, Renewable and Sustainable energy reviews, vol. 13 no. 2, pp. 318-45.

Smith, P & Reinertsen, D 1991, Developing products in half the time, Van Nostrand Reinhold, New York.

Smith, S 2009, Security and privacy challenges in the smart grid. Web.

Summerfield, A, Pathan, A, Lowe, R & Oreszczyn, T 2010, ‘Changes in Energy Demand from Low Energy Homes’, Building Research and Information, vol. 38 no. 1, pp. 42-9.

Thackara, J 2006, In the bubble: designing in a complex world, MIT press, Cambridge, Massachusetts.

Thompson, R 2007, Manufacturing processes for design professionals, Thames & Hudson, London.

Trott, P 2008, Innovation management and new product development, Pearson education, London.

UK Energy Research Centre 2007, The Rebound Effect: an assessment of the evidence for economy-wide energy savings from improved energy efficiency, Energy Research Centre, London, UK.

Ulrich, K 2003, Product design and development, Tata McGraw-Hill Education, India.

Van Trijp, J & Steenkamp, J 2005, ‘Consumer-oriented new product development: principles and practice’, Innovation in Agri-food Systems, vol. 17 no. 2006, pp. 87-124.

Wheelwright, S 2010, Managing New Product and Process Development: Text Cases, Simon and Schuster, New York, NY.

Will, G 2010, ‘The ten faces of innovation: strategies for heightening creativity’, Irish Journal of Management, vol. 29 no. 2, pp. 131.

Wong, S & Tong, C 2012, ‘The influence of market orientation on new product success’, European Journal of Innovation Management, vol. 15 no. 1,pp. 99-121.

Wood, G & Newborough, M 2003, ‘Dynamic energy-consumption indicators for domestic appliances: environment, behaviour, and design’, Energy and Buildings, vol. 35 no. 8, pp. 821-41.